Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

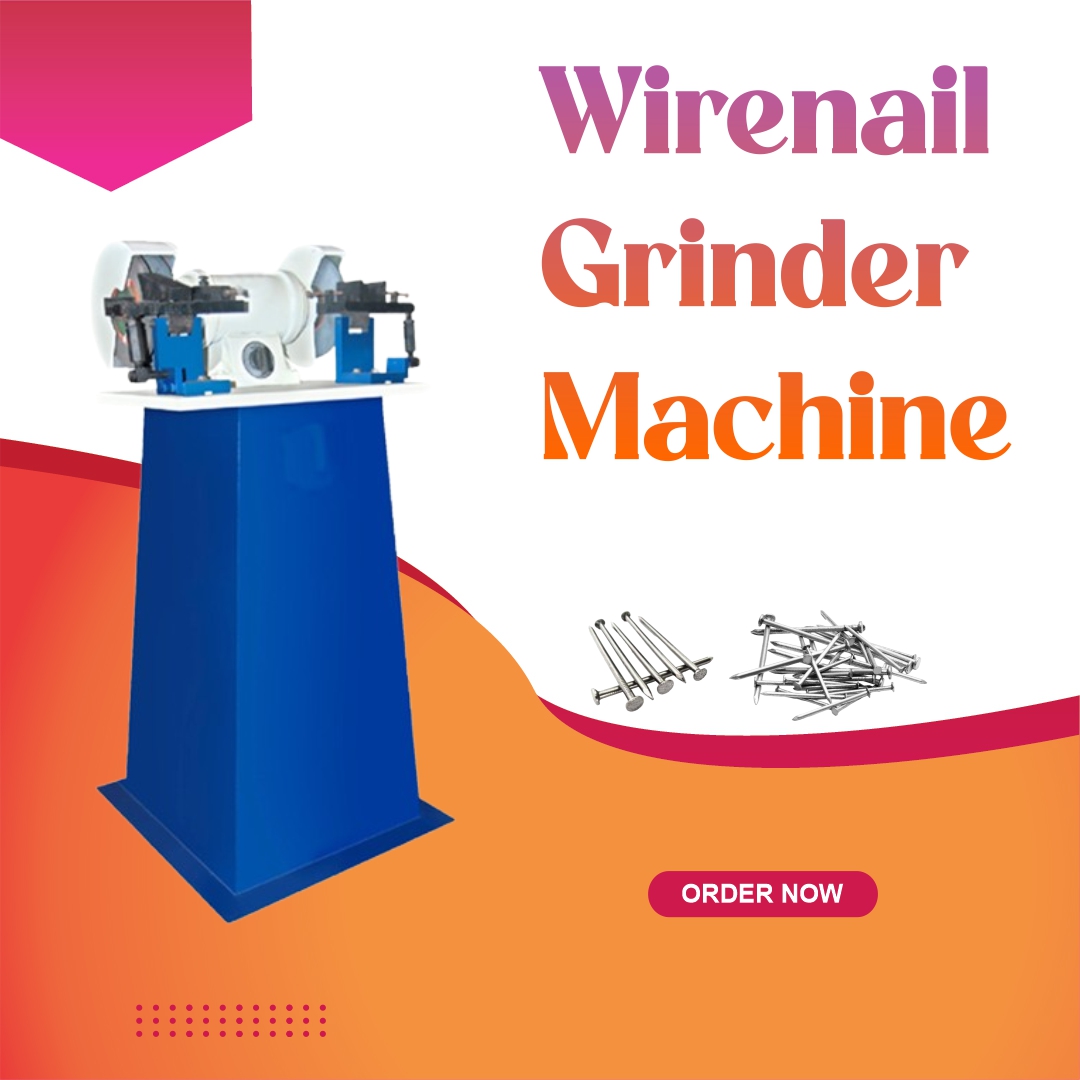

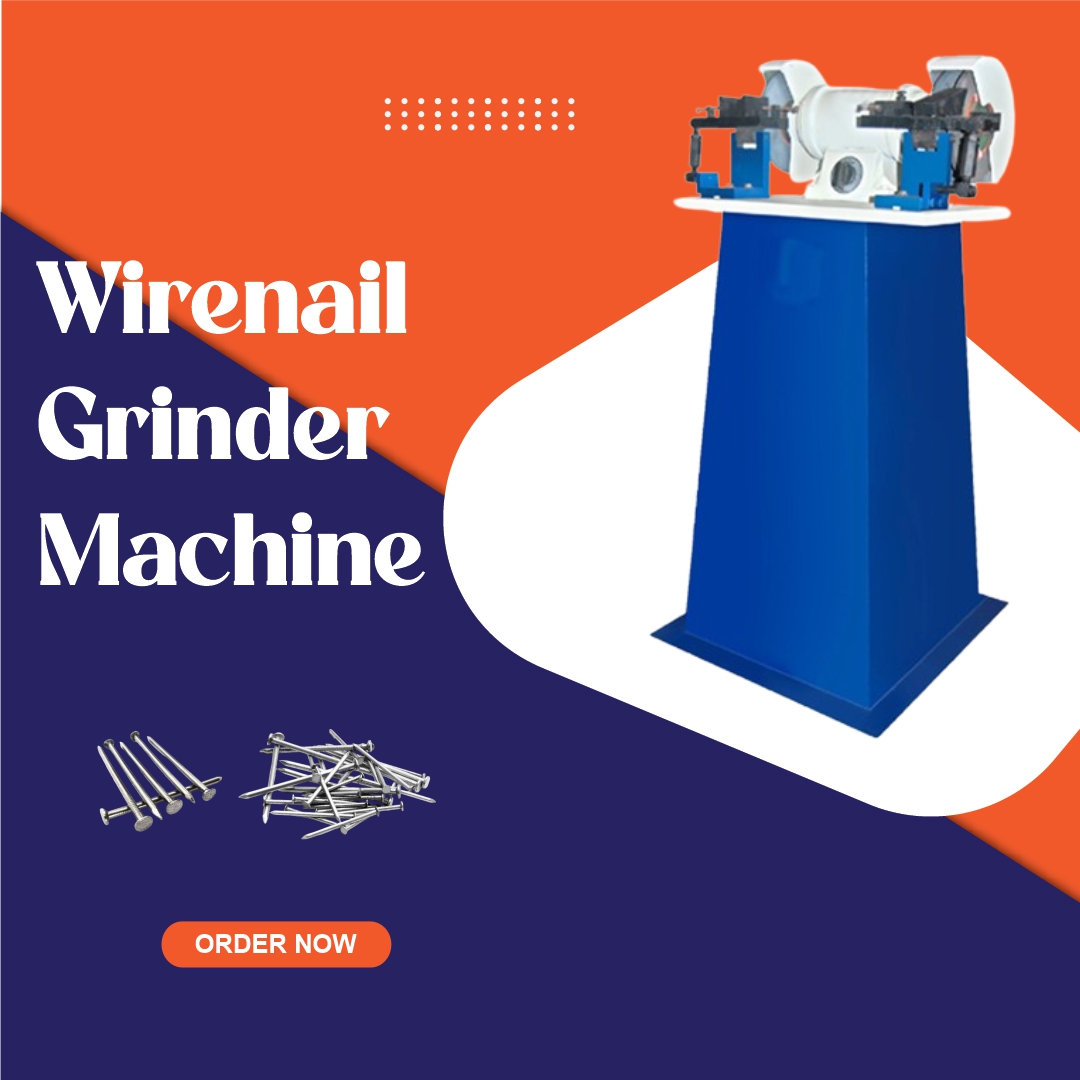

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Wire nail grinder machine

Price: ₹ 40000

| Product Generic Name |

Wire Nail Making Machine |

|---|---|

| Minimum Order Quantity |

1 Piece |

| Brand Name |

Customized |

| Body Material |

Iron |

| Usage/Application |

For Making Wire Nail |

Add To Cart

The Wire Nail Grinder Machine is an essential tool used in nail manufacturing units to sharpen and polish the nail head and tip after cutting. This machine enhances the finish and accuracy of wire nails, improving their market quality and usability. Built with a heavy-duty body and precision grinding wheels, it ensures consistent performance and long-term durability. Ideal for small-scale and industrial wire nail production, the machine operates efficiently with low noise and minimal maintenance requirements. Its compact design, ease of use, and high output capacity make it a valuable addition to any nail-making setup.

-

🧱 Improves Nail Finish: Sharpens and polishes nails for better quality and usability.

-

⚙️ Heavy-Duty Build: Sturdy construction suitable for industrial applications.

-

🔧 Low Maintenance: Simple mechanism ensures long-lasting operation.

-

🧼 Dust-Control Feature: Designed with a dust collection option for cleaner operation.

-

⏱️ Time-Saving: Speeds up finishing work for large batches of nails.

-

👨🏭 Easy to Operate: User-friendly interface, suitable for semi-skilled operators.

1. What is a wire nail grinder machine, and what is its primary function?

A wire nail grinder machine is a specialized industrial tool used to sharpen and polish the nail heads after they are cut and formed. Its primary purpose is to remove burrs, rough edges, and imperfections from the nails, resulting in smooth, evenly shaped nail heads that meet market standards.

2. Why is nail grinding necessary in wire nail manufacturing?

