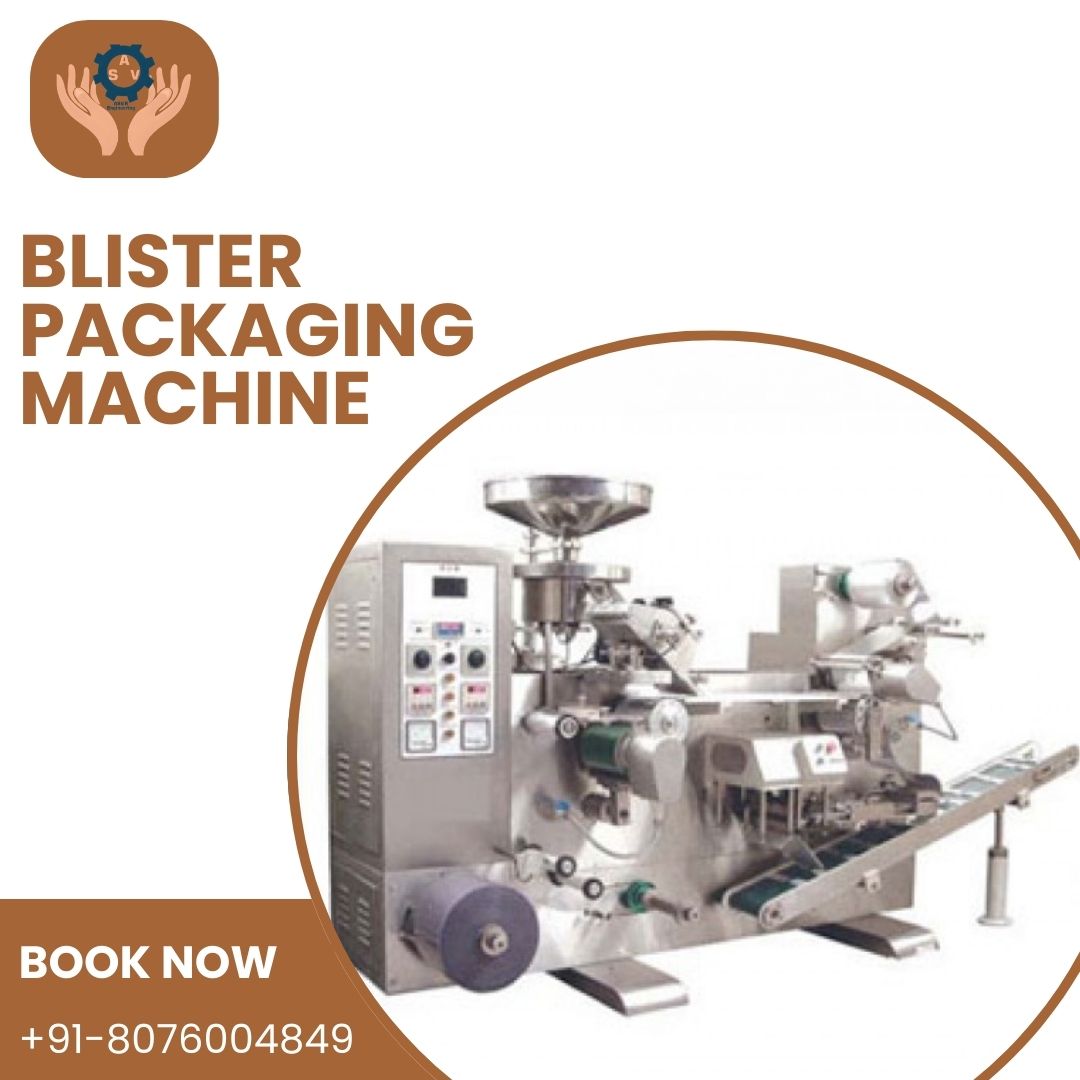

Automatic Blister Packaging Machine

Price: ₹250000

In today’s fast-paced pharmaceutical and consumer goods industries, efficient and precise packaging solutions are no longer optional—they are essential. One of the most vital innovations in packaging technology is the Automatic Blister Packaging Machine, a device designed to ensure accuracy, speed, and safety while packaging tablets, capsules, and other small products. ASVR Engineering, a leading manufacturer and supplier of industrial machinery in Delhi, has been at the forefront of providing cutting-edge blister packing solutions that cater to businesses of all sizes, delivering machines that combine durability, efficiency, and user-friendly operations.

