Leading Automatic FFS Packaging Machine Importers for Food, Pharma & FMCG Packaging Lines

About ASVR Engineering

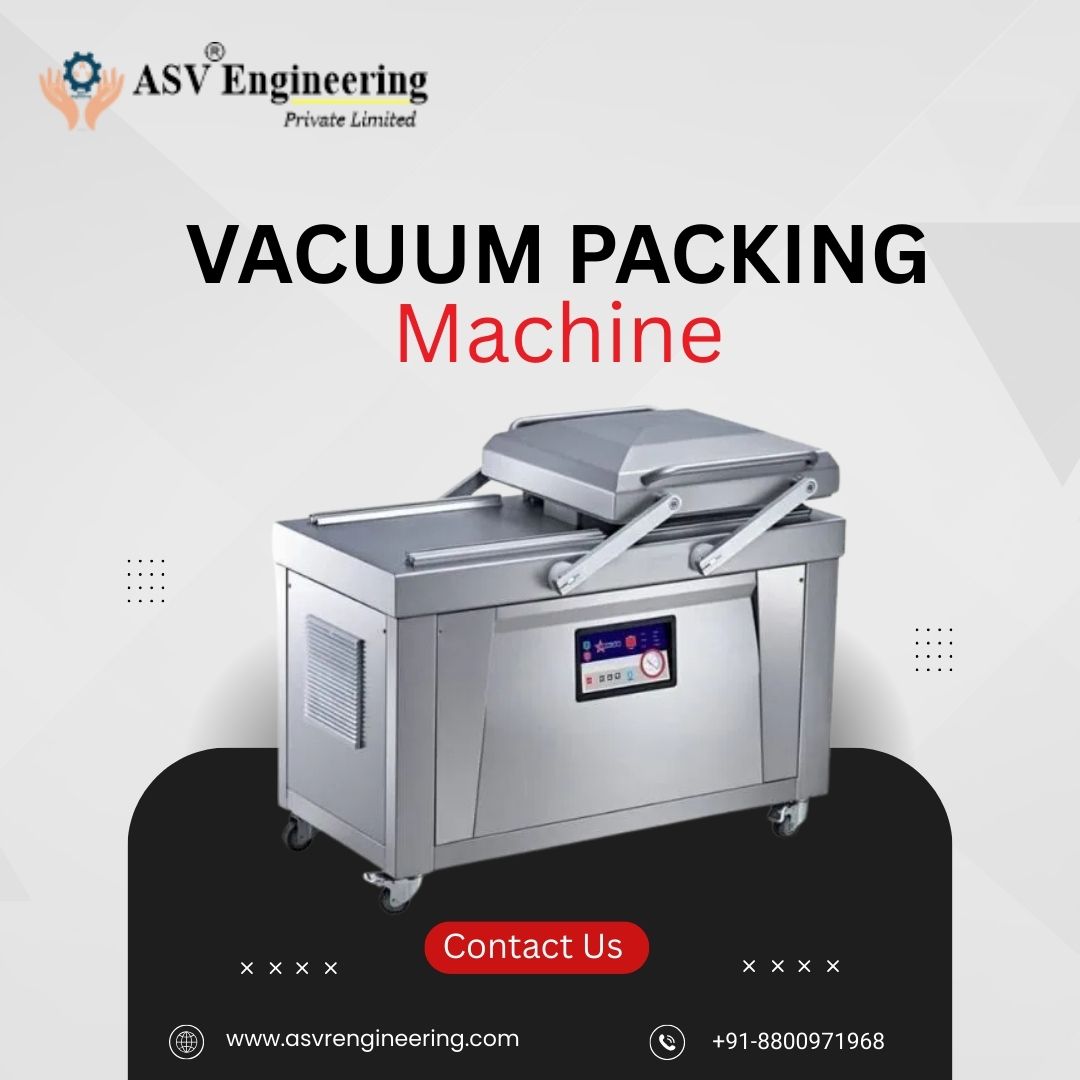

ASVR Engineering is a trusted name in the Indian packaging machinery ecosystem, recognized for importing and supplying high-performance Automatic Form-Fill-Seal (FFS) Packaging Machines for modern food, pharmaceutical, and FMCG packaging lines. With a sharp focus on quality, reliability, and after-sales support, ASVR Engineering partners with global manufacturers to bring advanced, production-ready solutions to Indian processors who demand speed, accuracy, and hygiene.

