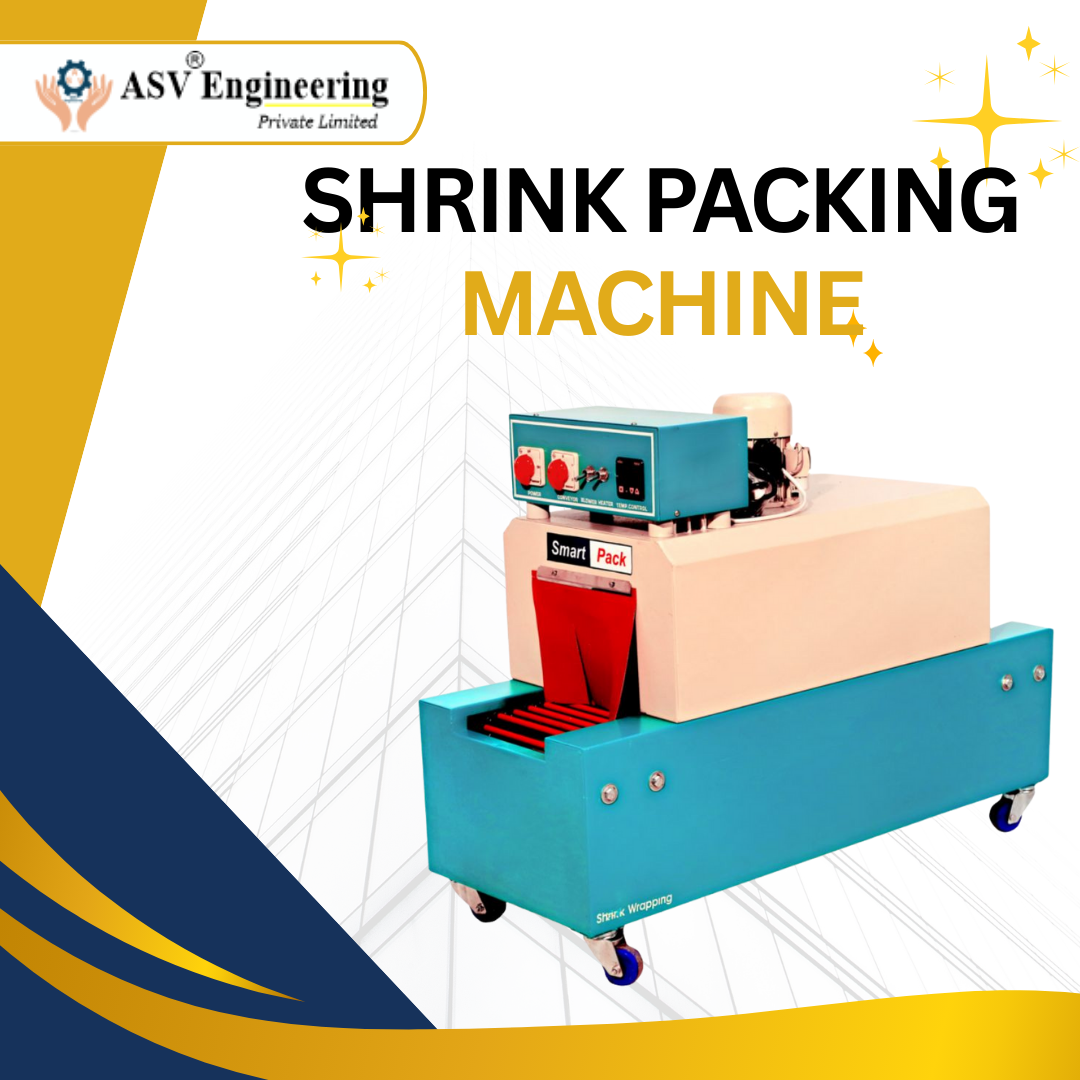

Top Shrink Packaging Machine Manufacturers in India Offering Advanced Automatic & Semi-Automatic Systems

Price: ₹39000

In today’s competitive manufacturing environment, packaging is no longer just the final step of production — it has become a powerful tool for branding, protection, and operational efficiency. Businesses across industries such as food processing, pharmaceuticals, cosmetics, beverages, FMCG, electronics, and logistics require reliable packaging systems that ensure product safety while enhancing visual appeal. This is where shrink packaging machines play a crucial role.

India has emerged as a strong hub for packaging machinery manufacturing, offering innovative and cost-effective solutions for domestic as well as international markets. Among the leading names in this industry is ASVR Engineering, known for designing and manufacturing advanced automatic and semi-automatic shrink packaging machines tailored to diverse industrial requirements.

