Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

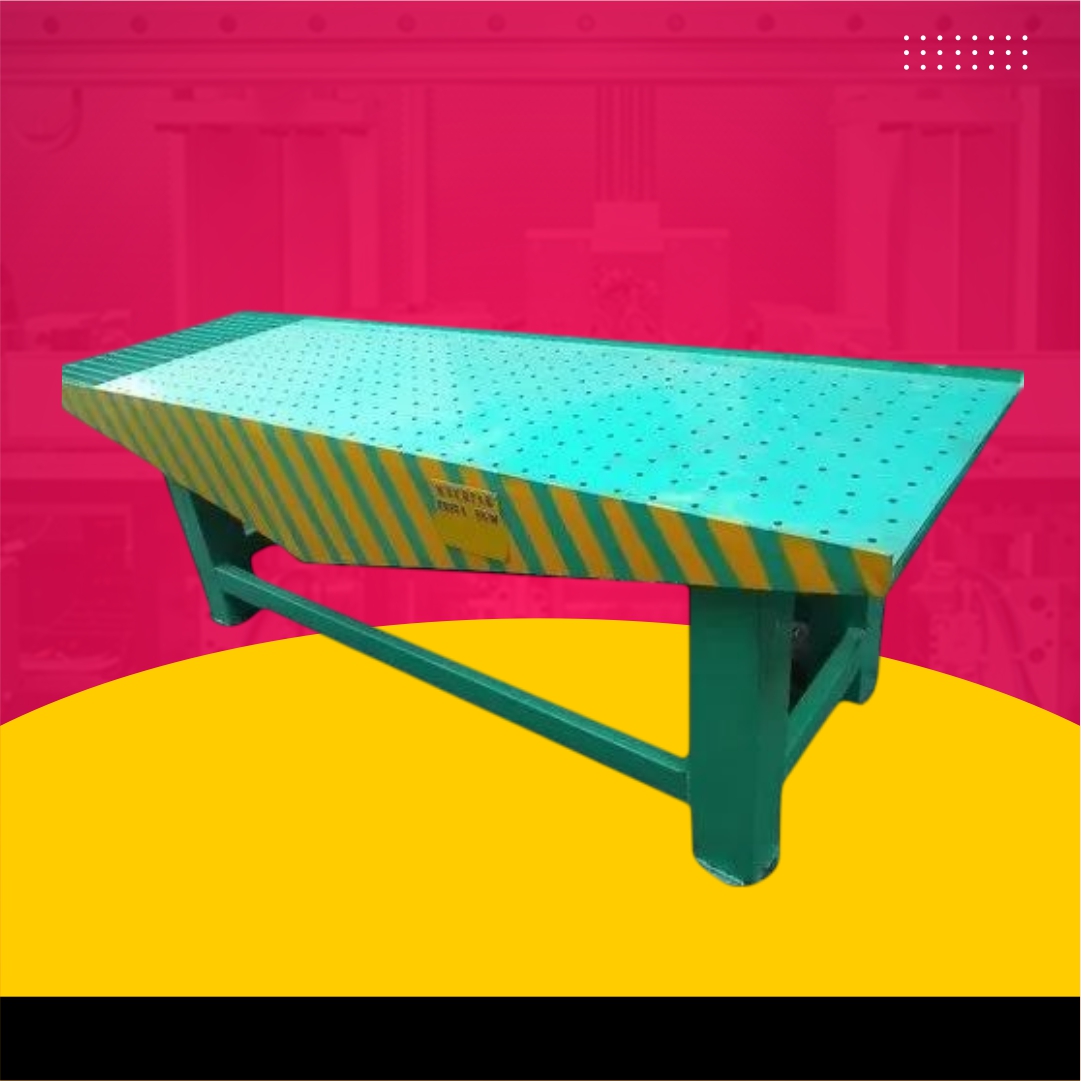

Concrete Vibrating Machine

Price: ₹ 65000

| Product Generic Name |

Concrete Vibrating Table |

|---|---|

| Minimum Order Quantity |

1 Piece |

| Brand Name |

Customized |

| Body Material |

Iron |

| Usage/Application |

For Concrete |

Add To Cart

The Concrete Vibrating Machine is an essential tool for ensuring smooth, compact, and durable concrete mixtures. It helps remove air pockets and evenly distribute the mixture, resulting in stronger and more stable concrete. Whether used in construction, precast manufacturing, or road paving, this machine is crucial for achieving the best concrete density and eliminating voids.

Built with high-quality materials, it offers reliable performance and longevity. Available in various sizes and types, the machine is designed to meet the needs of small and large-scale projects, making it versatile for different concrete processing applications.

Key Features:

-

Powerful Vibration – Effectively removes air bubbles and ensures smooth, uniform concrete.

