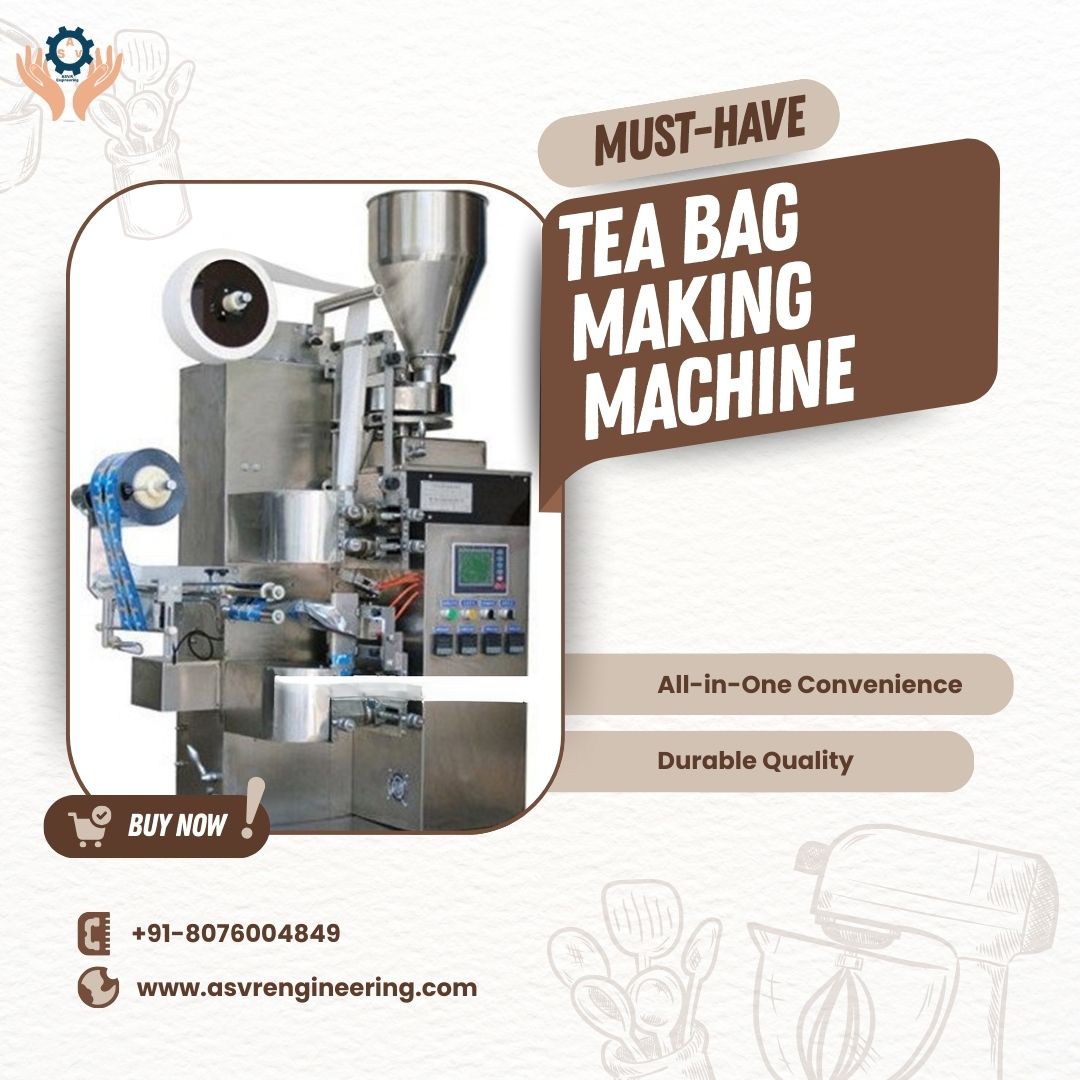

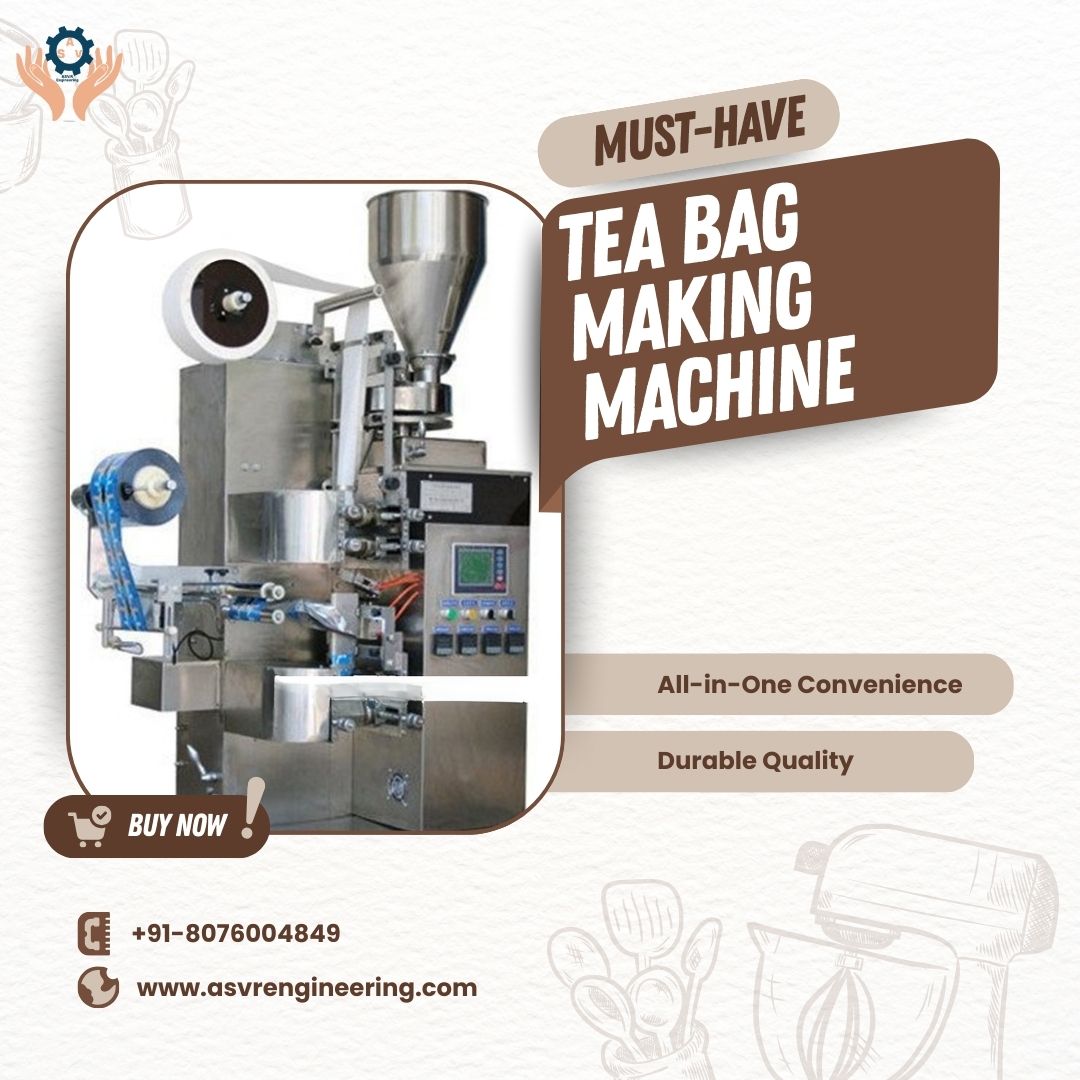

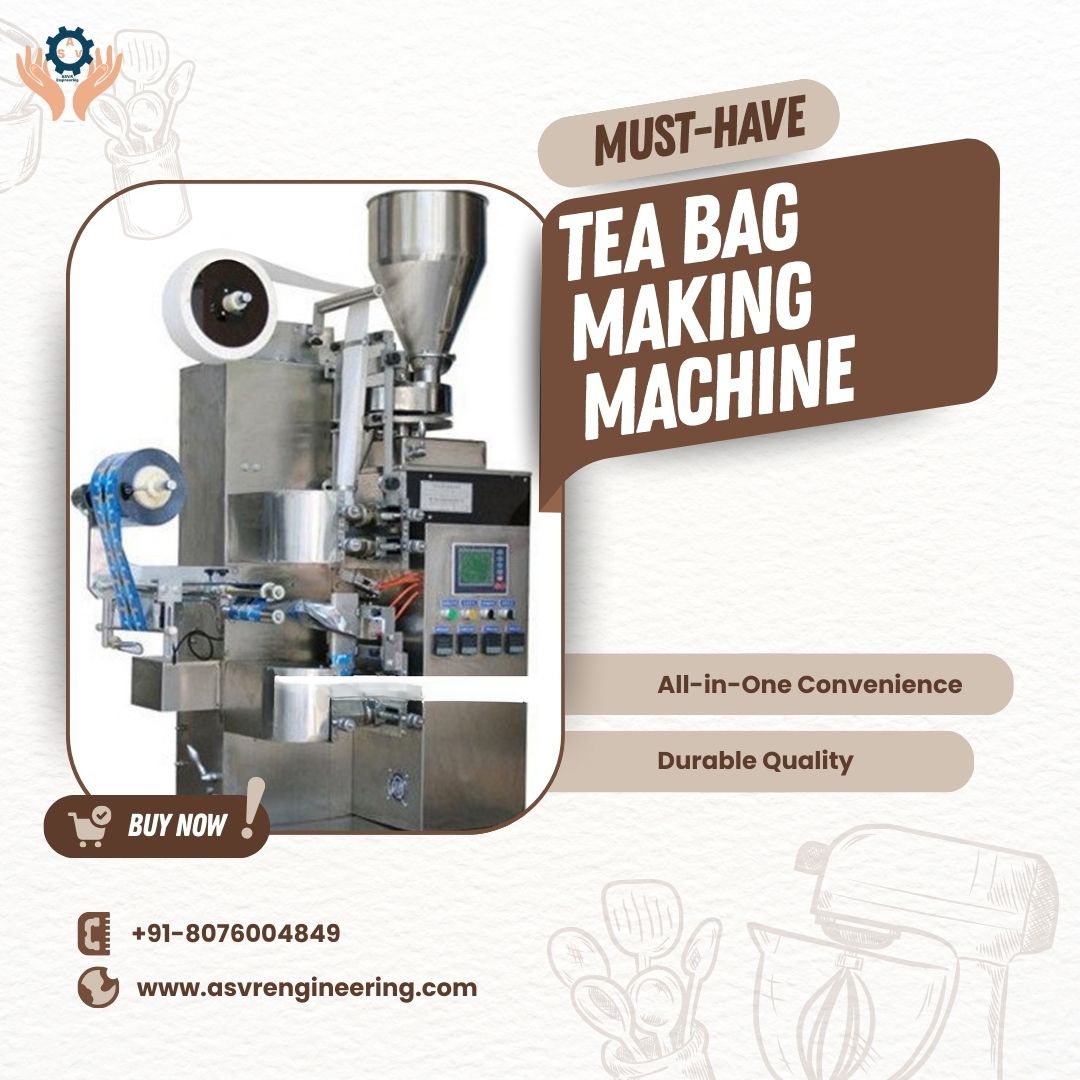

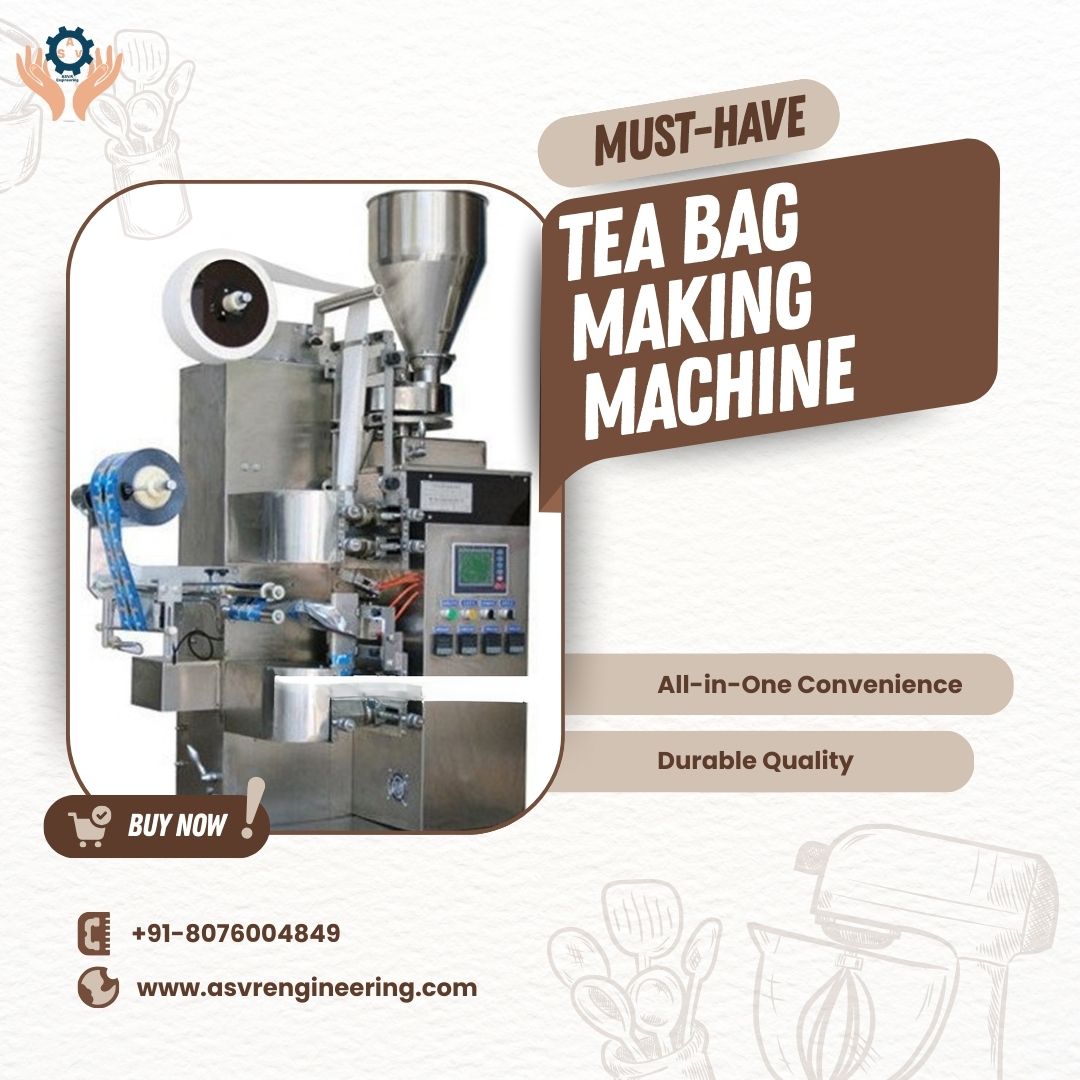

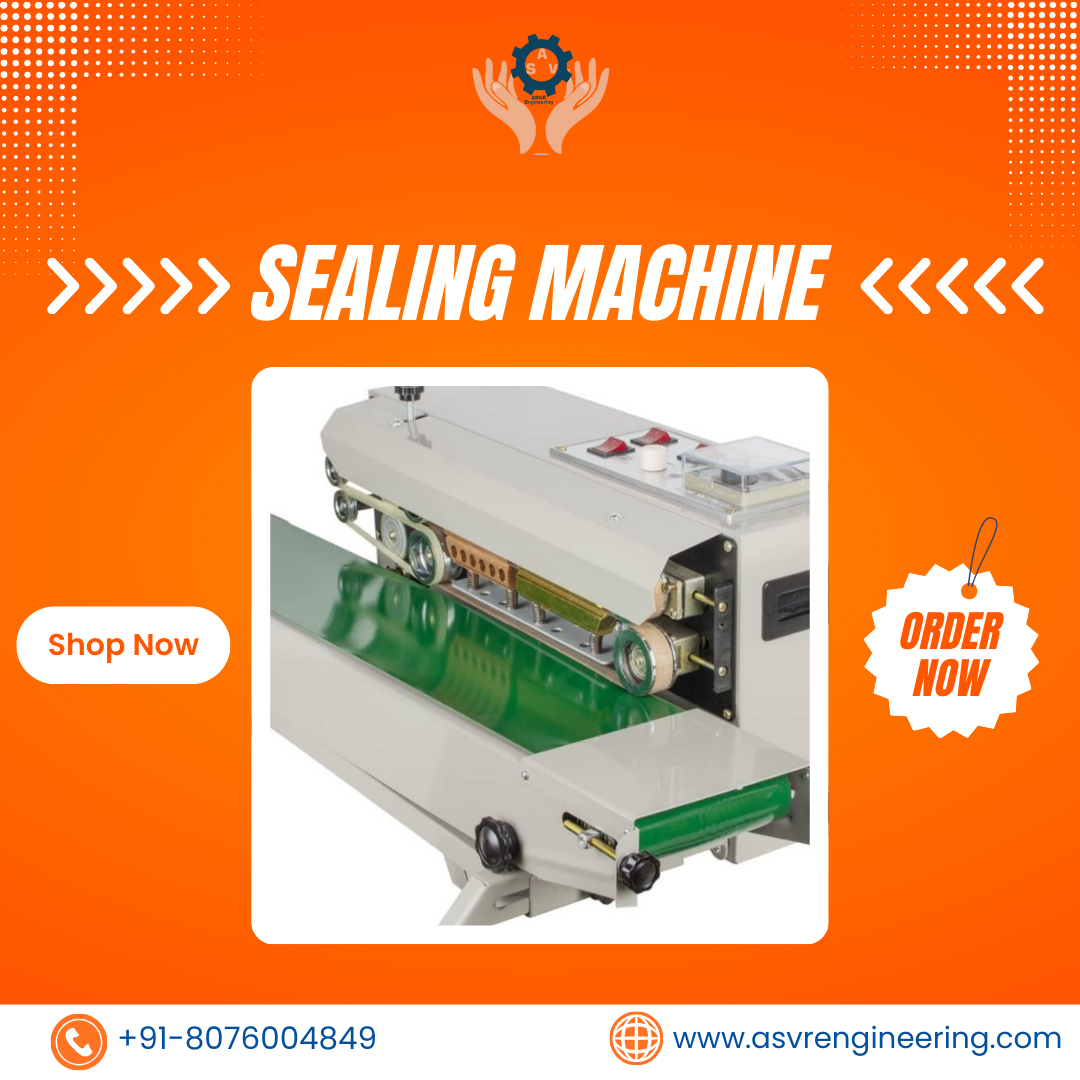

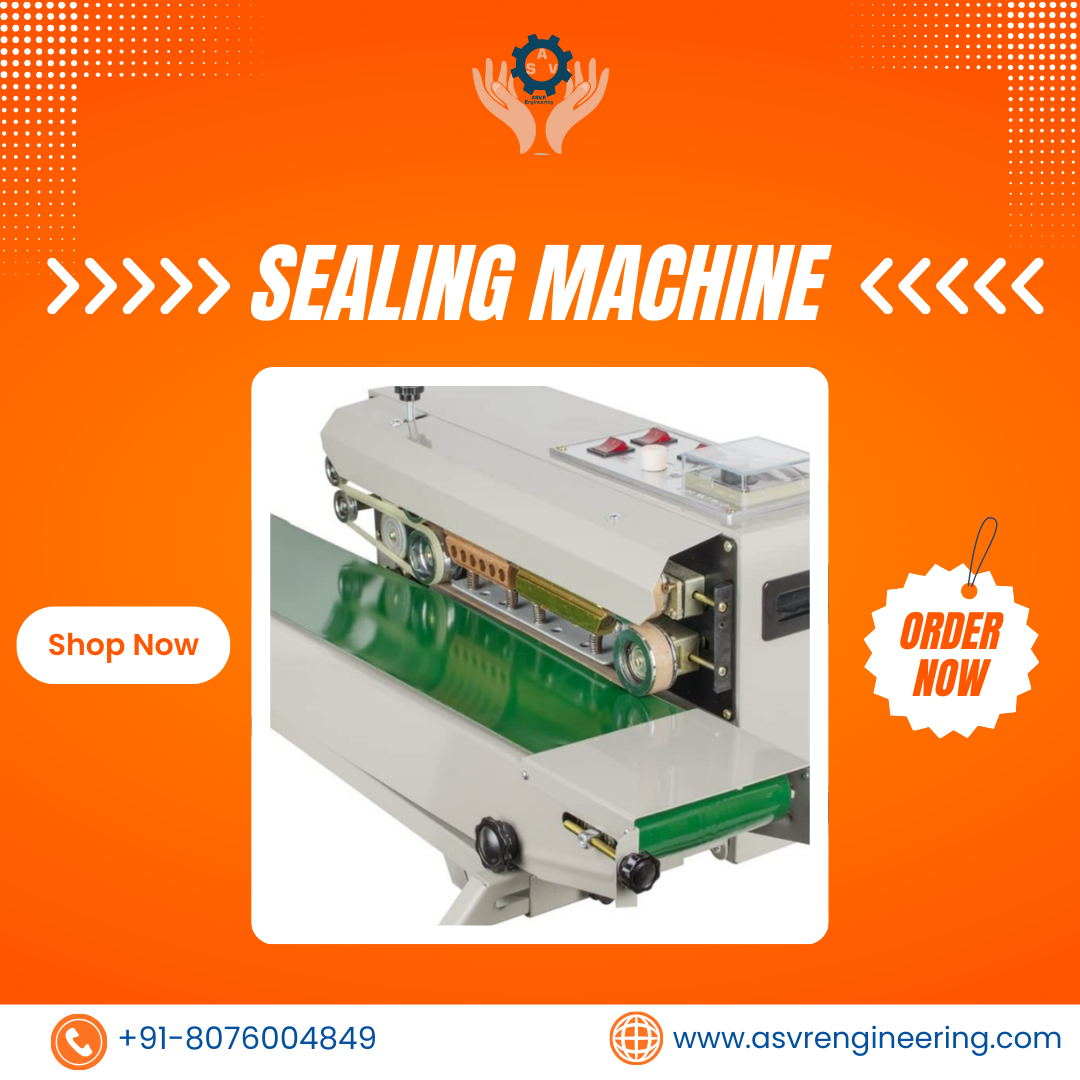

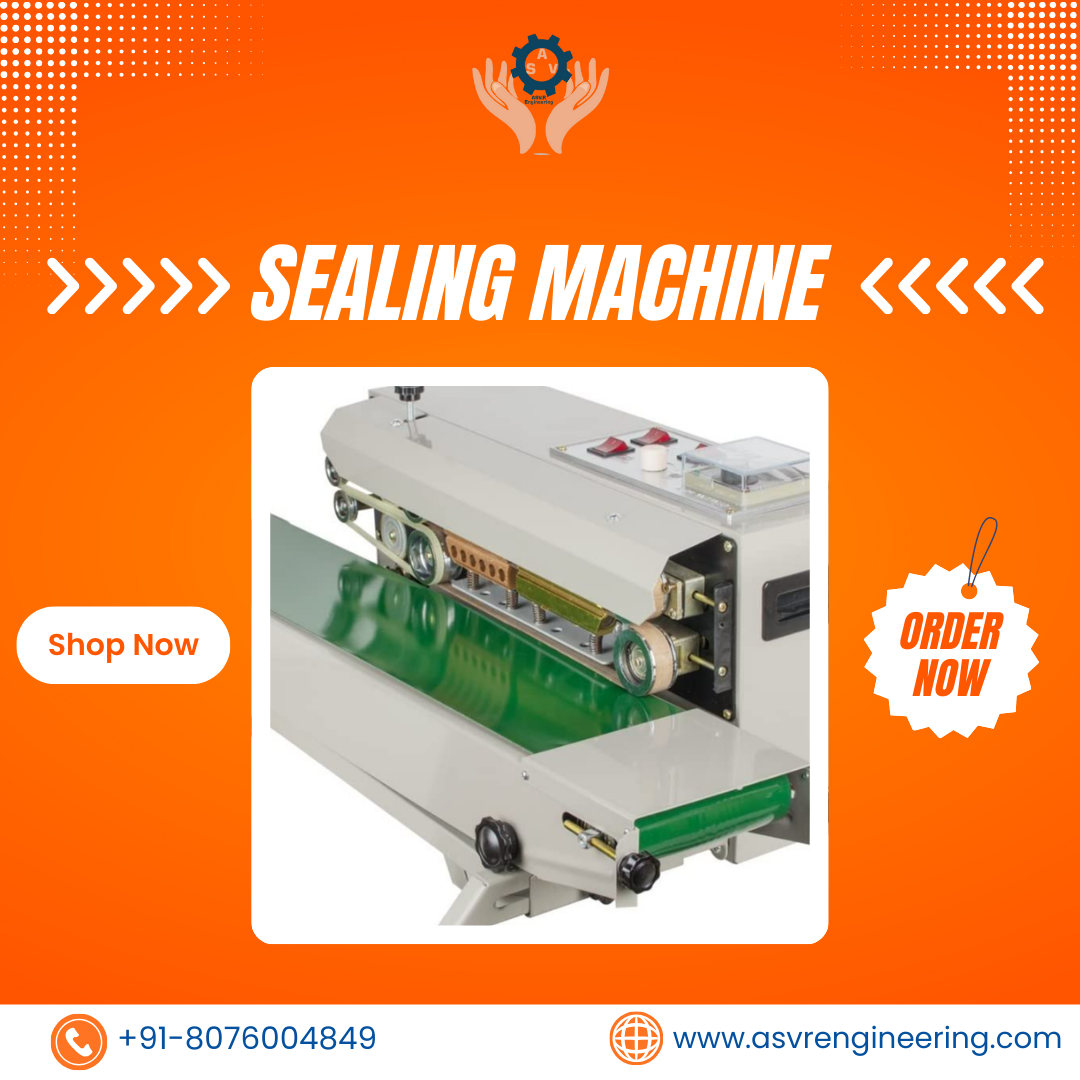

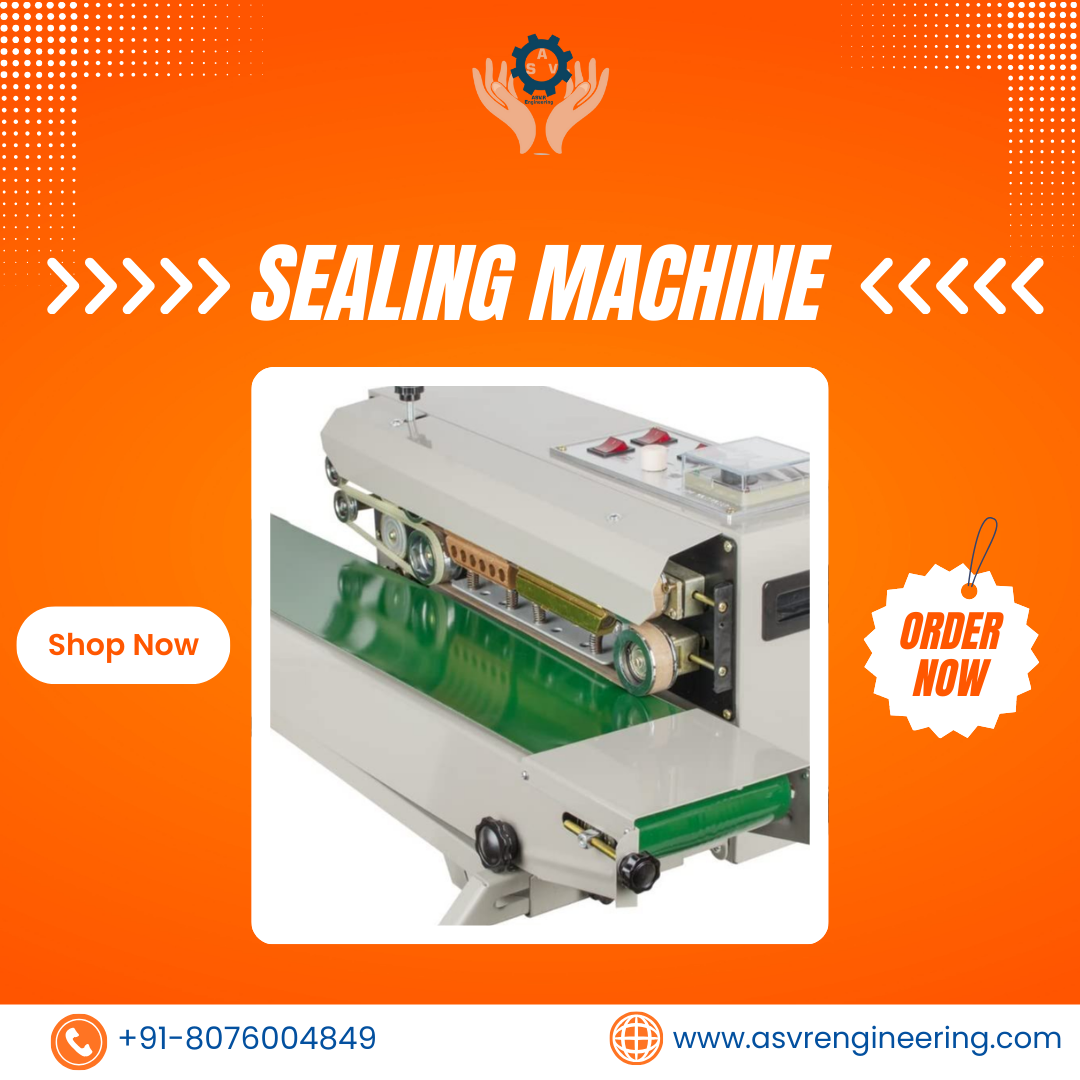

