Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

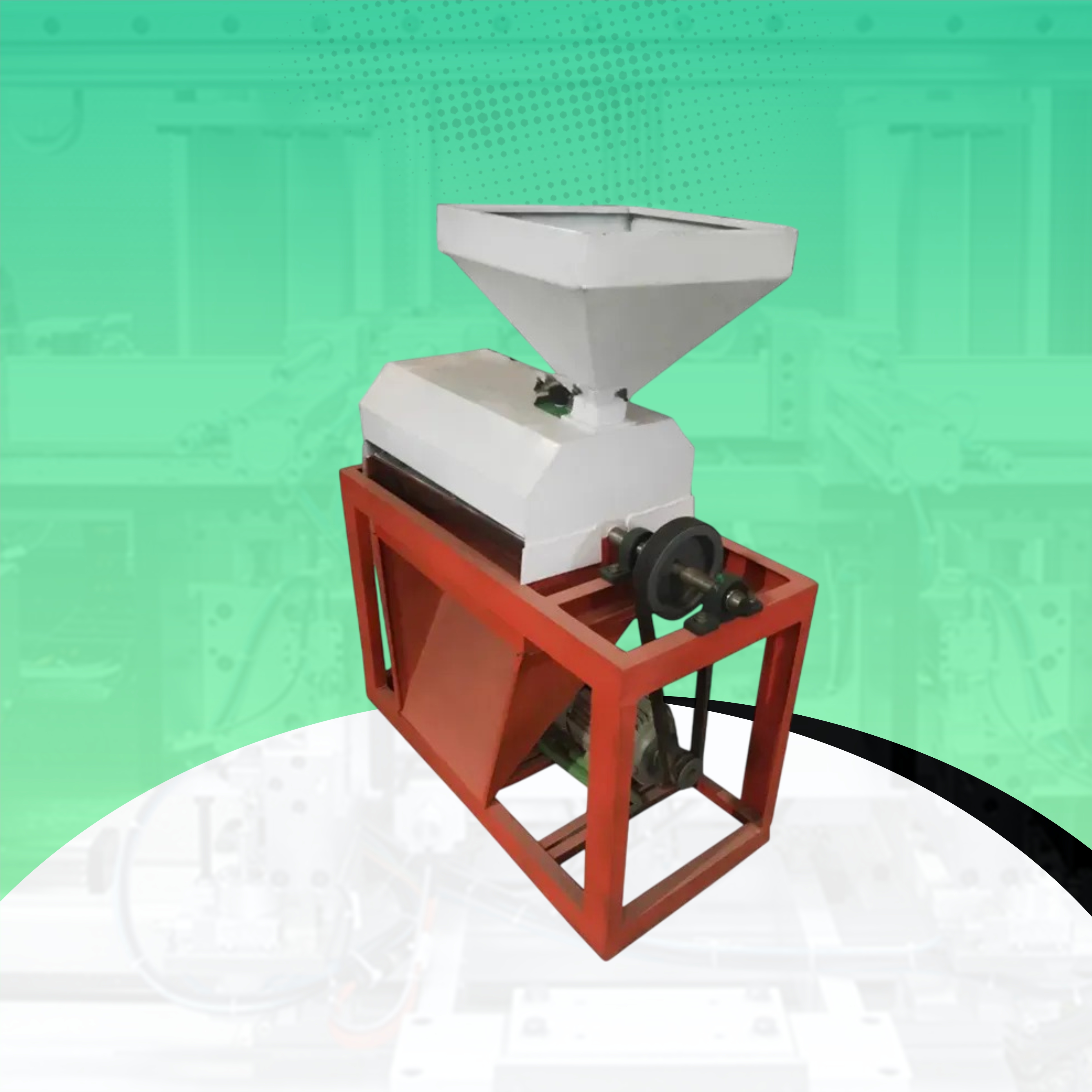

Dal polisher machine

Price: ₹ 70000

| Product Generic Name |

dal polisher machine |

|---|---|

| Minimum Order Quantity |

1 Piece |

| Brand Name |

Customized |

| Body Material |

Iron |

| Usage/Application |

For Dal Polisher |

Add To Cart

The Dal Polisher Machine is a specialized polishing unit used in dal mills to enhance the appearance, texture, and market value of pulses such as moong dal, toor dal, urad dal, and chana dal. This machine gently rubs and polishes the outer surface of the dal without damaging its structure or nutritional quality. Built with a durable body, efficient motor, and high-speed polishing rollers, it ensures uniform shine and minimal powder residue. Ideal for commercial dal processors looking to produce premium-grade polished pulses.

-

✨ Superior Finish: Provides uniform shine to enhance dal appearance.

-

🧺 Low Breakage: Gently polishes without cracking or crushing the pulses.

-

⚙️ Heavy-Duty Design: Built for continuous, industrial-scale operation.

-

🌾 Multi-Dal Compatible: Suitable for polishing moong, urad, chana, and toor dals.

-

🔧 Easy Maintenance: Simple to clean and service with minimal downtime.

-

⚡ Energy Efficient: Operates efficiently with low power consumption.

