Automatic Milk Bag Packaging Machine

Price: ₹115000

In today’s competitive dairy industry, packaging is no longer just about filling milk into a pouch—it is about hygiene, accuracy, speed, shelf life, and brand trust. An Automatic Milk Bag Packaging Machine is a critical investment for dairy plants, milk collection centers, cooperatives, and private milk processors who want consistent quality and efficient operations. Designed to handle liquid milk with precision, these machines ensure leak-proof sealing, uniform pouch sizes, and high production output while maintaining strict food safety standards.

At ASVR Engineering, we focus on providing advanced milk packaging solutions that meet the evolving needs of the dairy sector. Our machines are engineered for durability, ease of operation, and compliance with hygienic norms, making them suitable for small-scale dairies as well as large commercial milk processing units.

Understanding Automatic Milk Bag Packaging Machines

An automatic milk bag packaging machine is a fully integrated system that forms pouches from food-grade laminated film, accurately fills them with milk, and seals them securely—all in one continuous process. The entire operation is automated, minimizing human contact and reducing the risk of contamination.

These machines are widely used for packing:

-

Toned milk

-

Full cream milk

-

Double toned milk

-

Flavored milk

-

Skimmed milk

The packaging format is typically pillow-type or center-sealed pouches, which are easy to store, transport, and distribute.

Why Automation Matters in Milk Packaging

Manual or semi-automatic milk packing methods are often inconsistent and labor-intensive. Automation brings uniformity and reliability, which are essential for maintaining product quality and customer satisfaction.

Key benefits of automation include:

-

Consistent pouch weight and volume

-

Reduced spillage and wastage

-

Faster production cycles

-

Lower dependency on skilled labor

-

Improved hygiene and food safety

With rising consumer awareness about food safety, automated packaging has become a standard requirement rather than a luxury.

Key Features of Automatic Milk Bag Packaging Machines

1. Hygienic Stainless Steel Construction

Machines are manufactured using high-grade stainless steel that resists corrosion and is easy to clean. This ensures compliance with dairy hygiene standards and prolongs machine life.

2. Accurate Filling System

Advanced volumetric or flow-based filling mechanisms ensure precise milk quantity in every pouch, reducing overfilling or underfilling losses.

3. Leak-Proof Sealing

High-quality sealing jaws and temperature control systems create strong, uniform seals, preventing leakage during handling and transportation.

4. High-Speed Performance

Designed for continuous operation, these machines can pack hundreds to thousands of milk pouches per hour, depending on the model and pouch size.

5. User-Friendly Controls

Modern machines come with intuitive control panels that allow operators to easily set parameters like pouch size, fill volume, and sealing temperature.

6. Energy Efficient Design

Optimized motors and heating systems help reduce power consumption, keeping operating costs low without compromising output.

Working Principle: How the Machine Operates

The operation of an automatic milk bag packaging machine follows a streamlined process:

-

Film Feeding: The laminated packaging film is unwound and guided into the machine.

-

Pouch Formation: The film is shaped into a tube using forming collars.

-

Sealing: Vertical and horizontal sealing units create the pouch structure.

-

Milk Filling: Pre-measured milk is filled into the formed pouch through a hygienic filling nozzle.

-

Final Sealing & Cutting: The pouch is sealed and cut to the required size.

-

Output Collection: Finished milk pouches are discharged for secondary packing or storage.

This fully automatic cycle ensures speed, accuracy, and cleanliness.

Applications Across the Dairy Industry

Automatic milk bag packaging machines are used in a wide range of dairy operations, including:

-

Milk processing plants

-

Dairy cooperatives

-

Private milk brands

-

Rural milk collection centers

-

Milk chilling and distribution units

Whether you are packing milk for local delivery or large-scale distribution, these machines provide consistent and professional packaging.

Types of Milk Pouch Packaging Machines

Single-Lane Machines

Ideal for small and medium dairies with moderate production needs. Compact, economical, and easy to operate.

Multi-Lane Machines

Designed for high-output plants. Multiple pouches are packed simultaneously, significantly increasing production capacity.

Servo-Controlled Machines

Advanced machines with servo motors for enhanced accuracy, smoother operation, and reduced maintenance.

Advantages for Dairy Businesses

Investing in an automatic milk bag packaging machine offers long-term operational and financial benefits:

-

Improved Brand Image: Uniform, well-sealed pouches enhance customer trust.

-

Lower Operational Costs: Reduced labor and wastage lead to higher profitability.

-

Scalability: Machines can support business growth without frequent upgrades.

-

Compliance: Meets food safety and packaging regulations.

Maintenance & Ease of Cleaning

Regular cleaning and minimal maintenance are essential in dairy operations. These machines are designed with easy-access components, smooth surfaces, and minimal crevices, making cleaning quick and effective. Routine maintenance helps ensure consistent performance and long service life.

Choosing the Right Milk Packaging Machine

When selecting an automatic milk bag packaging machine, consider the following factors:

-

Daily milk production volume

-

Required pouch size and packaging material

-

Available floor space

-

Power availability

-

Budget and future expansion plans

Expert guidance from an experienced manufacturer ensures you choose a machine that fits your exact needs.

