Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

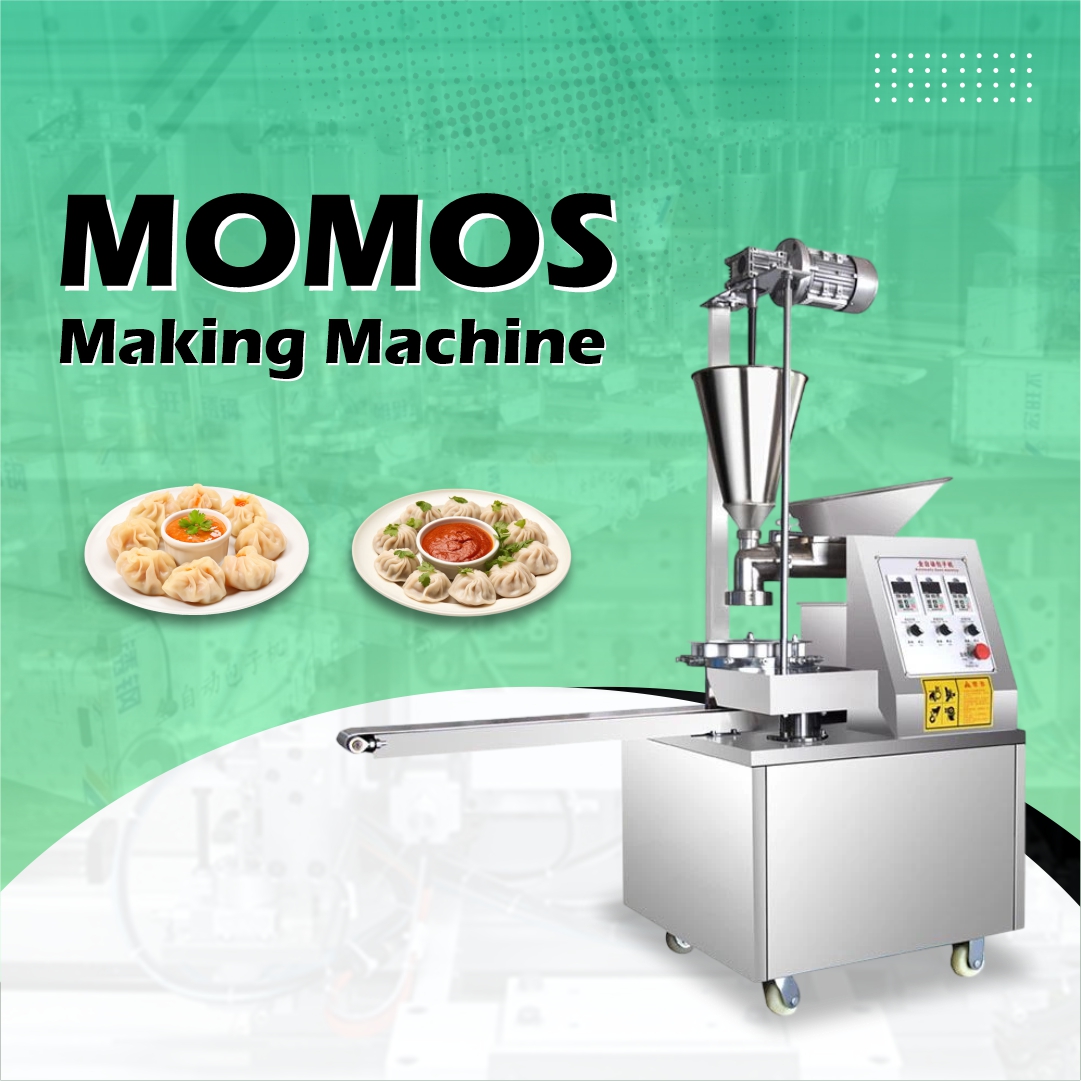

Momos Making Machine

Price: ₹ 210000

| Product Generic Name |

Momos Making Machine |

|---|---|

| Production |

6000 Pcs/Hr |

| Power |

2.2 Kw/220v |

| Weight |

165Kg (Apx) |

| Size Of Machine |

990x470x1100 mm |

Add To Cart

Momos Making Machine: Revolutionizing the Dumpling Industry

The momos making machine is an innovative and efficient solution for automating the production of momos, one of the most popular snacks across the globe, especially in Asian countries. Known for their delicious filling and soft dough, momos are loved by people of all ages. Traditionally, making momos was a labor-intensive process, but with the advent of the momos making machine, businesses can now produce large quantities of momos quickly and efficiently.

