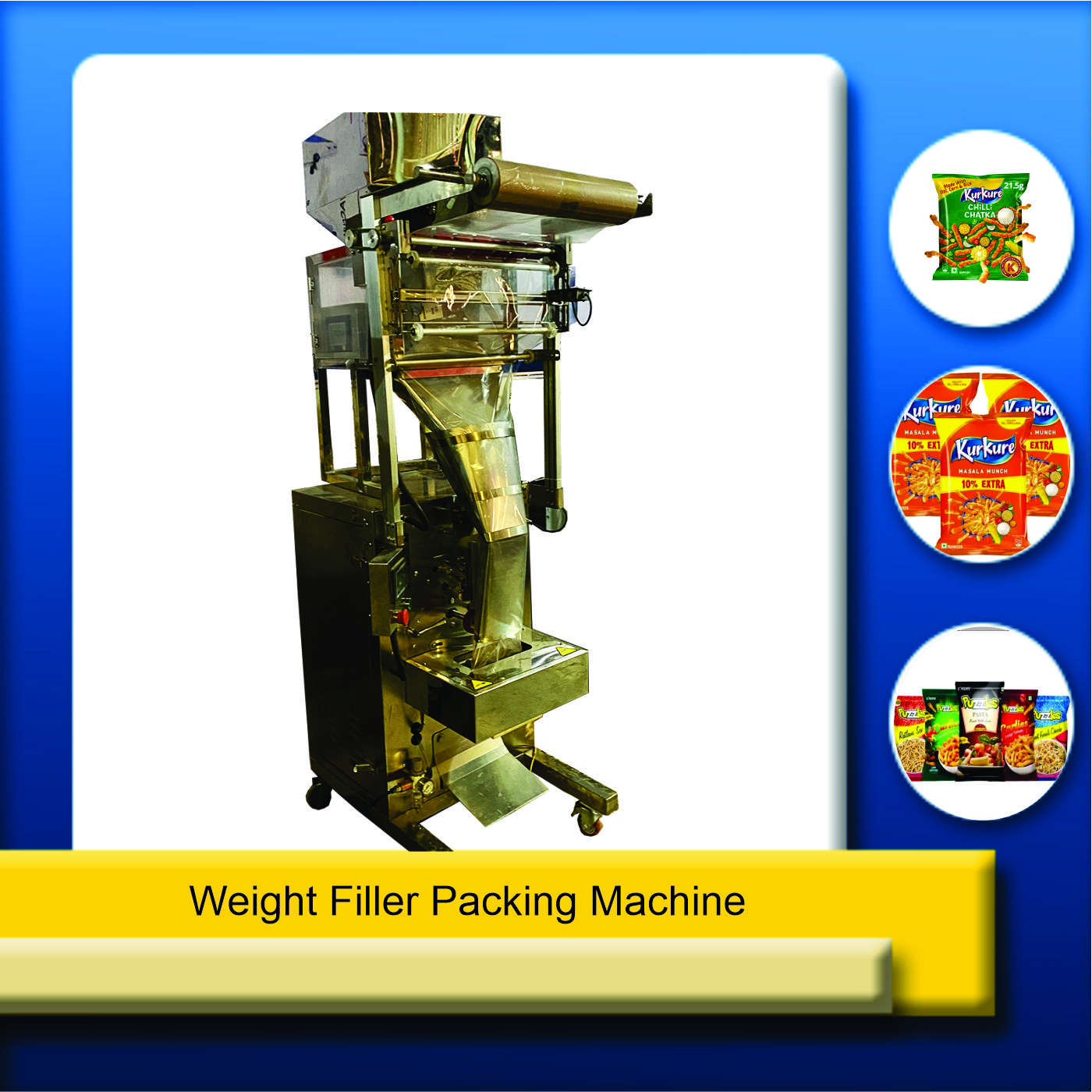

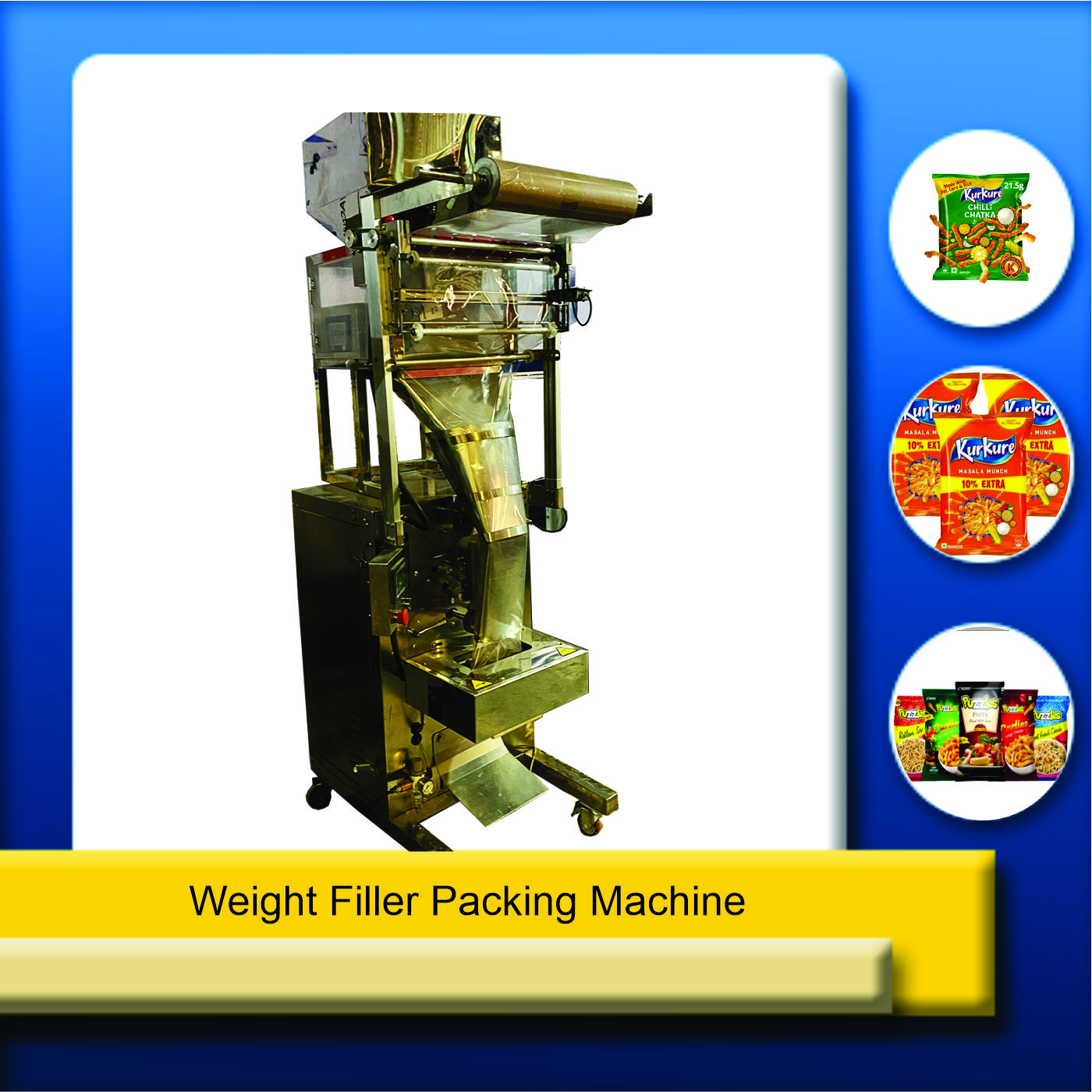

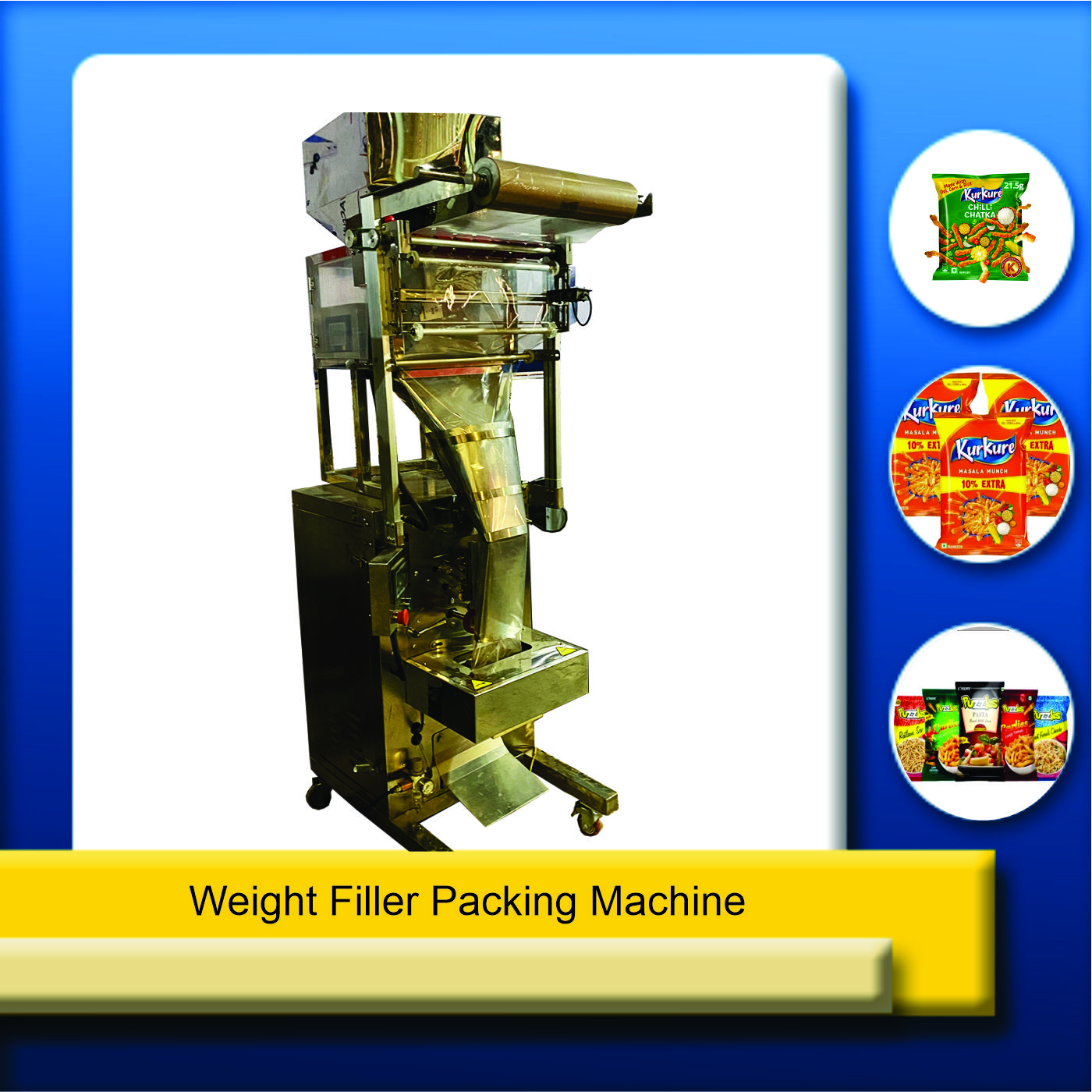

Advanced PLC-Based Pouch Packing Machine with Touchscreen Control

Price: ₹50000

Revolutionize Your Packaging with Our Advanced PLC-Based Pouch Packing Machine

In today’s fast-paced industrial environment, efficiency, accuracy, and automation are the keys to success. At ASVR Engineering Pvt Ltd, we introduce a next-generation PLC-based pouch packing machine with touchscreen HMI—designed to offer precision control, smart diagnostics, user-friendly interface, and exceptional reliability.

Whether you are packing powders, granules, or liquids, our advanced machine delivers seamless automation and flexibility, ensuring minimal wastage, consistent sealing, and high output.

