Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

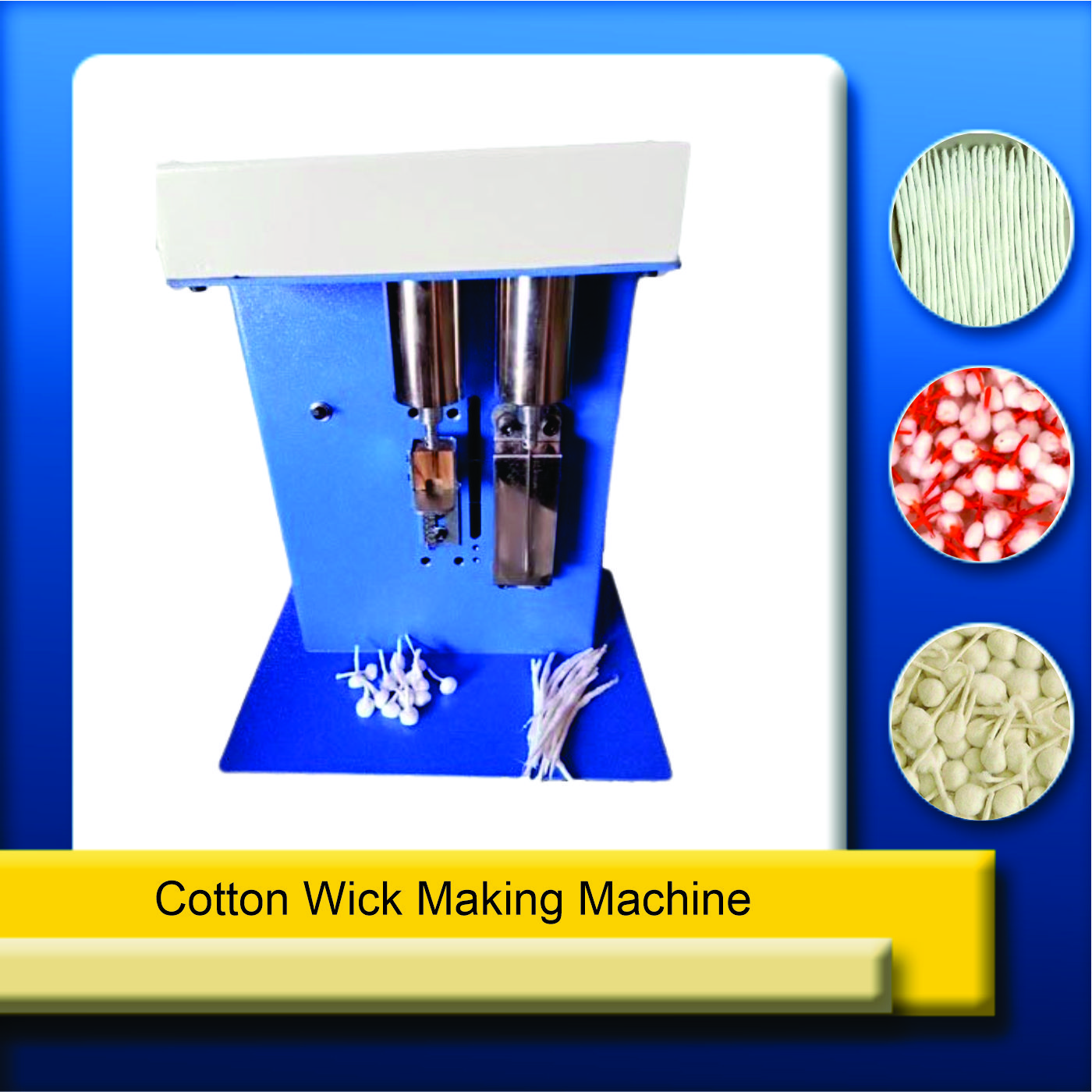

Cotton Wick Machine

Price: ₹ 32000

| Product Generic Name |

Cotton Wick Making Machine |

|---|---|

| Minimum Order Quantity |

1 Piece |

| Brand Name |

Customized |

| Body Material |

Iron |

| Usage/Application |

For Making Rui batti |

Add To Cart

Rui batti, commonly known as cotton wicks holds immense cultural significance in every Indian home and religious ceremonies.Whether it's used in temples, homes, or during festivals, the aromatic fragrance of Rui Battis is believed to purify the environment and create a serene atmosphere. Because of the high demand of cotton wicks in every city and rural areas this is very profitable business.

The Rui batti making business is a small scall business and can start from home at small budget. This is a profitable business for housewives and ladies.

