Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

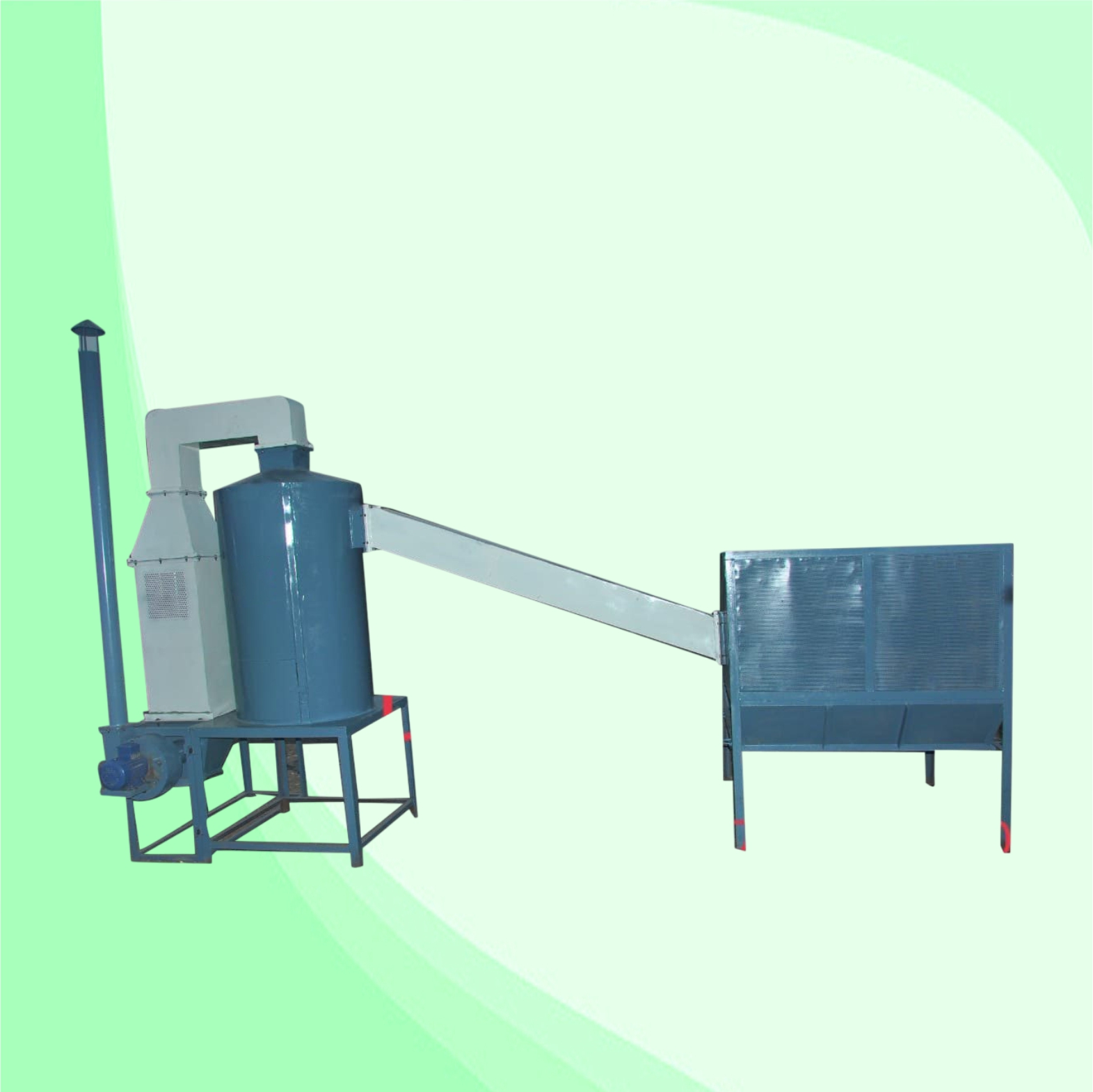

Dal dryer machine

Price: ₹ 75000

| Product Generic Name |

dal dryer machine |

|---|---|

| Minimum Order Quantity |

1 Piece |

| Brand Name |

Customized |

| Body Material |

Iron |

| Usage/Application |

For dal dryer |

Add To Cart

The Dal Dryer Machine is a specialized drying unit designed to remove moisture from pulses such as toor dal, moong dal, urad dal, and chana dal after the milling or soaking process. This machine ensures uniform drying, which helps in preserving the dal, enhancing shelf life, and preparing it for packaging or further processing. Ideal for dal mills and agro-processing units, the machine is built with high-quality components, energy-efficient heaters, and user-friendly controls, delivering consistent performance even in large-scale operations.

