Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

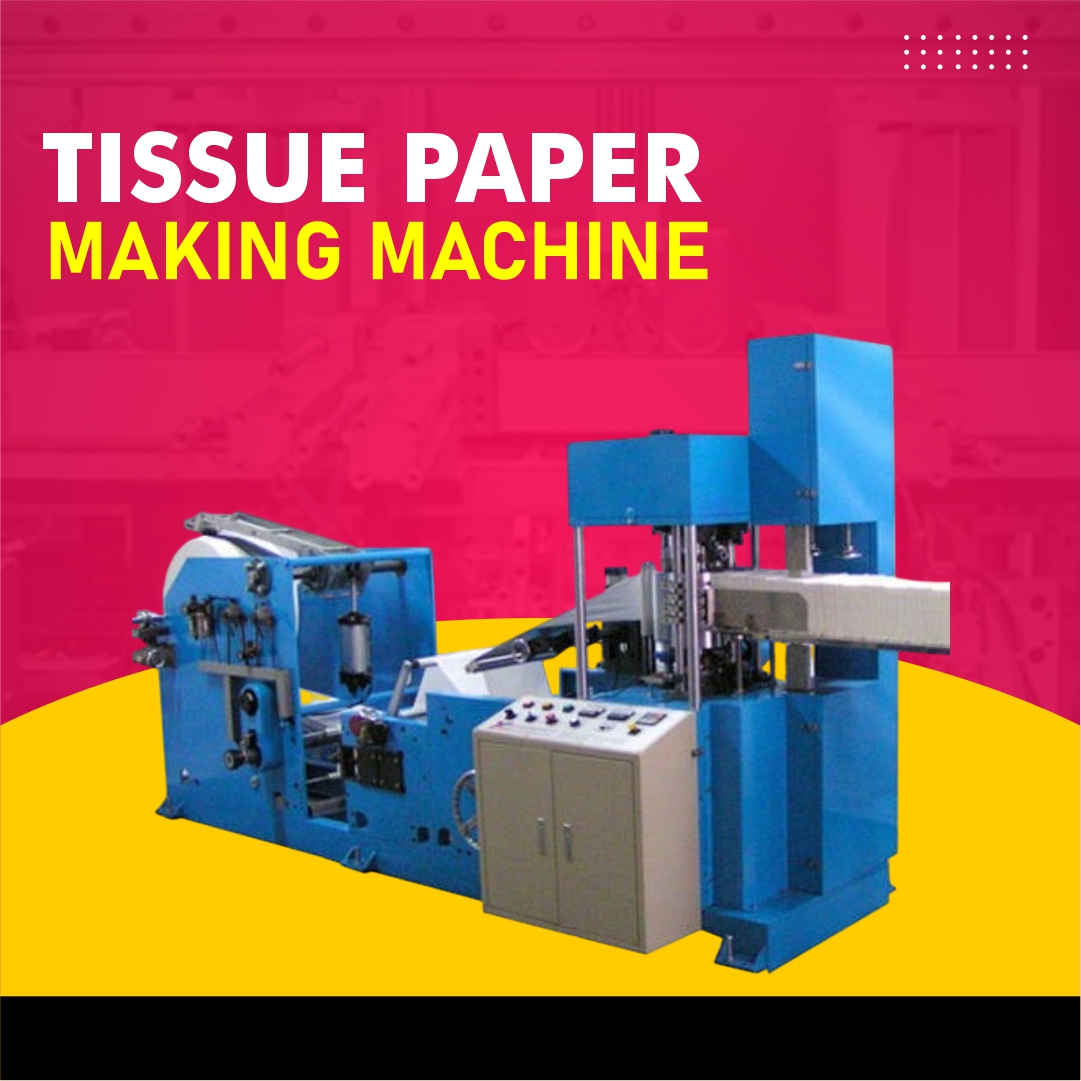

Tissue Paper Making Machine

Price: ₹ 450000

| Product Generic Name |

Tissue Paper Making Machine |

|---|---|

| Motor |

1HP-3 HP |

| Weight |

1500 kg (approx) |

| Capacity |

21500 Sheets /Hr |

Add To Cart

Tissue Paper Making Machine: Transforming Paper Production with Efficiency

A tissue paper making machine is an advanced piece of industrial equipment designed to manufacture tissue paper in various forms — including facial tissue, toilet rolls, kitchen towels, and napkins. Whether you're setting up a small-scale business or operating a large industrial unit, this machine plays a critical role in producing high-quality, soft, and absorbent tissue paper efficiently.

In this article, we’ll explore what a tissue paper making machine is, how it works, its benefits, features, applications, and what factors to consider before investing in one.

What is a Tissue Paper Making Machine?

