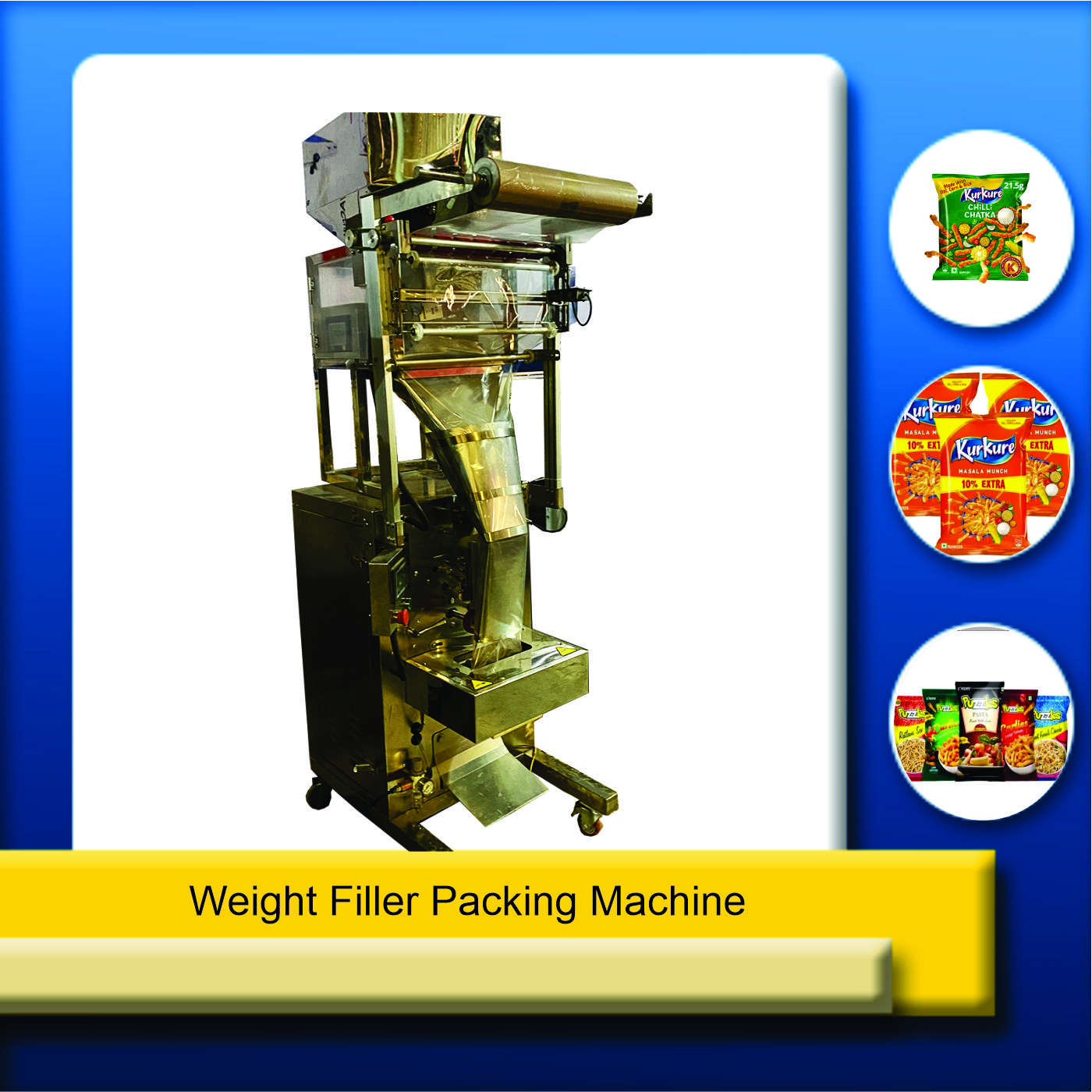

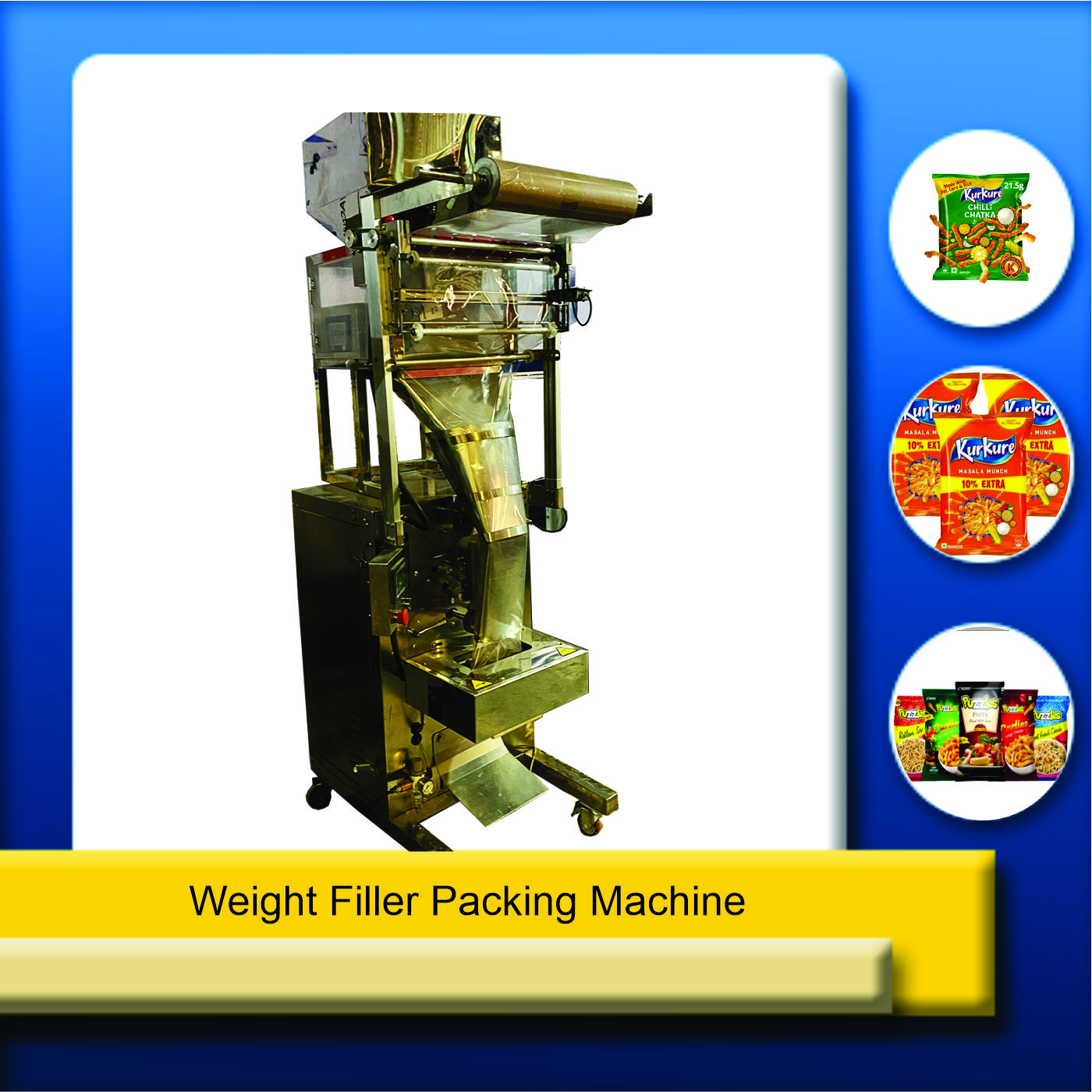

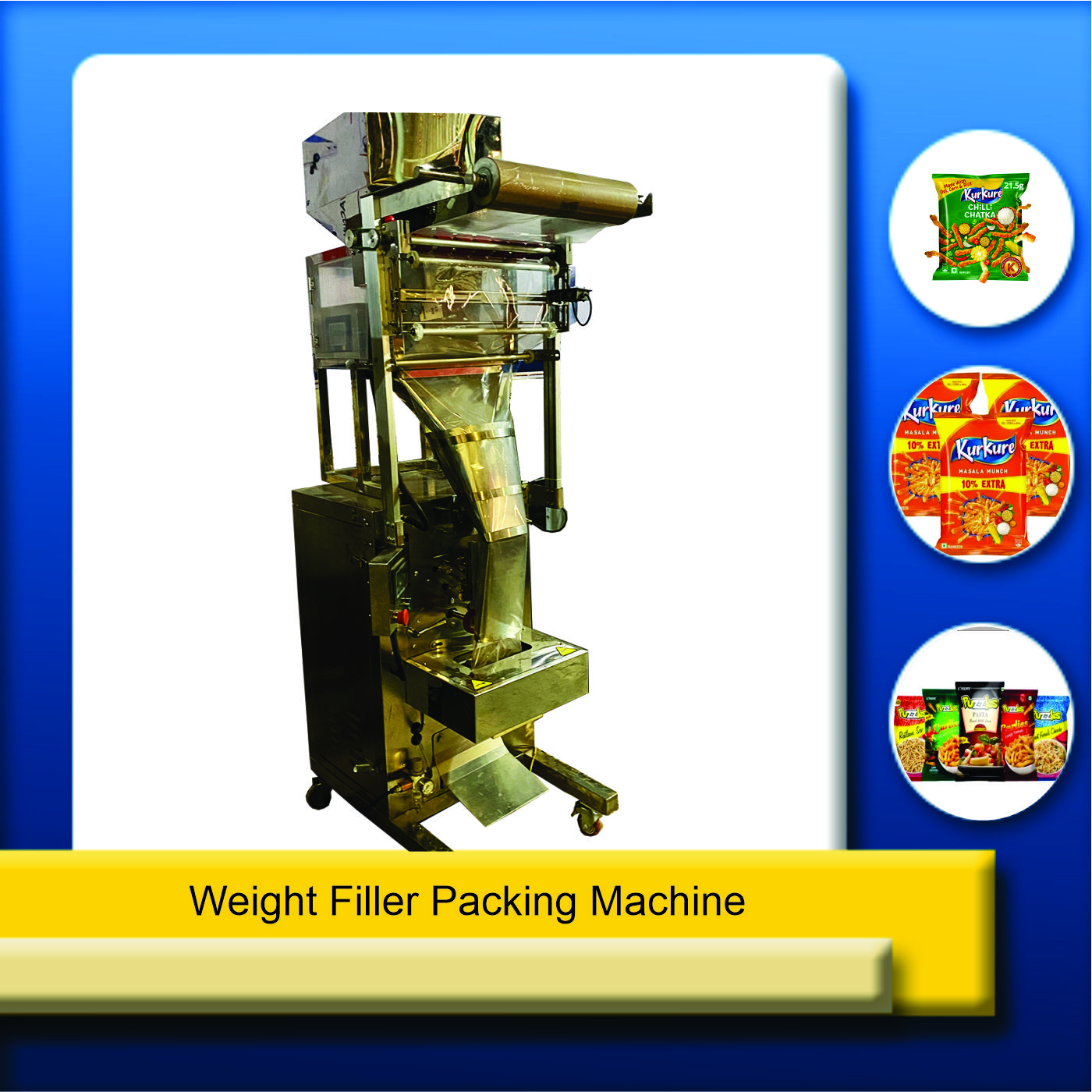

Pouch Filling and Sealing Machine for All Product Types

Pouch Filling and Sealing Machine for All Product Types – ASVR Engineering Pvt Ltd

In today's fast-paced manufacturing environment, versatility and speed are key. A pouch filling and sealing machine that handles powders, liquids, granules, and pastes gives businesses the flexibility they need to serve diverse markets. At ASVR Engineering Pvt Ltd, we specialize in manufacturing multi-purpose pouch packaging machines that are fully automatic, efficient, and built to last.