1. What exactly is a Dal Polisher Machine, and how does the polishing process work to improve the quality of dal?

A Dal Polisher Machine is a specialized piece of equipment used to polish pulses or lentils, known as dal, to enhance their visual appeal and overall quality. The machine works by tumbling the dal inside a rotating drum or cylinder, often with the help of abrasive materials or polishing agents. This process helps to remove any husk, dust, and broken pieces of dal, ensuring that the final product is shiny, clean, and free from impurities, improving its texture and market value.

2. Which types of dal are compatible with a Dal Polisher Machine, and is it suitable for all varieties of lentils?

Dal Polisher Machines are versatile and can be used to polish a variety of pulses, including chickpeas (chana), masoor dal, moong dal, toor dal, and other lentils. These machines are designed to handle different types of pulses, providing consistent results. Whether you're working with small, delicate pulses or larger varieties, the machine can adapt to different processing needs, making it an excellent choice for both small-scale and large-scale dal processing.

3. How does the Dal Polisher Machine contribute to the overall improvement in the quality and appearance of dal, and why is it important in the processing industry?

The Dal Polisher Machine plays a crucial role in improving the appearance and texture of dal by giving it a polished, shiny finish, which makes it more visually appealing to consumers. The polishing process also helps to remove residual husk, dust particles, and broken dal that are often left behind after initial processing. This results in a cleaner, more uniform product that is not only attractive but also safer to consume. In the processing industry, polished dal typically has higher market demand and can command better prices.

4. What are the key features of a Dal Polisher Machine, and how do these features help in improving the overall performance and efficiency of the polishing process?

Dal Polisher Machines come with several essential features, such as:

-

Adjustable polishing speed to tailor the process for different dal types and desired finishes.

-

Stainless steel construction to ensure durability, resistance to corrosion, and ease of cleaning.

-

Dust collection systems to minimize mess and maintain a clean working environment.

-

Rotating drum or cylinder that ensures even polishing, resulting in uniform-sized dal.

These features contribute to a more efficient and effective polishing process, leading to better quality products and higher production output.

5. How much dal can a Dal Polisher Machine handle at a time, and what is its processing capacity in terms of kilograms per hour?

The processing capacity of a Dal Polisher Machine varies based on its size and model. Smaller models are typically capable of polishing 100 kg to 500 kg per hour, while larger industrial machines can handle up to 1,000 kg per hour or more. The specific capacity you choose will depend on your production needs, whether you're running a small-scale operation or a large-scale industrial process.

6. What power requirements does a Dal Polisher Machine have, and how much electricity does it typically consume during operation?

The power requirements for a Dal Polisher Machine depend on its size and capacity. Smaller models generally require 1 HP to 3 HP of power, while larger machines can consume 5 HP to 10 HP or more. The machine's power consumption also depends on the duration and frequency of use, but generally, dal polishers are designed to be energy-efficient to keep operational costs low while maintaining high performance.

7. How much time does it typically take to polish dal using a Dal Polisher Machine, and what factors influence the polishing time?

The polishing time in a Dal Polisher Machine usually ranges from 15 to 30 minutes, depending on the type of dal and the desired finish. Factors such as dal variety, polishing speed, and machine capacity can all influence the time required. Some models allow you to adjust the polishing time to achieve the perfect level of shine and texture based on the specific requirements of your product.

8. What are the specific advantages of using a Dal Polisher Machine over manual polishing methods in terms of efficiency and product quality?

Using a Dal Polisher Machine offers several significant advantages over manual polishing:

-

Improved appearance: The machine gives dal a consistent shine that is difficult to achieve manually.

-

Faster processing: The machine can process much larger quantities of dal in less time compared to manual labor.

-

Consistency: The machine ensures uniform polishing, whereas manual methods often result in variations in texture and appearance.

-

Higher productivity: With automated processes, you can scale up production without compromising on quality.

9. How often does a Dal Polisher Machine require maintenance, and what are the basic maintenance tasks necessary to keep the machine running smoothly?

Regular maintenance is essential to keep the Dal Polisher Machine running at peak efficiency. Key maintenance tasks include:

-

Cleaning the drum to remove any leftover dal particles, dust, or abrasives.

-

Lubricating moving parts, such as bearings and motors, to ensure smooth operation and reduce wear.

-

Checking and replacing damaged polishing elements to maintain effective polishing performance.

-

Inspecting electrical components regularly to ensure everything is functioning correctly.

By performing these maintenance tasks, you can extend the lifespan of the machine and keep it operating at optimal performance.

10. What safety precautions should be followed while operating a Dal Polisher Machine to ensure safe and efficient use?

To ensure safe operation of the Dal Polisher Machine, consider the following precautions:

-

Wear protective gear, such as gloves, goggles, and ear protection, to avoid injury from the machine's moving parts and noise.

-

Avoid overloading the machine to prevent malfunctions and damage to its components.

-

Regularly inspect the machine for any signs of wear and tear or electrical issues.

-

Follow manufacturer guidelines for safe operation and maintenance procedures.

By adhering to these precautions, you can ensure safe and efficient use of the machine in your production process.