A tissue paper making machine is a type of paper converting machinery that processes raw materials (like wood pulp, recycled paper, or virgin pulp) to produce thin, lightweight, and soft tissue paper rolls or sheets. These machines are engineered to ensure precise control over thickness, softness, moisture content, and strength of the finished product.

Tissue paper is in high demand globally for personal hygiene, household cleaning, hospitality, and industrial applications, making tissue paper production a lucrative business opportunity.

How Does a Tissue Paper Making Machine Work?

The tissue paper production process using a tissue paper making machine typically follows these steps:

-

Raw Material Preparation:

Raw materials such as virgin wood pulp or recycled paper are mixed with water and chemicals to form a slurry (pulp). This step ensures the fiber is properly broken down and mixed evenly. -

Pulping and Refining:

The pulp undergoes refining to improve fiber bonding. This process enhances the strength and softness of the finished tissue paper. -

Sheet Formation:

The pulp is fed onto a wire mesh conveyor (forming section), where water is drained, leaving behind a thin mat of fibers. -

Pressing:

The wet sheet passes through press rollers to remove excess water and to compact the fibers, making the sheet stronger. -

Drying:

The semi-dry sheet passes over heated drying cylinders (Yankee dryer) to evaporate remaining moisture and smoothen the sheet. -

Creping:

The dried sheet is scraped off the Yankee dryer with a creping blade, giving the tissue its characteristic softness and stretch. -

Reeling and Slitting:

The finished tissue paper is wound onto jumbo rolls. The rolls can later be slit, cut, or perforated into desired sizes for different products (toilet rolls, facial tissues, napkins, etc.).

Key Features of Tissue Paper Making Machines

-

High Production Speed:

Modern machines can produce tissue paper at speeds ranging from 600 to 1500 meters per minute, depending on the model and capacity. -

Automatic Control Systems:

Equipped with PLC-based control panels for monitoring and adjusting parameters like temperature, moisture, and speed to ensure consistent output. -

Energy Efficiency:

Advanced machines use energy-efficient drying systems and motors to reduce operational costs. -

Customization Options:

Machines are available with customizable features like embossing units, perforation rollers, and automatic cutting systems for different types of tissue products. -

Durable Construction:

Made with corrosion-resistant stainless steel and high-quality components to ensure longevity and low maintenance.

Benefits of Using a Tissue Paper Making Machine

-

High Productivity:

Capable of producing large volumes of tissue paper in a short time, meeting market demand efficiently. -

Versatility:

With the ability to produce different types of tissue paper (toilet rolls, kitchen towels, facial tissues, napkins), one machine can serve multiple markets. -

Consistent Quality:

Advanced control systems ensure uniformity in thickness, softness, and texture across batches. -

Cost-Effective:

Efficient use of raw materials, water, and energy reduces production costs, improving profitability. -

Scalability:

Available in different capacities, from small-scale units suitable for startups to large industrial setups for high-volume production. -

Eco-Friendly Production:

Machines designed to use recycled paper reduce environmental impact and align with sustainable manufacturing practices.

Applications of Tissue Paper Making Machines

-

Toilet Paper Manufacturing

-

Facial Tissue Production

-

Kitchen Towel Making

-

Napkin Production for Restaurants and Hotels

-

Industrial and Medical Tissue Production

Factors to Consider Before Buying a Tissue Paper Making Machine

-

Production Capacity:

Assess your target market and production needs to choose a machine with the right output capacity (tons per day). -

Automation Level:

Decide whether you want a semi-automatic or fully automatic machine based on labor availability and production scale. -

Raw Material Availability:

Ensure a consistent supply of virgin pulp, recycled paper, or other materials suited to the product you plan to manufacture. -

Machine Footprint and Space Requirement:

Check the machine dimensions and ensure you have sufficient space for installation, operation, and maintenance. -

Energy Consumption:

Evaluate power requirements and choose energy-efficient models to save on operational costs. -

After-Sales Support:

Opt for manufacturers that provide installation assistance, operator training, maintenance support, and spare parts availability. -

Budget:

Consider the total investment cost, including machinery, installation, and working capital, to ensure financial feasibility.

Why Invest in a Tissue Paper Making Machine?

-

Growing Demand:

Tissue paper consumption is rising due to increased awareness of hygiene and disposable products, offering a profitable market. -

Diverse Product Line:

The ability to produce multiple tissue paper products allows for market diversification and risk reduction. -

Low Raw Material Cost:

Recycled paper and other raw materials are readily available and affordable. -

High Return on Investment:

The combination of low production cost, high demand, and versatility results in attractive profit margins.