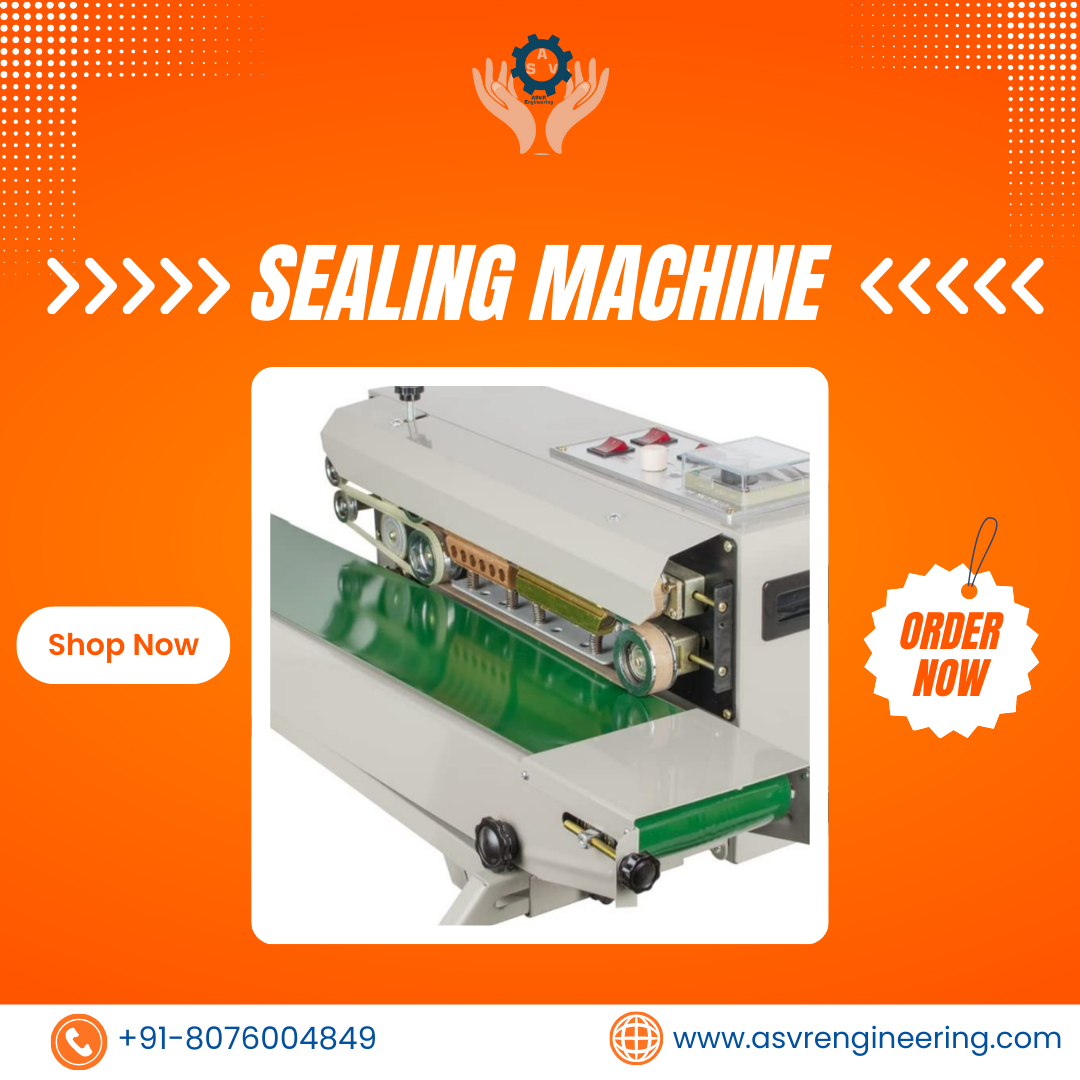

Seal Bag Making Machine

Price: ₹49000

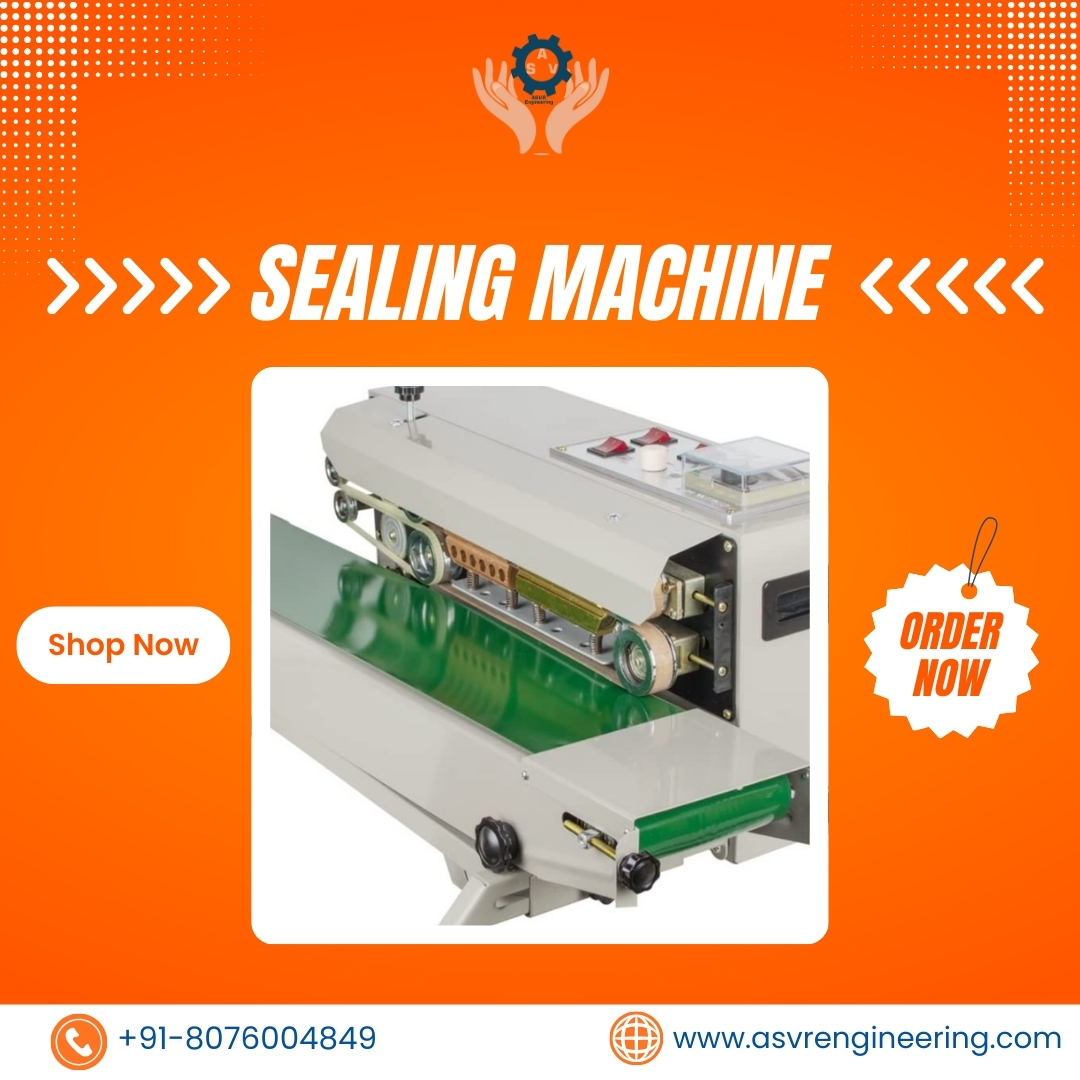

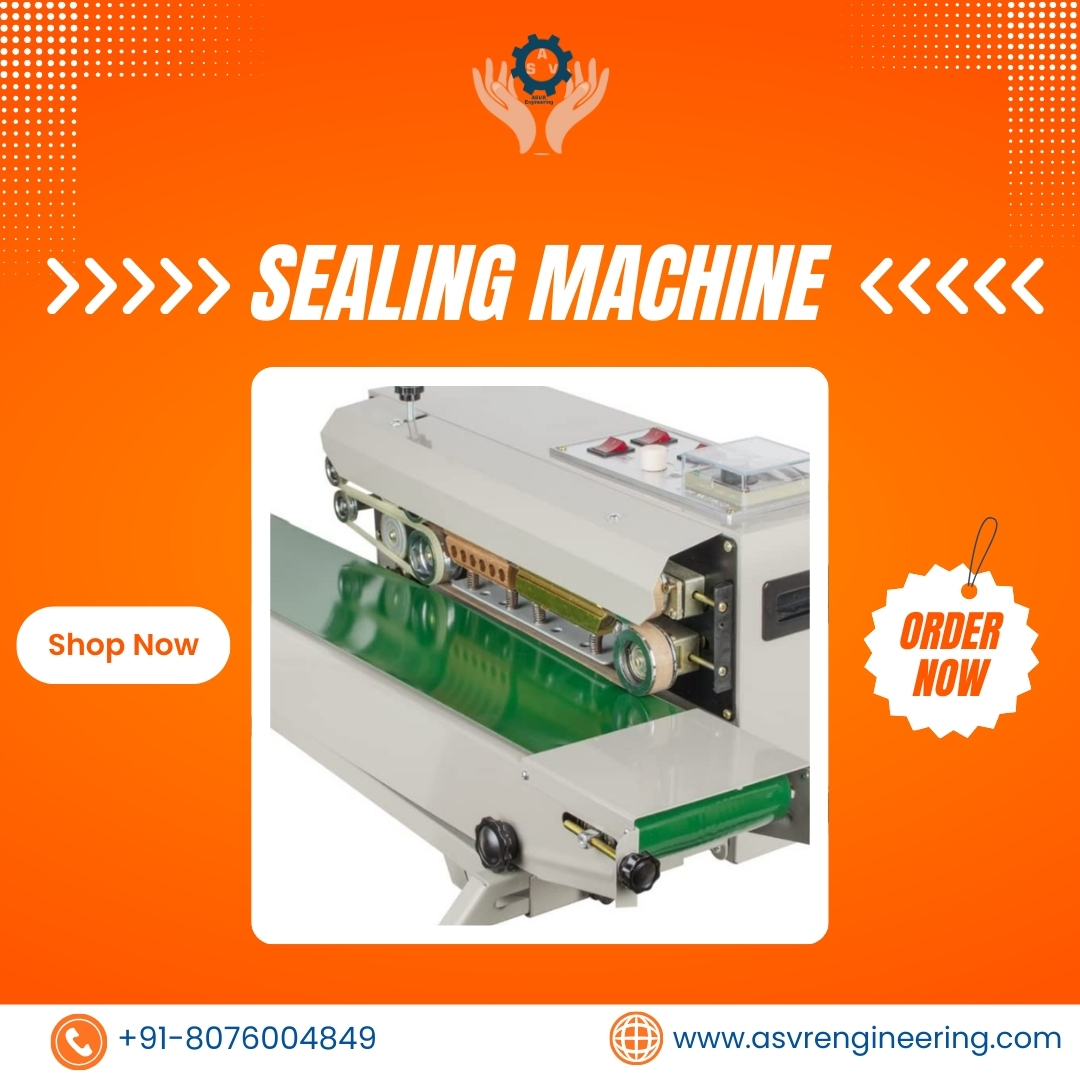

In today’s fast-moving manufacturing and packaging environment, efficient and reliable sealing solutions play a crucial role in maintaining product safety, shelf life, and brand reputation. Among the most essential equipment used across multiple industries is the Seal Bag Making Machine. From food packaging units to pharmaceutical companies and industrial product manufacturers, seal bag machines have become an integral part of modern packaging operations.

A Seal Bag Making Machine is designed to produce consistently sealed bags with high precision, ensuring durability, leak resistance, and uniformity. Whether you are packaging food items, medical products, hardware components, or consumer goods, the quality of bag sealing directly affects product protection and customer trust.