Contact: +91-8076004849, +91-8800971968

Website: https://www.asvrengineering.com

Introduction: Why Automatic FFS Packaging Is the Backbone of Modern Manufacturing

Packaging is no longer just about wrapping a product; it is about preserving quality, ensuring compliance, improving shelf life, and communicating brand value—at scale. As production volumes increase and regulations tighten, manufacturers across food, pharma, and FMCG are turning to automatic FFS packaging machines to standardize output while controlling costs. These systems convert flat packaging film into finished, sealed packs in a continuous, automated process—delivering consistency that manual or semi-automatic methods cannot match.

ASVR Engineering understands the operational realities of Indian factories: variable climates, diverse product types, and the need for dependable service. By importing proven FFS technologies and supporting them locally, ASVR Engineering helps plants upgrade confidently and competitively.

Understanding Automatic FFS Packaging Machines

Form-Fill-Seal (FFS) machines perform three integrated steps in one seamless workflow:

-

Form – Packaging film is shaped into a pouch or sachet.

-

Fill – The product is dosed accurately using volumetric, gravimetric, auger, or liquid fillers.

-

Seal – Heat or ultrasonic sealing ensures leak-proof closure and tamper resistance.

Key Formats

-

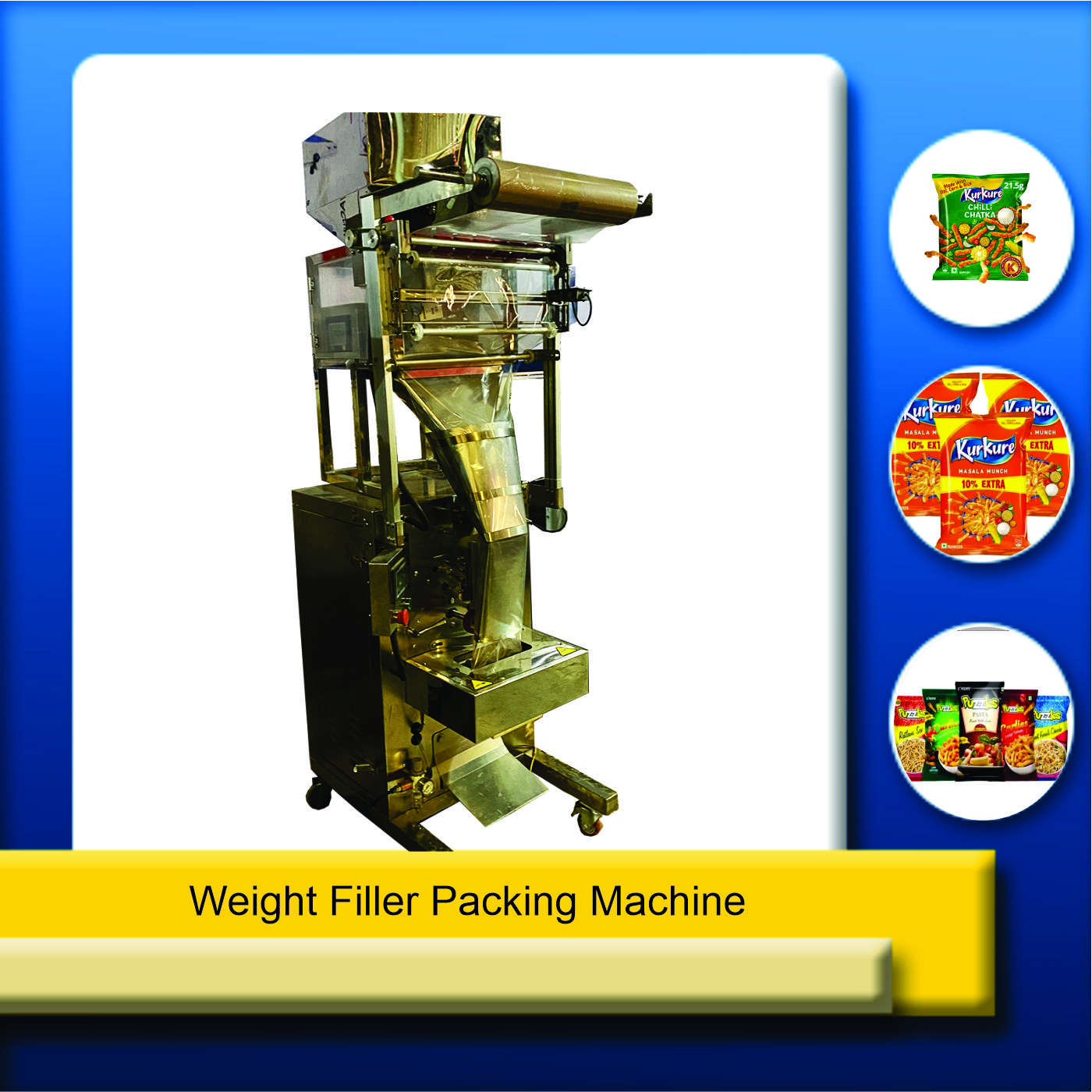

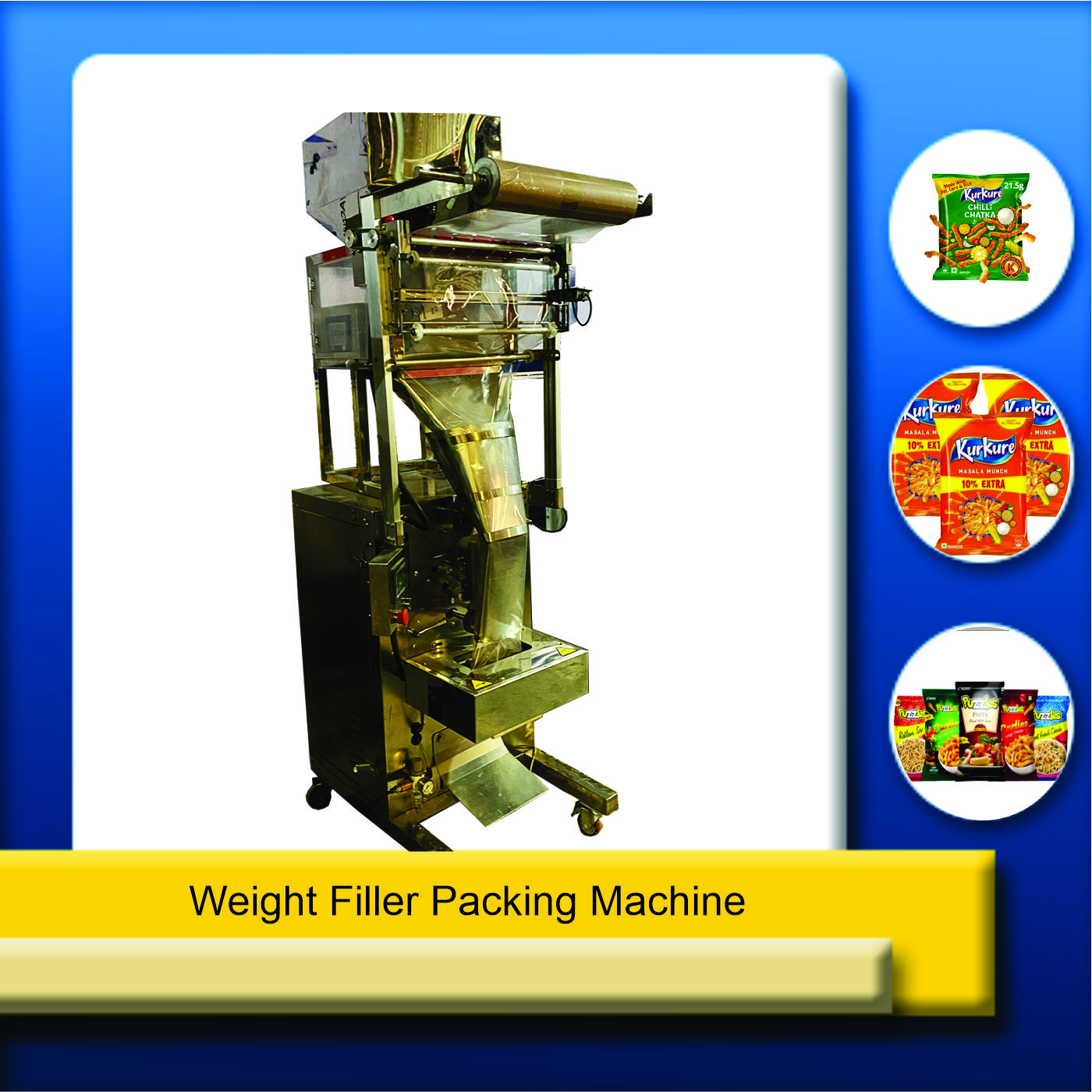

Vertical FFS (VFFS): Ideal for powders, granules, snacks, and liquids packed in pillow packs or gusseted pouches.

-

Horizontal FFS (HFFS): Best for solid or flow-wrapped items like biscuits, bars, and medical devices.

ASVR Engineering imports both configurations, customized to product behavior, pack style, and output targets.