This guide will take you through the features, benefits, and importance of a momos making machine in enhancing productivity in the food industry.

What is a Momos Making Machine?

A momos making machine is an automated or semi-automated device designed to streamline the process of preparing momos. It automates the dough preparation, filling, and folding processes, ensuring that every momo is uniform in size, shape, and texture. This machine is especially useful for restaurants, food chains, and food processing companies looking to meet the growing demand for momos while maintaining consistent quality.

How Does a Momos Making Machine Work?

The operation of a momos making machine generally involves the following stages:

-

Dough Preparation:

The machine automatically kneads the dough to the right consistency, ensuring that it is smooth and soft, which is crucial for making perfect momos. -

Filling:

The prepared filling, whether it’s vegetarian, chicken, pork, or any other variant, is automatically dispensed into the dough. The machine is capable of handling various types of fillings, ensuring a balanced amount in each momo. -

Shaping and Folding:

The momo-making machine shapes and folds the dough around the filling. It creates uniform, perfectly shaped momos with consistent sealing, reducing the risk of the momos opening during steaming or frying. -

Ejection:

Once the momos are shaped and folded, they are automatically ejected from the machine, ready to be steamed or fried, depending on your preparation method. -

Packaging (optional):

Some advanced momo-making machines are integrated with packaging systems that can automatically pack the momos in trays, ready for sale or distribution.

Benefits of Using a Momos Making Machine

-

High-Speed Production:

A momos making machine can significantly increase production speed, allowing businesses to produce hundreds or even thousands of momos per hour. This high-speed production is crucial for meeting large-scale demand, especially in commercial food operations. -

Consistency and Uniformity:

The machine ensures that every momo is identical in shape, size, and weight. This uniformity is important for businesses that want to maintain a high level of product consistency, especially in food chains or packaged food production. -

Labor Cost Reduction:

By automating the process, the momos making machine reduces the need for manual labor. This not only lowers labor costs but also minimizes human error, leading to more efficient and effective operations. -

Improved Hygiene and Quality:

With minimal human interaction, the risk of contamination is greatly reduced. The machine ensures that the dough and fillings are handled in a clean and controlled environment, improving the overall hygiene and quality of the momos. -

Customization Options:

Modern momo-making machines can be customized to make different types and sizes of momos. Whether you want to make large momos, small bite-sized ones, or momos with specific fillings, the machine can be adjusted to meet your needs. -

Reduced Wastage:

The machine minimizes wastage by precisely controlling the amount of dough and filling used for each momo. This ensures that resources are used efficiently, reducing material costs. -

Energy Efficiency:

Many modern momo-making machines are designed to be energy-efficient, reducing the operational costs for businesses. The low power consumption ensures that businesses can run the machine for long hours without significant energy expenses.

Key Features of a Momos Making Machine

-

High Production Capacity:

Depending on the machine model, it can produce hundreds or thousands of momos per hour, making it ideal for businesses with high demand. -

Adjustable Filling Dispenser:

The machine comes with an adjustable filling dispenser that allows you to control the amount of filling for each momo, ensuring that the momos are consistently packed. -

Durable Construction:

These machines are built from high-quality stainless steel, which is not only durable but also easy to clean and maintain. -

User-Friendly Control Panel:

The control panel is intuitive, allowing operators to easily adjust settings for dough thickness, filling amount, and speed of production. -

Compact Design:

Many momo-making machines are designed with a compact footprint, which makes them suitable for kitchens with limited space. -

Easy to Clean:

The machine is designed to be easily disassembled for cleaning, ensuring that it stays hygienic and operational for longer periods.

Applications of a Momos Making Machine

-

Restaurants and Food Chains:

For restaurants and fast-food chains that serve momos as a popular menu item, using a momo-making machine ensures fast production and consistency, especially during peak hours. -

Food Processing and Packaging Companies:

Companies that pack frozen or ready-to-eat momos rely on these machines to meet mass production demands while ensuring each momo is perfectly made. -

Catering Services:

Catering services can benefit from the speed and uniformity of the momo-making machine, ensuring large orders are prepared quickly and consistently. -

Frozen Food Manufacturers:

For businesses producing frozen momos, the machine ensures large-scale production while maintaining the quality of the product, which is crucial for the retail market.