What is an Automatic Blister Packaging Machine?

An Automatic Blister Packaging Machine is a specialized device used for packaging products into pre-formed blisters or cavities. These cavities are typically made of PVC, PVDC, or aluminum foils and are designed to protect tablets, capsules, or similar products from environmental factors such as moisture, dust, and oxygen. The machine automates the entire process of forming the blister, filling the cavities with the product, sealing it with a suitable lidding material, and cutting the final product into desired shapes or sizes.

The automation reduces manual labor, increases production speed, and ensures consistent product quality, making it ideal for pharmaceutical, nutraceutical, and small consumer goods industries.

Key Components of a Blister Packaging Machine

To understand the efficiency of the Automatic Blister Packaging Machine, it is important to look at its primary components:

-

Blister Forming Station:

This is where the base material, usually PVC or aluminum, is heated and formed into the desired blister cavities. High-quality machines maintain precision during forming to ensure uniform cavity depth and shape. -

Product Loading Station:

Tablets, capsules, or other items are accurately dispensed into each cavity. Advanced machines have automatic feeders to minimize product spillage and ensure precise placement. -

Sealing Station:

Once the products are loaded, the machine seals them using lidding foil or films. Sealing is done under controlled temperature and pressure to maintain product integrity and avoid leakage. -

Cutting Station:

After sealing, the continuous blister strip is cut into individual packs or desired sizes using cutting dies. This ensures uniform, ready-to-distribute packaging. -

Control Panel:

Modern machines come with PLC or touchscreen interfaces that allow operators to monitor and control speed, temperature, and sealing pressure. This improves efficiency and reduces the likelihood of errors.

Benefits of Using an Automatic Blister Packaging Machine

Switching from manual to automatic blister packaging brings several advantages for businesses:

-

High Efficiency:

Automated machines can package thousands of tablets or capsules per hour, significantly increasing production capacity compared to manual packaging. -

Consistency and Accuracy:

Automation ensures precise filling and sealing of each blister, reducing product wastage and maintaining uniform quality. -

Cost-Effective:

Though the initial investment may seem high, the reduction in labor costs, minimized wastage, and increased production speed make these machines highly cost-effective in the long run. -

Hygienic and Safe:

With minimal human contact, the risk of contamination is significantly reduced, which is critical in the pharmaceutical and nutraceutical industries. -

Customizable Options:

Many machines are designed to handle different blister sizes, shapes, and materials, allowing businesses to adapt to changing product lines without investing in a new machine. -

Durable and Low Maintenance:

Machines from ASVR Engineering are built with high-quality materials to withstand continuous industrial use and require minimal maintenance.

Applications of Blister Packaging Machines

The Automatic Blister Packaging Machine is not limited to one industry. Its applications include:

-

Pharmaceutical Industry:

Packaging tablets, capsules, soft gels, lozenges, and other medicinal products into secure blisters. -

Nutraceuticals and Supplements:

Efficiently packing vitamins, minerals, and dietary supplements in tamper-proof blisters. -

Consumer Goods:

Packaging small items like chewing gum, candies, or small electronic components. -

Cosmetics Industry:

Packaging small beauty products such as eyeshadow tablets, single-use creams, or serums.

Why Choose ASVR Engineering for Blister Packaging Machines?

ASVR Engineering has established itself as a trusted manufacturer and supplier of industrial machinery in India since its inception in 2008. Here’s why businesses prefer ASVR for blister packing solutions:

-

High-Quality Manufacturing:

Every machine is crafted using premium-grade materials and components to ensure long-lasting performance and reliability. -

Advanced Technology:

ASVR Engineering machines are equipped with PLC control systems, servo motors, and other advanced automation features that ensure precision and efficiency. -

Customization Services:

Understanding that each business has unique requirements, ASVR Engineering offers tailor-made solutions for different industries, sizes, and product types. -

Affordable Pricing:

The company ensures its automatic blister packaging machines are competitively priced, offering maximum ROI to businesses without compromising on quality. -

After-Sales Support:

ASVR Engineering provides installation, training, and maintenance support, ensuring that clients can operate their machines smoothly and maximize productivity. -

Proven Track Record:

With years of experience and thousands of satisfied clients, ASVR Engineering has earned a reputation for reliability, trustworthiness, and high-quality products.