Ideal for Various Industries

-

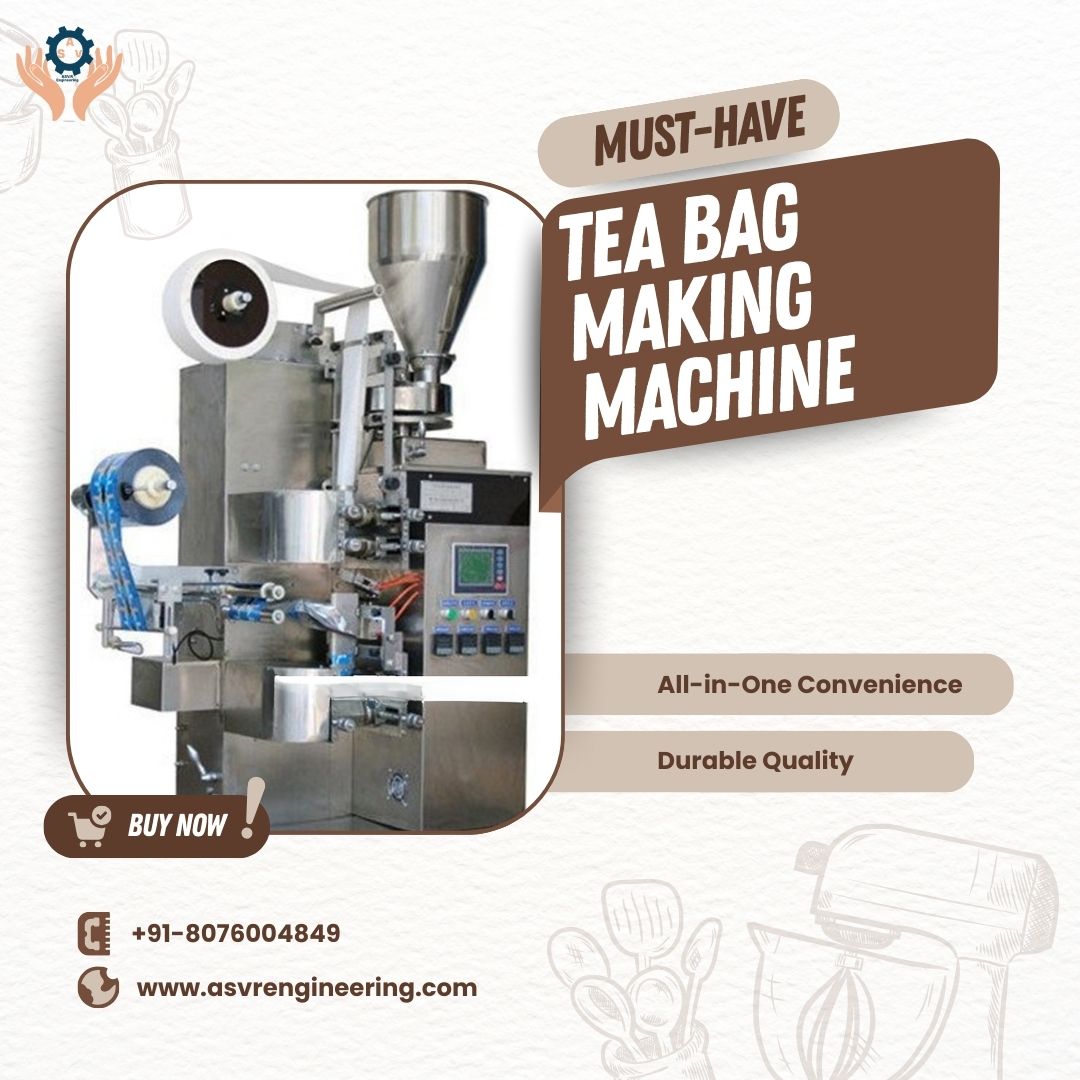

Food & Beverage: Spices, tea, coffee, snacks, flour, sugar

-

Pharmaceutical: Powdered medicines, tablets, syrups

-

Chemical: Detergents, powders, granules

-

Cosmetics: Face powders, creams, gels

-

Agro & Fertilizers: Pesticides, plant nutrients

Top Features of Our PLC-Based Packing Machines

| Feature | Description |

|---|---|

| Advanced PLC Control | Industrial-grade Programmable Logic Controller for precision operations |

| Touchscreen HMI | Easy-to-use interface for settings, diagnostics & real-time monitoring |

| Auto Product Detection | Sensor-based product and pouch detection to prevent wastage |

| Multi-Pouch Format Support | Center seal, 3-side, 4-side, stand-up, zip-lock, etc. |

| Adjustable Fill Quantity | Digital adjustment via HMI – no manual changeover needed |

| Error Alerts & Logs | Auto display of fault codes, maintenance alerts, usage history |

| Speed Control | Variable frequency drive (VFD) for speed optimization |

| Remote Diagnostics | Optional Ethernet/USB for software updates or remote support |

Machine Specifications

| Parameter | Specification |

|---|---|

| Filling Range | 10 gm – 5 kg (customizable) |

| Supported Product Types | Powders, granules, semi-liquids |

| Output Speed | 25–100 pouches/min (depends on pouch & product) |

| Sealing System | Heat sealing with PID temperature control |

| Filling Mechanism | Auger filler / volumetric cup / piston filler |

| Pouch Dimensions | Width: 50–300 mm, Length: up to 350 mm |

| Control Interface | 7” or 10” color touchscreen HMI |

| Electrical Requirements | 220V/440V, Single/Three Phase, 50 Hz |

| Power Consumption | 2 – 6 kW (based on model & configuration) |

| Construction Material | SS304/SS316 Contact Parts |

| Air Pressure Requirement | 6–8 bar for pneumatic operations |

Benefits of a PLC-Based System

-

✅ High Accuracy – Digital control ensures consistent fill weight and seal

-

✅ Reduced Human Error – Automates complex operations with fewer manual steps

-

✅ Customizable Settings – Save multiple product configurations for faster changeover

-

✅ Diagnostics & Alerts – Maintenance reminders, troubleshooting guidance

-

✅ Expandable System – Can integrate with printers, conveyors, nitrogen flush, etc.