Conclusion

A tissue paper making machine is a smart investment for entrepreneurs and manufacturers aiming to enter or expand in the booming hygiene products industry. With its efficiency, versatility, and scalability, the machine enables consistent production of high-quality tissue products, meeting both domestic and commercial market demands.

By carefully selecting the right machine based on your production needs, budget, and business goals, you can build a profitable and sustainable tissue paper manufacturing business.

-

High Production Efficiency

Automates the complete tissue paper manufacturing process, enabling high-speed production and meeting large-scale demands effortlessly. -

Consistent Quality Output

Ensures uniform thickness, texture, and softness in every sheet, maintaining superior product quality across batches. -

Versatile Production Capabilities

Capable of producing various tissue paper products, including facial tissues, toilet rolls, napkins, and kitchen towels, offering flexibility for different markets. -

Energy Efficient

Optimized for low power consumption while maintaining high productivity, reducing operational costs and maximizing profitability. -

User-Friendly Operation

Equipped with intuitive controls and automation systems, making it easy to operate even for users with minimal technical knowledge. -

Hygienic & Safe Processing

Built with food-grade, rust-resistant materials and designed for easy cleaning, ensuring hygienic and safe production of tissue products. -

Durable & Long-Lasting

Constructed with high-quality materials and robust engineering, offering long service life and reliable operation under continuous use. -

Compact & Space-Saving Design

Despite its high output capacity, the machine is compact and can fit in small to medium-sized production facilities efficiently. -

Low Maintenance

Requires minimal maintenance thanks to its sturdy components and simple mechanism, reducing downtime and maintenance costs. -

Cost-Effective & Profitable

Speeds up production, reduces labor costs, and ensures consistent quality — all contributing to higher profitability for businesses.

1. What is a Tissue Paper Making Machine, and how does it work?

A Tissue Paper Making Machine uses a combination of rollers, pressure, and drying processes to convert wood pulp or recycled paper into tissue paper. The machine takes raw materials, processes them into a pulp, and then forms them into thin, soft sheets. These sheets are dried, cut, and rolled into finished tissue paper products.

2. What types of tissue products can be made using the machine?

The tissue-making machine can produce a variety of tissue products, including toilet paper rolls, facial tissues, paper napkins, kitchen towels, and industrial wipes. The specific product produced depends on the settings and configuration of the machine, allowing for customization based on production needs.

3. . What are the benefits of using a Tissue Paper Making Machine?

Tissue paper machines offer several advantages, including high production speed, making them ideal for businesses requiring large-scale output. Automation in these machines reduces labor costs and enhances production efficiency. They also provide quality control, ensuring consistent tissue quality with desired softness, absorbency, and strength. Additionally, these machines are cost-effective, as they process raw materials in bulk, reducing material wastage and improving profitability.

4. What raw materials are required for the Tissue Paper Making Machine?

The primary raw materials for making tissue paper include wood pulp, which is commonly sourced from trees like pine, eucalyptus, or bamboo. Some machines also accept recycled paper, offering a more environmentally friendly option. Additionally, additives such as softeners and fragrances may be used, depending on the type of tissue, to enhance the product's quality and appeal.

5. What is the production capacity of a Tissue Paper Making Machine?

The production capacity of tissue paper machines varies based on their size and design. Small-scale machines typically produce around 100-500 kg of tissue paper per day, suitable for smaller businesses. On the other hand, industrial-scale machines can produce anywhere from 1 to 10 tons per day, catering to large-scale manufacturing needs and high-volume production.

6. How much power does a Tissue Paper Making Machine consume?

The power consumption of a Tissue Paper Making Machine varies based on its size and model. Small machines typically consume 10-30 kW of power, suitable for smaller production scales. In contrast, large-scale machines can consume 100-200 kW, depending on the machine's capacity and automation level, supporting high-volume, industrial production.

7. How do I maintain and clean my Tissue Paper Making Machine?

-

Regular Cleaning: Clean the rollers, drying units, and other components regularly to avoid pulp buildup.

-

Lubrication: Periodically lubricate the moving parts to ensure smooth operation.

-

Inspection: Check for wear and tear on components like the rollers and cutting blades to ensure continuous production.

8. Can the Tissue Paper Making Machine be used for different types of tissue products?

Yes, many Tissue Paper Making Machines are versatile and can be configured to produce various types of tissues, including toilet rolls, facial tissues, paper towels, and napkins. Different attachments, dies, and settings allow for easy customization, enabling the production of a variety of tissue products to meet specific business needs.

9. How can I order a Tissue Paper Making Machine?

To inquire about a Tissue Paper Making Machine or place an order, visit ASVR Engineering – Tissue Paper Making Machine. You can also contact our sales team for personalized quotes and more information.