Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

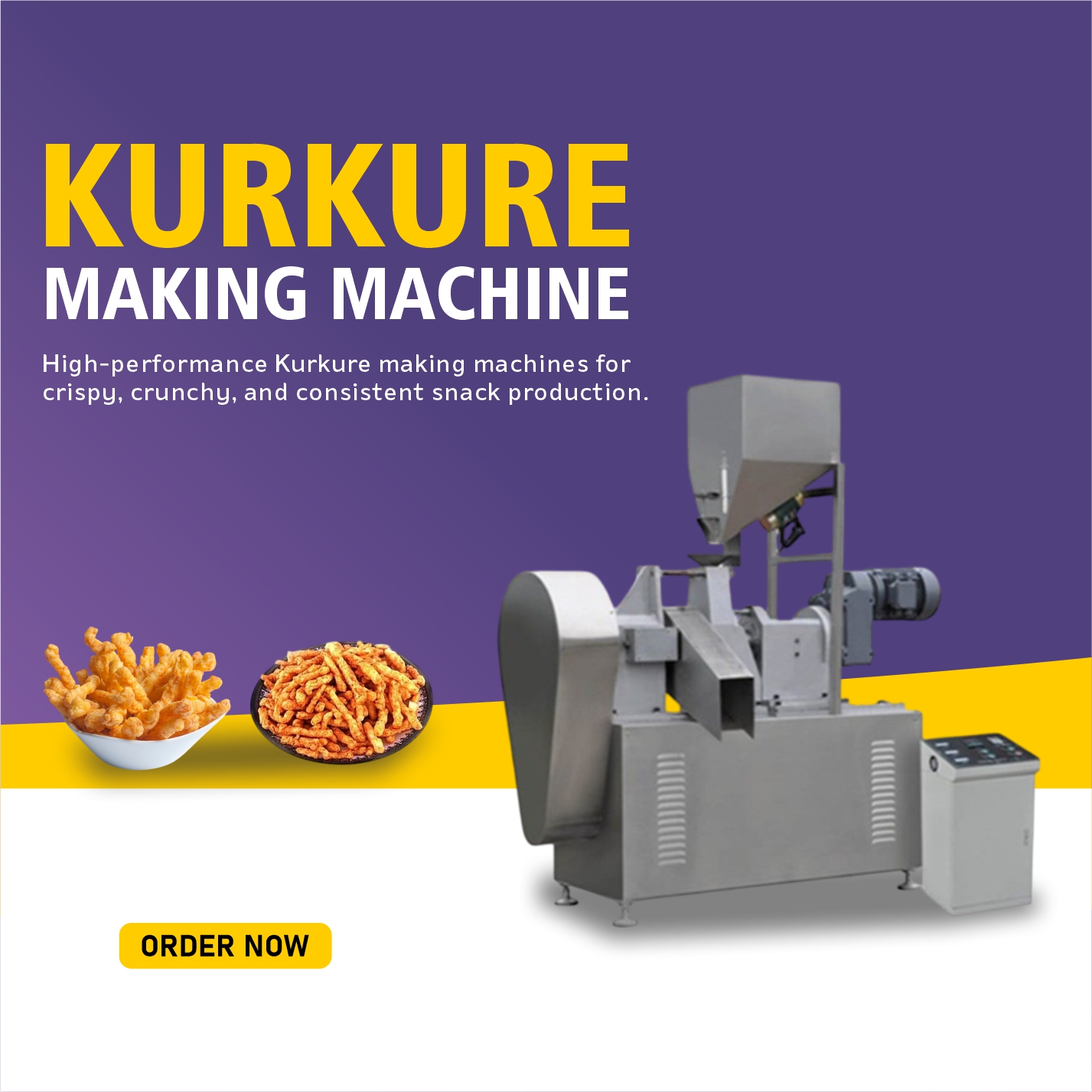

Kurkure Making Machine

Price: ₹ 450000

| Product Generic Name |

Kurkure/ Puffs Making Machine |

|---|---|

| Minimum Order Quantity |

1 Piece |

| Brand Name |

Customized |

| Body Material |

SS |

| Usage/Application |

For Making Kurkure/ Puffs |

Add To Cart

Kurkure snacks have gained immense popularity around the world for their unique crunch and delicious flavors. People worldwide love these kurkure snacks.

ASVR Engineering is the best manufacturer and supplier of the automatic Kurkure machine in Delhi, India. We achieve recognition as a leading company in the machine manufacturing industry.

A kurkure making machine, also known as a kurkure extruder machine or puffs extruder machine. It is a specialized equipment designed to produce Kurkure snacks.