-

✅ Enhanced Safety – Interlocks and fault detection minimize operator error

Industries Already Using Our Machines

| Industry | Use Case |

|---|---|

| FMCG | Spices, tea, detergent pouching |

| Agrochemicals | Pesticide powders & granules in small pouches |

| Pharmaceuticals | Powder-based sachets with tight tolerances |

| Contract Packers | Flexible machines for multiple SKU handling |

Price Range (2025 Estimate)

| Model | Price Range (INR) |

|---|---|

| Standard PLC Pouch Packing Unit | ₹4.5 – ₹7.5 Lakhs |

| Touchscreen + Advanced Sensors | ₹6 – ₹9 Lakhs |

| Fully Customized Multi-Lane Unit | ₹10 – ₹15 Lakhs+ (project-based) |

Final cost depends on pouch size, speed, fillers, sealing type, and add-ons.

Real-World Use Case

Client: Herbal product manufacturer in Gujarat

Challenge: Frequent changeovers, inconsistent weights, and manual operation

Solution: Installed PLC-based ASVR pouch packing machine with touchscreen

Result:

-

Reduced downtime by 70%

-

Increased output by 40%

-

Minimized operator training time

-

Achieved ROI in less than 8 months

FAQs

Q1: Can the machine handle multiple products?

Yes, you can save and switch between multiple product settings via the touchscreen.

Q2: Does it support nitrogen flushing and date coding?

Yes, both are available as optional integrations.

Q3: Is training and warranty included?

Absolutely. We offer onsite training, full documentation, and 1-year warranty with remote assistance.

Q4: How complex is the software?

The HMI interface is intuitive, with icons, multilingual support, and quick setting adjustments.

Why Choose ASVR Engineering Pvt Ltd?