Understanding Shrink Packaging Technology

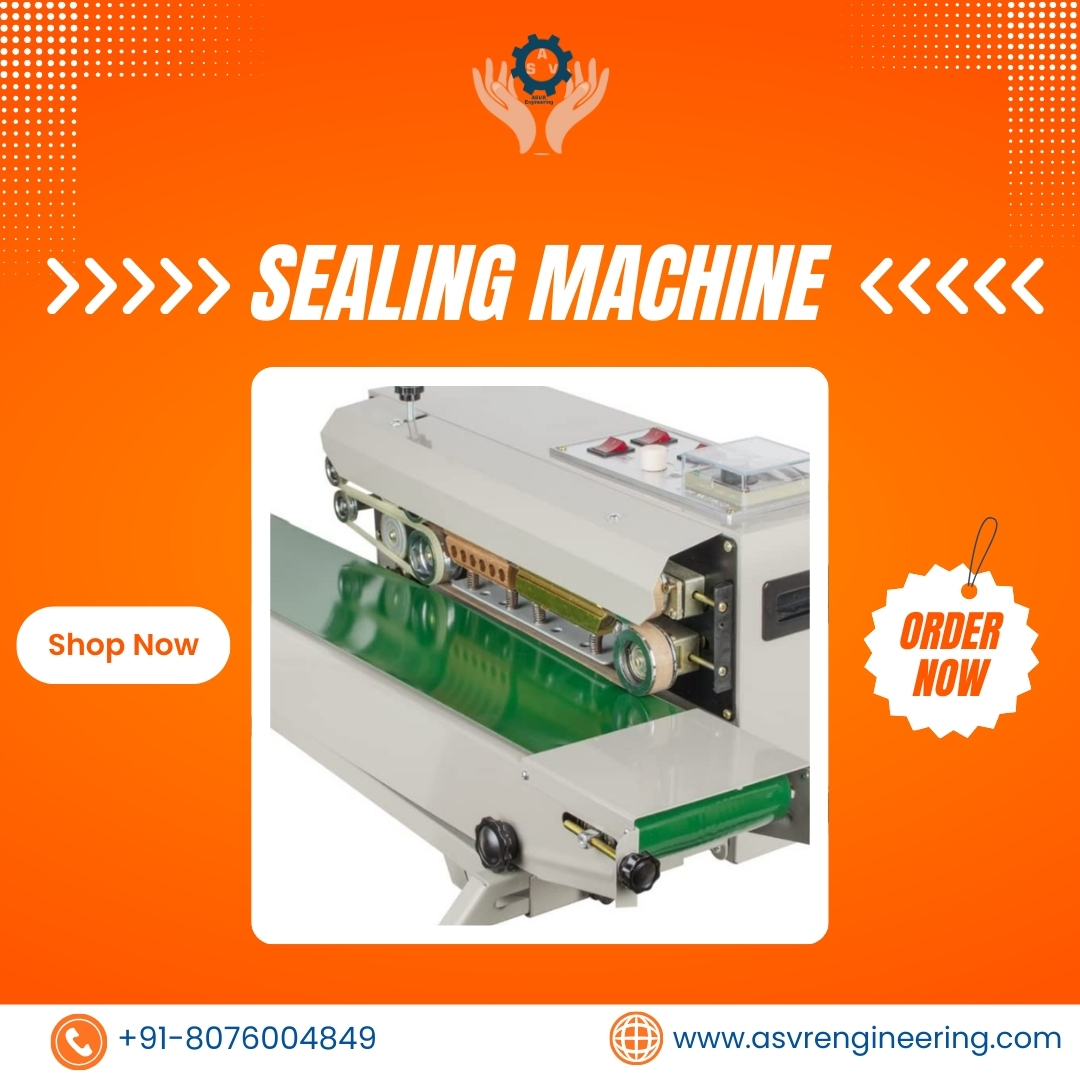

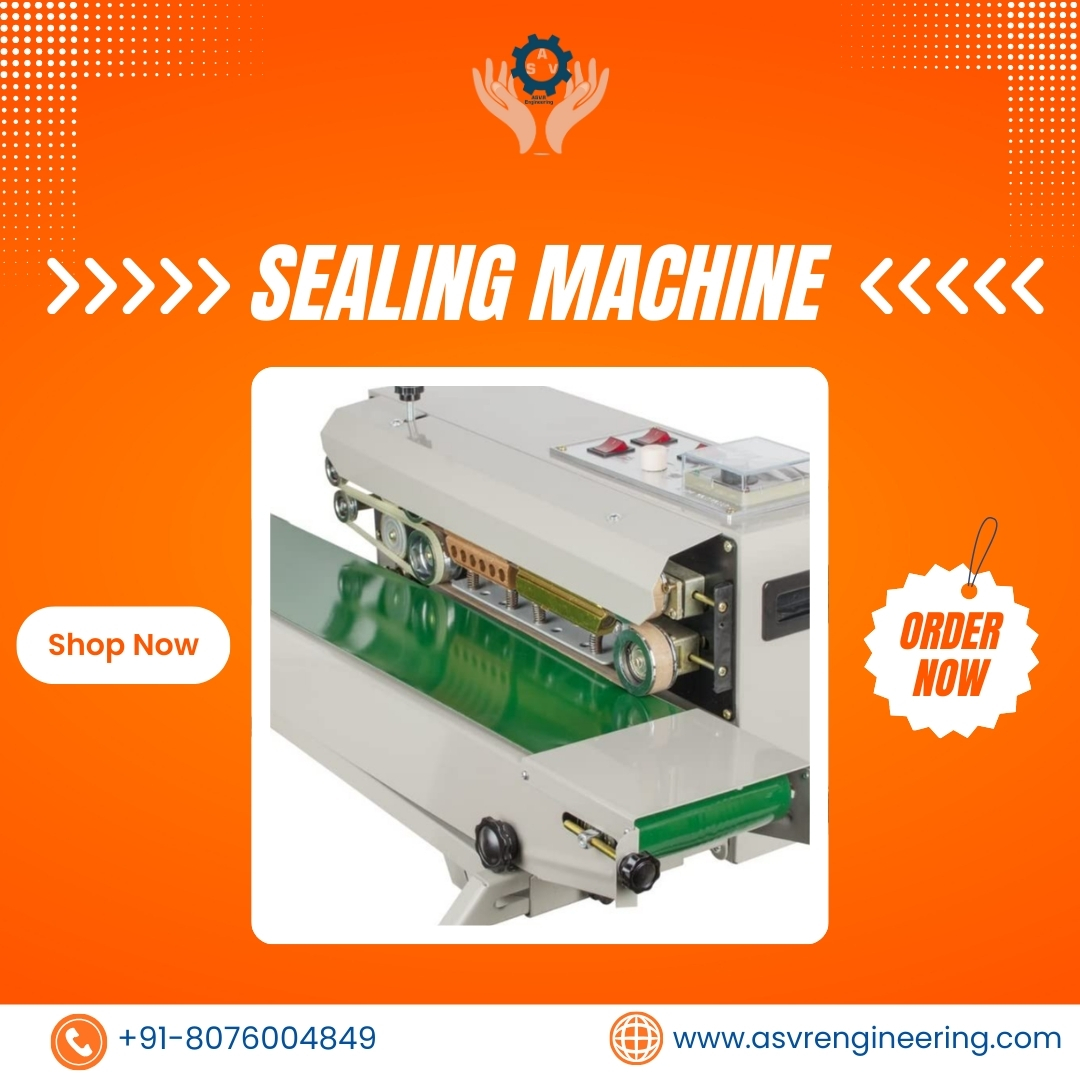

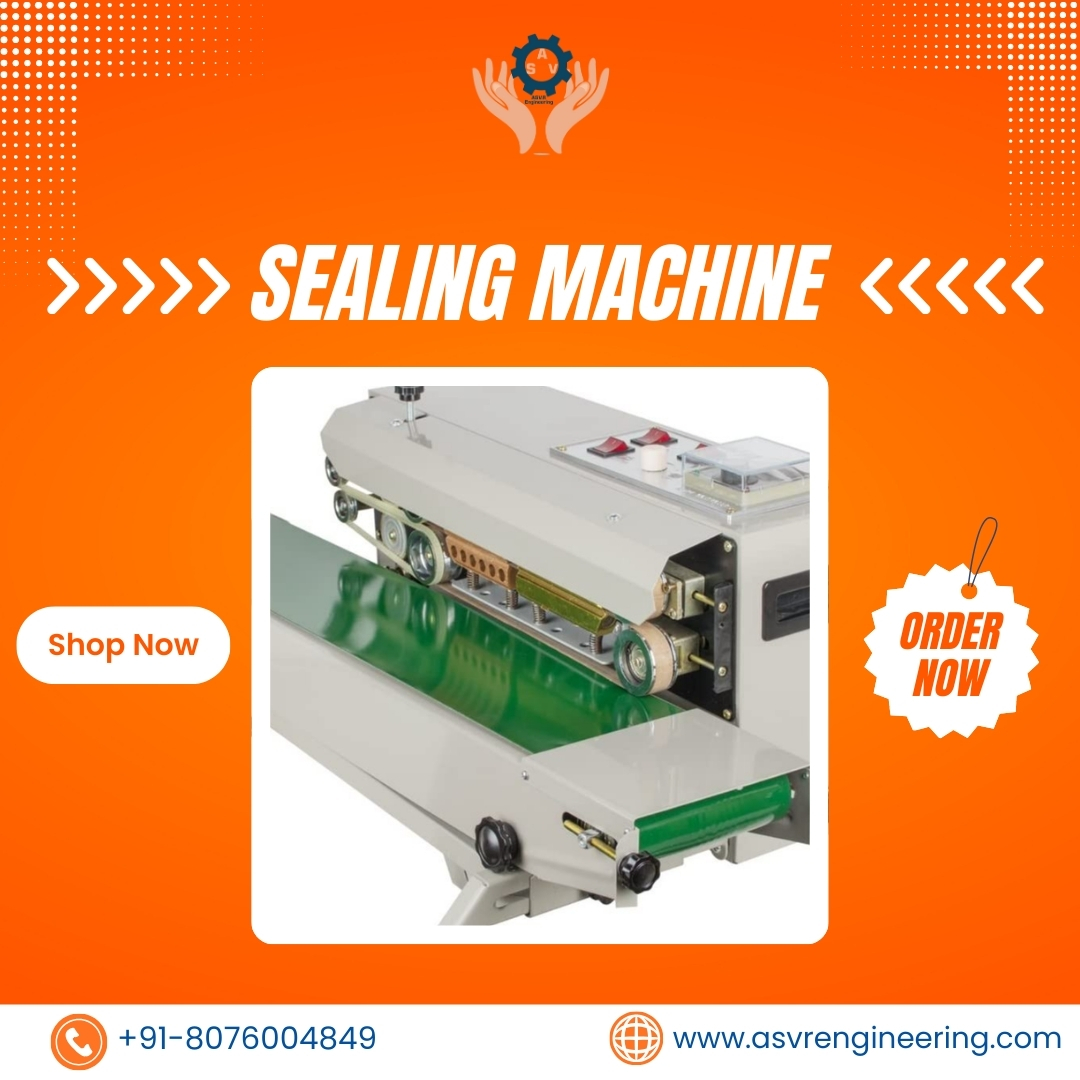

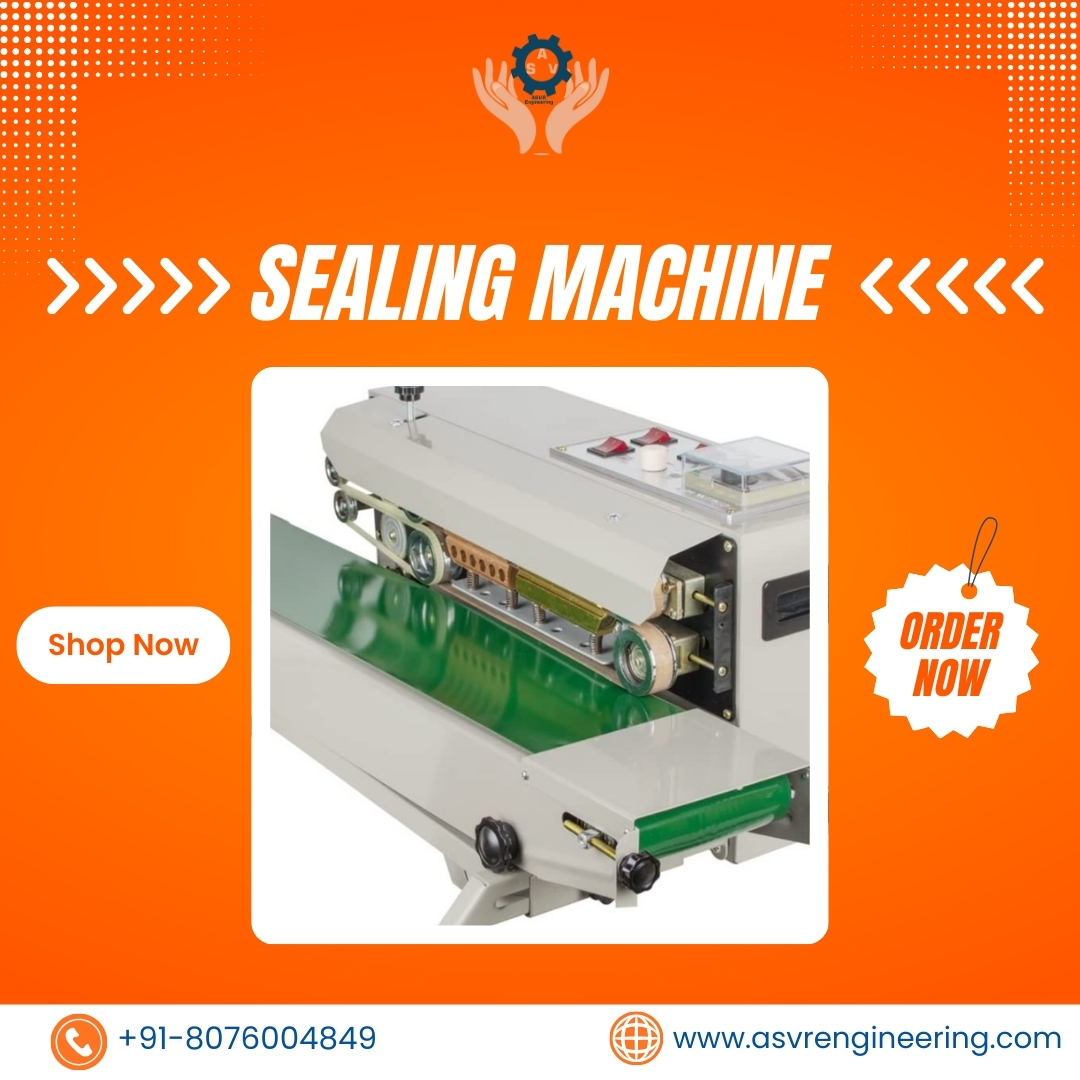

Shrink packaging is a modern method of wrapping products using a polymer plastic film. When heat is applied, the film shrinks tightly around the product, creating a secure, tamper-evident, and visually appealing package. This method is widely preferred because it provides excellent protection against dust, moisture, and external damage during storage and transportation.

Shrink packaging systems generally consist of two primary components:

-

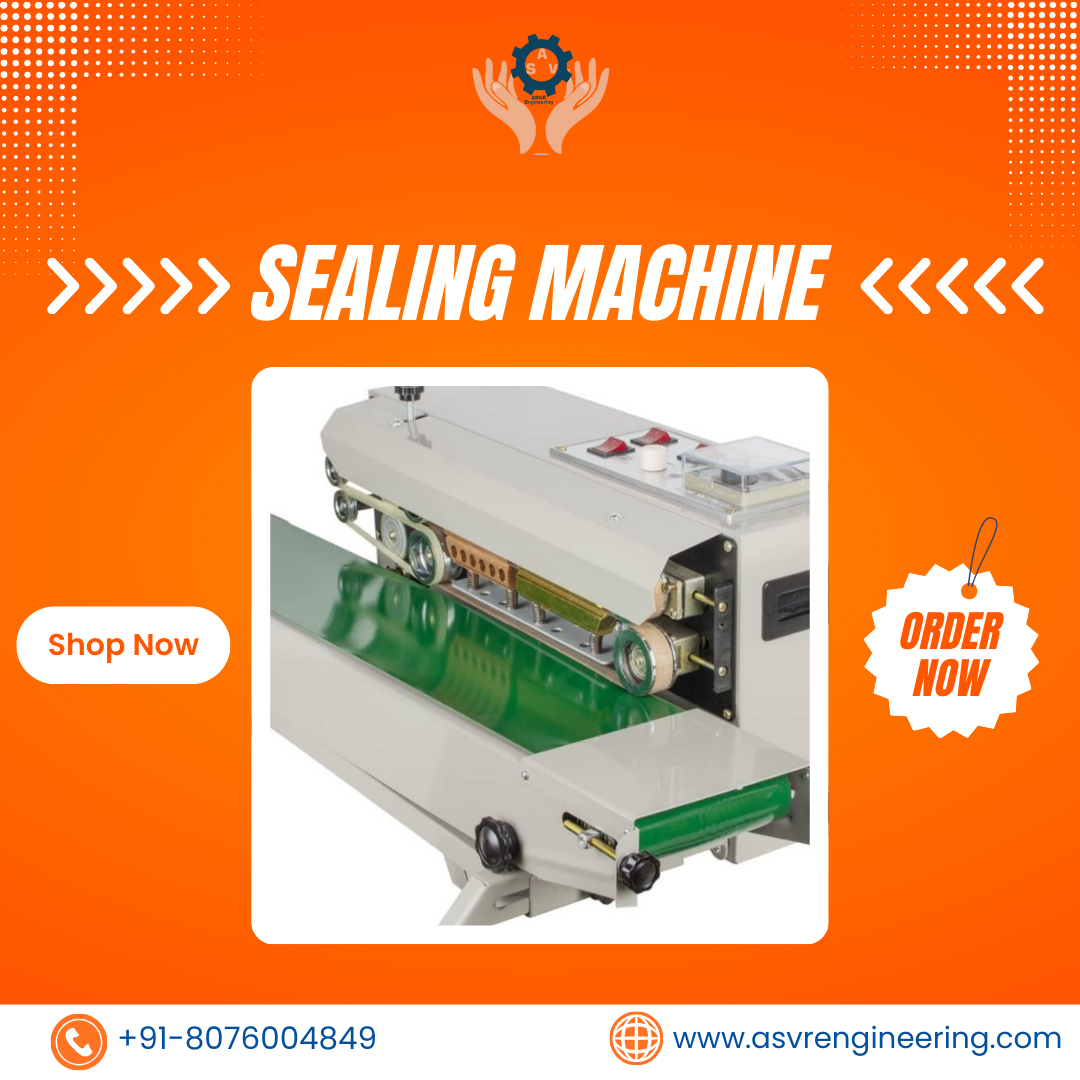

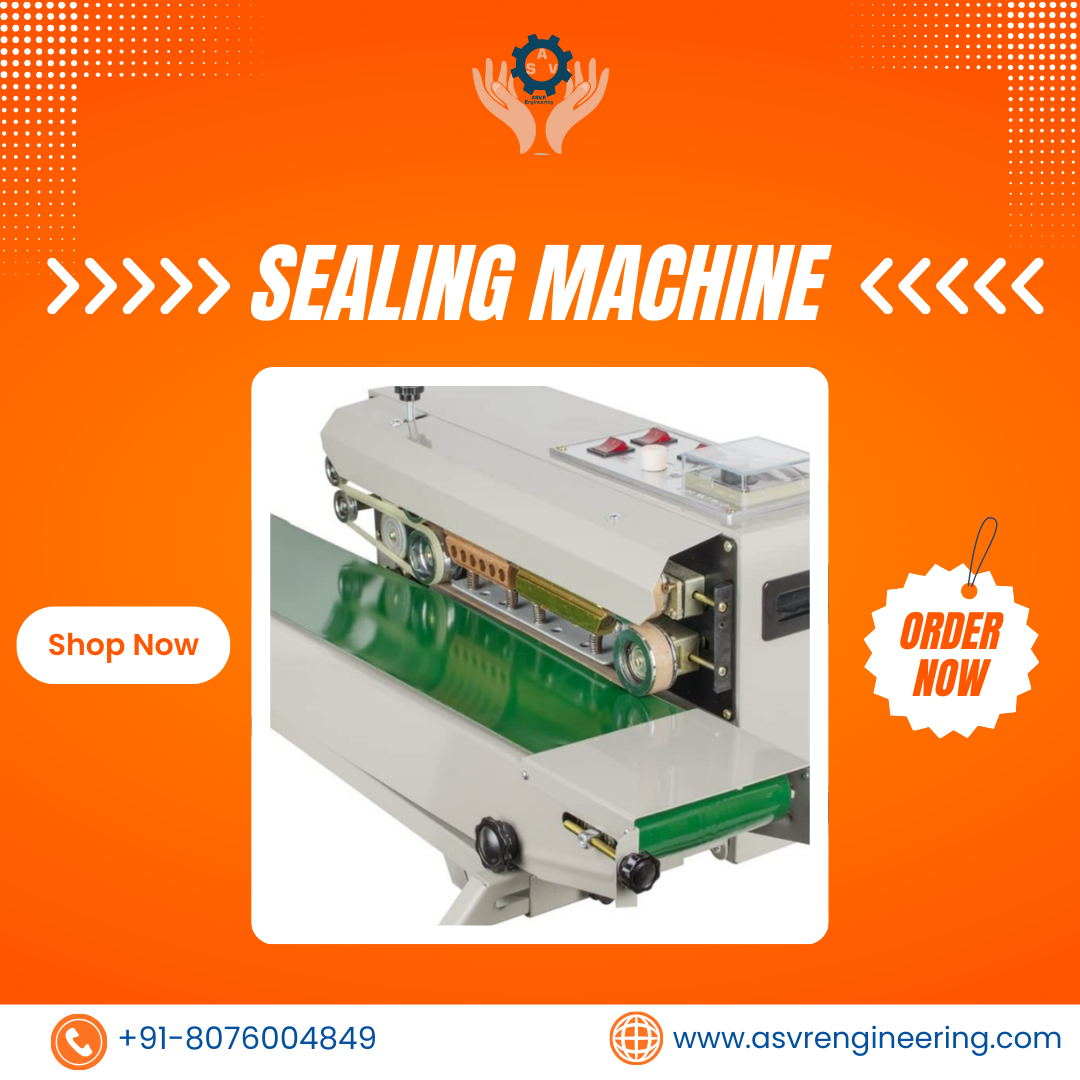

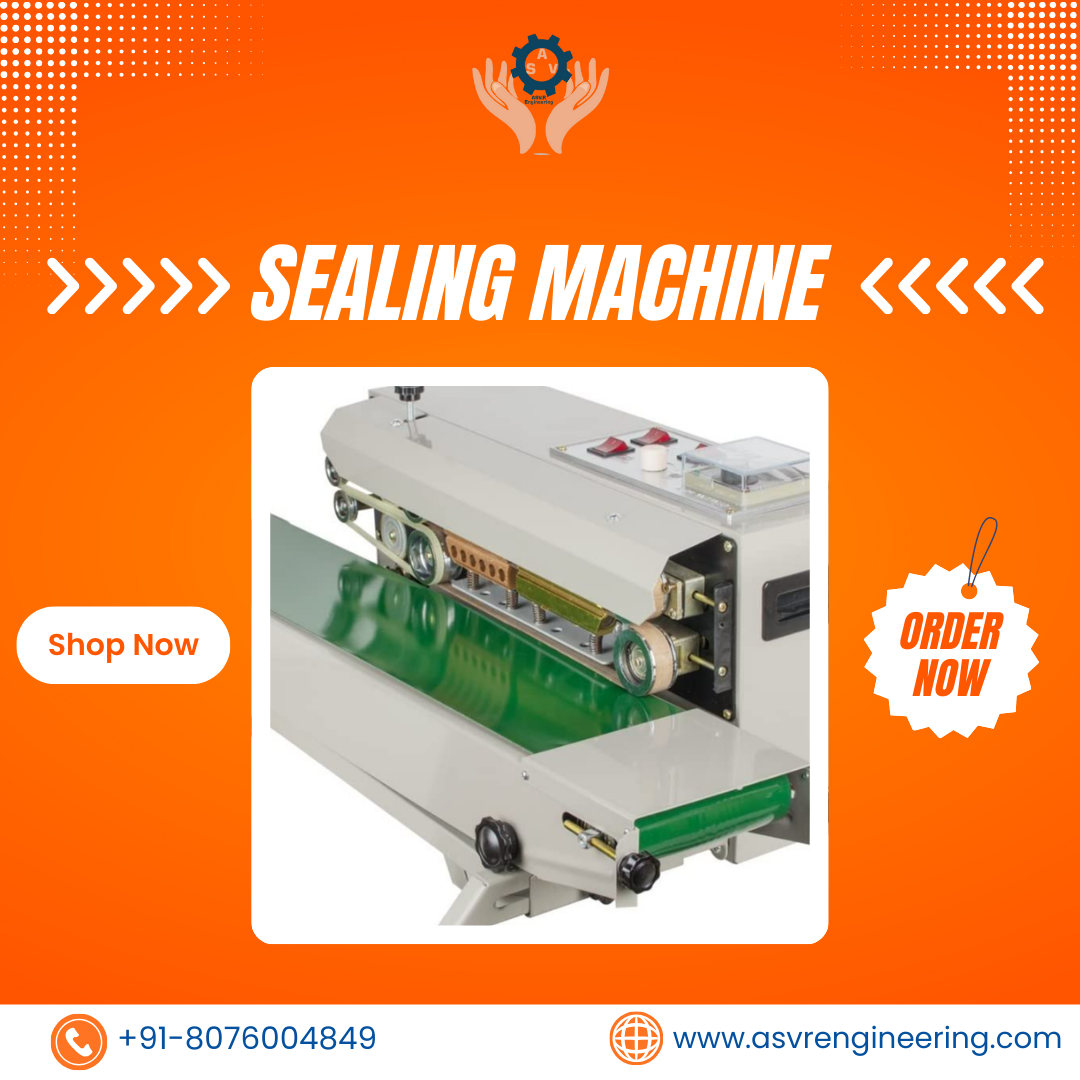

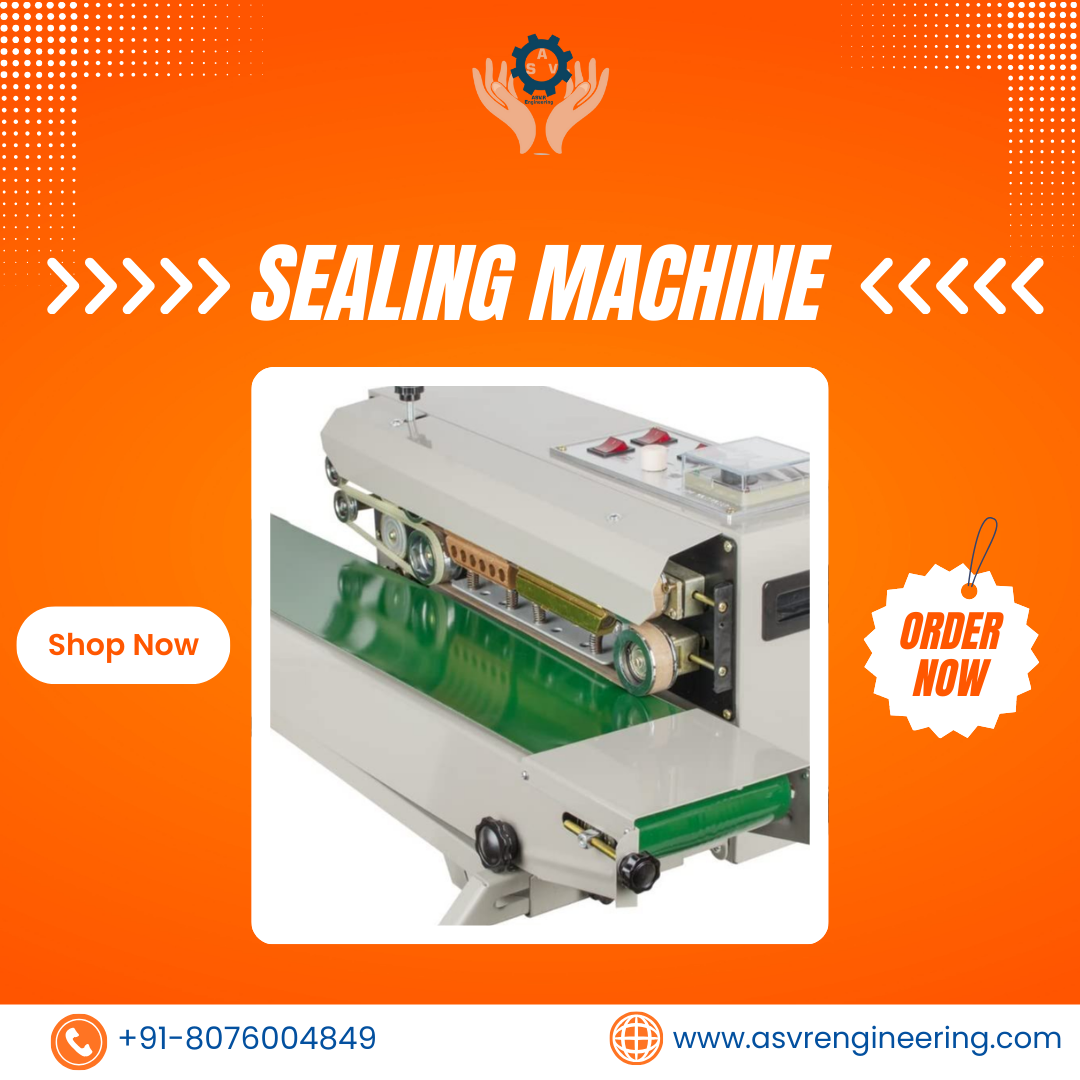

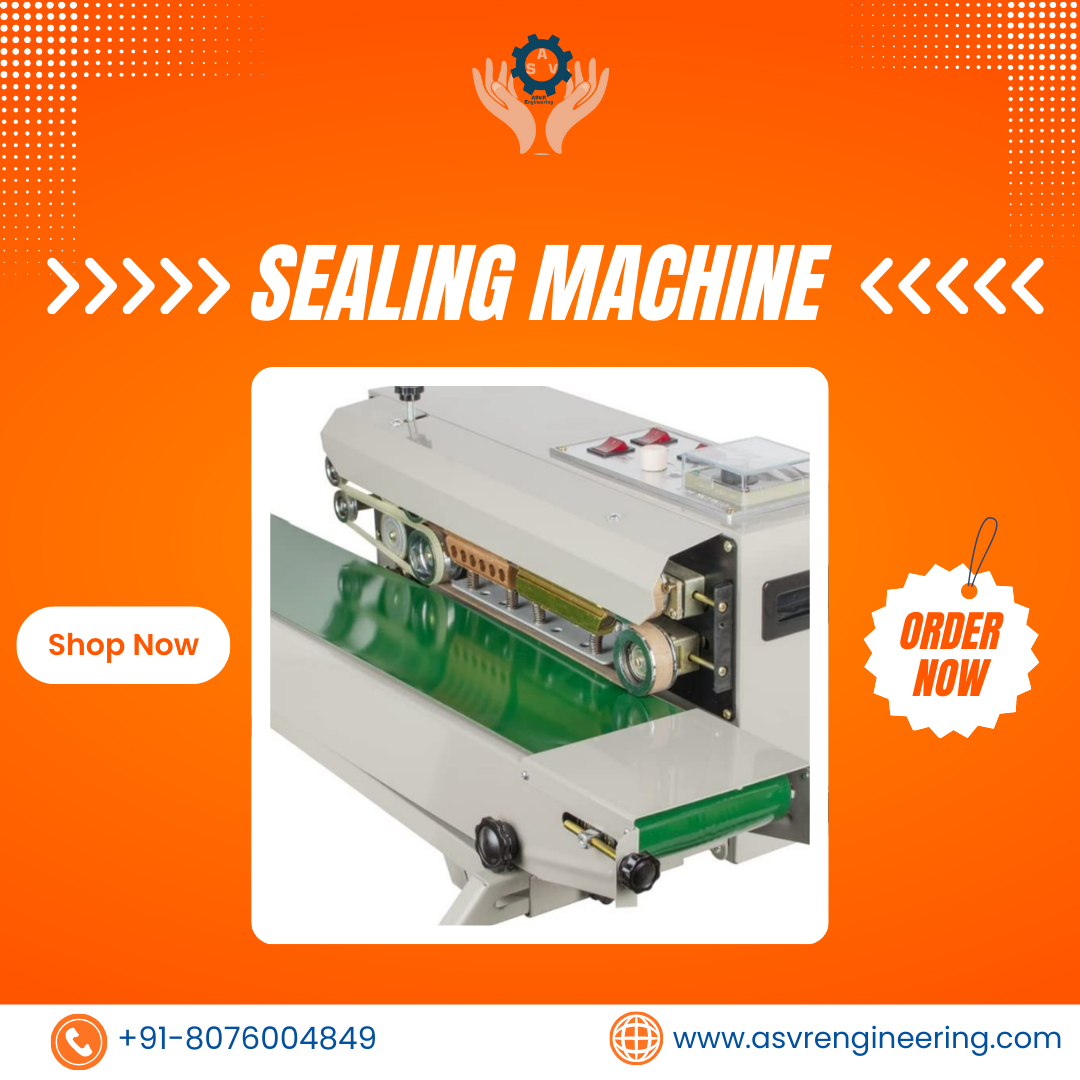

Sealing Machine (L-Sealer or Side Sealer) – Wraps and seals the shrink film around the product.

-

Shrink Tunnel – Applies controlled heat to shrink the film tightly around the product.

Depending on production capacity and automation requirements, businesses can choose between automatic and semi-automatic shrink packaging machines.

Automatic Shrink Packaging Machines

Automatic shrink packaging machines are designed for high-speed production lines. These machines minimize manual intervention and significantly improve operational efficiency. They are ideal for medium to large-scale industries where packaging speed and consistency are essential.

Key Features:

-

Fully automated film feeding and sealing system

-

High-speed operation

-

PLC control panel for easy monitoring

-

Adjustable temperature and conveyor speed

-

Minimal labor requirement

-

Consistent and uniform shrink results

Automatic systems are commonly used for packaging cartons, bottles, jars, cans, books, pharmaceutical boxes, and multipacks. Their ability to handle bulk production makes them suitable for FMCG and beverage industries.