Understanding Seal Bag Making Machines

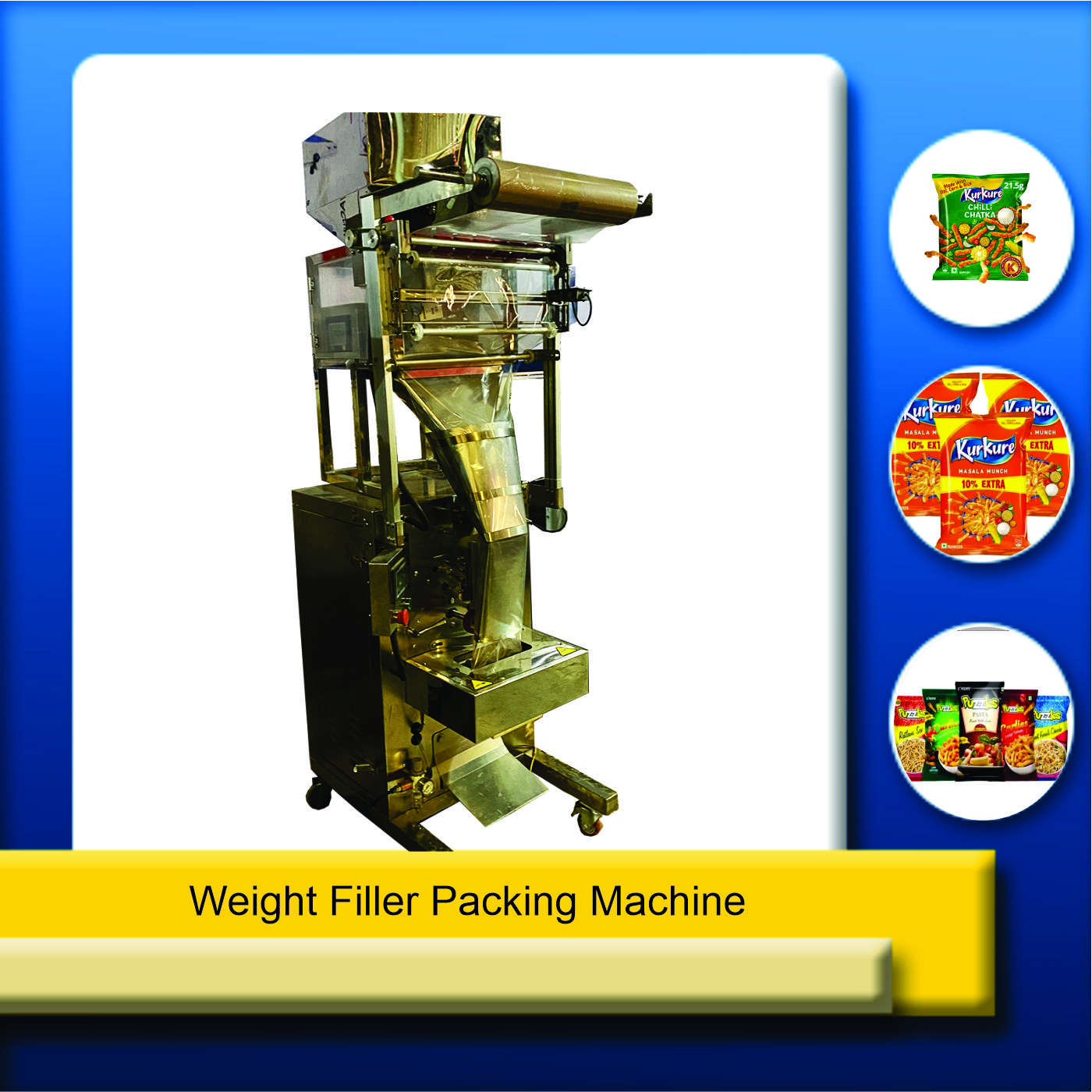

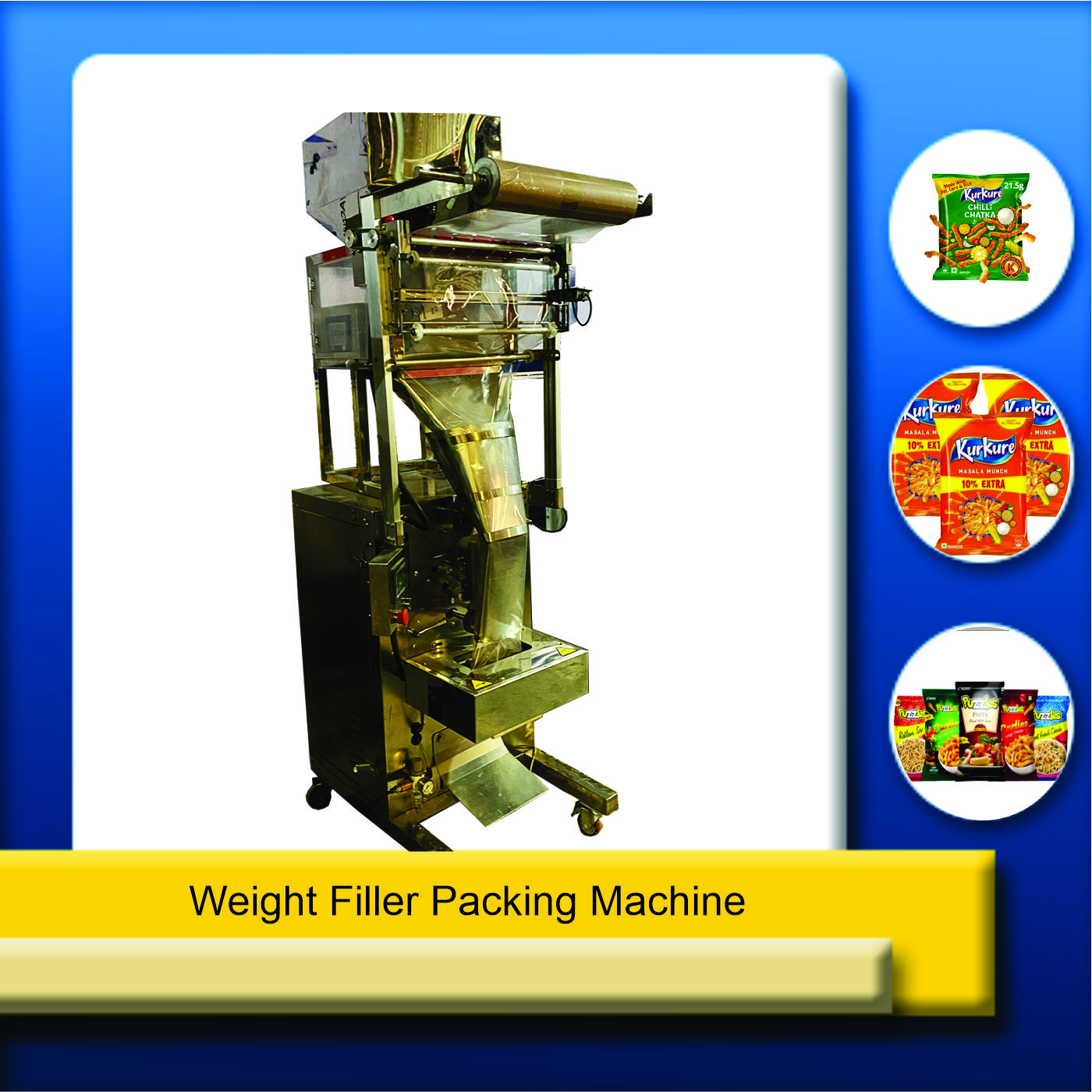

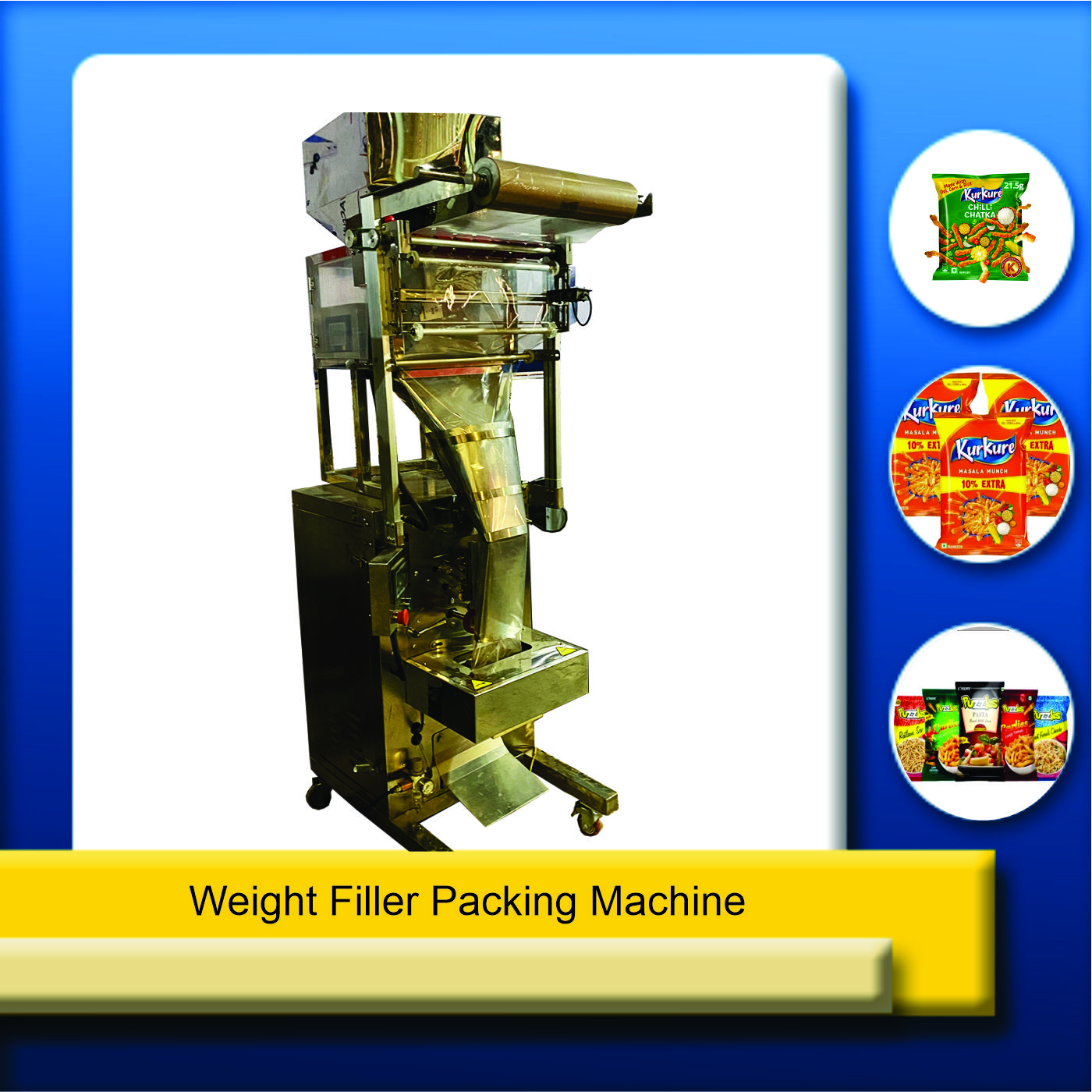

A Seal Bag Making Machine is an advanced packaging solution that forms, seals, and cuts bags from plastic films or laminates. These machines are engineered to handle various materials such as LDPE, HDPE, PP, and laminated films. Depending on production requirements, the machine can be semi-automatic or fully automatic, allowing manufacturers to achieve high output with minimal manual intervention.