Our mini Kurkure manufacturing machine produces a large quantity of Kurkure snacks in a shorter time frame. We understand that each snack manufacturer has unique requirements.

This kurkure extruder machine is available according to your specific requirements at competitive pricing for our clients. The puffs extruder machine or snack manufacturer machine is affordable for small scall business to a large scale business.

How kurkure machine works?

A typical kurkure machine comprises several components working together to create the perfect snacks. The Kurkure production line combines a raw material mixer, dough hopper, extruder, fryer, seasoning unit, and packaging system to create the beloved snack.

This machine automates forming, shaping, and frying the Kurkure dough, ensuring uniformity and quality in every batch.

-

High Production Capacity

Delivers a large volume of Kurkure snacks efficiently, meeting the demands of commercial snack manufacturers. -

Consistent Shape & Texture

Ensures uniform size, crispiness, and texture in every batch, enhancing product quality and customer appeal. -

Fully Automated Process

Automates mixing, extrusion, cutting, frying, and seasoning — reducing manual intervention and increasing efficiency. -

Versatile Production

Can produce different flavors and varieties of Kurkure by simply adjusting ingredients and seasonings. -

Energy Efficient

Designed to consume minimal electricity or gas while maintaining high performance, lowering operational costs. -

User-Friendly Operation

Equipped with simple, intuitive controls that make operation easy even for users with minimal technical skills. -

Hygienic & Food-Safe

Stainless steel construction and minimal human handling ensure hygienic production and compliance with food safety standards. -

Low Maintenance & Durable

Built with robust materials to withstand continuous production cycles, ensuring long-term durability and minimal maintenance needs. -

Compact & Space-Efficient Design

Occupies less space in production units while offering high output, ideal for small to medium-sized snack factories. -

Enhances Profitability

Increases productivity, reduces labor costs, and ensures consistent quality, all contributing to higher profitability and business scalability.

1. What exactly is a Kurkure manufacturing machine, and what is its purpose?

Kurkure maker is created to facilitate the manufacturing of Kurkure snacks. It processes cornmeal and other grains, mixes the grains with salt and water, and then extrudes them out of a die to create Kurkure's distinctive twist shape. Kurkure. The extruded product is either baked or cooked to get the crispness. The machine guarantees consistency, speed of production, and consistency of quality.

2. 1. What is a Kurkure making machine and what is its purpose?

-

Purpose:

To automate the manufacturing process of Kurkure snacks, ensuring consistent quality and speed.

-

Functionality:

It takes raw materials like cornmeal, mixes them with water and salt, extrudes the mixture into a unique shape, and then cooks or bakes the extruded pieces to achieve their crispness.

3. What are the key components of a Kurkure making machine?

- Raw material handling system: This includes the feeding and mixing of raw materials.

- Extruder: This part uses heat and pressure to extrude the mixture, shaping it into Kurkure.

- Cooking/Baking system: This step ensures the extruded pieces become crisp.

- Cutting system: This section cuts the extruded product into desired lengths.

4. What raw materials are used in a Kurkure making machine?

- Main ingredient: Cornmeal is the primary ingredient.

- Other ingredients: Water, salt, and flavorings may also be added.

5. How does a Kurkure making machine differ from a regular extruder?

-

Specific Die:

Kurkure machines use a specialized die to create the unique twisted shape of Kurkure.

-

Cooking/Baking:

Kurkure machines incorporate a cooking or baking process to make the snack crisp, while regular extruders may not.

6. Are there different sizes or types of Kurkure making machines?

-

Commercial vs. Small-Scale:

Machines come in various sizes, ranging from small-scale, manual machines to large commercial ones.

-

Types:

Some manufacturers offer machines specifically designed for different Kurkure varieties or flavors.

7. How does the manufacturing process of Kurkure work?

- Raw Material Preparation: Cornmeal is prepared and mixed with water and other ingredients.

- Extrusion: The mixture is extruded through a die, forming the Kurkure shape.

- Cooking/Baking: The extruded pieces are cooked or baked to achieve their crisp texture.

- Flavoring and Packaging: Kurkure is flavored and then packaged for distribution.

8. What are the benefits of using a Kurkure making machine?

- Consistency: Ensures consistent quality and production.

- Efficiency: Increases production speed.

- Automation: Reduces manual labor and time.

9. Are there any specific considerations when purchasing a Kurkure making machine?

- Capacity: Choose a machine that meets your production needs.

- Power requirements: Ensure the machine has the necessary power requirements.

- Maintenance: Consider maintenance needs and availability of spare parts.

10. Where can I find suppliers of Kurkure making machines?

Directly purchasing from established manufacturers ensures better pricing, after-sales support, and customization options.