Why Importer Expertise Matters

Choosing an importer is as important as choosing the machine. A capable importer ensures:

-

Verified manufacturing partners with international quality benchmarks

-

Correct machine configuration for Indian operating conditions

-

Installation, training, and spares availability

-

Long-term ROI through uptime and performance optimization

ASVR Engineering’s importer-led approach bridges global innovation with local execution.

Applications Across Core Industries

Food Packaging Lines

Food processors demand hygiene, speed, and versatility. FFS machines supplied by ASVR Engineering handle:

-

Snacks, namkeen, chips, cereals

-

Rice, flour, pulses, spices, sugar

-

Sauces, oils, dairy liquids, beverages

Advantages: stainless steel contact parts, easy wash-down, quick changeovers, consistent weights, and strong seals for extended shelf life.

Pharmaceutical Packaging Lines

Precision and compliance are non-negotiable. Imported pharma-grade FFS machines support:

-

Powders and granules

-

Sachets for oral solids

-

Medical disposables and kits (HFFS)

Advantages: GMP-compliant designs, dust control, accurate dosing, validation-friendly controls, and documentation support.

FMCG Packaging Lines

FMCG brands compete on speed, consistency, and appearance. FFS systems enable:

-

Personal care sachets

-

Detergents and household products

-

Promotional multi-packs

Advantages: high output, attractive pack formats, brand-ready printing alignment, and low per-unit packaging cost.

Technical Features That Drive Performance

ASVR Engineering prioritizes machines with features that translate directly into productivity:

-

Servo-driven motion control for accuracy and speed

-

PLC + HMI interfaces for intuitive operation

-

Multi-head weighers / auger fillers for precise dosing

-

Advanced sealing technology to prevent leaks

-

Film compatibility with laminated, recyclable, and mono-material films

-

Quick changeover kits to reduce downtime

-

Safety interlocks and guards for operator protection

Customization for Indian Manufacturing Needs

Every factory is unique. ASVR Engineering works closely with customers to tailor solutions:

-

Pack sizes from single-serve sachets to bulk pouches

-

Speed ranges matched to upstream/downstream equipment

-

Environmental adaptations for heat, dust, and humidity

-

Integration with conveyors, check-weighers, metal detectors, and date coders

This consultative approach ensures machines deliver from day one.

Quality Assurance & Compliance

Imported FFS machines meet global standards and are selected for:

-

Build quality and longevity

-

Consistent sealing under continuous operation

-

Food-grade materials and pharma compliance

-

Traceability and batch coding compatibility

ASVR Engineering also supports commissioning protocols and operator training to maintain compliance over the machine lifecycle.

Energy Efficiency & Cost Control

Automation should reduce—not increase—operating costs. Modern FFS machines focus on:

-

Optimized heating zones to save energy

-

Reduced film wastage through precise control

-

Minimal compressed air consumption

-

Predictive maintenance alerts

The result is a lower total cost of ownership and faster payback.

After-Sales Support That Protects Uptime

A machine’s true value is measured over years of operation. ASVR Engineering backs its imports with:

-

Installation and commissioning support

-

Operator and maintenance training

-

Genuine spare parts availability

-

Preventive maintenance guidance

-

Technical assistance for upgrades and expansions

This commitment keeps lines running and protects production schedules.

Scaling Your Packaging Line with Confidence

Whether you are a startup scaling from manual packing or an established brand modernizing a high-speed line, ASVR Engineering provides a clear upgrade path:

-

Entry-level automation for quick wins

-

Mid-speed systems for growing demand

-

High-output configurations for national distribution

Each recommendation is grounded in throughput goals, product characteristics, and budget realities.

Why Choose ASVR Engineering as Your FFS Machine Importer?

-

Proven importer network with reliable global partners

-

Industry-specific solutions for food, pharma, and FMCG

-

Hands-on consultation from selection to commissioning

-

Strong service ethos with accessible technical support

-

Focus on ROI through efficiency, quality, and uptime

Conclusion

Automatic FFS packaging machines are essential for manufacturers who want to compete on quality, compliance, and cost. As Leading Automatic FFS Packaging Machine Importers for Food, Pharma & FMCG Packaging Lines, ASVR Engineering delivers not just machines—but dependable, future-ready packaging solutions. By combining imported technology with local expertise and support, ASVR Engineering helps Indian manufacturers package smarter, faster, and better.

For consultations, demos, or specifications, connect with ASVR Engineering today.

Buy Now

(14).jpg)

(14).jpg)

(14).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)