Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

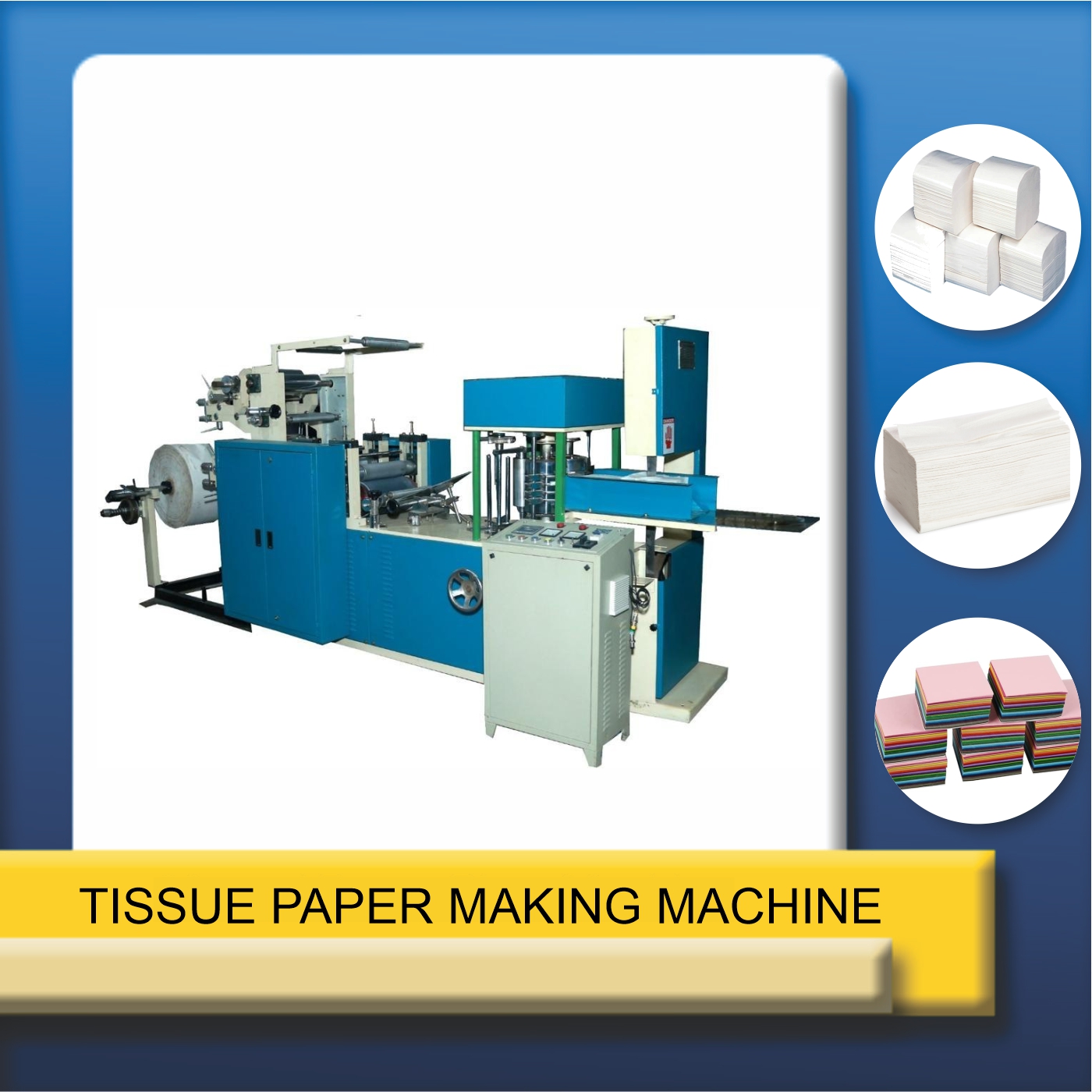

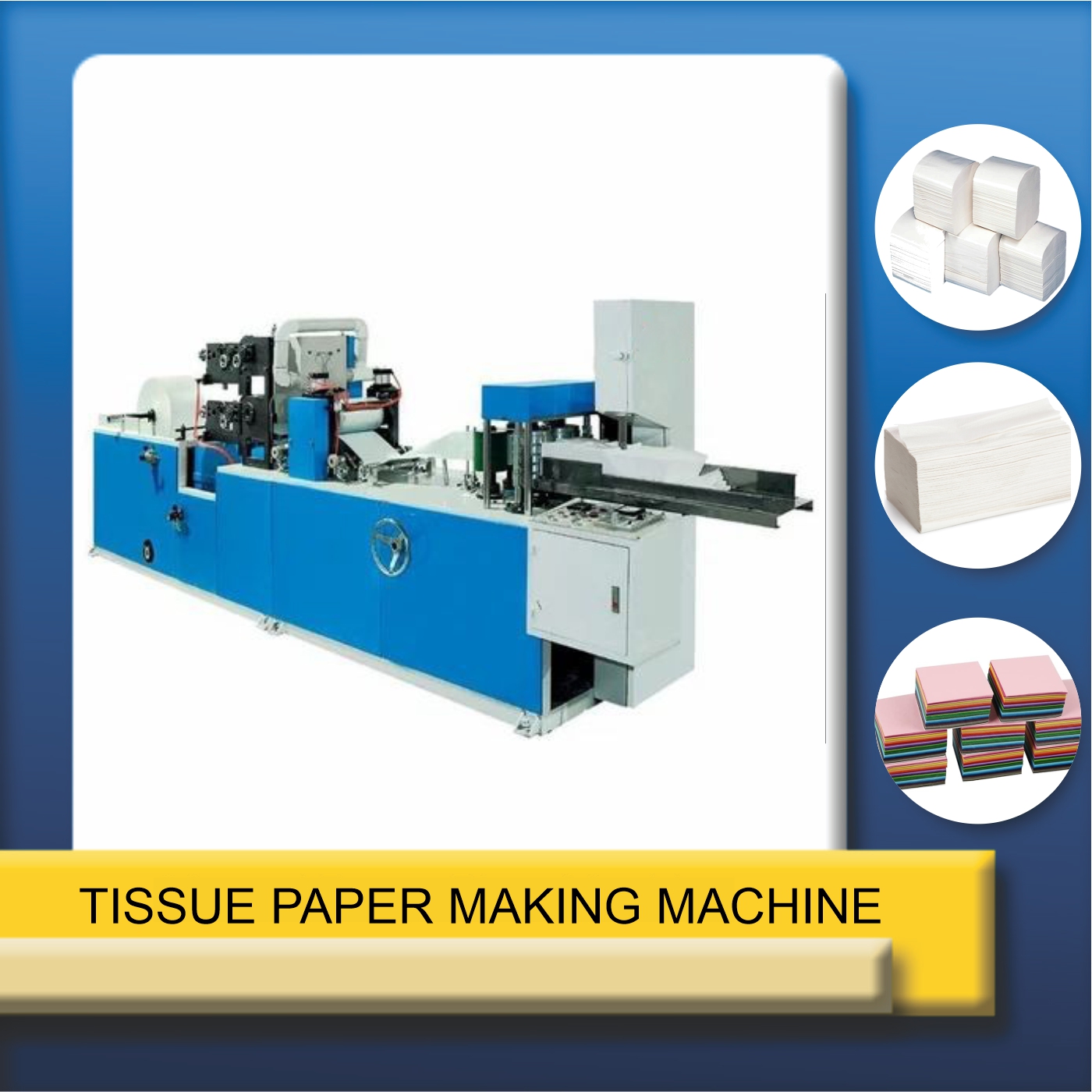

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Tissue Paper Making Machine

| Product Generic Name |

Tissue Paper Making Machine |

|---|---|

| Motor |

1HP-3 Hp |

| Weight |

1500 kg (approx) |

| Capacity | 21500 Sheets /Hr |

1. What's an electric wire nail maker? How does it work?

A machine for making wire nails can be designed to produce nails from metal wire coils. The machine shapes, cuts, and shapes the nails precisely, resulting in uniform size and high quality. It manages the entire process, from straightening the wire to shaping the head and then sharpening the point of the nail. This is a cost-effective method to make nails in huge quantities.

2. What kinds of wire nail machines can be found in ASVR Engineering?

In ASVR Engineering, we offer various varieties of wire nail machines. We have semi-automatic and fully automated versions. They are made for varying manufacturing capacities in small-scale or industrial production. The machines we offer are customizable choices of different dimensions and lengths of nails.

3. What's the price of the equipment for making wire nails?

The machine for making wire nails costs are based on the machine used, the production capacity, and other features like the degree of automation. Semi-automatic and manual machines are less expensive and fully automated, offering greater productivity and faster production costs. For a specific price quote dependent on the specifics of your requirements for production, get in touch with us directly.