After nails are produced using a wire nail making machine, they may have uneven or sharp heads due to the cutting and forming process. A wire nail grinder ensures that the nail heads are uniform, smooth, and safe to handle. This step also improves the aesthetic and quality of the final product, increasing its market value.

3. What types of nails can be processed using a wire nail grinder machine?

Wire nail grinder machines are designed to work with a wide variety of nails, including common wire nails, panel pins, concrete nails, and roofing nails, ranging from 1 inch to 6 inches or more depending on the machine model.

4. What is the output capacity of a wire nail grinder machine?

Output capacity varies by model, but most wire nail grinder machines can process 100 to 300 kg of nails per hour. High-capacity models may offer even greater output to support industrial-scale operations.

5. What materials are used to build a wire nail grinder machine?

These machines are generally constructed using heavy-duty steel and abrasive grinding wheels, ensuring durability and long service life. The internal components are built to withstand continuous operation in industrial environments.

6. Is the operation of a wire nail grinder machine manual or automatic?

Wire nail grinder machines can be semi-automatic or fully automatic. Semi-automatic models require an operator to load and unload nails, while automatic versions offer continuous feeding and collection systems, reducing labor and increasing productivity.

7. Is training required to operate the machine?

Basic training is recommended but not mandatory. The controls are generally simple and user-friendly, and a new operator can learn to run the machine effectively with minimal guidance.

8. Is the machine noisy or does it require safety precautions?

Yes, grinding machines do generate noise and vibration, so it is essential to use proper safety gear such as ear protection, gloves, and goggles. Most machines also feature safety guards and emergency stop functions for added protection.