How to Choose the Right Momos Making Machine

When choosing the right momos making machine, consider the following factors:

-

Production Volume:

The machine’s capacity should align with your business needs. For smaller businesses, a machine with a lower production capacity may be sufficient, while large-scale operations will require machines with higher production rates. -

Type of Filling:

Ensure that the machine can handle the type of filling you plan to use, whether it’s vegetarian, non-vegetarian, or specialized fillings like cheese or noodles. -

Machine Durability:

Choose a machine made from high-quality materials like stainless steel to ensure long-term durability and ease of cleaning. -

Ease of Maintenance:

Consider machines that are easy to maintain and clean. Regular maintenance will keep the machine running smoothly and extend its lifespan. -

Budget:

While automatic momo-making machines can be an investment, they can pay off in the long run by reducing labor costs and increasing production efficiency. -

Customization Options:

If you need to produce different sizes or shapes of momos, ensure that the machine can be adjusted for these variations.

Conclusion

Investing in a momos making machine is a smart decision for businesses looking to increase production speed, consistency, and quality. Whether you're running a restaurant, a food processing unit, or a catering service, a momo-making machine can streamline your production process, reduce labor costs, and help you meet high demand while maintaining the quality your customers expect. With the ability to customize the machine to suit various types of fillings and sizes, it's a versatile addition to any food manufacturing setup.

-

High Production Efficiency

Automates the entire process of making momos, including dough rolling, filling, and steaming, significantly increasing output and reducing production time. -

Consistent Size & Shape

Ensures uniformity in momo size and shape, providing a professional and consistent product every time. -

Labor-Saving

Reduces the need for extensive manual labor, allowing operators to focus on other aspects of production while the machine handles the bulk of the work. -

Versatile Production

Capable of producing various types of momos, including steamed, fried, and pan-fried, with different fillings such as vegetables, chicken, or pork. -

Energy Efficient

Designed to use minimal energy while maintaining high output, helping reduce operational costs for large-scale production. -

Hygienic & Food-Safe

Made with food-grade stainless steel, ensuring that the machine complies with hygiene standards and delivers safe, clean products. -

User-Friendly Operation

Simple controls make it easy to operate, even for users with little technical expertise, ensuring smooth production flow. -

Compact & Space-Saving Design

Despite its high output, the machine is compact enough to fit in small to medium-sized kitchens or production areas. -

Low Maintenance

Easy to maintain with minimal downtime, ensuring consistent production and reducing maintenance costs. -

Improves Business Efficiency

By speeding up production and ensuring consistency, it helps businesses meet customer demand more effectively and increase profitability.

1. What is a Momos Making Machine, and how does it work?

A Momos Making Machine is an automated device designed to prepare and shape momos, a popular steamed dumpling. The machine mixes the dough, fills it with filling, and shapes it into perfectly formed momos for steaming, saving time and ensuring consistency.

2. What types of momos can the machine make?

The machine can be used to make vegetable momos, chicken momos, paneer momos, and other variations. It can also handle different types of dough and fillings, allowing for customization based on your recipe.

3. What is the production capacity of the Momos Making Machine?

The production capacity varies depending on the model. Small-scale machines produce around 1000 to 3000 momos per hour, while larger machines designed for commercial use can produce up to 5000 momos per hour.

4. How much electricity does the Momos Making Machine consume?

The power consumption of the machine depends on the size and model. On average, machines consume 1 to 3 kW of power, which is efficient for most commercial kitchens.

5. Can the machine be used for making different shapes and sizes of momos?

Yes, many Momos Making Machines come with interchangeable molds, allowing you to make different shapes and sizes, such as round or crescent-shaped momos, depending on your preference.

6. What materials are used to make the Momos Making Machine?

The machines are typically made of stainless steel and food-grade materials, ensuring durability, ease of cleaning, and compliance with food safety standards.

7. Is there any maintenance required for the Momos Making Machine?

Regular maintenance includes cleaning the dough and filling compartments, lubricating moving parts, and checking for wear and tear. Proper care ensures the machine lasts longer and operates efficiently.

8. How can I order a Momos Making Machine?

To place an order or inquire further, you can visit ASVR Engineering’s Momos Making Machine Page or contact our sales team for a quote tailored to your business needs.