4. What are the significant advantages that come from employing a wire nail maker machine?

The wire nail machine provides many benefits, such as rapid production speeds, constant quality of nails, less cost of labour, and minimal materials scrap. They are made to make nails in large quantities, which makes them perfect for firms looking to expand their production quickly.

5. What capacity of production is the wire nail-making machine able to handle?

The output capacity of the wire nail machines we use depends on the machine type. The machines can make anywhere between 200-600 nails per minute, based on the type and size of the nail. Businesses can choose one appropriate for the required quantity and size of production.

6. What kinds of nails can be made with the wire nail maker machine?

Wire nail machines can produce various sizes of nails, from the most petite nails used for applications with delicate requirements to the larger ones required for construction projects requiring a lot of force. The dimensions of the nails will be determined by the thickness of the wire and the machine's settings, which may be adjusted according to the production's specific needs.

7. Are the wire nail-making machines simple to maintain?

Our wire nail makers are designed for long-lasting use and ease of maintenance. A regular cleaning and lubrication routine and regular checks of mechanical parts will ensure that the machine is operating effectively for many long periods. Maintenance support is also provided to keep your equipment operating at its peak.

8. What is the power usage of a wire nail-making machine?

The amount of power consumed is based on the machine type and the device's capacity to be produced. Our machines are engineered to reduce energy consumption and have high productivity, which helps you cut operating expenses.

9. Does ASVR Engineering offer after-sales service for machines that make wire nails?

ASVR Engineering provides full after-sales support all over India, including installation, training, and maintenance assistance. The ASVR Engineering team is at hand to resolve all technical problems and will ensure that your wire nail manufacturing machine is running smoothly and effectively.

10. Why should I pick ASVR Engineering for my wire nail machine?

ASVR Engineering specializes in manufacturing high-quality and durable wire nail-making machines. We provide customized options, affordable pricing, and comprehensive after-sales service. Whether you're a small firm or an enterprise with a vast production capacity, the machines we offer are engineered to ensure high efficiency and consistent nail quality. They are a solid investment for your company.

Tissue Paper Making Machine Information

- Tissue Paper Processing Machine – Complete Tissue Manufacturing Solutions

- Buy Tissue Paper Making Machine – Quality Machines from ASVR Engineering

- Tissue Paper Making Machine in India – Trusted Machines by ASVR Engineering

- Tissue Paper Making Machine in Delhi – Reliable Machines & Services

- Tissue Paper Machine Price in India – Affordable & Quality Machines

- Buy Tissue Paper Making Machine Online – Easy Purchase from ASVR Engineering

- Jumbo Roll Tissue Making Machine – Efficient Large-Scale Tissue Production

- Tissue Paper Machine with Embossing – Enhance Tissue Quality & Appearance

- Low Cost Tissue Paper Machine – Affordable Tissue Making Solutions

- High Speed Tissue Paper Making Machine – Fast & Efficient Tissue Production

- Industrial Tissue Paper Making Machine – High Capacity Tissue Machines

- Tissue Paper Machine Suppliers – Reliable Suppliers for Quality Tissue Machines

- Tissue Paper Machine Manufacturers in India – Quality Machines by ASVR Engineering

- Semi Automatic Tissue Paper Machine – Affordable & Efficient Tissue Production

- Mini Tissue Paper Machine – Compact & Efficient Tissue Making Solutions

- Napkin Tissue Making Machine – Efficient Napkin Production Machines

- Toilet Tissue Paper Machine – Efficient Toilet Roll Making Machines

- Facial Tissue Paper Making Machine – High-Quality Facial Tissue Production

- Tissue Paper Machine for Small Business – Affordable & Easy-to-Use Tissue Machines

- Tissue Paper Production Machine – Efficient Machines for High-Quality Tissue Manufacturing

- Tissue Paper Making Machine for Business – Start Your Tissue Manufacturing Unit

- Automatic Tissue Paper Making Machine – High-Speed Fully Automatic Tissue Machines

- Tissue Paper Manufacturing Machine – High-Speed, Cost-Effective Solutions by ASVR Engineering

- Tissue Paper Machine Price – Affordable & High-Performance Tissue Paper Machines

- Tissue Paper Making Machine – High-Speed Production for Soft, Hygienic Tissue Rolls