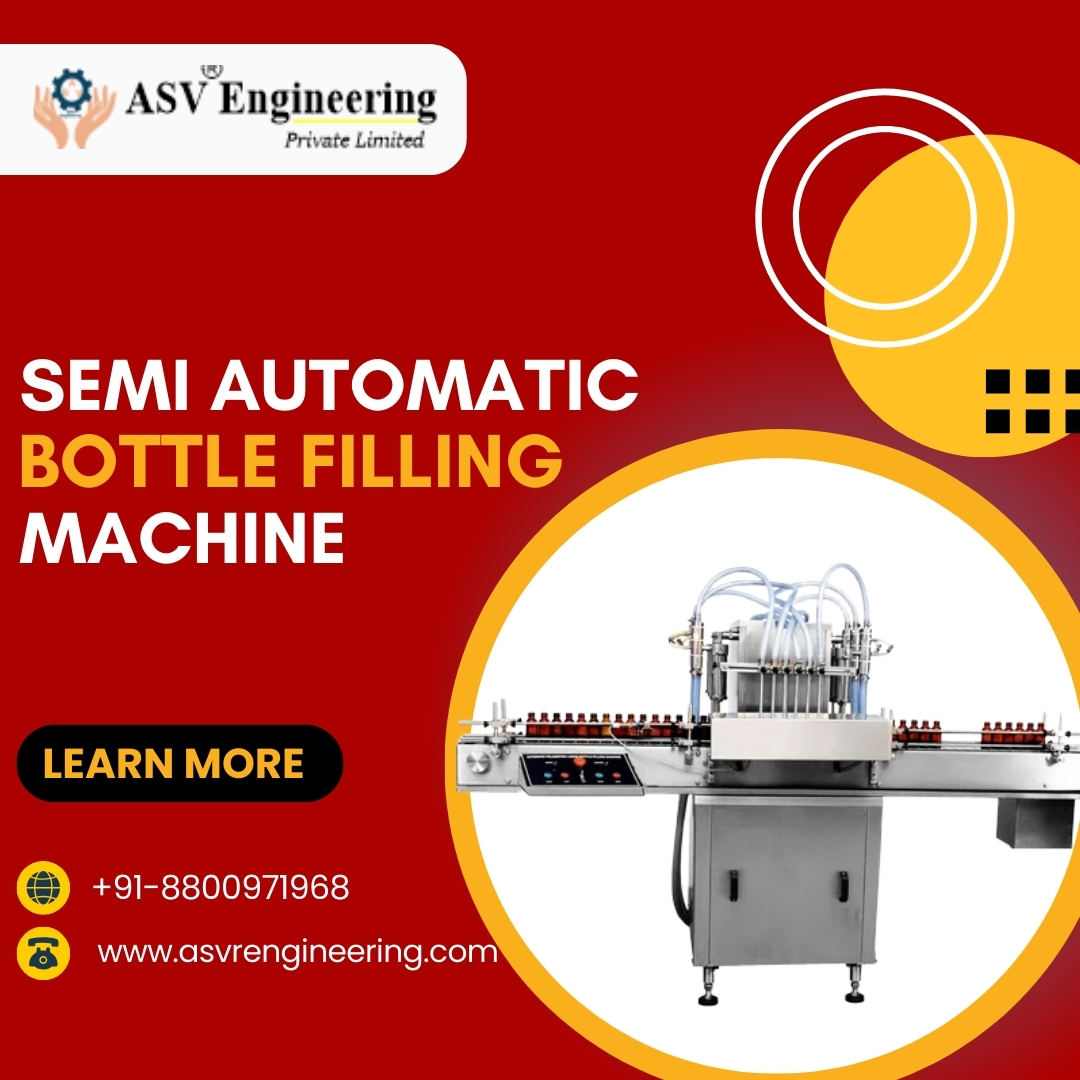

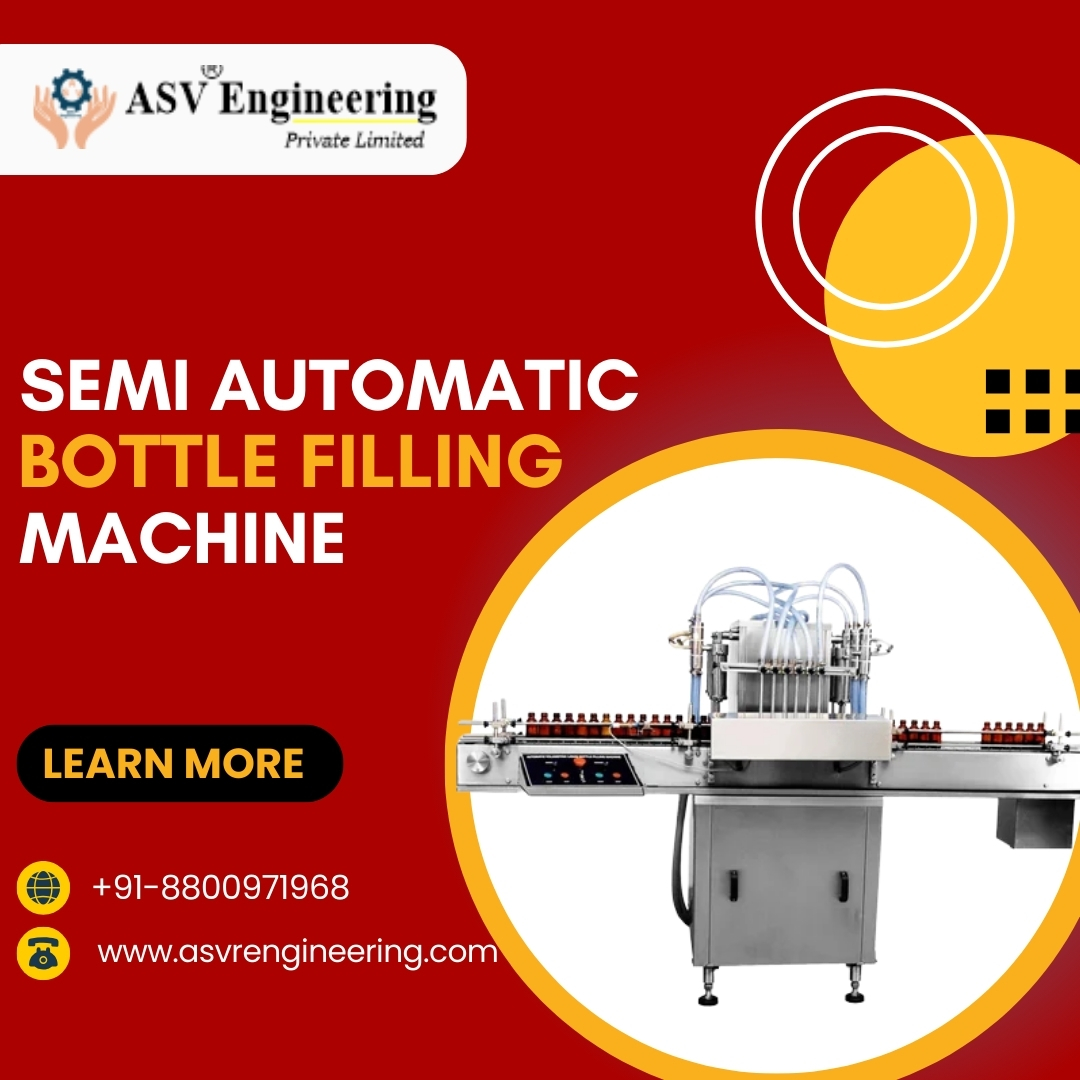

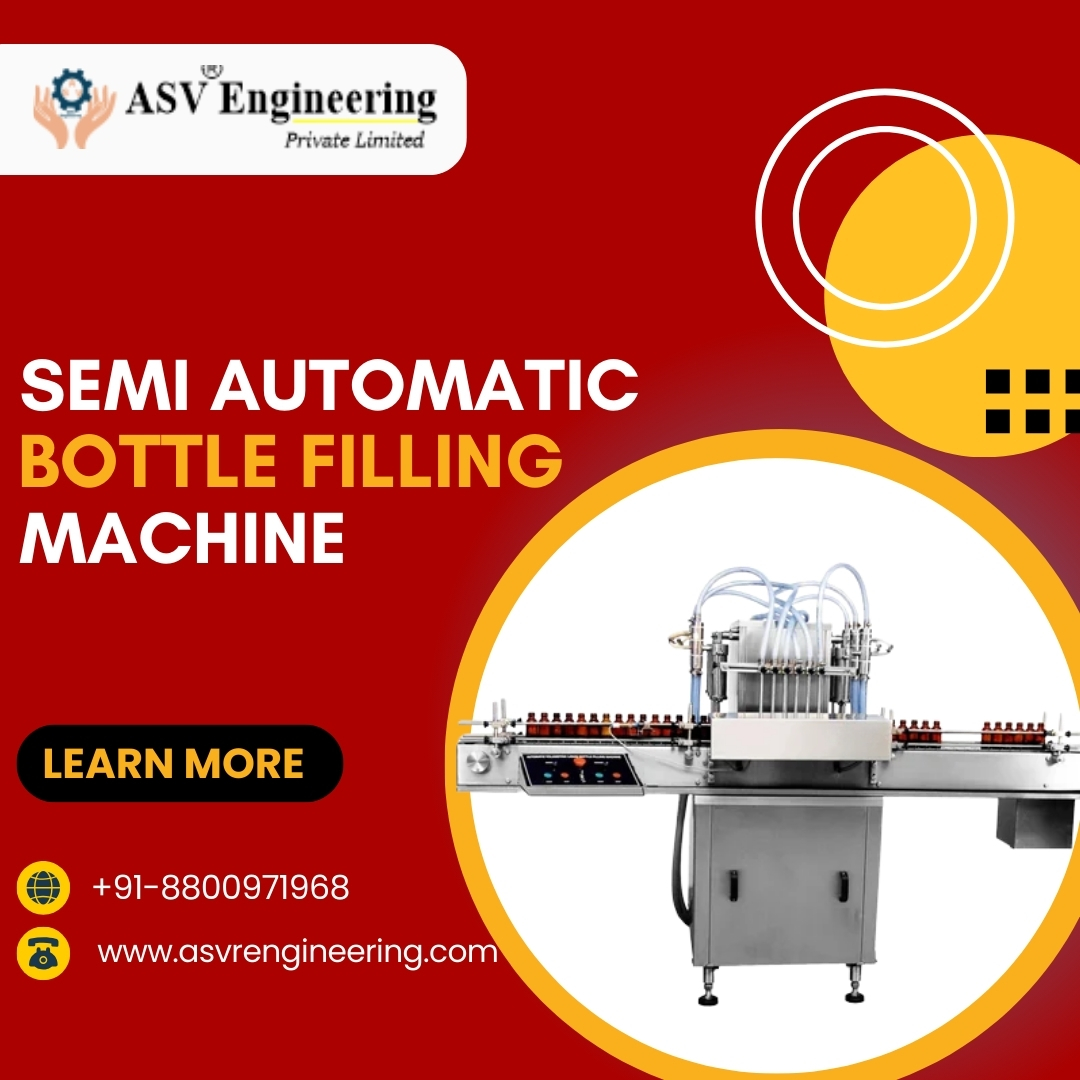

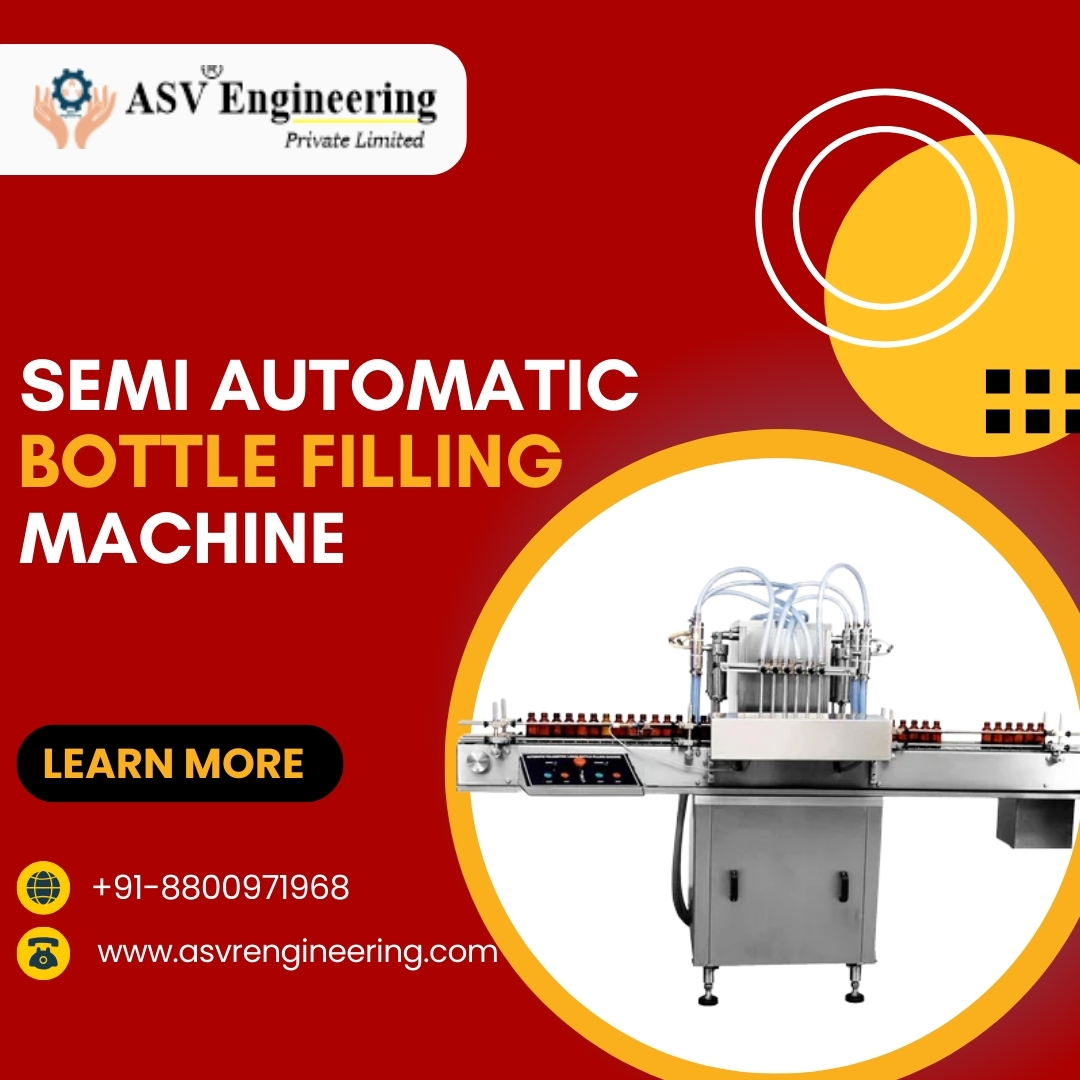

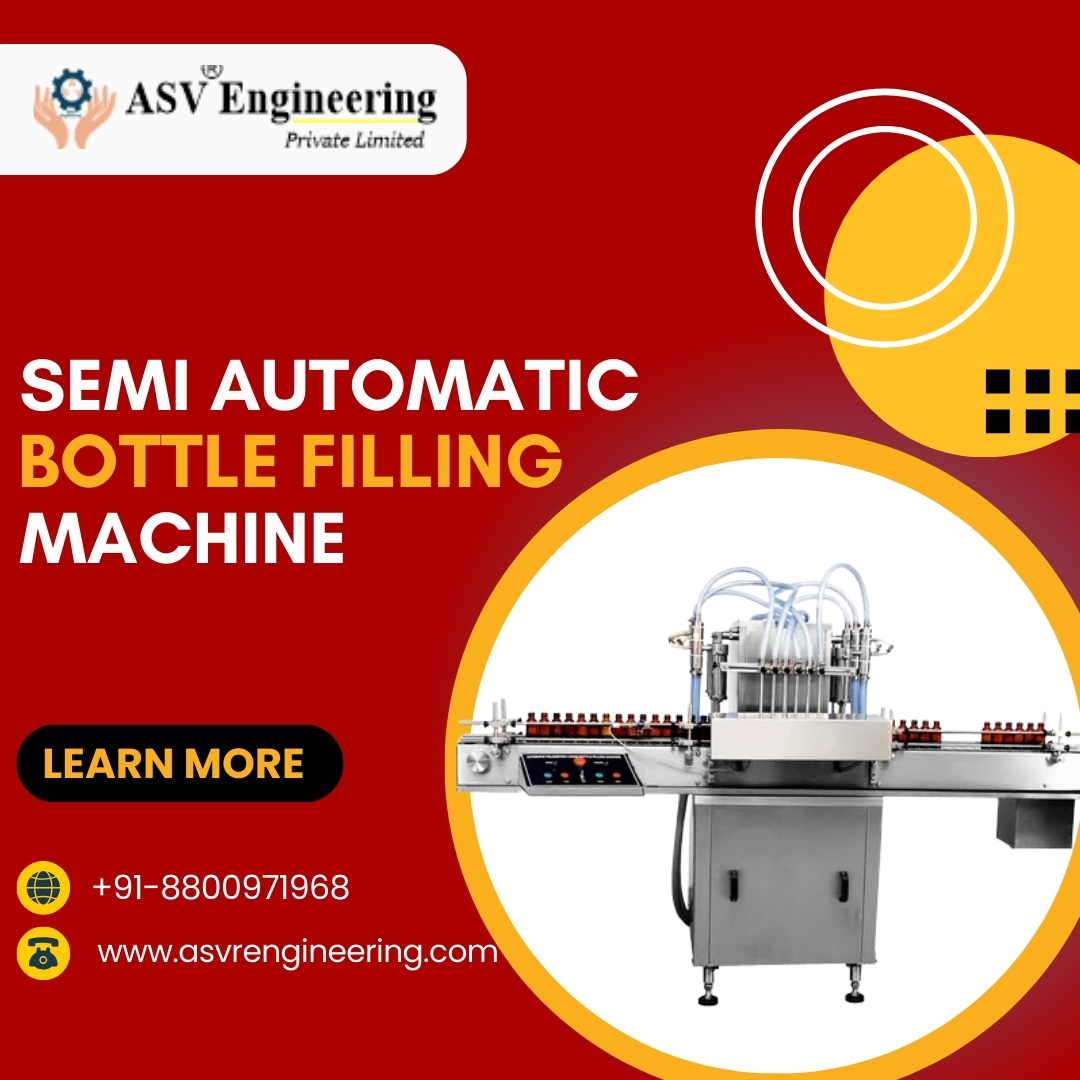

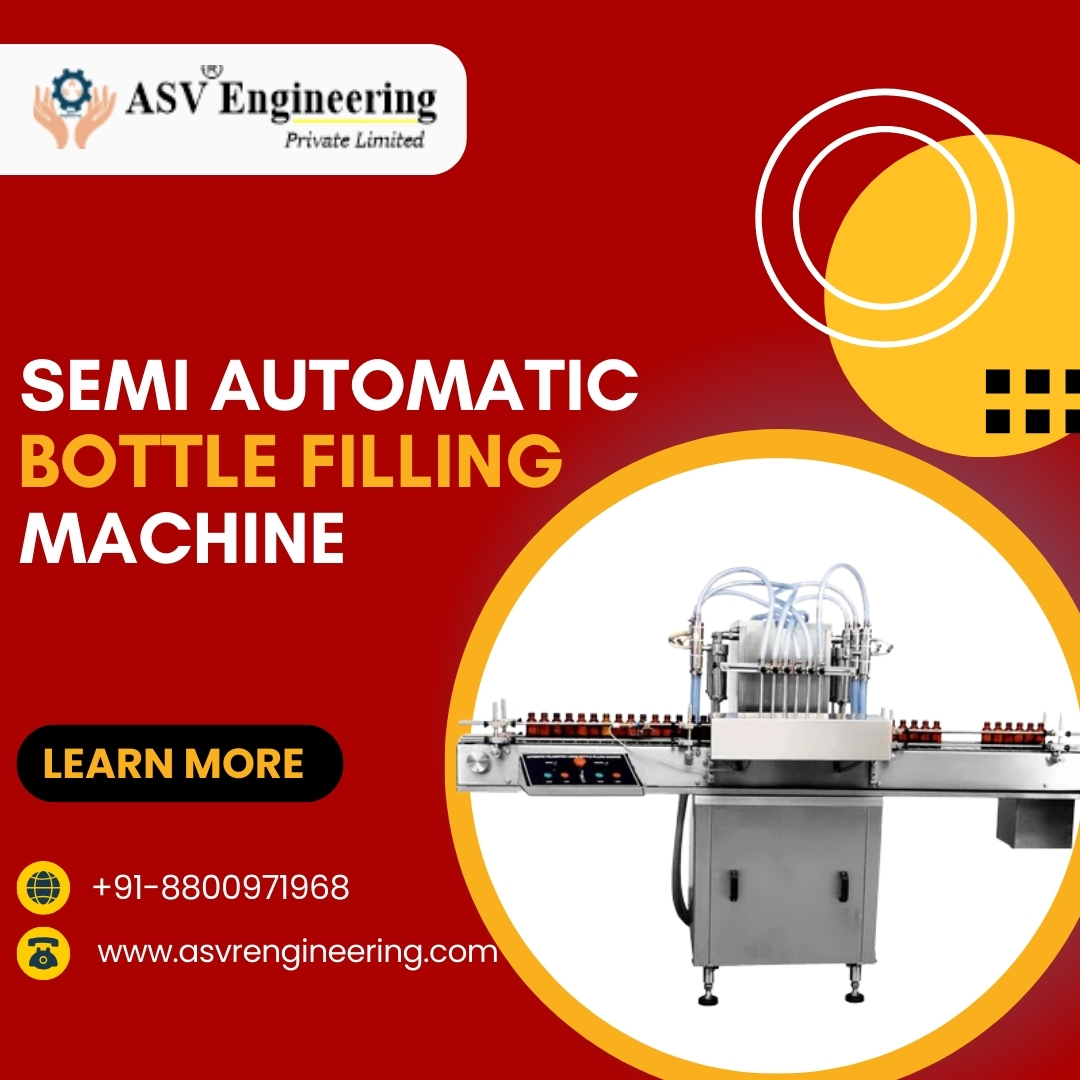

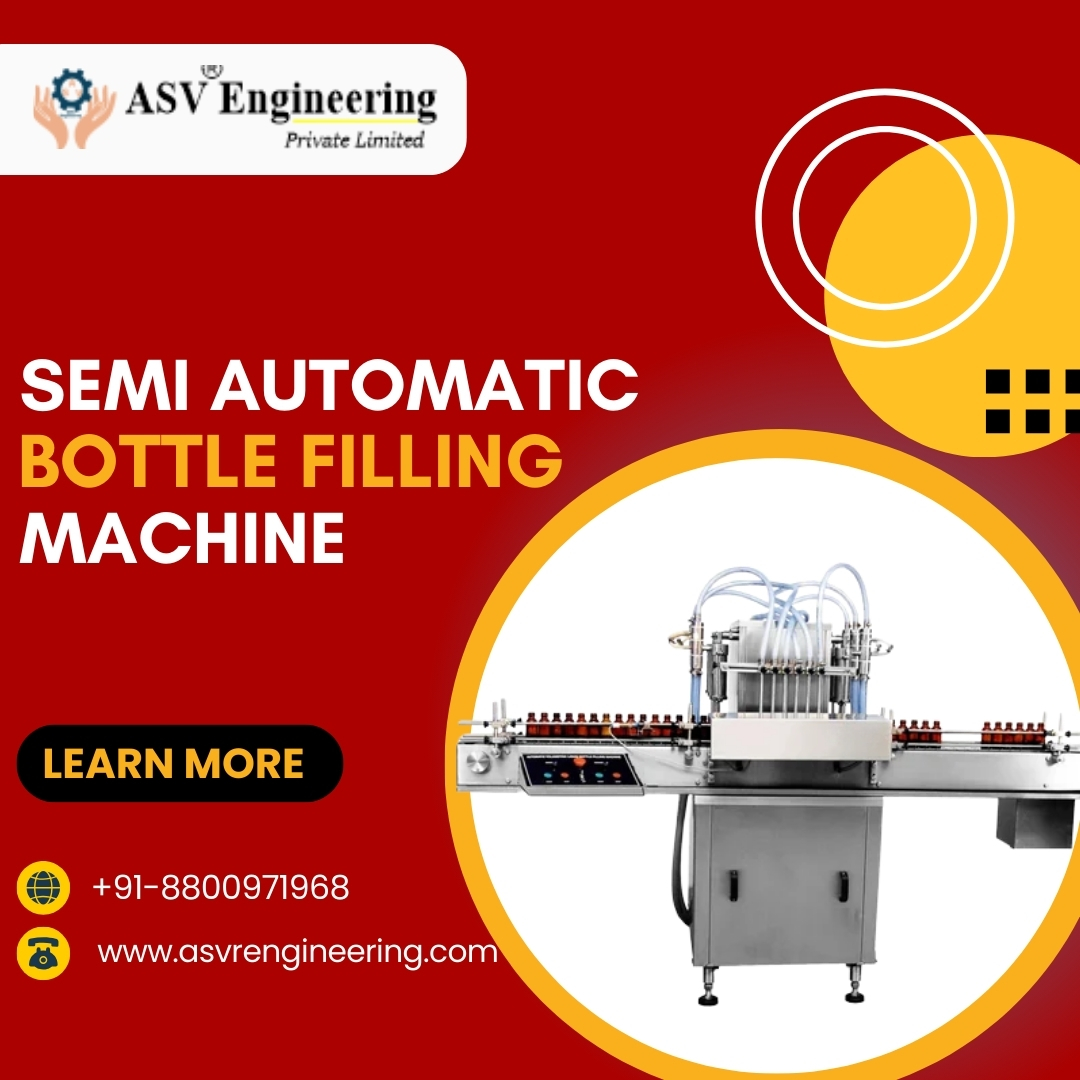