Key Features of ASVR Engineering Automatic Blister Packaging Machines

-

Fully Automatic Operation: Reduces manual intervention and labor costs.

-

High-Speed Performance: Suitable for large-scale production without compromising quality.

-

User-Friendly Interface: Touchscreen control panels for easy operation and monitoring.

-

Durable Build: Made with stainless steel and high-quality components to resist wear and tear.

-

Multi-Size Packaging Capability: Handles different blister shapes and sizes efficiently.

-

Energy-Efficient Design: Low power consumption for cost-effective operation.

-

Safety Features: Includes emergency stop buttons, protective covers, and sensors to prevent accidents.

Maintenance and Safety Tips

To ensure the longevity and safe operation of an Automatic Blister Packaging Machine, consider the following tips:

-

Regular Cleaning: Keep the machine clean to prevent product contamination.

-

Periodic Lubrication: Lubricate moving parts as per manufacturer guidelines to prevent wear and tear.

-

Routine Checks: Inspect sealing temperature, pressure, and cavity alignment regularly.

-

Operator Training: Ensure operators are trained to handle the machine safely and efficiently.

-

Emergency Protocols: Familiarize staff with emergency stop procedures and safety precautions.

How to Choose the Right Blister Packaging Machine

When selecting a machine for your business, consider:

-

Production Capacity: Assess your daily production requirements to choose an appropriately sized machine.

-

Product Type: Ensure the machine can handle the size, shape, and type of products you manufacture.

-

Automation Level: Fully automatic machines provide better efficiency but are costlier than semi-automatic models.

-

Budget: Consider both the initial investment and long-term operational costs.

-

Support and Warranty: Choose a manufacturer that offers reliable after-sales service and warranty coverage.

Conclusion

An Automatic Blister Packaging Machine is an indispensable tool for businesses looking to streamline their packaging process, ensure product safety, and increase production efficiency. ASVR Engineering, with its years of expertise and commitment to quality, provides some of the most reliable, efficient, and cost-effective blister packing machines in India. Whether you are a pharmaceutical company, nutraceutical manufacturer, or consumer goods producer, investing in a high-quality automatic blister packaging machine from ASVR Engineering can transform your packaging process, save costs, and ensure consistent, professional-quality products for your customers.

For more details, product specifications, and pricing, contact ASVR Engineering today at 91-8076004849 | +91-8800971968 or visit our website: https://www.asvrengineering.com.