Modern sealing machines are designed with heat sealing technology, which ensures strong, uniform seals that can withstand handling, transportation, and storage conditions. This makes them ideal for both lightweight and heavy-duty packaging applications.

Importance of Seal Bag Making Machines in Packaging

Packaging is no longer just about wrapping a product; it is about preserving quality, enhancing presentation, and meeting industry standards. A high-quality seal bag making machine ensures:

-

Airtight and tamper-proof packaging

-

Consistent sealing quality

-

Reduced material wastage

-

Increased production efficiency

-

Professional and uniform bag appearance

For businesses aiming to scale operations or improve packaging quality, investing in a reliable seal bag machine is not an option—it is a necessity.

Applications Across Industries

Seal Bag Making Machines are widely used in a variety of sectors due to their versatility and efficiency:

Food Industry:

Used for sealing snacks, grains, pulses, frozen foods, bakery products, and dry food items. Proper sealing helps maintain freshness and prevents contamination.

Pharmaceutical Industry:

Essential for sealing medicine pouches, medical devices, and healthcare products where hygiene and safety are critical.

Retail and Consumer Goods:

Ideal for packaging garments, stationery, cosmetics, and household items with neat and attractive sealing.

Industrial Packaging:

Used for sealing hardware items, spare parts, chemicals, and industrial components that require durable packaging.

Agricultural Sector:

Commonly used for packaging seeds, fertilizers, and agro-based products to protect them from moisture and external damage.

Types of Seal Bag Making Machines

Seal bag machines are available in different configurations to suit varied production needs:

Manual Seal Bag Machines

Best suited for small-scale operations or low production volumes. These machines are cost-effective and easy to operate.

Semi-Automatic Seal Bag Machines

Designed for medium-scale industries, offering a balance between productivity and affordability.

Fully Automatic Seal Bag Making Machines

Ideal for large-scale manufacturing units requiring high output, consistent quality, and minimal labor involvement.

Each type can be customized based on bag size, sealing width, material thickness, and production speed.

Key Features of a High-Quality Seal Bag Making Machine

A reliable seal bag making machine should be built with precision engineering and durable components. Some essential features include:

-

Strong and uniform heat sealing mechanism

-

Adjustable temperature control for different materials

-

High-speed operation with consistent output

-

Robust structure for long-term industrial use

-

Easy operation and low maintenance requirements

-

Safety features to protect operators

Machines designed with these features help businesses achieve maximum productivity with minimal downtime.

Advantages of Using Seal Bag Making Machines

Investing in a seal bag making machine offers several long-term benefits:

Improved Efficiency:

Automated sealing reduces manual effort and increases production speed.

Cost Savings:

Lower labor costs and reduced material wastage result in significant operational savings.

Consistent Quality:

Uniform sealing ensures professional packaging and customer satisfaction.

Scalability:

Machines can handle increasing production demands as business grows.

Enhanced Product Safety:

Strong seals protect products from moisture, dust, and external damage.