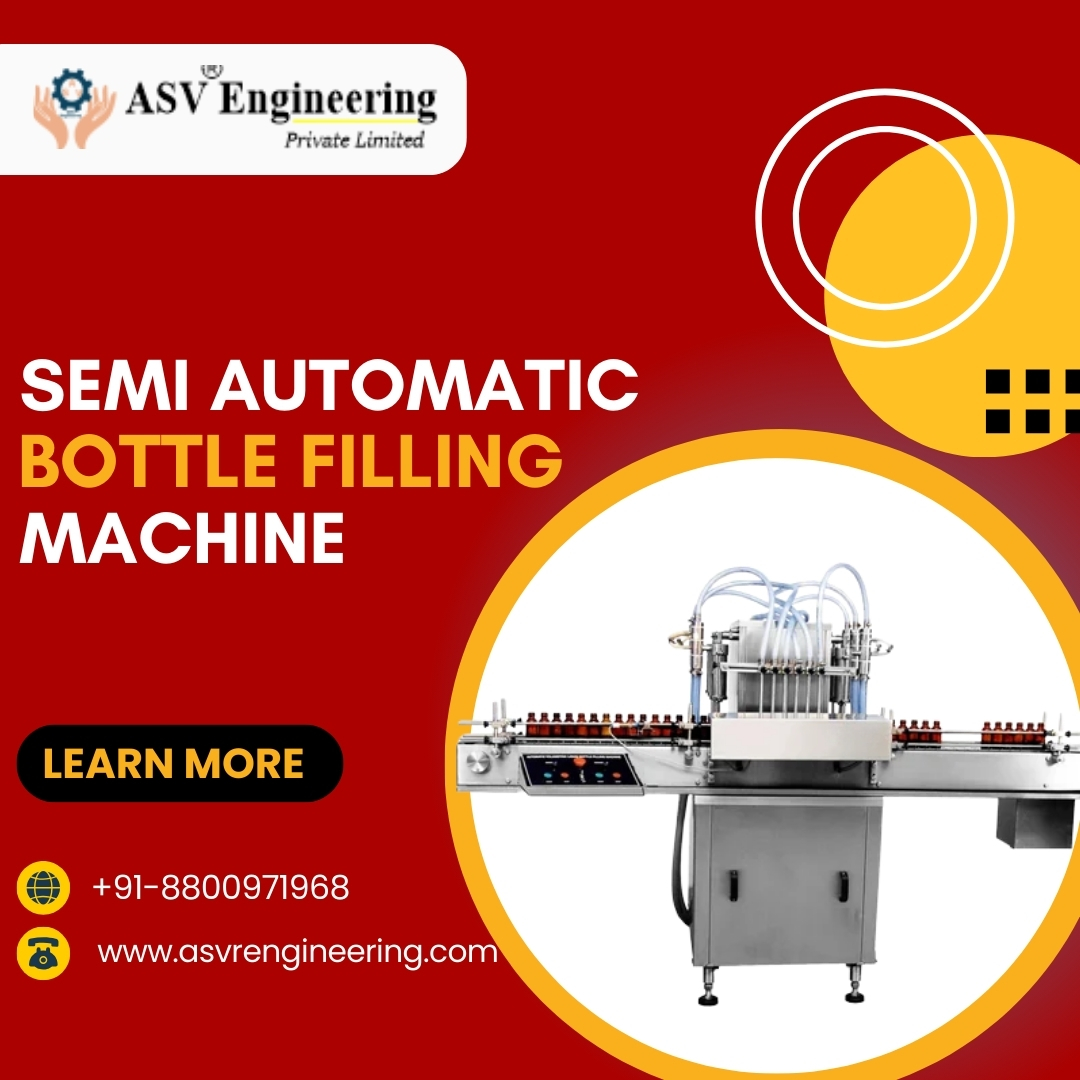

Semi-Automatic Shrink Packaging Machines

Semi-automatic machines offer flexibility and affordability for small and medium enterprises. While they require partial manual assistance, they still provide efficient and reliable packaging performance.