-

🌬️ Uniform Drying: Ensures even moisture removal for better storage and quality.

-

⚙️ Robust Construction: Built with heavy-duty materials for industrial use.

-

🔥 Energy Efficient: Equipped with optimized heating systems to save energy.

-

🧼 Hygienic Processing: Designed for clean, contamination-free drying of pulses.

-

🕹️ Easy Operation: Simple control panel for temperature and timing adjustments.

-

🧺 High Capacity Options: Available in multiple sizes for small and large dal mills.

1. What is a Dal Dryer Machine, and how does it function to dry pulses like chickpeas, lentils, and beans effectively?

A Dal Dryer Machine is specifically designed to remove excess moisture from pulses (dal), including chickpeas, lentils, and beans. The machine uses controlled heat and air circulation, or sometimes rotating drums, to ensure even and thorough drying of the dal, which is essential for enhancing its shelf life, reducing spoilage, and improving its quality for storage and further processing.

2. Can the Dal Dryer Machine be used to dry different types of dal, and if so, which varieties can be processed?

Yes, the Dal Dryer Machine is versatile and can be used for drying a variety of dal types. Some of the most common pulses that can be processed in the machine include chickpeas (chana), masoor dal, moong dal, toor dal, and other legumes that require drying after cleaning and processing.

3. What is the typical drying capacity of a Dal Dryer Machine, and how much dal can it handle in one batch or over time?

The drying capacity of Dal Dryer Machines can vary greatly depending on the model and size. Generally, smaller machines can process about 100 kg of dal per hour, while industrial models can handle up to 1,000 kg per hour or more, allowing businesses to scale production based on their needs.

4. What power source is used to operate a Dal Dryer Machine, and how much power is required for efficient functioning?

Dal Dryer Machines typically operate using electric motors or diesel engines, depending on the availability of power at the location of use. The power consumption varies by model, with electric machines usually requiring between 3 HP to 15 HP, depending on the drying capacity and complexity of the machine.

5. How does a Dal Dryer Machine ensure even drying of dal, and what features are incorporated to maintain the quality of the pulses during drying?

The Dal Dryer Machine uses hot air circulation, rotating drums, or conveyor systems to ensure the even distribution of heat and efficient moisture removal from the dal. The machine typically includes adjustable temperature and time settings, allowing users to customize the drying process based on the specific requirements of different dal varieties.

6. How long does it take for the Dal Dryer Machine to dry dal, and what factors affect the drying time?

The drying time in a Dal Dryer Machine typically ranges from 1 to 3 hours, depending on the type of dal, the initial moisture content, and the machine’s settings. For example, thicker pulses like chickpeas may require a longer drying time compared to smaller varieties like masoor dal. The ambient temperature and humidity can also influence drying times.

7. What are the key benefits of using a Dal Dryer Machine over traditional drying methods for pulses like dal, and how does it improve the overall process?

Using a Dal Dryer Machine offers several advantages, including:

-

Improved Shelf Life: By removing excess moisture, the machine helps prevent spoilage and fungal growth.

-

Consistent Drying: Ensures uniform drying across all grains, preventing under-drying or over-drying.

-

Energy Efficiency: Uses controlled heating systems that consume less energy than traditional sun drying or manual methods.

-

Increased Production Capacity: It speeds up the drying process, allowing for higher throughput and faster drying of large quantities.

8. the Dal Dryer Machine suitable for small-scale farmers or large commercial operations, and how do the machines vary in size and capacity?

Dal Dryer Machines are available in various sizes and capacities, making them suitable for both small-scale farmers and large commercial operations. Smaller models can handle a few hundred kilograms of dal per hour, while industrial versions are capable of drying large quantities (up to 1,000 kg per hour) for larger processing units or food manufacturers.

9. What kind of regular maintenance does a Dal Dryer Machine require to ensure long-term performance and efficiency?

To keep the Dal Dryer Machine functioning efficiently, regular maintenance is essential. This includes:

-

Cleaning the drying chamber to remove any residual dal or dust.

-

Checking and replacing heating elements if needed.

-

Lubricating moving parts like conveyor belts or drum rollers.

-

Inspecting electrical components to ensure they are in good working condition and calibrated properly for optimal performance.

10. What safety features are included in a Dal Dryer Machine, and how can operators ensure safe use during daily operations?

Dal Dryer Machines are typically equipped with several safety features to ensure safe operation, including safety guards, overload protection systems, and emergency stop buttons. Additionally, many models have automatic shut-off systems to prevent overheating or malfunctioning. Operators should always follow safety guidelines, ensure the machine is properly maintained, and use protective gear like gloves and goggles when necessary