Why Choose ASVR Engineering?

ASVR Engineering is a trusted name in packaging machinery, known for quality engineering and reliable after-sales support. Our automatic milk bag packaging machines are designed to deliver consistent performance, durability, and value for money.

What sets us apart:

-

Robust machine design

-

Customizable solutions

-

Competitive pricing

-

Technical support and service assistance

Contact Us

For detailed specifications, pricing, and customized solutions for Automatic Milk Bag Packaging Machines, get in touch with our team today.

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Upgrade your dairy packaging process with reliable, hygienic, and high-performance milk pouch packing solutions that support your business growth and brand success.

Buy Now

Related Posts

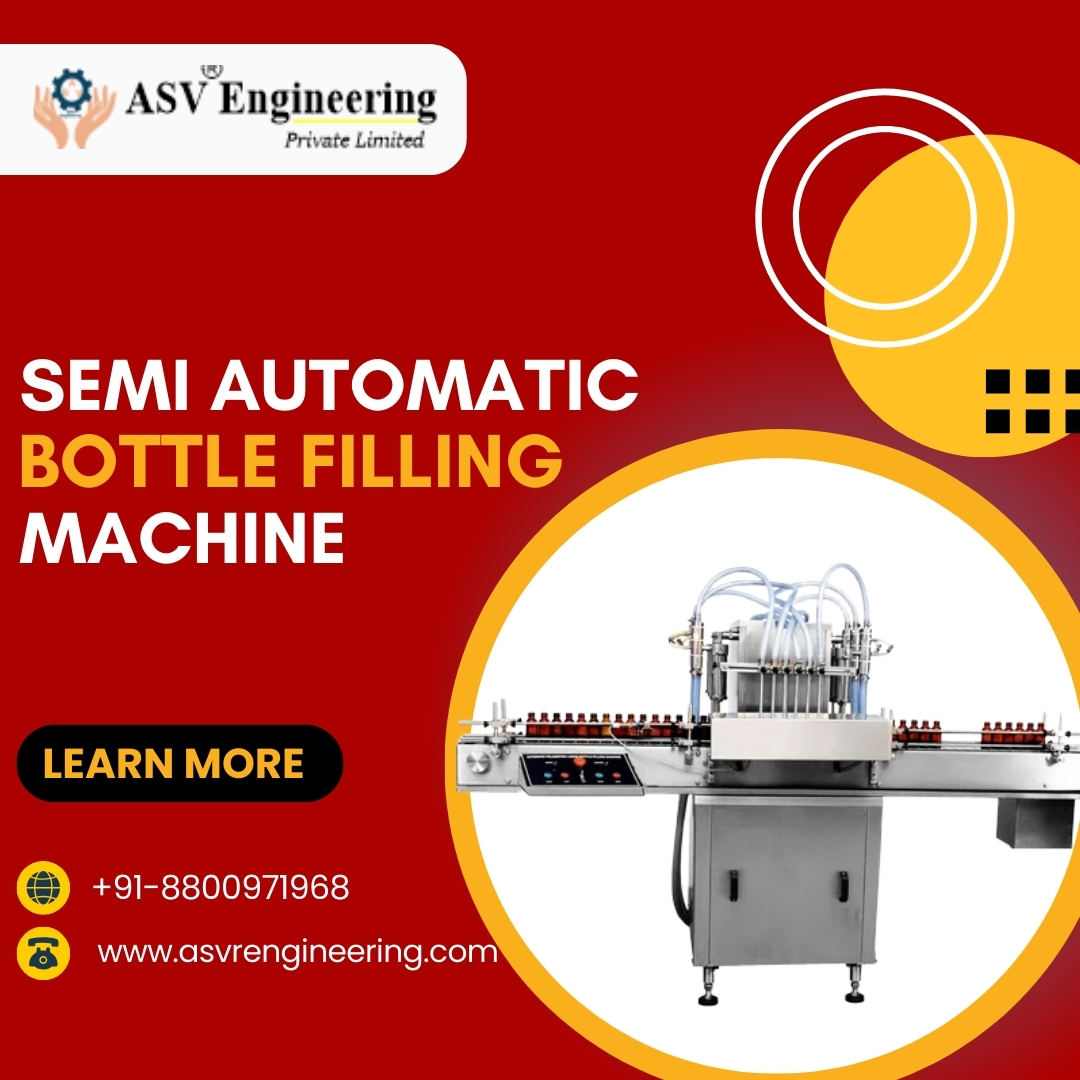

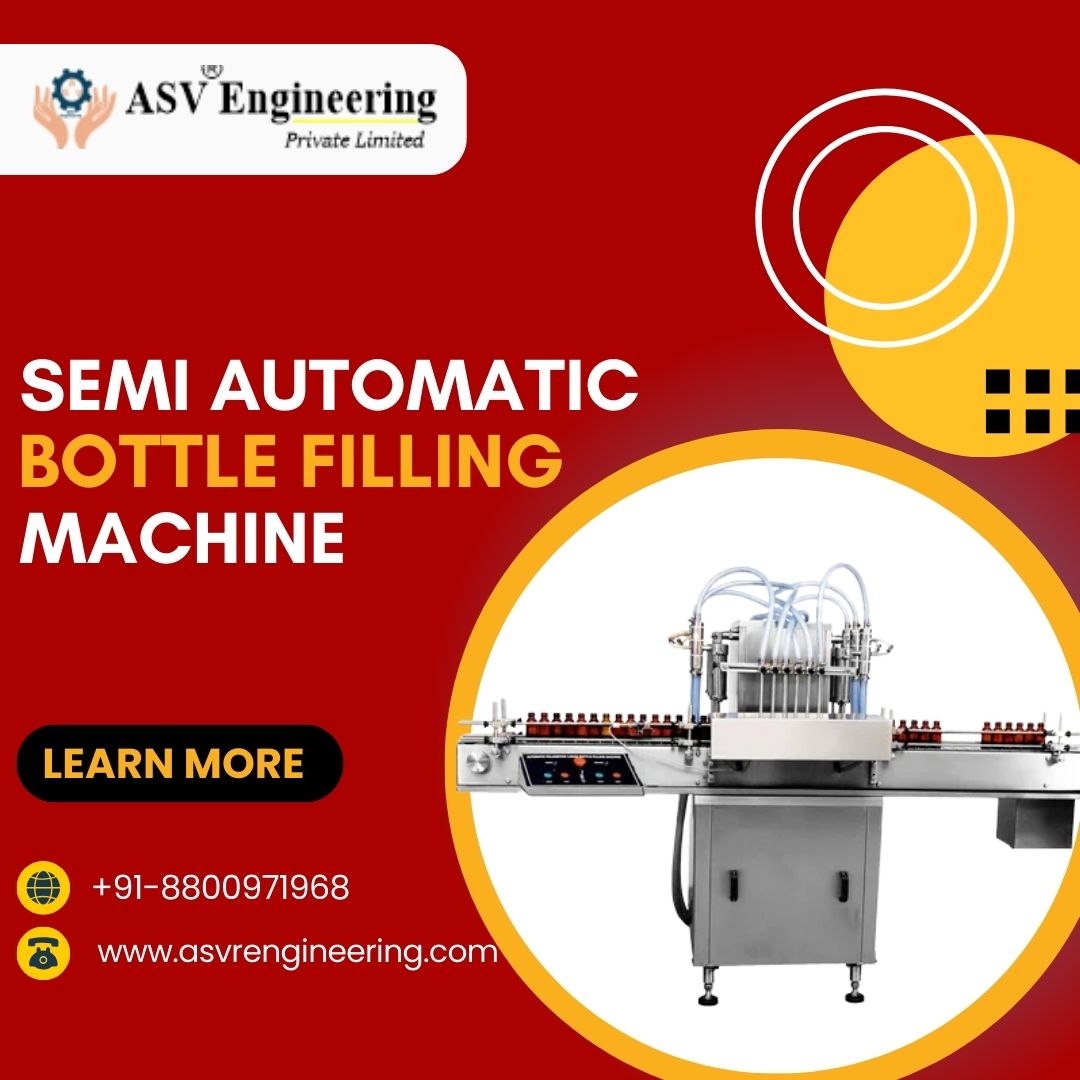

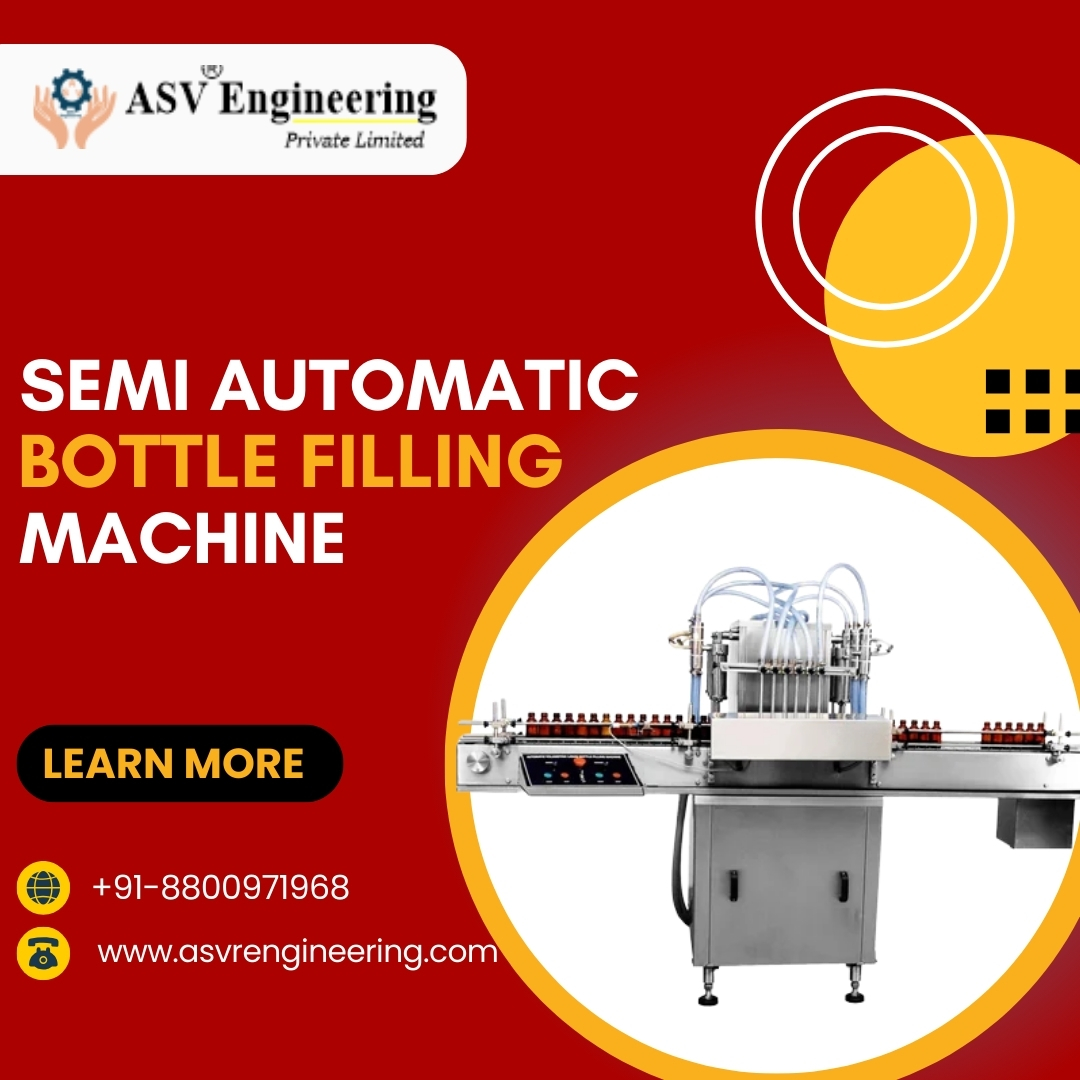

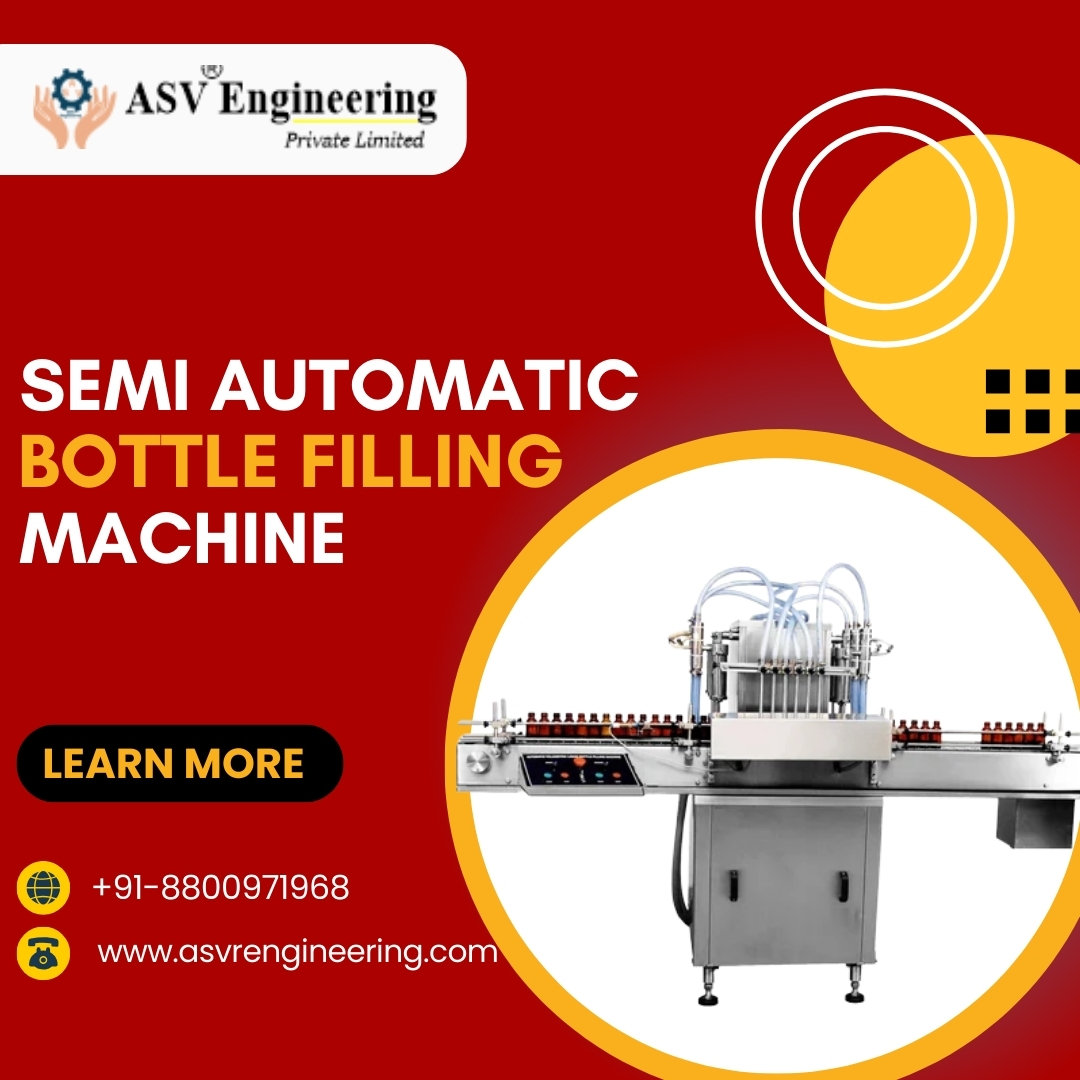

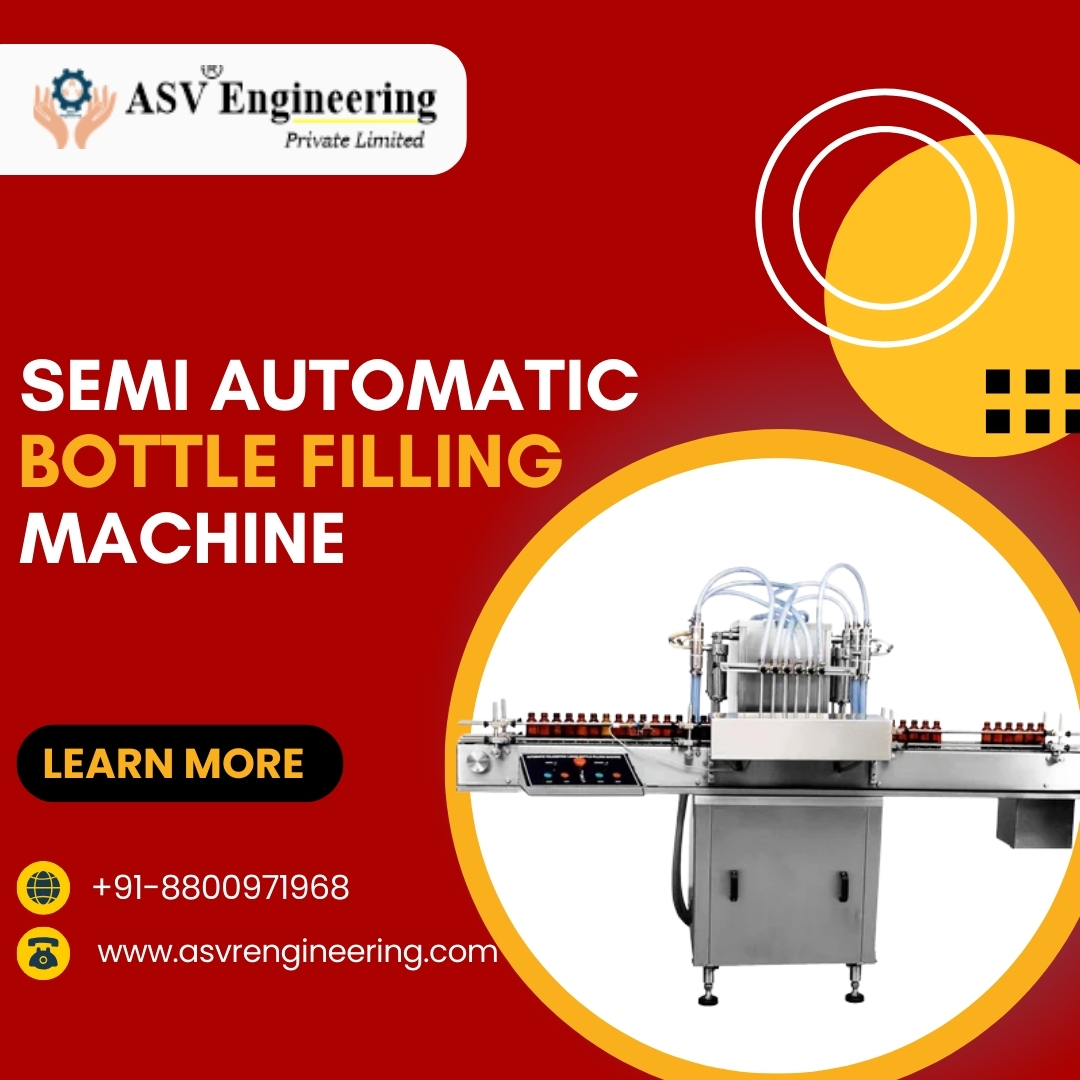