-

✅ Decades of engineering expertise

-

✅ Fully customizable machinery as per your operation

-

✅ Local support and nationwide delivery

-

✅ Made in India, designed for rugged, long-term use

-

✅ Trusted by hundreds of clients across India

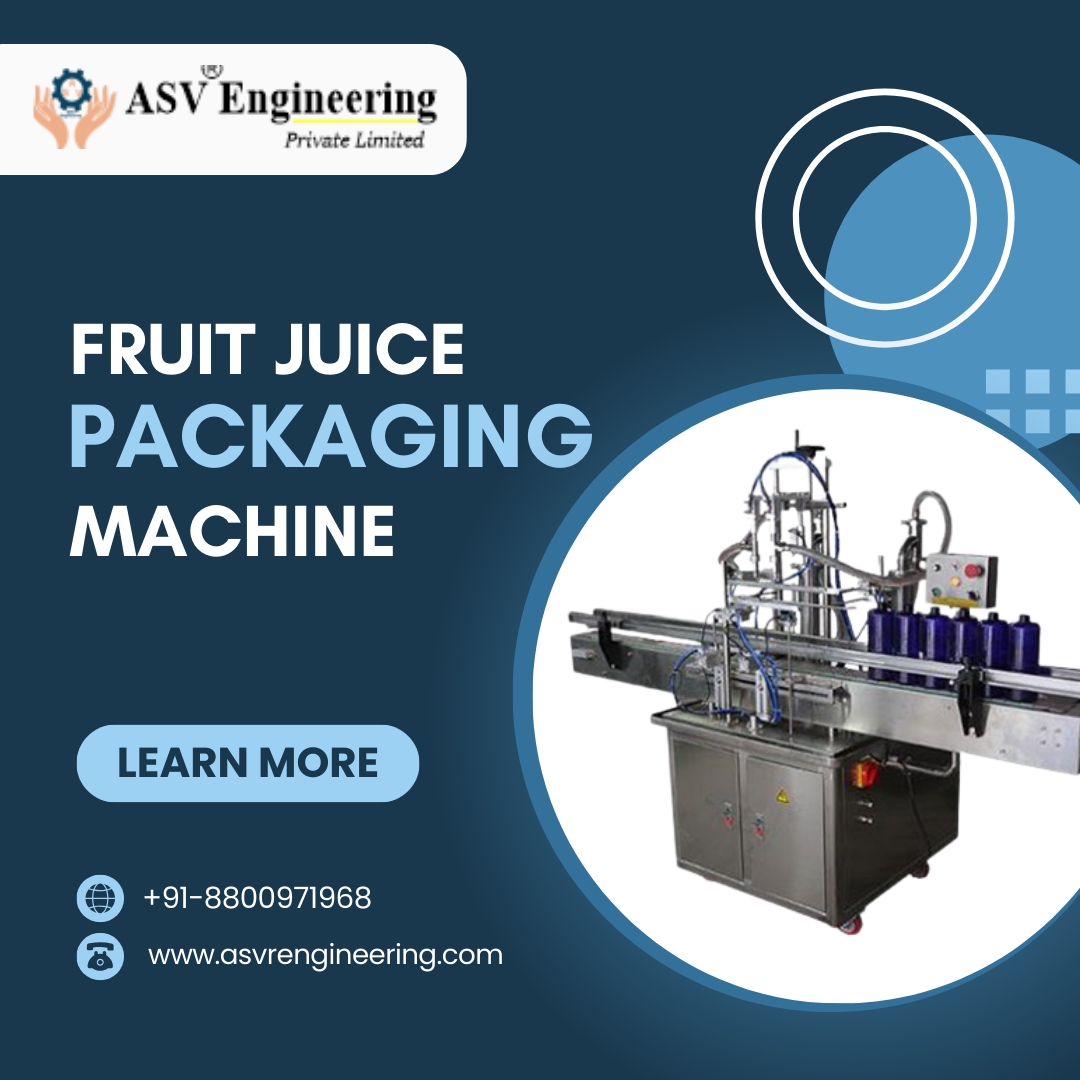

Contact Us Today

ASVR Engineering Pvt Ltd

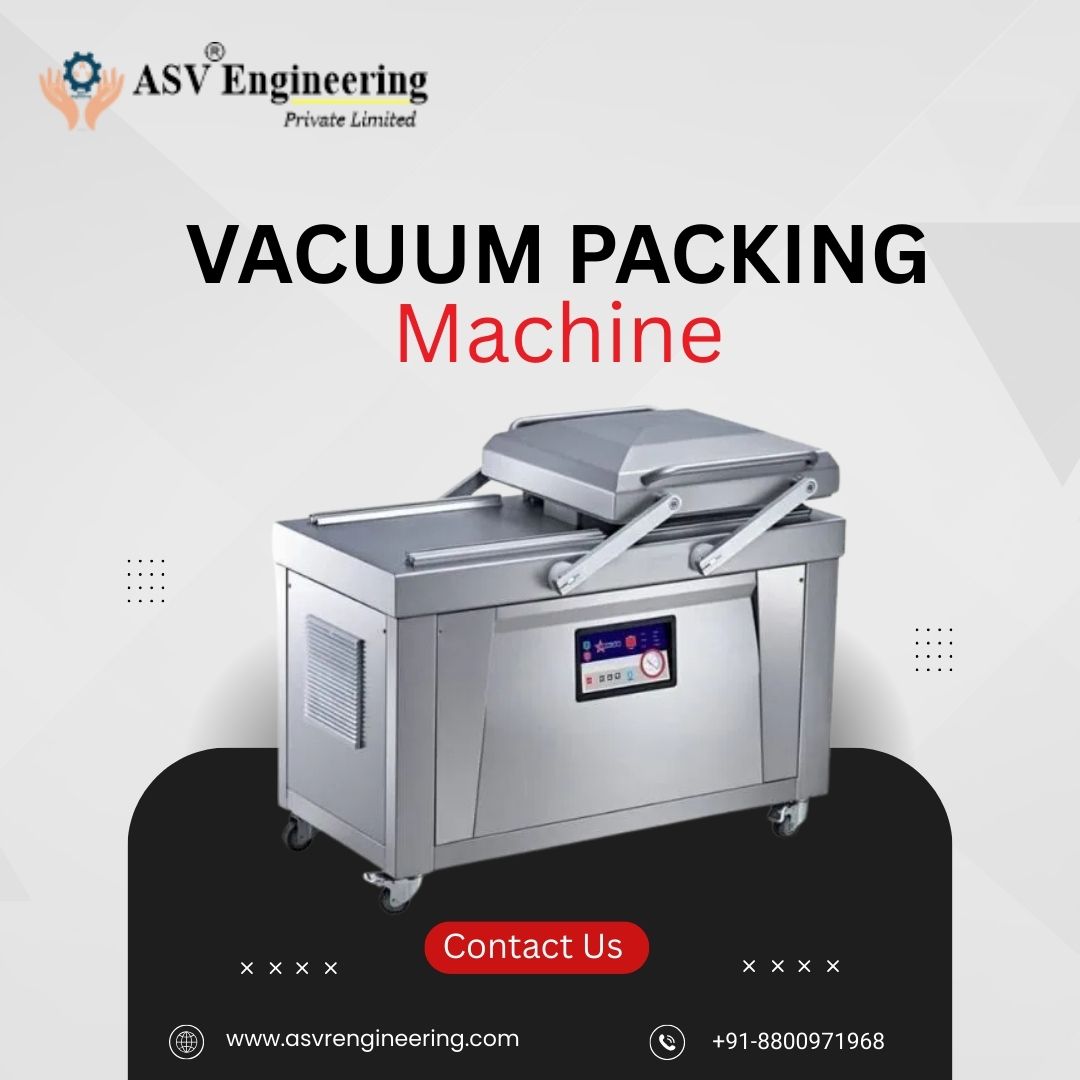

📞 Phone: 8800971968

🌐 Website: https://asvrengineering.com

📧 Email: (Insert your email here)

📍 Address: (Insert office/factory location)

Conclusion

Upgrade your packaging line with a PLC-based pouch packing machine from ASVR Engineering Pvt Ltd and experience the power of smart automation and intuitive control. With high accuracy, touch-based setup, and flexible configurations, it’s the ideal solution for modern, growth-focused businesses.

Get in touch today for a customized quote and live demo.