ASVR Engineering is the leading manufacturer and supplier of cotton wick making machine, fully automatic long cotton wick making machine as well as round wick making machine in Delhi and across all over India.

This Rui batti making machine is easy to operate and do more production at less electricity consumption. Our machines are manufactured using high quality material which makes it sturdy. It requires less maintenance cost. This high quality machine has a capacity to make 3-4 Kg Rui batti per day.

These machines have gained immense popularity for their ability to streamline and automate the process of making Rui Battis, making it faster and more efficient than traditional methods.

We can produce large quantities of Rui Battis in a shorter span of time, reducing the manual effort and increasing productivity.

-

High Production Efficiency

Automates the wick-making process, allowing for rapid production of uniform cotton wicks in large quantities, saving both time and labor. -

Consistent Quality Output

Ensures uniform size, shape, and density of each wick, improving product quality and customer satisfaction. -

Versatile Production

Capable of producing different types of wicks — long wicks, round wicks, and batti — to meet various religious and household needs. -

User-Friendly Operation

Equipped with simple controls, making the machine easy to operate, even for beginners or small business owners with minimal technical experience. -

Low Power Consumption

Designed to operate efficiently with minimal electricity use, keeping operational costs low while maintaining excellent productivity. -

Compact & Space-Saving Design

Small, lightweight, and portable — ideal for home-based businesses or small-scale production setups with limited space. -

Hygienic & Clean Production

The machine ensures that wicks are produced without manual handling, promoting cleanliness and maintaining the purity of the cotton material. -

Durable & Long-Lasting

Built with high-quality materials and sturdy construction, offering long service life and consistent performance with minimal wear and tear. -

Low Maintenance

Simple mechanical design requires minimal maintenance, reducing downtime and repair costs over the long term. -

Ideal for Small-Scale Entrepreneurs

Affordable and easy to set up, making it perfect for women entrepreneurs, self-help groups, and cottage industries aiming to start a profitable home business. -

Increases Profitability

Speeds up production, ensures consistency, reduces manual labor, and improves output — all contributing to better margins and increased profitability.

1. What is a Cotton Wick Making Machine, and how does it work?

A Cotton Wick Making Machine is used to produce cotton wicks by twisting cotton threads into the desired thickness and length. The machine feeds cotton yarn through rollers, where it is twisted into wicks, and then cut into the required sizes. The wicks are then packed for distribution or retail use.

2. What are the benefits of using a Cotton Wick Making Machine?

Cotton Wick Making Machines provide high efficiency, producing large quantities of wicks quickly for both small and large-scale production. They ensure consistency in size and quality, reduce labor costs through automation, and maintain quality control for optimal burning performance.

3. What raw materials are required for the Cotton Wick Making Machine

The primary raw material used is cotton yarn. The cotton is typically fed into the machine in yarn form, which is then twisted into wicks. Other materials may include thread wax or oil for treating the cotton wicks, ensuring they burn evenly and efficiently.

4. What is the production capacity of a Cotton Wick Making Machine?

The production capacity of Cotton Wick Making Machines varies based on the model. Small-scale machines can produce between 500-2,000 wicks per hour, making them suitable for smaller operations. In contrast, large-scale industrial machines can produce anywhere from 10,000 to 50,000 wicks per hour, depending on their size and automation level, catering to high-volume production needs.

5. How do I maintain and clean my Cotton Wick Making Machine?

-

Regular Cleaning: Clean the machine after every use to remove cotton residue and prevent clogging.

-

Lubrication: Lubricate moving parts, such as rollers and cutters, to prevent wear and tear.

-

Inspection: Periodically check for any broken or damaged parts, such as rollers or motors, and replace them as needed.

6. Can the machine make wicks of different sizes and thicknesses?

Yes, many Cotton Wick Making Machines offer adjustable settings, allowing you to produce wicks of various sizes, thicknesses, and lengths. Some models also allow you to customize the wick's tightness to ensure it burns optimally.

7. What is the power requirement for a Cotton Wick Making Machine?

The power consumption of Cotton Wick Making Machines varies based on their size. Small-scale machines typically consume around 1-2 kW, while large-scale machines can consume 5-15 kW, depending on the production speed and automation features.

8. How can I order a Cotton Wick Making Machine?

To inquire about or place an order for a Cotton Wick Making Machine, visit ASVR Engineering – Cotton Wick Making Machine. For more details or a personalized quote, feel free to contact our team.

9. How long does it take to receive a Cotton Wick Making Machine after placing an order?

Delivery time for Cotton Wick Making Machines varies based on the model, location, and customization. Standard machines typically have a delivery time of 2-4 weeks, while customized models may take longer, depending on the specific requirements and specifications.

.jpg)