Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

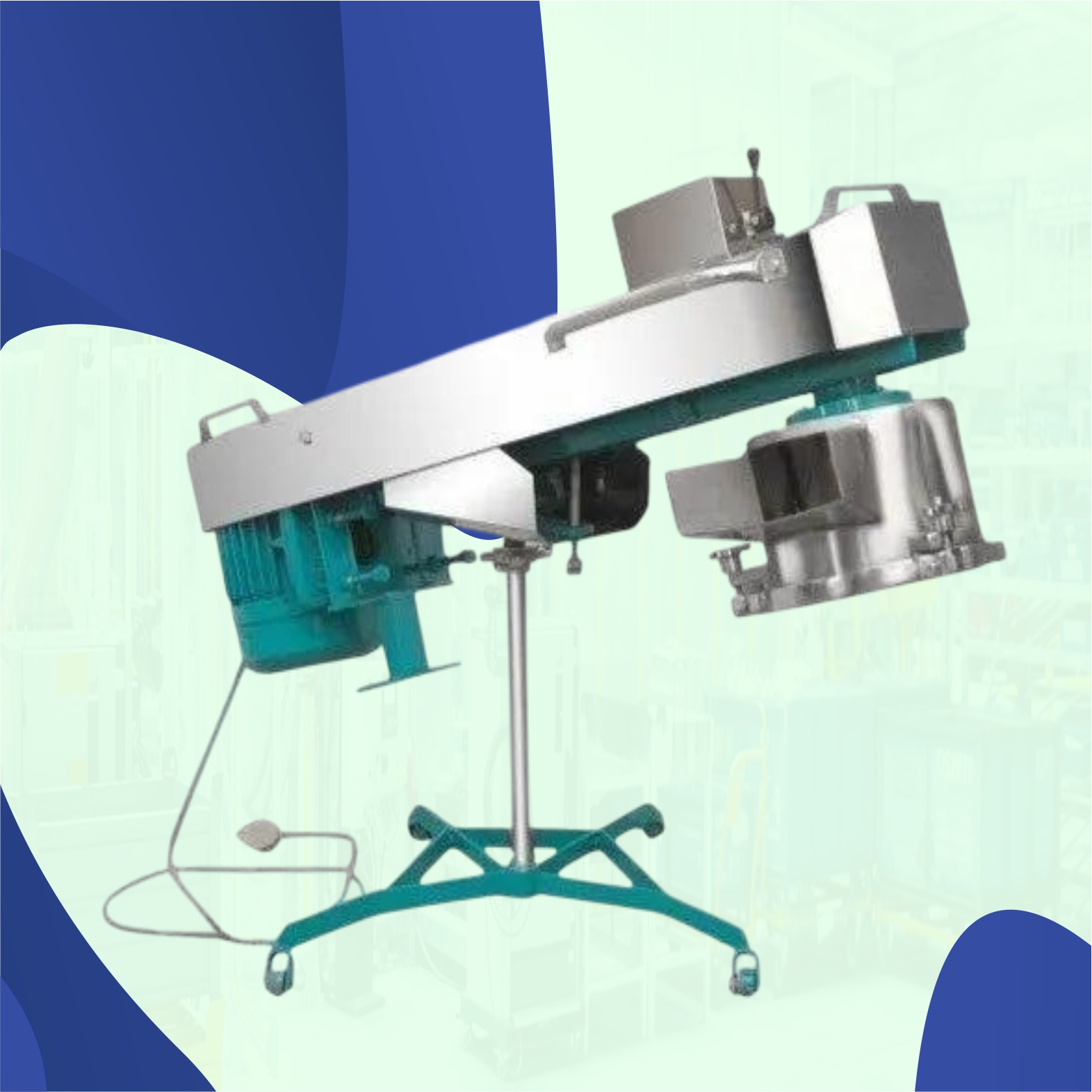

Namkeen making machine

Price: ₹ 45000

| Product Generic Name |

Namkeen making machine |

|---|---|

| Minimum Order Quantity |

1 Piece |

| Brand Name |

Customized |

| Body Material |

SS |

| Usage/Application |

For Namkeen making |

Add To Cart

The Namkeen Making Machine is an advanced, high-efficiency food processing unit designed to produce a variety of traditional Indian snacks like sev, bhujia, gathiya, chakli, and more. Suitable for both small-scale and large-scale production, this machine is built with food-grade stainless steel and provides a reliable, hygienic, and consistent way of making crispy and flavorful namkeen. With adjustable extrusion speeds and multiple die options, it allows you to create different textures and shapes of namkeen, ensuring your snacks have the perfect crunch every time. Ideal for snack manufacturers, sweet shops, and large-scale food production units.