Buy Now

Related Posts

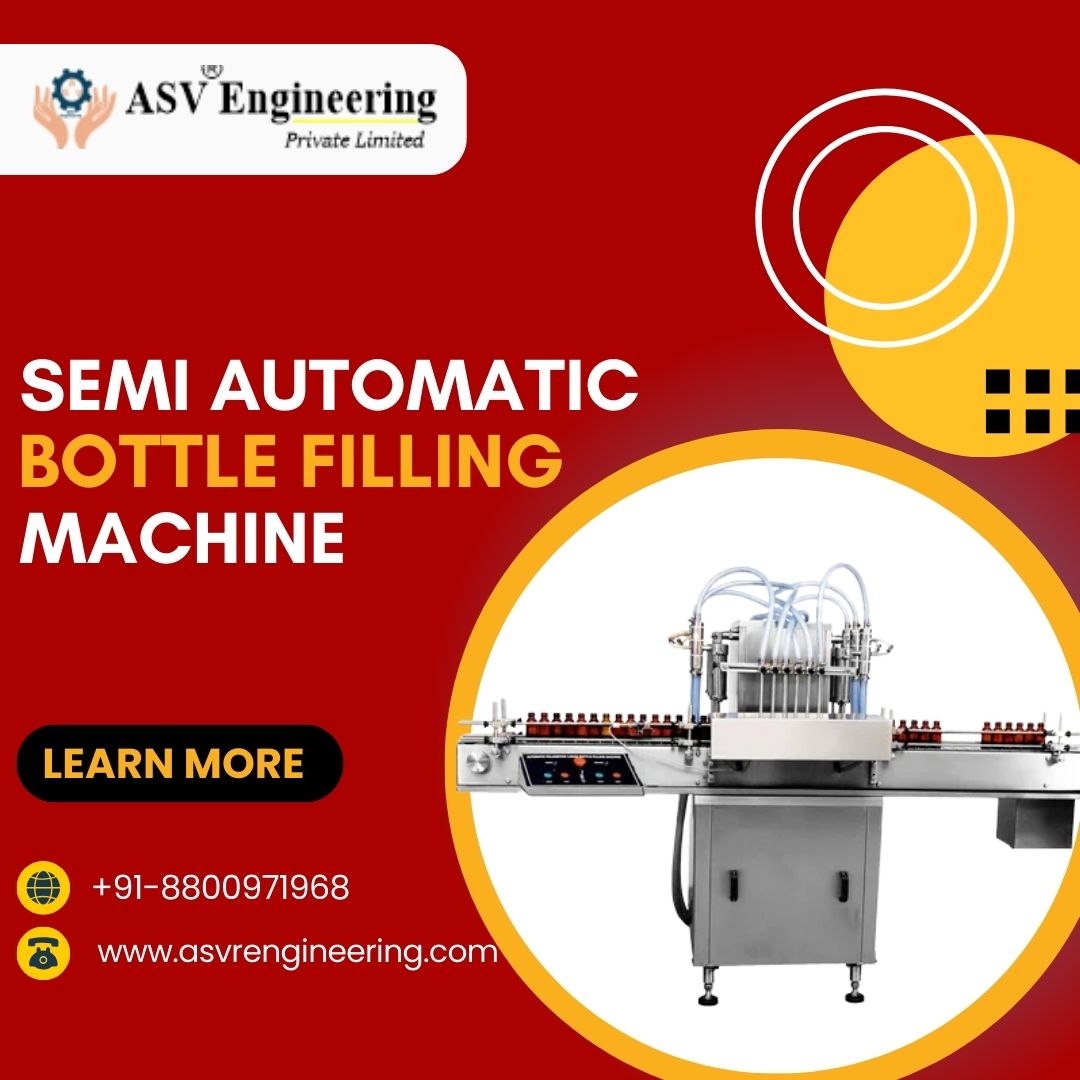

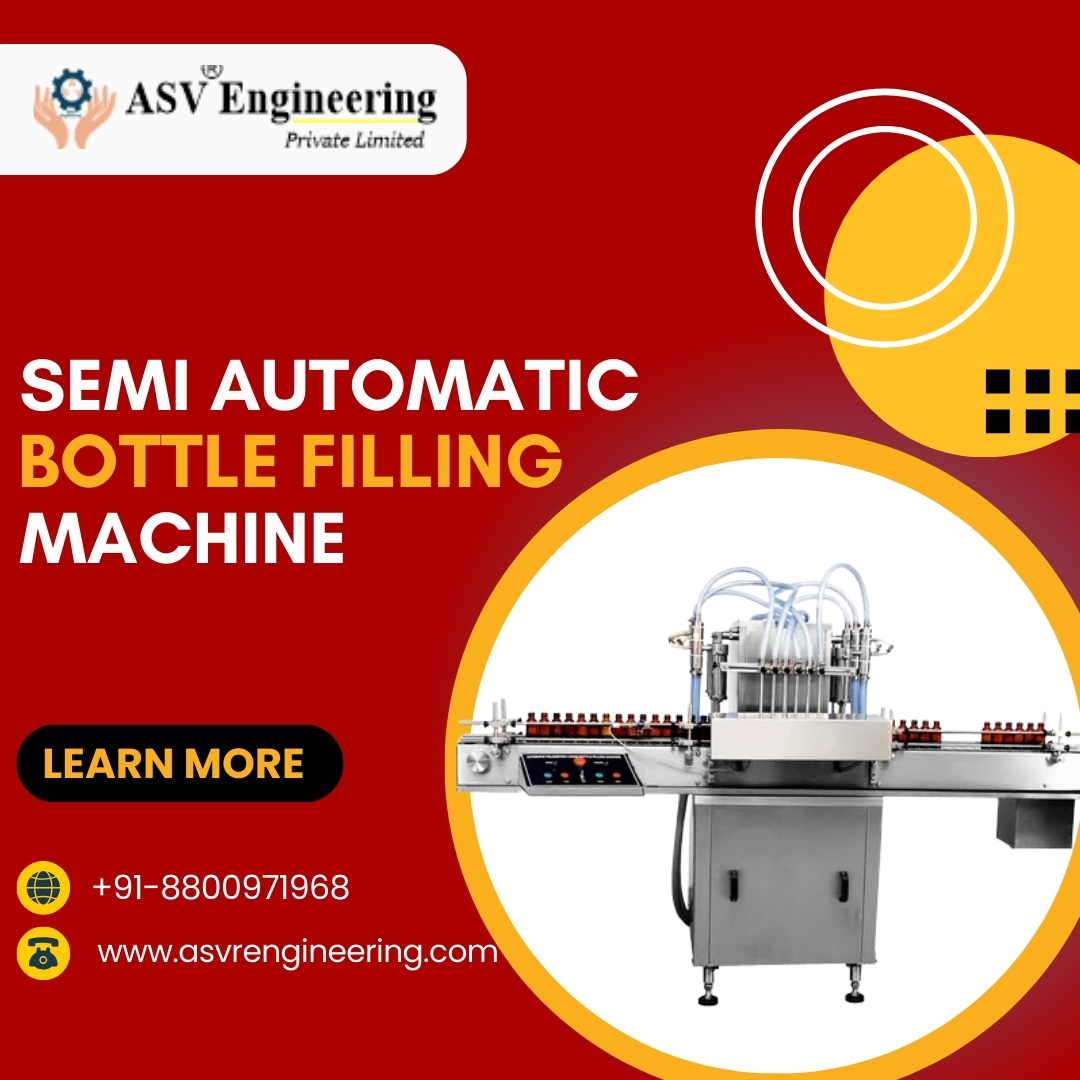

Leading Automatic Bottle Filling Machine Manufacturers for High-Speed Industrial Packaging Solutions

Trusted Automatic Milk Bag Packaging Machine Distributors for Dairy Plants, Milk Booths & FMCG Units

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)