-

Durable Construction – Made from high-quality steel for long-lasting use.

-

User-Friendly – Simple controls make it easy to operate for workers with minimal training.

-

Portable & Compact – Easy to transport and use at various job sites.

-

Adjustable Vibration Intensity – Allows customization based on project requirements.

-

Improved Concrete Quality – Ensures a smooth, bubble-free surface and uniform mixture for stronger concrete.

-

Faster Curing Time – Reduces the time required for concrete curing by improving its density and compactness.

-

Increased Strength – Eliminates voids and air pockets, resulting in more durable concrete.

-

Energy Efficient – Designed to offer powerful vibration while consuming minimal energy.

-

Versatile Use – Ideal for use in construction, road paving, precast concrete production, and more.

-

Enhanced Work Efficiency – Speeds up the concrete mixing process, improving overall productivity.

-

Cost-Effective – Reduces waste by maximizing the use of concrete and ensuring consistent, high-quality results.

1. What is a Concrete Vibrating Machine?

A Concrete Vibrating Machine is a specialized construction tool used to improve the consistency and strength of concrete by eliminating air bubbles and ensuring an even distribution of aggregate materials. The machine vibrates the concrete, helping it to settle properly and fill molds, leading to smoother, stronger, and more durable concrete surfaces.

2. How does a Concrete Vibrating Machine work?

The Concrete Vibrating Machine works by vibrating the concrete mixture during the pouring process. This vibration removes trapped air and helps the concrete flow more easily into molds or forms. The result is a denser and more compact mixture, which leads to higher-quality, durable concrete.

3. What types of concrete projects can benefit from using a Concrete Vibrating Machine?

A Concrete Vibrating Machine is essential for a wide range of concrete projects, including building foundations, where it ensures a strong, solid base by compacting the concrete evenly. It is also crucial in road construction, helping create smooth, durable surfaces, and in bridge construction, where it compacts concrete for stability and strength. Additionally, the machine is used in flooring and slabs to achieve smooth surfaces and uniform consistency in floors, walls, and other concrete structures.

4. What are the advantages of using a Concrete Vibrating Machine?

The Concrete Vibrating Machine improves concrete quality by reducing air pockets and ensuring even mix distribution, resulting in a stronger, more durable product. It speeds up compaction, allowing for faster project completion, and ensures uniform compaction for consistent results. The machine enhances surface finish, reducing rework, and increases strength for better load-bearing capacity in concrete structures.

5. How do I choose the right Concrete Vibrating Machine for my project?

The right Concrete Vibrating Machine depends on project size, with larger projects needing powerful industrial models and smaller jobs using portable ones. Vibration frequency is important, with adjustable settings for different mixes, and the type of work determines whether high or low-frequency vibration is needed for finer or coarser concrete.

6. Is the Concrete Vibrating Machine easy to operate?

Yes, most Concrete Vibrating Machines are designed to be user-friendly, with simple controls and ergonomic handles for easy operation. Many models also feature adjustable settings for vibration intensity to match specific concrete needs.

7. How much power does a Concrete Vibrating Machine require?

The power requirement for a Concrete Vibrating Machine depends on the model and size of the machine. Typically, they are electric-powered, with some larger models requiring more power (up to 3-phase electricity) for industrial use. Smaller, portable models may be suitable for standard household power sources.

8. What maintenance is required for a Concrete Vibrating Machine?

-

Cleaning: After each use, clean the machine thoroughly to remove concrete residue.

-

Lubrication: Regularly lubricate the moving parts to ensure smooth operation and prevent wear.

-

Inspection: Check the motor and vibration components for any signs of damage or wear.

-

Storage: Store the machine in a dry area to avoid rusting or corrosion.

9. Can a Concrete Vibrating Machine be used for other materials besides concrete?

Generally, Concrete Vibrating Machines are designed specifically for concrete. However, depending on the model and attachments, some machines may also be used for compacting other materials, such as sand, gravel, or soil, in certain construction applications.

10. What safety precautions should be followed when using a Concrete Vibrating Machine?

For safe operation of the Concrete Vibrating Machine, always wear safety gear like gloves, goggles, and ear protection to avoid injury from vibration and noise. Avoid overloading the machine to prevent damage, and regularly inspect and maintain it to ensure it's in good condition. Always follow the manufacturer's guidelines for proper operation and maintenance.

11. How much does a Concrete Vibrating Machine cost, and how long does it last?

The cost of a Concrete Vibrating Machine can vary based on its size, features, and brand, with industrial-grade models typically costing more due to their advanced features and durability. As for its lifespan, a well-maintained Concrete Vibrating Machine can last anywhere from 5 to 10 years, depending on usage, maintenance, and the type of projects it’s used for.