-

🍘 Versatile Production: Produce various types of namkeen like sev, bhujia, gathiya, and more.

-

⚙️ Stainless Steel Build: Ensures durability, hygiene, and long-lasting performance.

-

⏱️ High Output: Increased productivity with continuous, automatic operation.

-

🔧 Customizable Dies: Multiple molds for different shapes and textures.

-

🔌 Energy-Efficient: Low power consumption with high-speed operation.

-

🧽 Easy Maintenance: Quick to clean, with a user-friendly design.

1. What is a Namkeen Making Machine, and what is its primary function?

A Namkeen Making Machine is a specialized piece of equipment designed for the automated production of Namkeen—a popular category of Indian savory snacks, such as bhujia, chakli, sev, and chips. The machine handles the mixing, frying, and packaging of Namkeen products, making it ideal for large-scale production in the food industry.

2. What types of Namkeen products can be made using the machine?

The Namkeen Making Machine can produce a wide variety of Namkeen snacks, including bhujia (crispy, fried snack made from gram flour and spices), chakli (spiral-shaped, crunchy snack), sev (thin, crispy noodles made from gram flour), mathri (flaky, spiced crackers), potato chips, and murmura (puffed rice). Additionally, the machine can accommodate various flavors and seasonings, allowing for customization of products to suit different tastes.

3. What are the key features of a Namkeen Making Machine?

The Namkeen Making Machine offers several advantages, including automatic operation, ensuring continuous production with minimal manual intervention. It provides consistent frying with a uniform frying system that guarantees even cooking for better texture and taste. The machine also offers versatile shaping, enabling the production of a variety of Namkeen shapes and sizes, such as strips, spirals, or flakes. Temperature control allows for precise regulation during frying, ensuring the right texture and flavor. With its high production capacity, the machine is ideal for commercial-scale operations. Additionally, its stainless steel construction ensures durability, safety, and long-term performance.

4. How does a Namkeen Making Machine improve efficiency in snack production?

A Namkeen Making Machine improves efficiency by automating processes such as mixing, frying, and shaping, which reduces the need for manual labor and increases speed. It helps in increasing production output, allowing businesses to meet high demand while maintaining consistency. The machine ensures uniformity in size, shape, and taste of each snack, which is essential for mass production. Additionally, it saves energy and reduces wastage by providing precise control over frying temperature and time.

5. What industries benefit from using a Namkeen Making Machine?

The Namkeen Making Machine is widely used in commercial snack manufacturers producing large quantities of Namkeen snacks for retail and wholesale markets. It's also used in food processing units focused on ready-to-eat snack foods, catering services or food chains offering Namkeen as part of their menu or packaged offerings, and supermarkets and convenience stores that require bulk production of various types of Namkeen snacks.

6. How easy is it to operate and maintain a Namkeen Making Machine?

Operating a Namkeen Making Machine is straightforward, with many models featuring simple controls for temperature, frying time, and shaping functions. Maintenance typically involves cleaning the machine after each batch to prevent residue buildup, checking the oil regularly for quality and replenishing it when necessary to maintain optimal frying conditions, lubricating moving parts to ensure smooth operation and prevent wear, and inspecting the motor and other components for signs of damage or wear, replacing them promptly when needed.

7. What are the different power configurations available for a Namkeen Making Machine?

Namkeen Making Machines come in various power configurations, including:

-

Electric-powered machines, which provide precise temperature and timing control.

-

Gas-powered machines, ideal for high-efficiency frying and used in larger-scale operations.

-

Combination models, offering flexibility by using both gas and electric power depending on the production requirements.

8. How long does a Namkeen Making Machine last, and how can its lifespan be extended?

The lifespan of a Namkeen Making Machine typically ranges from 5 to 10 years, depending on factors like usage and maintenance. To extend the machine’s lifespan:

-

Perform regular maintenance and timely repairs to prevent major malfunctions.

-

Clean the machine thoroughly after each use, especially the frying section, to avoid oil buildup.

-

Lubricate moving parts to reduce friction and wear.

-

Store the machine in a dry and clean environment to prevent corrosion.