Advantages:

-

Lower initial investment

-

Easy operation and maintenance

-

Suitable for moderate production volumes

-

Compact design for limited workspace

These machines are ideal for startups, regional manufacturers, and businesses looking to upgrade from manual packaging methods.

Why Shrink Packaging Machines Are Essential for Modern Industries

Shrink packaging machines offer numerous operational and commercial advantages:

1. Enhanced Product Protection

Shrink film tightly wraps around products, preventing exposure to dust, moisture, and tampering.

2. Improved Presentation

Transparent shrink film enhances product visibility and shelf appeal, increasing customer trust.

3. Cost-Effective Packaging

Compared to rigid packaging materials, shrink film reduces material costs and storage space.

4. Increased Productivity

Automated systems accelerate packaging speed and reduce human error.

5. Multipack Capability

Shrink machines allow bundling of multiple products together, ideal for promotional packs.

Industries Using Shrink Packaging Machines in India

Shrink packaging machines are widely used in:

-

Food and Beverage Industry

-

Pharmaceutical Sector

-

Cosmetic and Personal Care Industry

-

Electronics Manufacturing

-

Printing and Publishing

-

FMCG Production Units

-

Logistics and Warehousing

Indian manufacturers are constantly upgrading their technology to meet the growing demand for energy-efficient and high-performance packaging solutions.

Why Choose ASVR Engineering?

When it comes to selecting a shrink packaging machine manufacturer in India, quality, reliability, and after-sales support are critical factors. ASVR Engineering stands out for several reasons:

1. Advanced Engineering Design

Machines are built using high-quality components ensuring durability and long service life.

2. Customization Options

Every business has unique packaging requirements. Customized machine configurations are available to suit specific product sizes and production capacities.

3. Energy Efficient Systems

Modern shrink tunnels are designed to optimize heat distribution, reducing power consumption.

4. Competitive Pricing

Cost-effective solutions without compromising on performance.

5. Strong After-Sales Support

Technical assistance, spare parts availability, and installation guidance ensure smooth operations.

Factors to Consider Before Buying a Shrink Packaging Machine

Before investing in a shrink packaging machine, businesses should evaluate:

Production Capacity

Determine daily packaging volume to choose between automatic and semi-automatic models.

Product Dimensions

Machine configuration should match product size and shape.

Type of Shrink Film

Common films include PVC, POF, and LDPE. Machine compatibility is essential.

Power Consumption

Energy-efficient systems reduce long-term operational costs.

Maintenance Requirements

Choose machines with easy access to components for routine servicing.

Types of Shrink Packaging Machines Available

Indian manufacturers offer various models to meet different needs:

-

L-Sealer with Shrink Tunnel

-

Chamber Shrink Packaging Machine

-

Automatic Side Sealer Machine

-

Sleeve Wrapping Machine

-

Continuous Shrink Tunnel System

Each type serves specific industrial applications and production volumes.

Growing Demand for Shrink Packaging Machines in India

With rapid industrialization and expansion of retail markets, the demand for reliable packaging machinery in India is increasing steadily. E-commerce growth has also boosted the need for secure transit packaging.

Indian manufacturers are exporting shrink packaging machines to various countries due to their competitive pricing and robust engineering standards. This global demand highlights India’s growing reputation as a reliable packaging machinery manufacturing hub.

Maintenance and Operational Tips

To ensure long-lasting machine performance:

-

Regularly clean sealing blades

-

Monitor temperature settings

-

Check conveyor alignment

-

Replace worn-out heating elements

-

Use high-quality shrink film

Routine maintenance not only improves machine efficiency but also reduces downtime.

Conclusion

Shrink packaging machines have become indispensable for industries seeking efficient, durable, and cost-effective packaging solutions. Whether you require a high-speed automatic system or a budget-friendly semi-automatic machine, choosing the right manufacturer is crucial for long-term productivity.

ASVR Engineering continues to deliver advanced shrink packaging solutions across India, combining innovation, reliability, and affordability. Their machines are designed to meet modern industrial demands while ensuring excellent packaging quality.

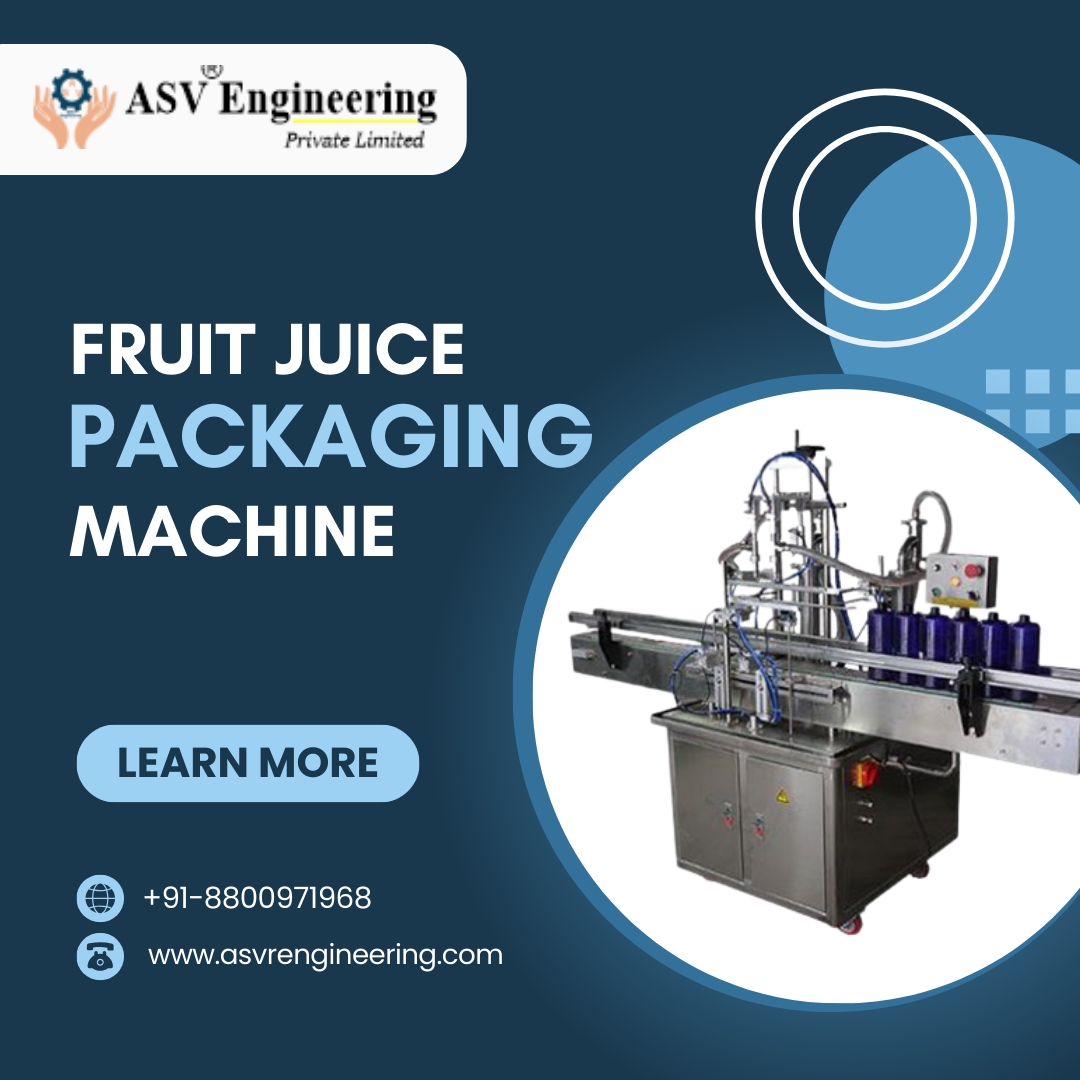

For inquiries, product details, or customized solutions, contact:

+91-8076004849

+91-8800971968

Website: https://www.asvrengineering.com

Upgrade your packaging line today with advanced shrink packaging technology and experience enhanced efficiency, protection, and professional product presentation.

