Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

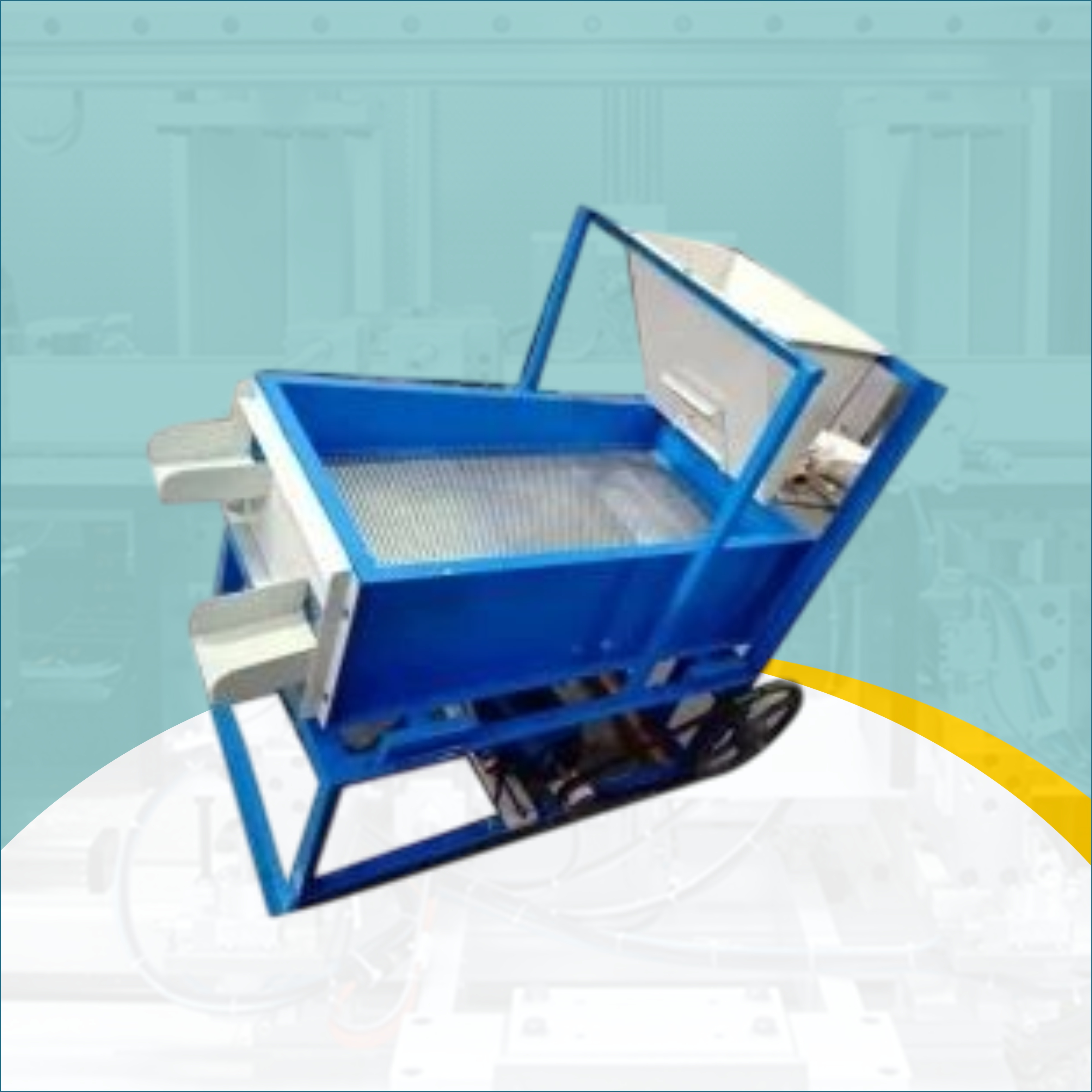

Centrifugal chalna seperator

Price: ₹ 50000

| Product Generic Name |

centrifugal chalna seperator |

|---|---|

| Minimum Order Quantity |

1 Piece |

| Brand Name |

Customized |

| Body Material |

MS |

| Usage/Application |

For Makhan Making |

Add To Cart

The Centrifugal Chalna Separator is a high-efficiency equipment designed to separate impurities and unwanted particles from raw materials such as flour, spices, pulses, and grains. It operates using centrifugal force to sift and separate materials based on particle size, ensuring a cleaner and more refined product. Widely used in the food processing, chemical, and pharmaceutical industries, this separator ensures high-quality output with minimal human intervention. Built with high-quality stainless steel and precision engineering, it guarantees durability, easy maintenance, and consistent performance over long periods of time.

-

🌀 High Separation Efficiency: Effectively separates fine particles and impurities from raw materials.

-

⚙️ Precise Sifting: Ensures accurate particle size classification for improved product quality.

-

🧼 Hygienic Design: Constructed from food-grade stainless steel for safety and cleanliness.

-

⏱️ High-Speed Operation: Processes large batches in less time for greater productivity.

-

🔧 Low Maintenance: Simple design for quick cleaning and minimal maintenance.

-

💪 Durable: Long-lasting performance in demanding industrial environments.

1. What is a Centrifugal Chalna Separator?

A Centrifugal Chalna Separator is a high-performance industrial machine used for separating materials based on their size and weight. It operates using centrifugal force to effectively separate particles in various industries, such as agriculture, food processing, and mining.

2. How does a Centrifugal Chalna Separator work?

The Centrifugal Chalna Separator works by using high-speed rotational motion to create centrifugal force. As materials are fed into the separator, the lighter particles move to the center, while heavier particles are forced outward, facilitating a precise separation process.

3. Is the Centrifugal Chalna Separator easy to maintain?

Yes, the Centrifugal Chalna Separator is designed with minimal maintenance needs. Routine checks, cleaning, and occasional lubrication ensure smooth operation. Its simple design also reduces the need for frequent repairs.

4. Can the Centrifugal Chalna Separator be customized?

Yes, Centrifugal Chalna Separators can be customized according to the specific needs of your business. Depending on the material type, size, and separation requirements, adjustments can be made to enhance efficiency and performance.

5. What is the maintenance cost of a Centrifugal Chalna Separator?

The maintenance cost of a Centrifugal Chalna Separator is relatively low. It mainly involves routine cleaning, lubrication, and occasional part replacements, which ensures cost-effective long-term operation.

6. How much does a Centrifugal Chalna Separator cost?

The cost of a Centrifugal Chalna Separator depends on factors such as its size, capacity, and customization options. It's best to contact manufacturers for an accurate price quote based on your specific requirements.