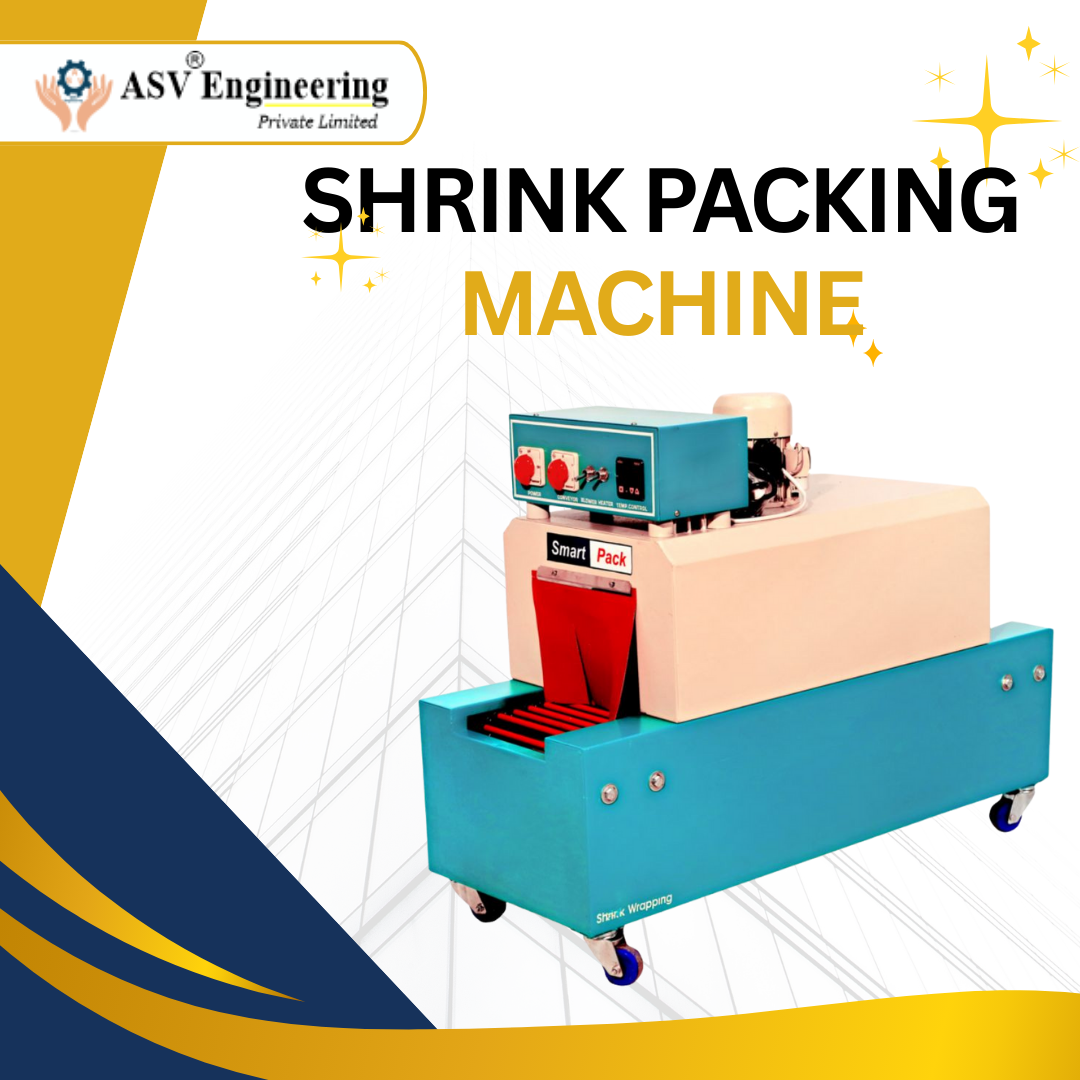

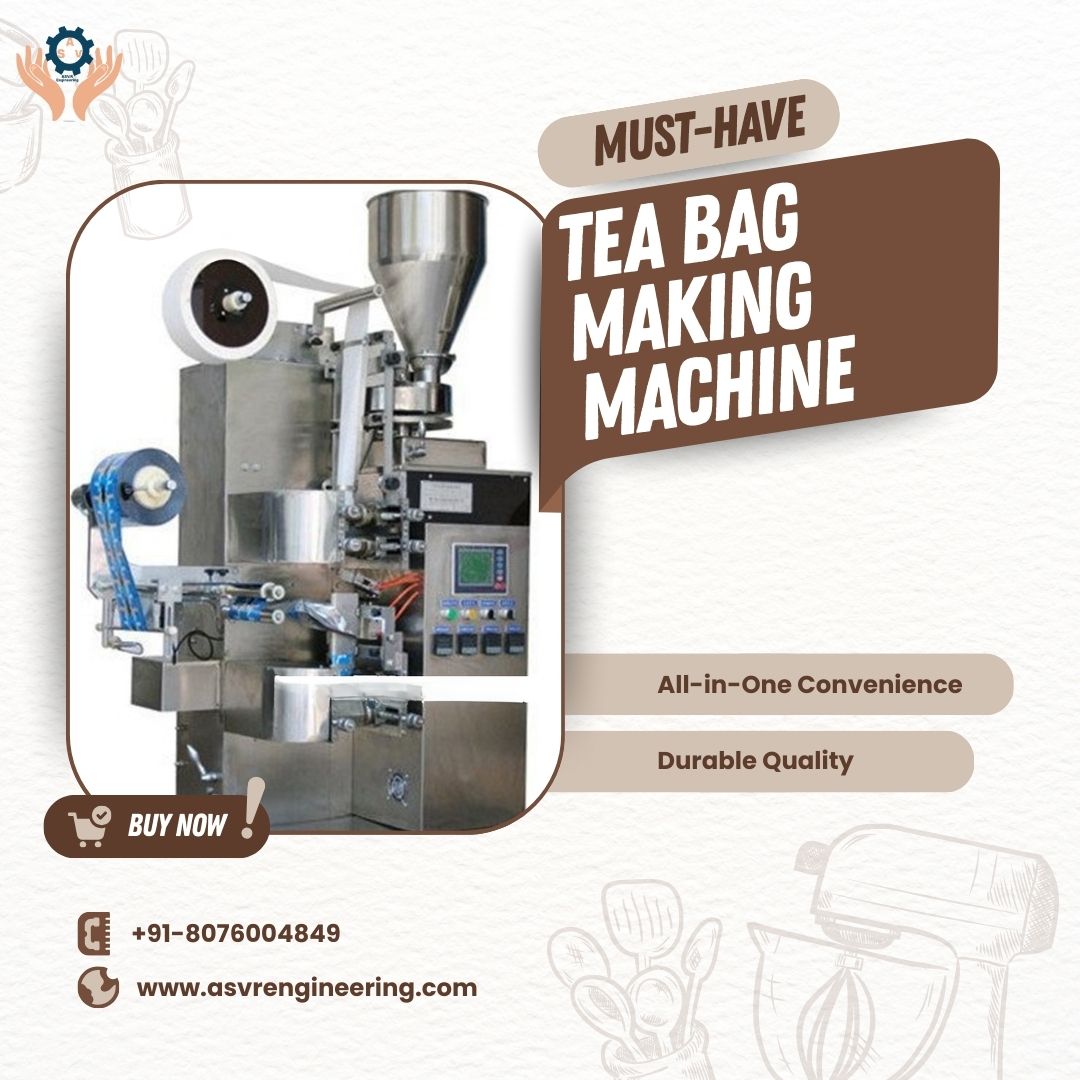

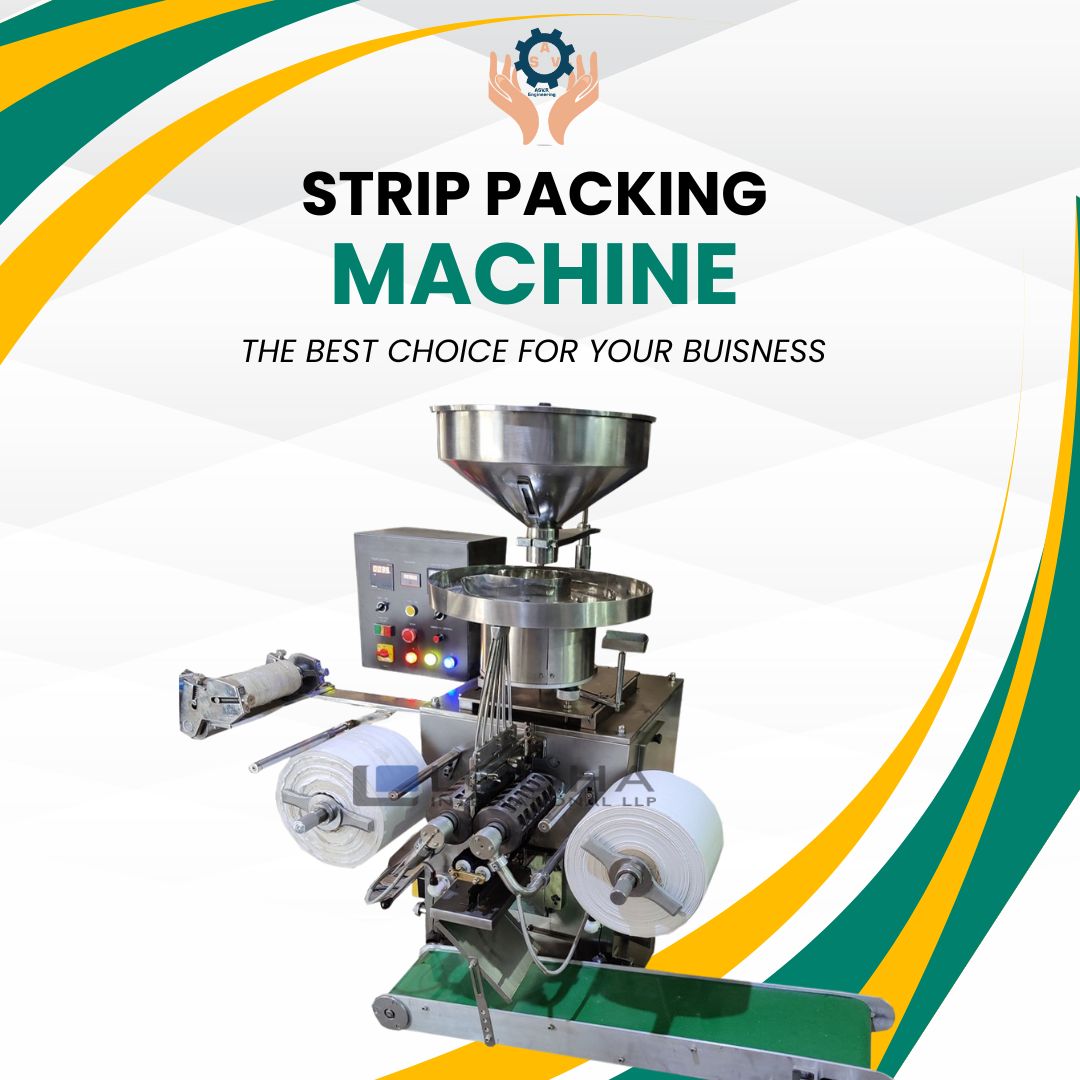

Why Choose ASVR Engineering for Seal Bag Making Machines

When it comes to high-performance packaging machinery, ASVR Engineering stands out as a trusted name in the industry. With years of experience in manufacturing and supplying industrial machines, the company focuses on delivering durable, efficient, and cost-effective solutions.

ASVR Engineering designs seal bag making machines that meet the demands of modern manufacturing units. Each machine is built using quality components, tested for performance, and engineered to deliver consistent results even in demanding production environments.

Their machines are known for:

-

Reliable performance

-

Strong build quality

-

Precision sealing

-

Competitive pricing

-

Excellent after-sales support

Whether you are setting up a new packaging line or upgrading existing equipment, ASVR Engineering provides solutions tailored to your specific requirements.

Maintenance and Long-Term Performance

Proper maintenance plays a vital role in ensuring the long life of a seal bag making machine. Regular cleaning, temperature calibration, and timely replacement of worn parts help maintain sealing quality and machine efficiency.

Machines supplied by ASVR Engineering are designed for easy maintenance, allowing operators to perform routine checks without technical complexity. This reduces downtime and keeps production running smoothly.

Choosing the Right Seal Bag Making Machine

Before purchasing a seal bag making machine, it is important to consider:

-

Type and thickness of packaging material

-

Required production speed

-

Bag size and sealing width

-

Level of automation needed

-

Available workspace and power supply

Selecting the right machine ensures optimal performance and better return on investment.

Future of Seal Bag Making Technology

With the growing demand for efficient and sustainable packaging solutions, seal bag making machines are continuously evolving. Modern designs focus on energy efficiency, automation, and adaptability to different materials. Businesses that invest in advanced sealing technology stay ahead in competitive markets by offering better packaging quality and faster delivery.

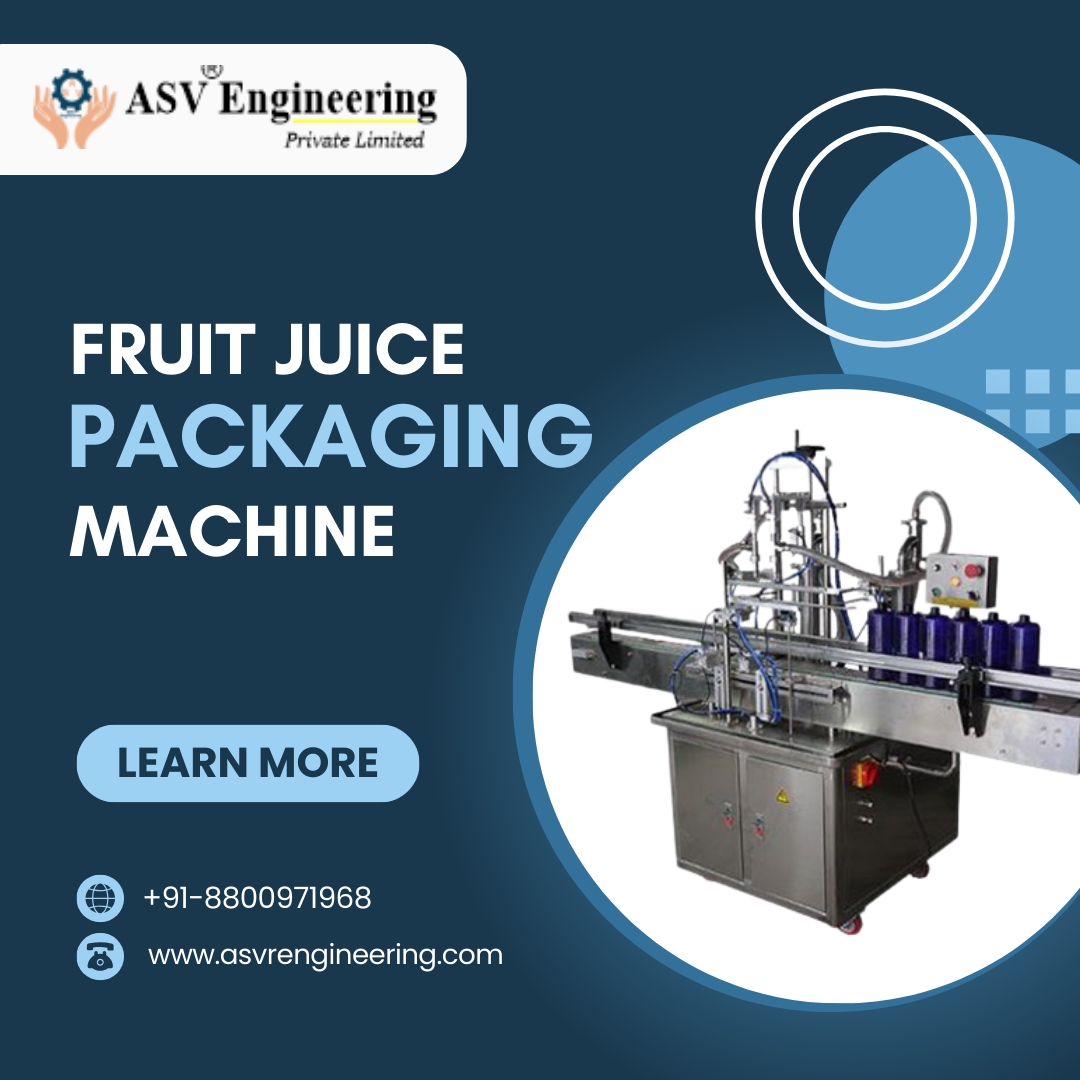

Contact ASVR Engineering

If you are looking for a high-quality Seal Bag Making Machine that delivers performance, durability, and value, ASVR Engineering is your reliable partner.