Buy Now

Related Posts

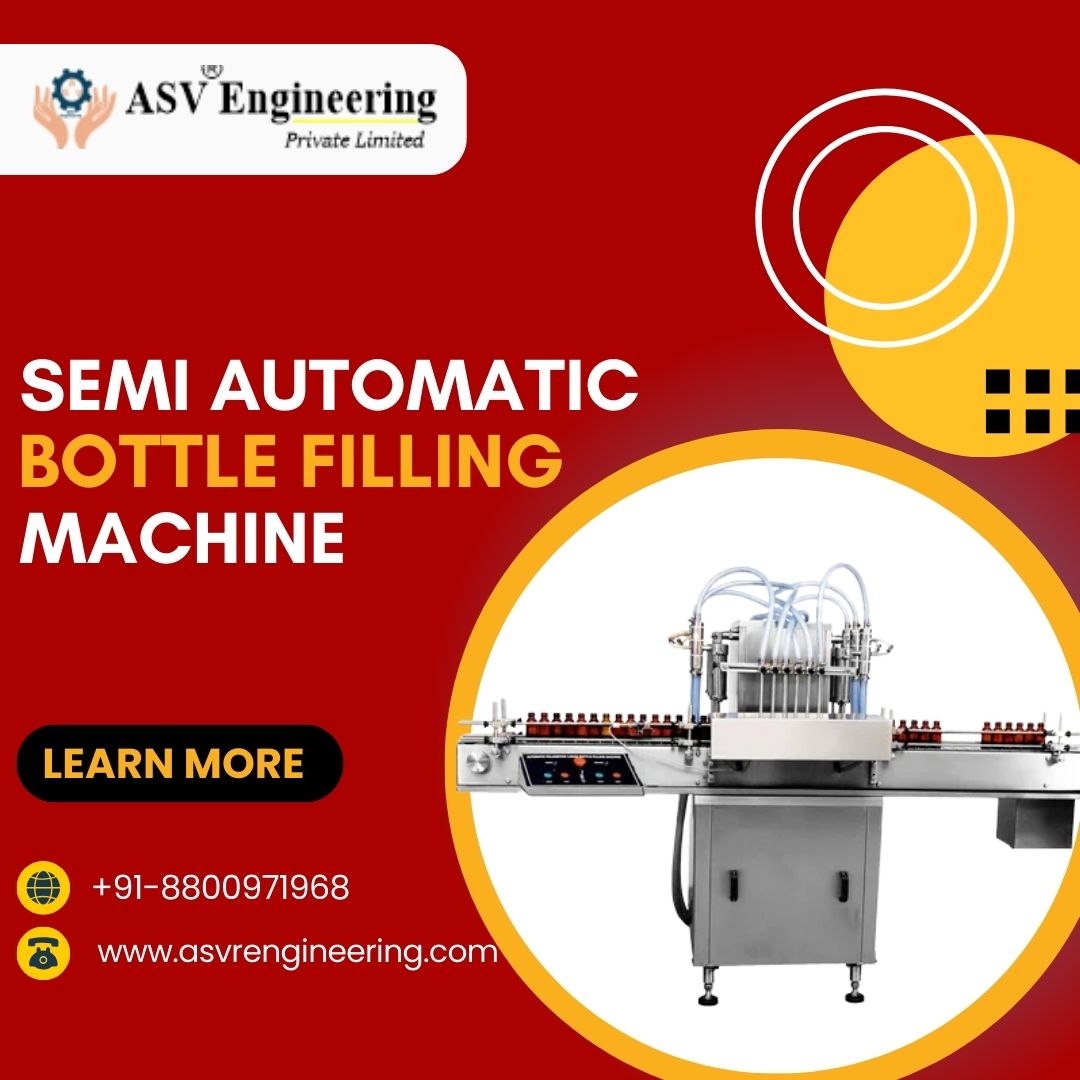

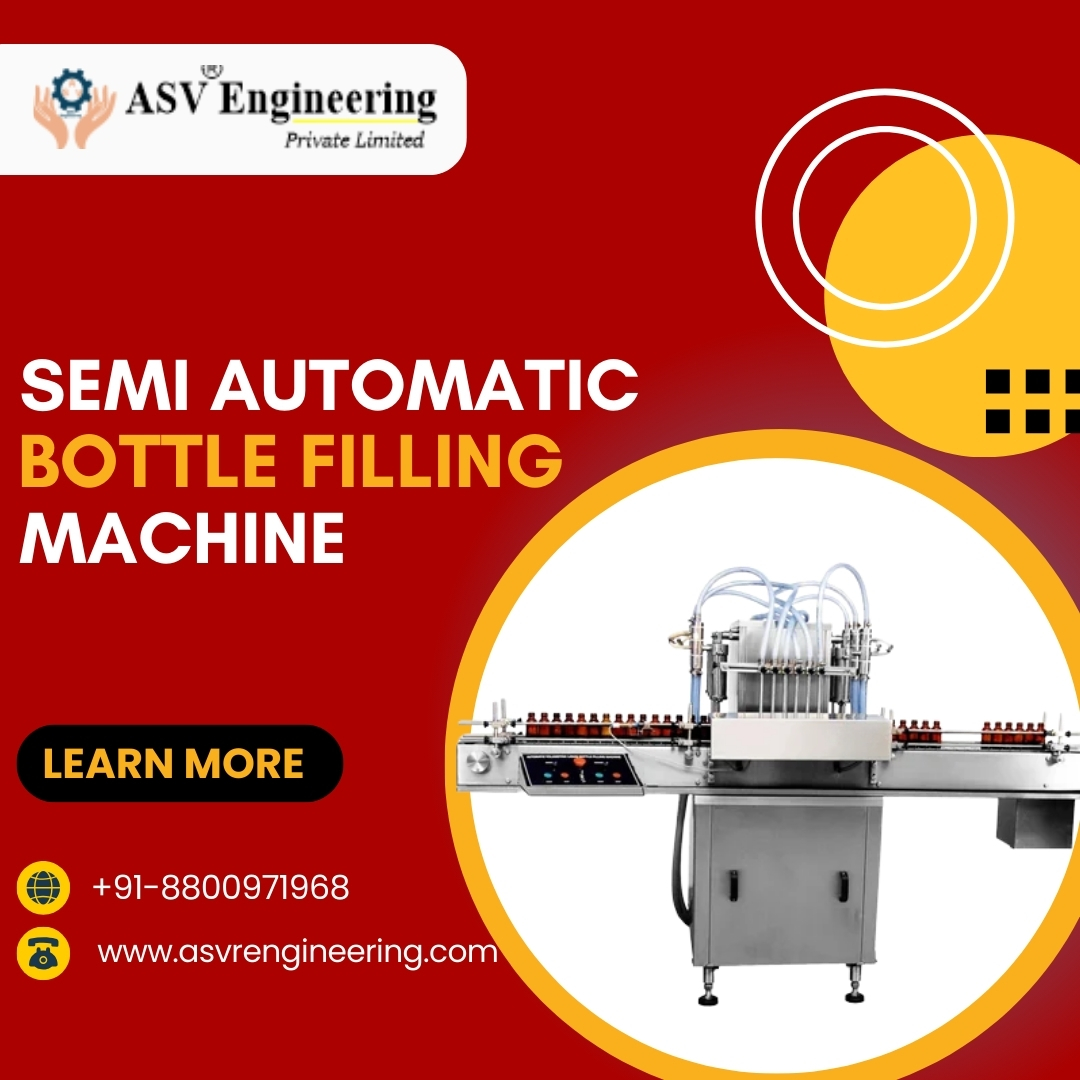

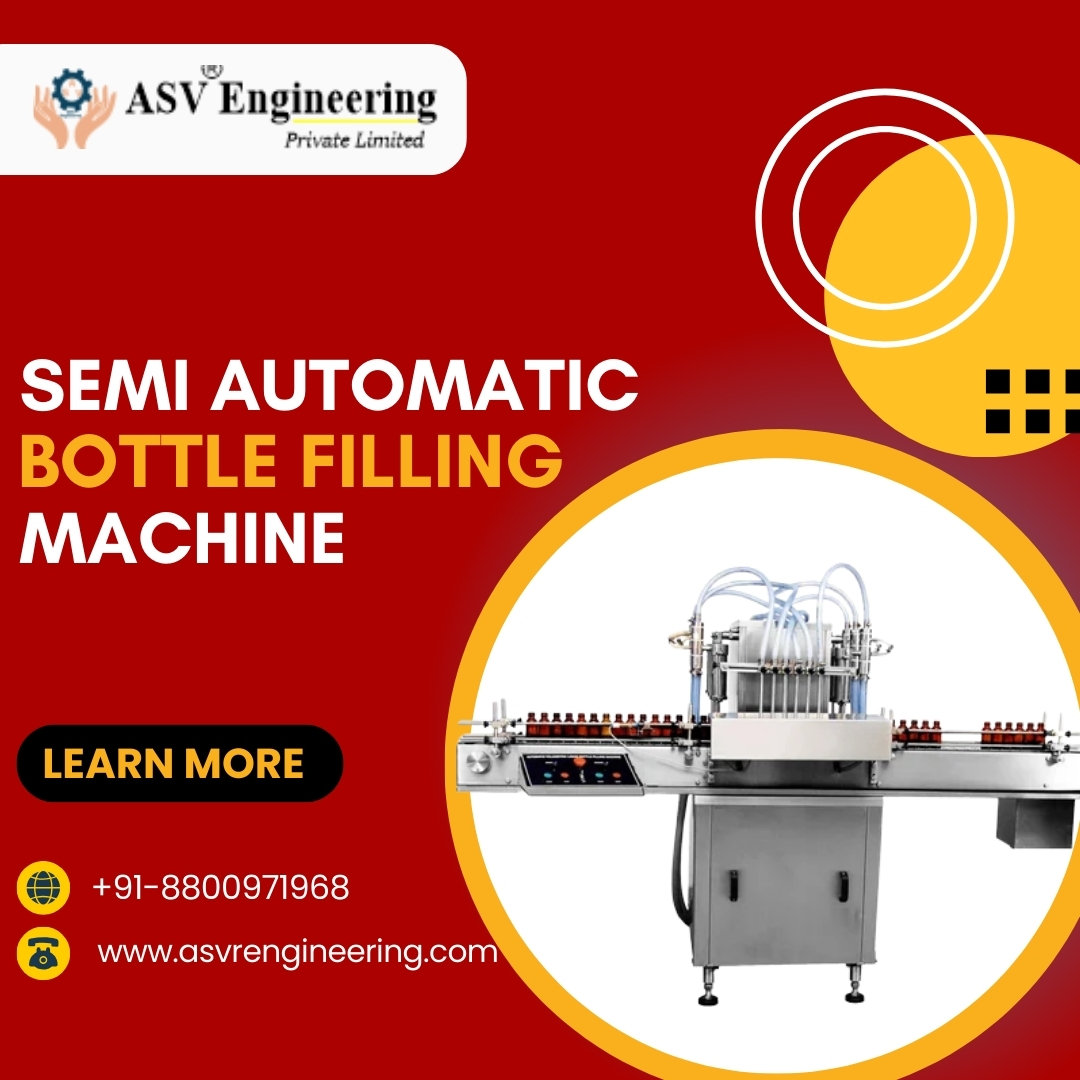

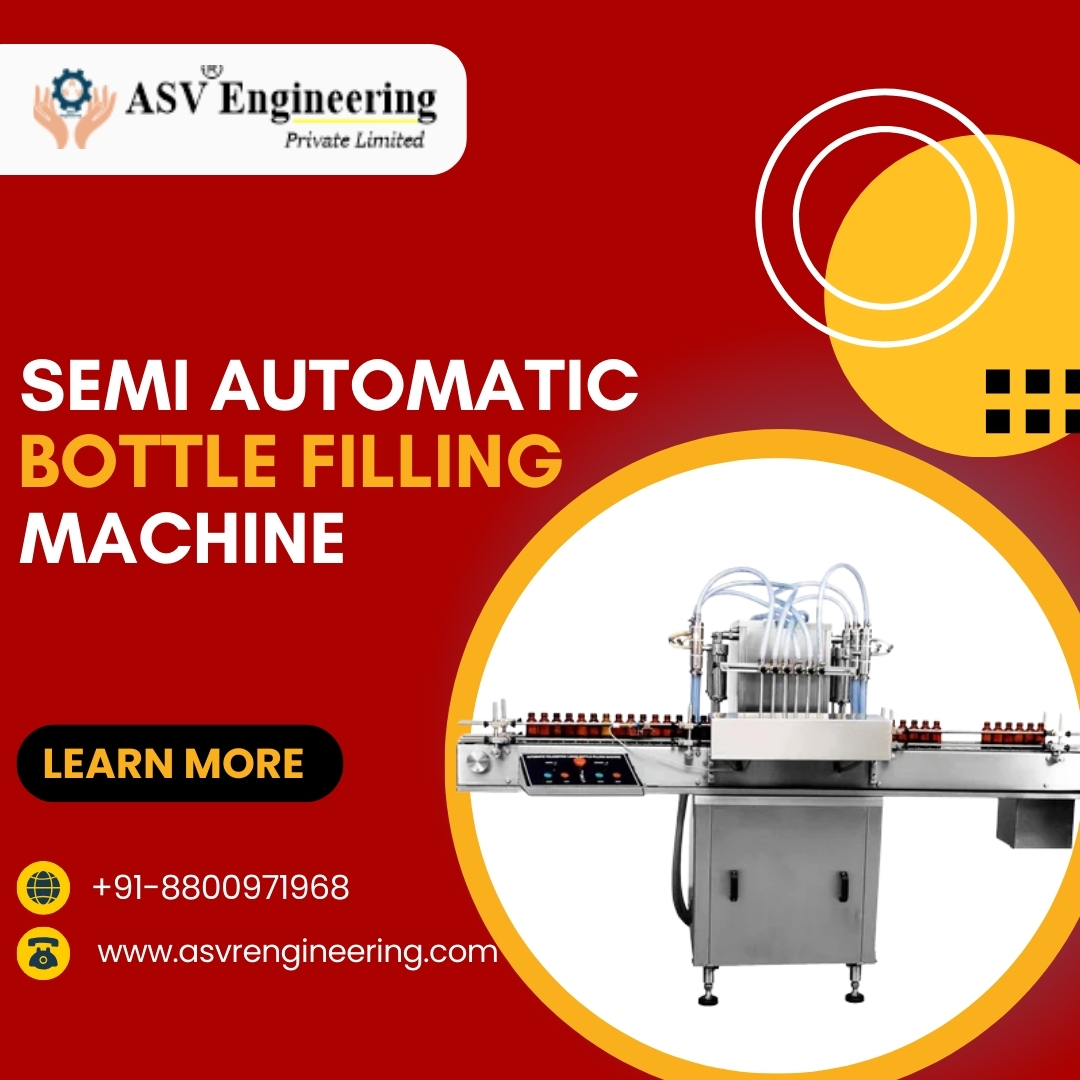

Leading Automatic Bottle Filling Machine Manufacturers for High-Speed Industrial Packaging Solutions

Trusted Automatic Milk Bag Packaging Machine Distributors for Dairy Plants, Milk Booths & FMCG Units

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)