Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

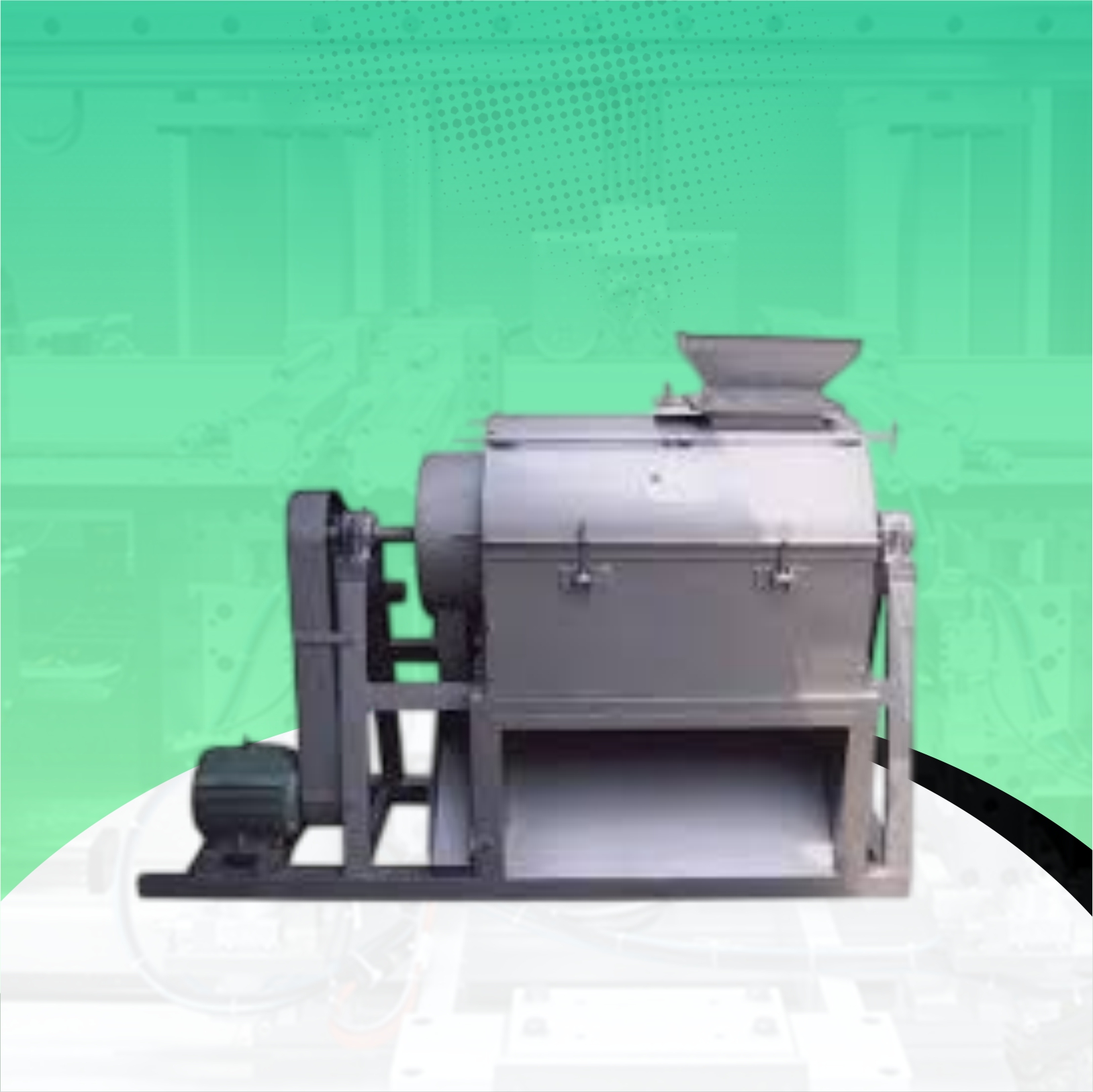

Cage mill machine

Price: ₹ 90000

| Product Generic Name |

cage mill machine |

|---|---|

| Minimum Order Quantity |

1 Piece |

| Brand Name |

Customized |

| Body Material |

MS |

| Usage/Application |

For Making Surf and Detergent |

Add To Cart

The Cage Mill Machine is a robust, high-speed crushing equipment designed for pulverizing and mixing materials like detergent powder, chemicals, minerals, and agricultural inputs. It features a series of rotating cages with bars or paddles that collide and break down materials into fine particles. Widely used in industries such as detergent manufacturing, fertilizer production, and mineral processing, this machine ensures uniform particle size and excellent mixing efficiency. Built with heavy-duty steel, it offers long-lasting performance, minimal maintenance, and easy operation.

-

⚙️ High Crushing Efficiency: Breaks down lumps and hard materials into fine powder.

-

🔄 Uniform Mixing: Ensures even blending of ingredients in detergent and chemical industries.

-

🧱 Heavy-Duty Build: Built with strong steel components for continuous industrial use.

-

👨🔧 Low Maintenance: Simple design with minimal moving parts.

-

⏱️ Time-Saving: Fast processing for high-volume production.

-

🧼 Easy to Clean: Smooth finish and accessible design for quick cleaning.

1. What is a cage mill machine and how does it work?

A cage mill machine is a type of grinding mill used for crushing and pulverizing materials, such as minerals, chemicals, and agricultural products. It consists of a rotating cage with high-speed pins or hammers that crush the material as it moves through the machine. The material is repeatedly broken down in multiple stages, allowing for finer particles.

2. How does the cage mill machine differ from other mills?

Unlike traditional mills, a cage mill machine features multiple stages of crushing, which provides more uniform particle sizes. Its high-speed rotating cage, along with hammers or pins, creates a more efficient grinding process, making it ideal for tough materials and high-volume production.

3. What is the output capacity of a cage mill machine?

The output capacity varies depending on the model and the materials being processed, but most cage mill machines can handle capacities ranging from 500 kg/hour to several tons per hour.

4. How does the cage mill machine help with particle size control?

Cage mill machines can achieve fine and consistent particle sizes through the multiple crushing stages. The speed and design of the rotating cage, along with adjustable screen sizes, allow operators to control the fineness of the output material, making it ideal for specific industrial applications.

5. Can the cage mill machine be adjusted to suit different materials?

Yes, many cage mill machines come with adjustable settings that allow operators to customize the crushing process for different materials. This includes changes in the speed of rotation, the size of the screens, and the force applied by the hammers or pins.

6. Can a cage mill machine be used for both dry and wet materials?

Yes, a cage mill machine is capable of processing both wet and dry materials. However, the operational settings might need to be adjusted depending on whether the material is wet or dry to achieve the desired output.