📞 Contact Numbers:

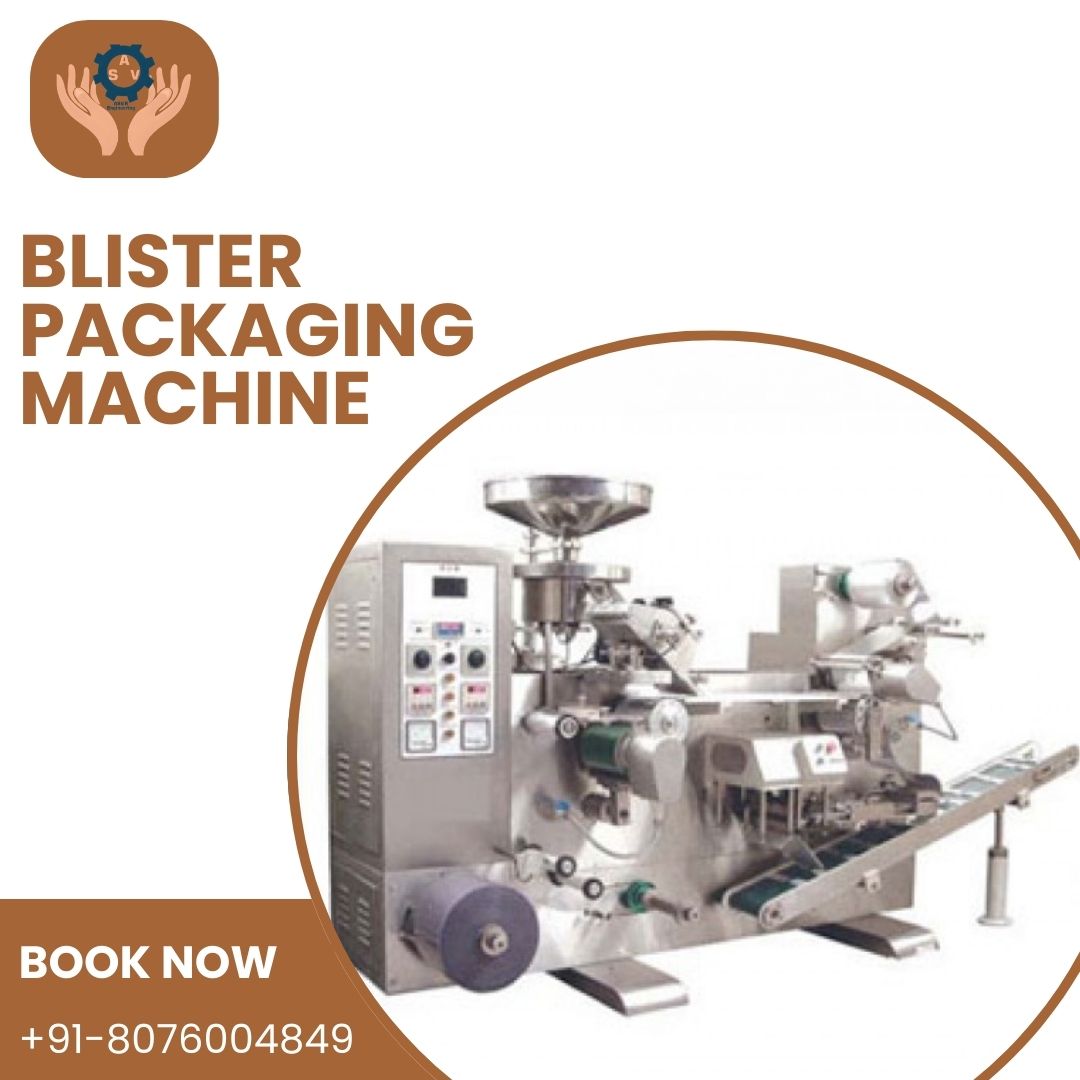

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Get in touch today to discuss your packaging requirements and find the perfect seal bag making solution for your business.

Buy Now

Related Posts

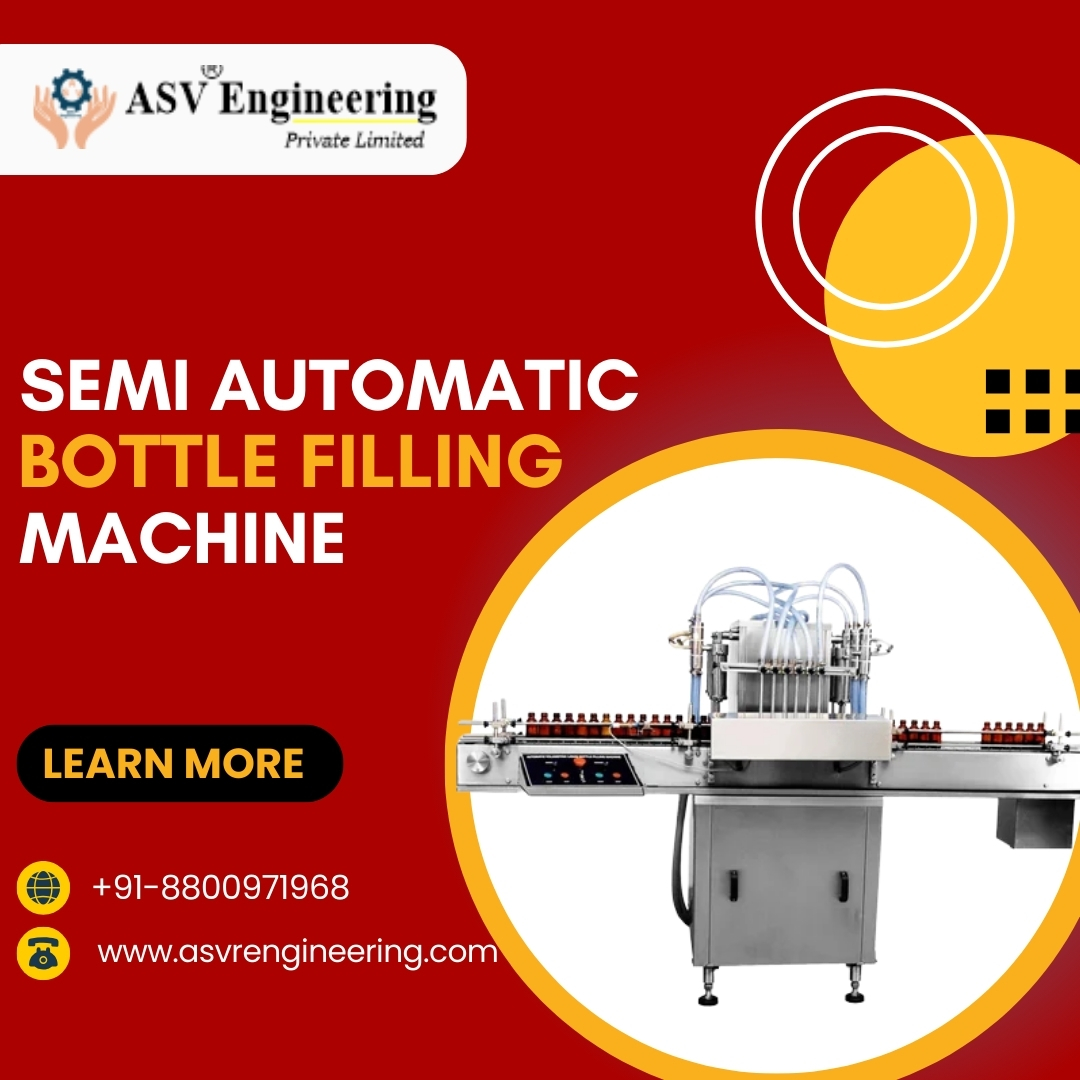

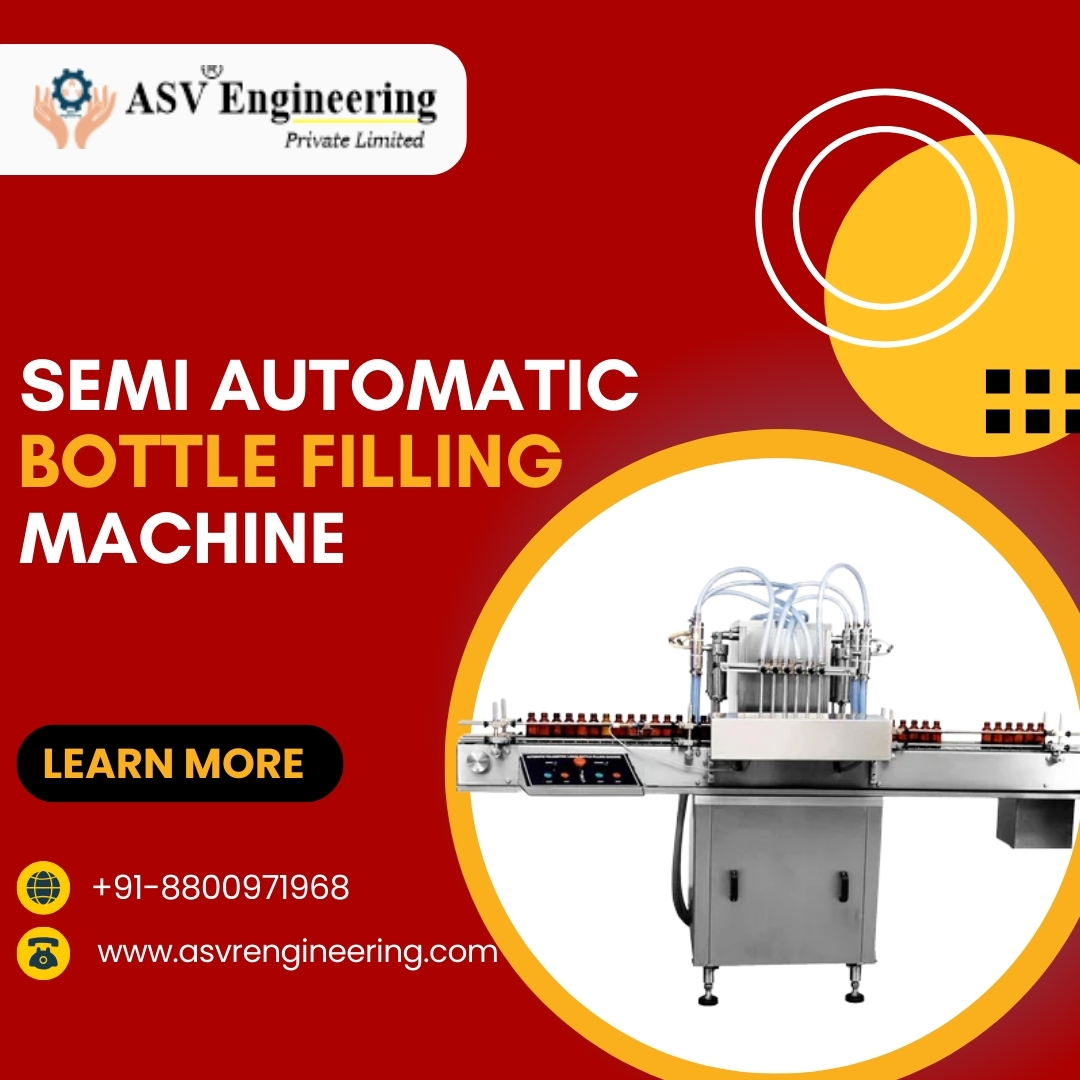

Leading Automatic Bottle Filling Machine Manufacturers for High-Speed Industrial Packaging Solutions

Trusted Automatic Milk Bag Packaging Machine Distributors for Dairy Plants, Milk Booths & FMCG Units

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)