Buy Now

Related Posts

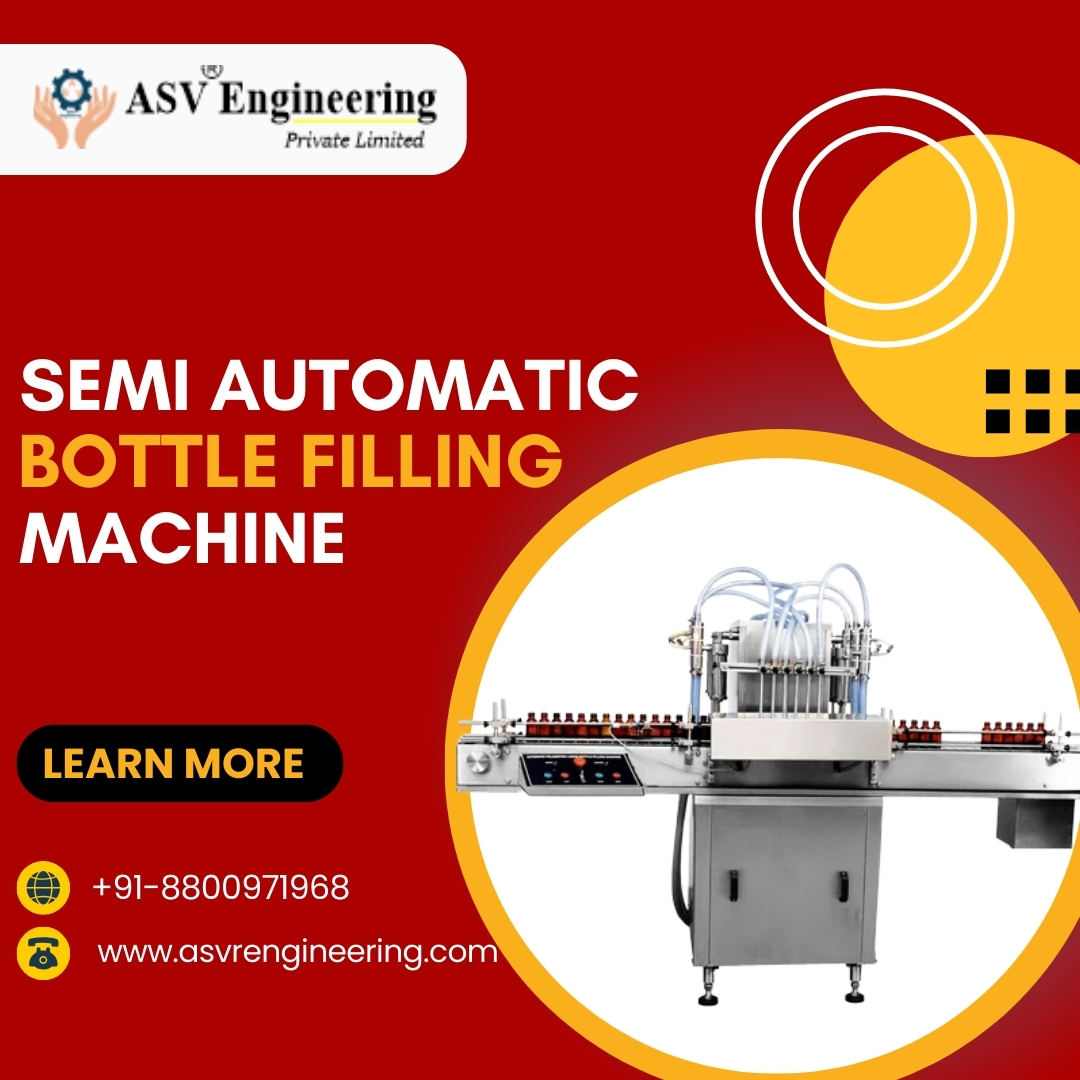

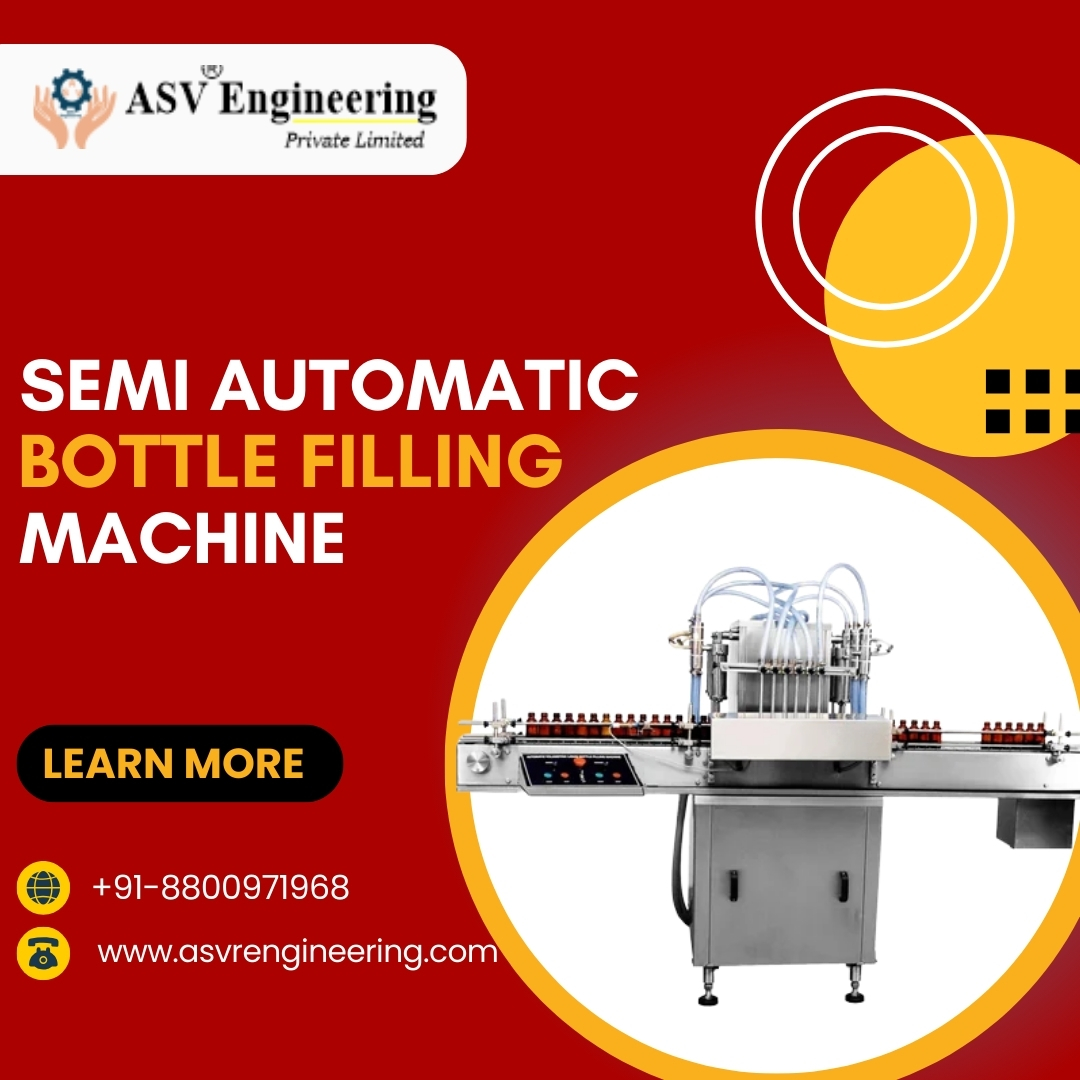