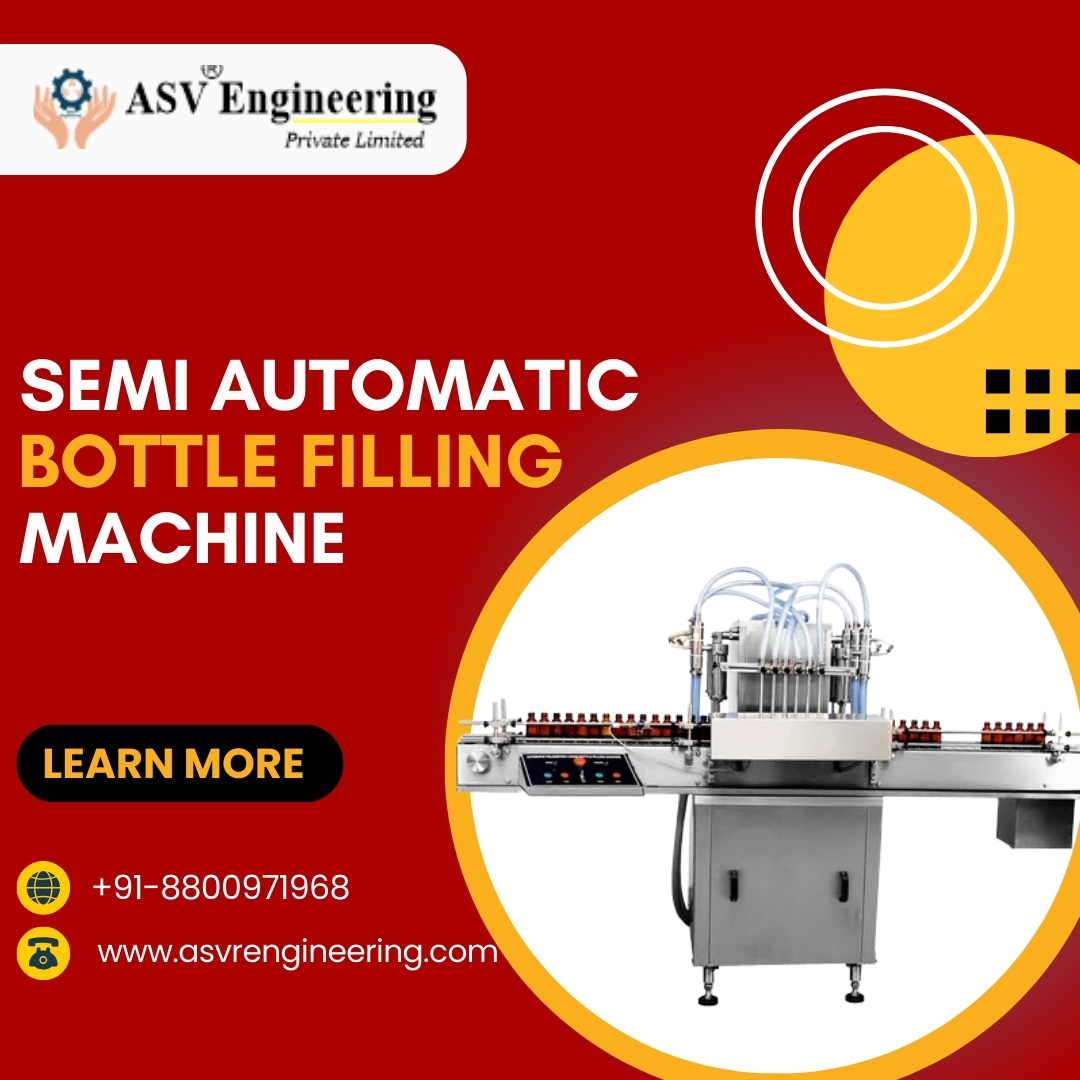

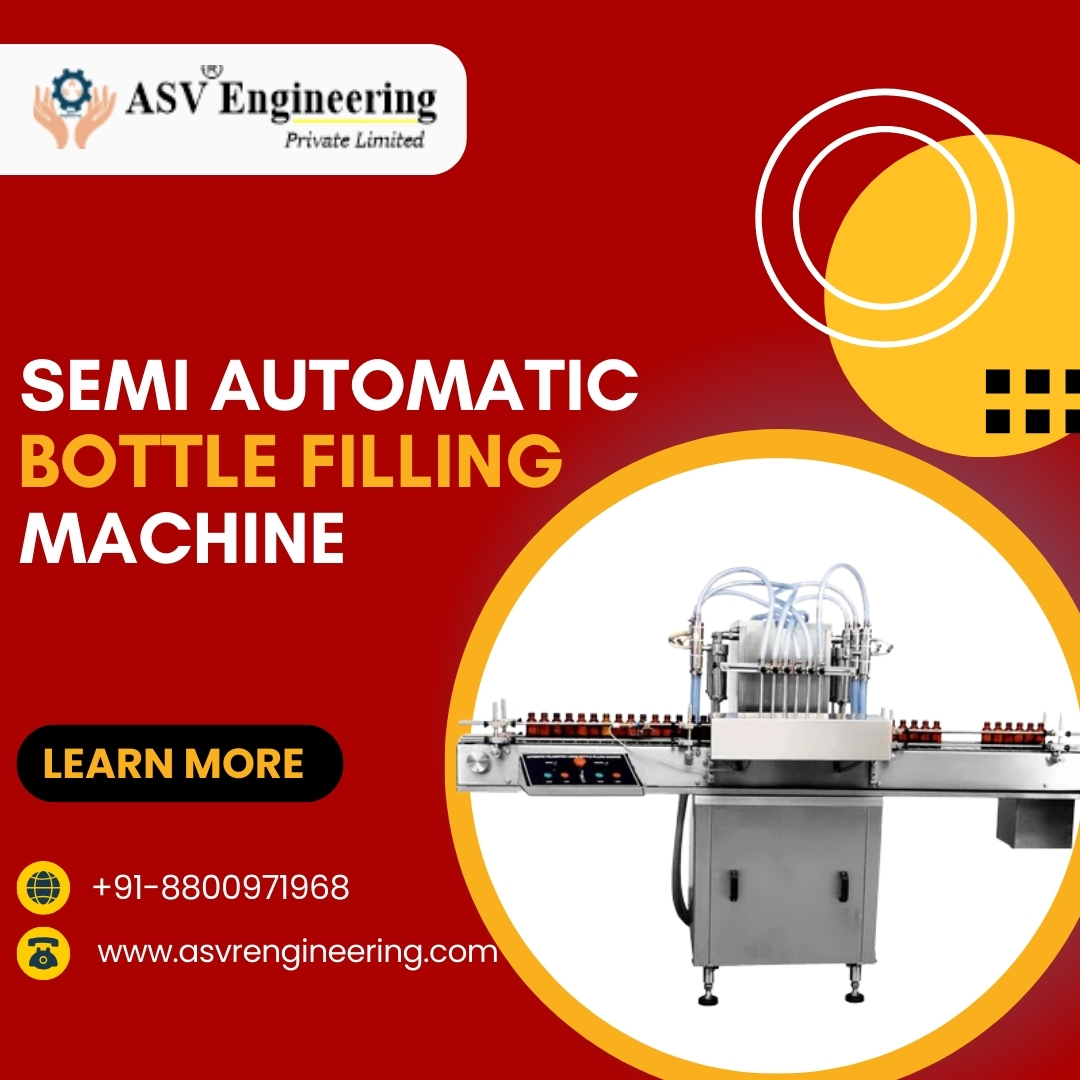

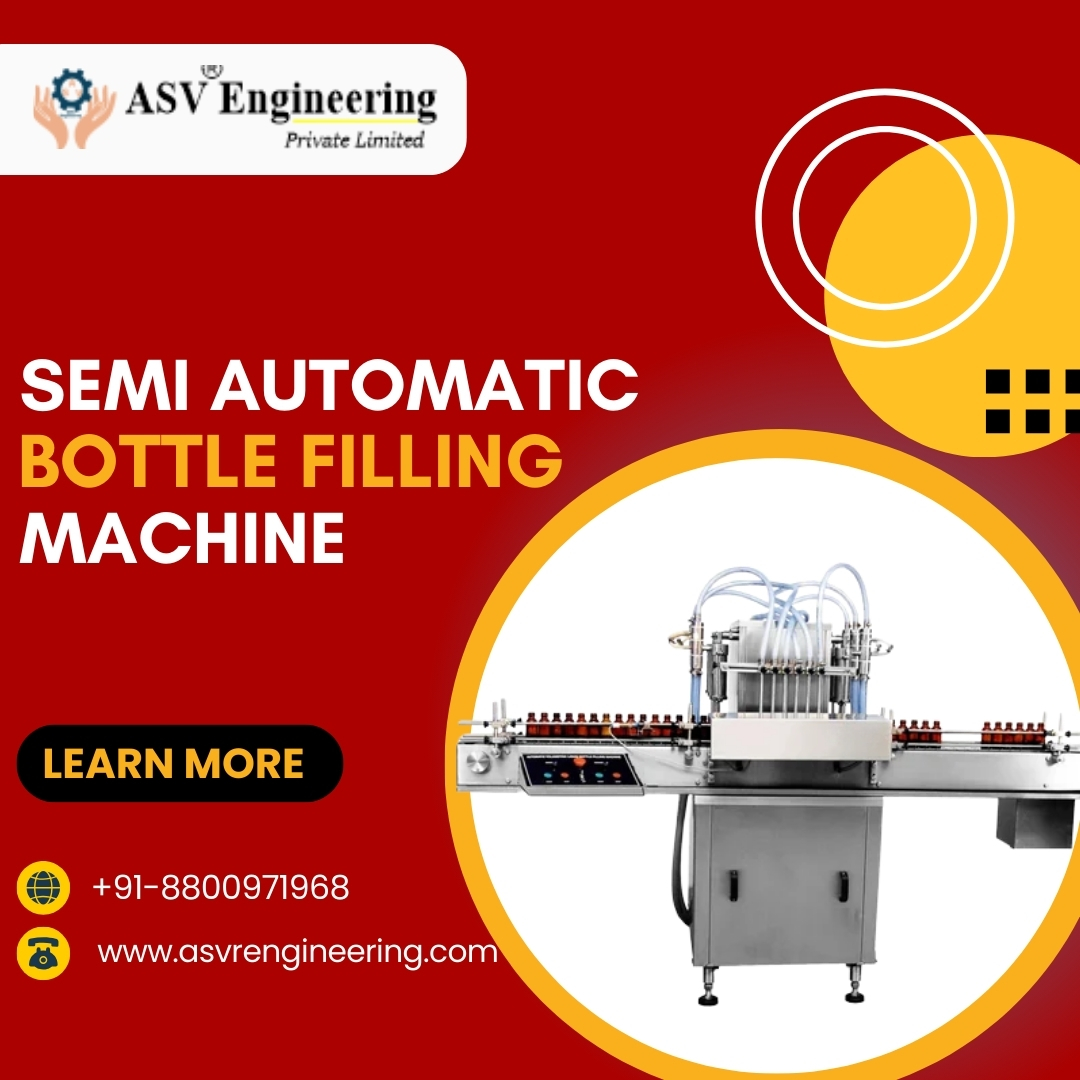

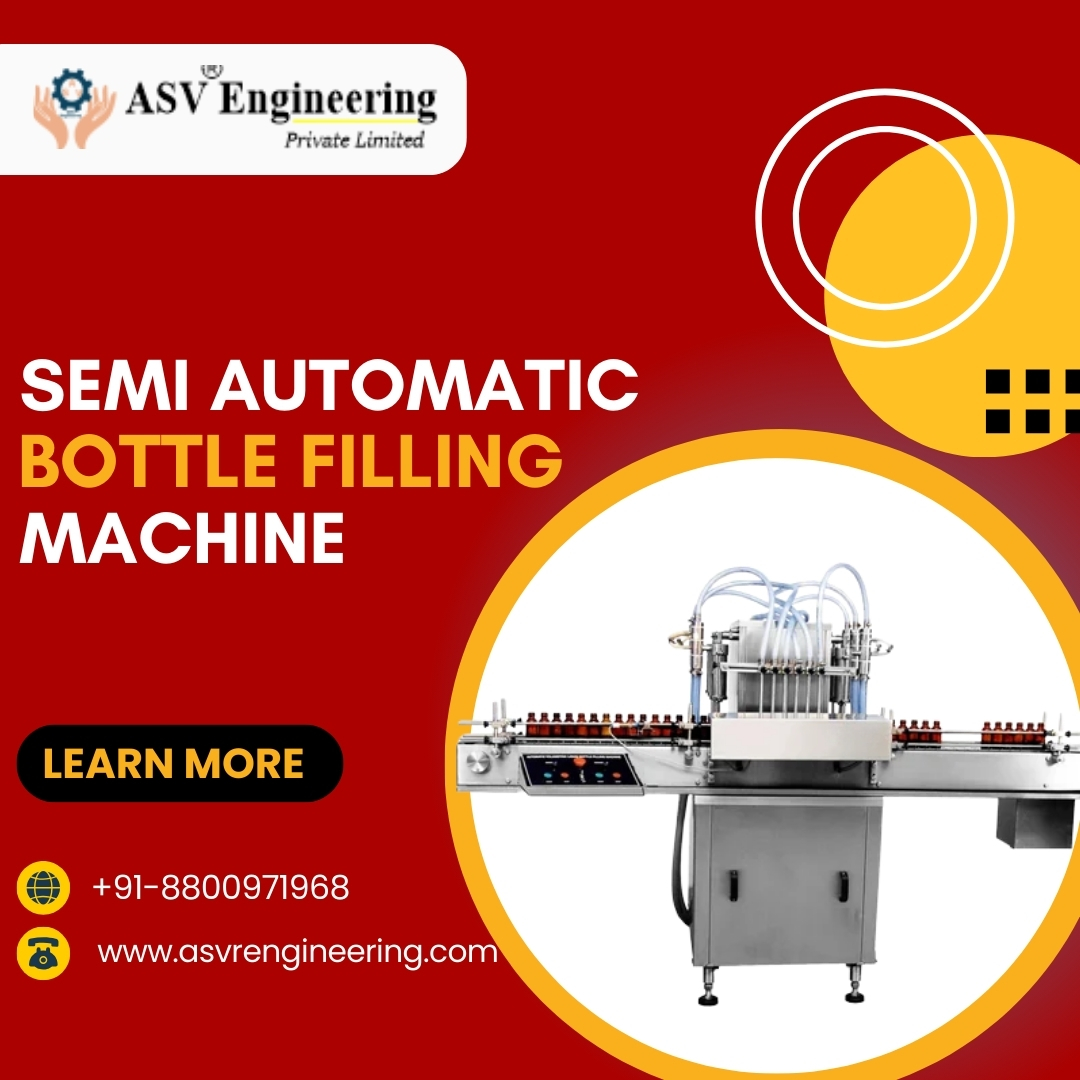

Leading Automatic Bottle Filling Machine Manufacturers for High-Speed Industrial Packaging Solutions

Trusted Automatic Milk Bag Packaging Machine Distributors for Dairy Plants, Milk Booths & FMCG Units

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)