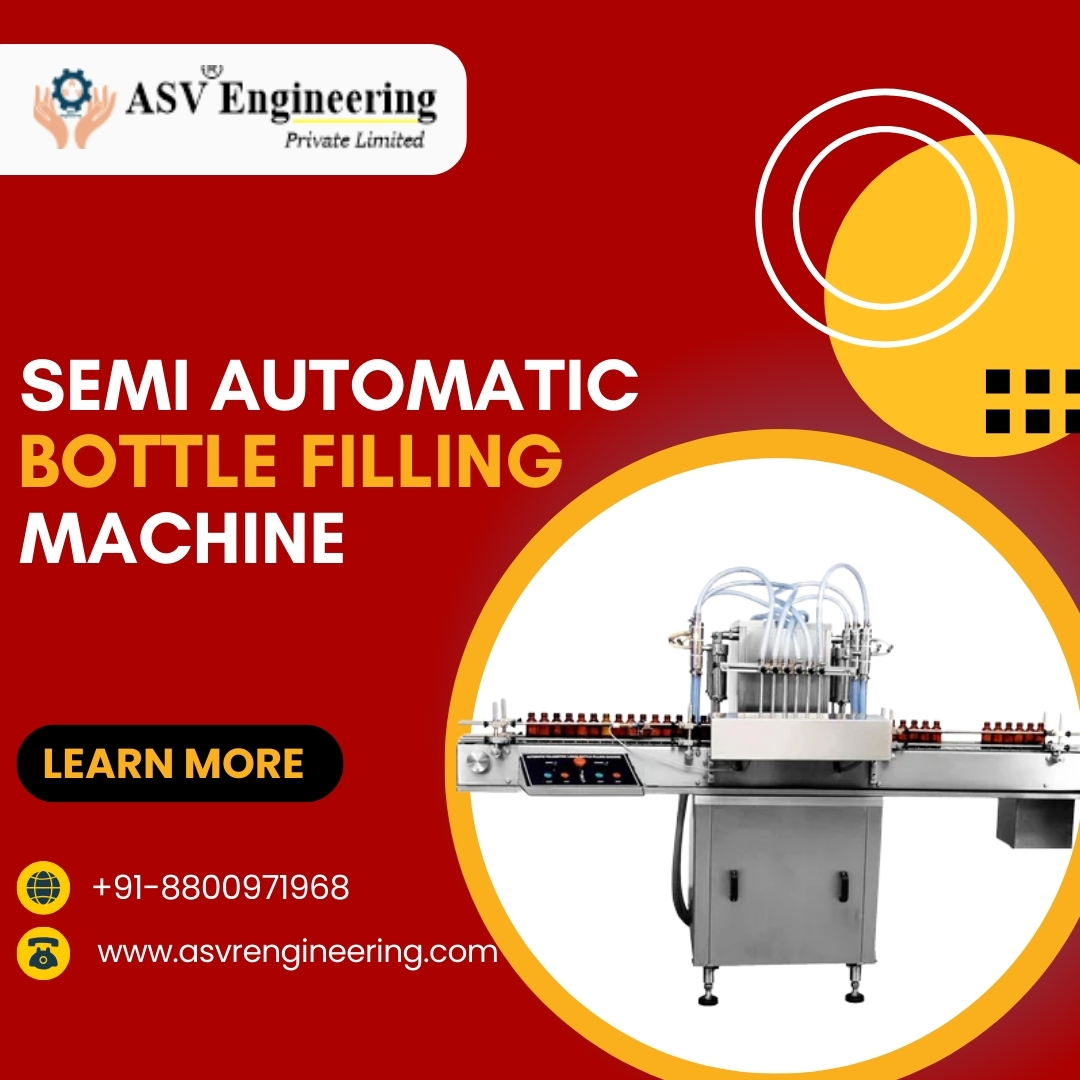

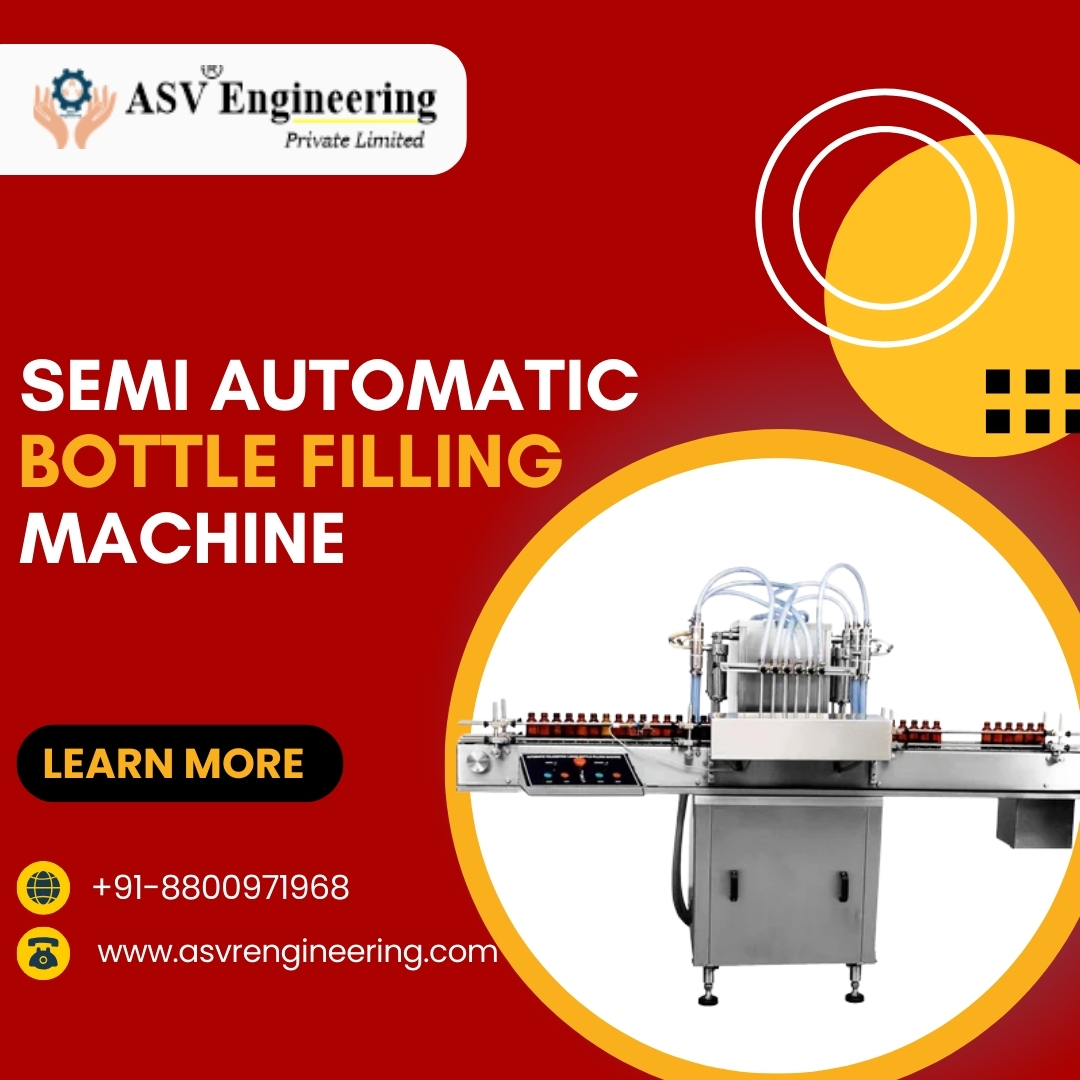

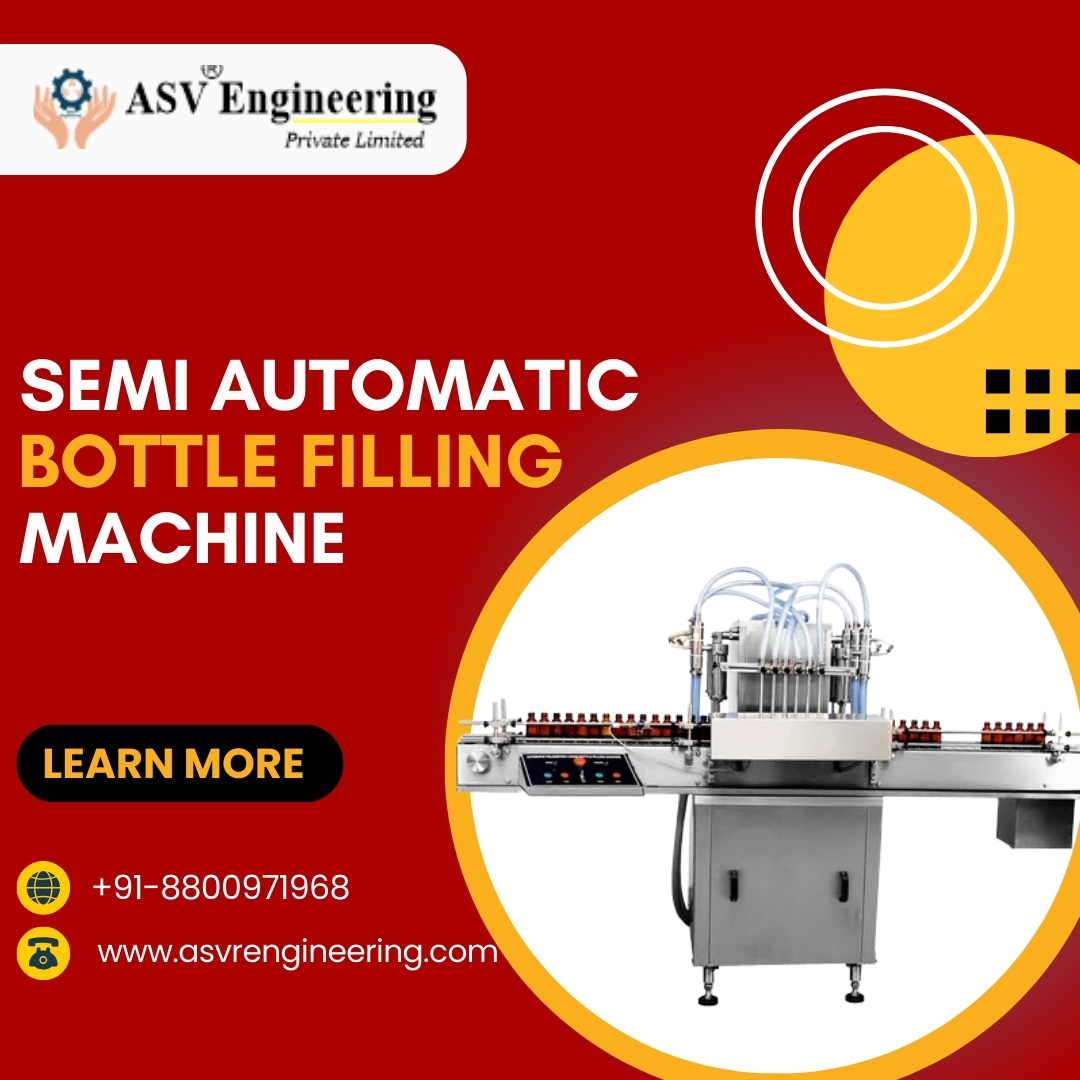

Leading Automatic Bottle Filling Machine Manufacturers for High-Speed Industrial Packaging Solutions

Trusted Automatic Milk Bag Packaging Machine Distributors for Dairy Plants, Milk Booths & FMCG Units

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)