Whether you're in the food, pharmaceutical, chemical, cosmetic, or agricultural sector, our machines offer an all-in-one packaging solution that saves time, reduces manpower, and boosts output.

What is a Pouch Filling and Sealing Machine?

A pouch filling and sealing machine is used to automatically fill product into preformed or form-fill-seal pouches and seal them with precision. It is widely used in industries that package products in sachets, packets, and pouches of varying sizes and materials.

Core Functions:

-

Pouch forming (if applicable)

-

Product dosing/filling

-

Sealing (heat sealing or ultrasonic sealing)

-

Cutting and discharge

-

Optional: Nitrogen flushing, coding, labeling

Key Features of ASVR Pouch Filling and Sealing Machines

| Feature | Details |

|---|---|

| Product Types Supported | Powders, liquids, granules, pastes |

| Operation Type | Fully automatic or semi-automatic |

| Pouch Formats | Center seal, 3-side, 4-side, zipper, stand-up pouches |

| Material Compatibility | PET, PP, PE, laminated films, aluminum foils |

| Capacity Range | 10g to 2kg and above |

| Output Speed | Up to 100 pouches per minute (depends on product) |

| Construction | SS304/SS316 for food & pharma use |

| Controls | PLC + HMI touchscreen interface |

| Add-ons Available | Batch coding, date printing, nitrogen flushing |

Why Choose ASVR Engineering Machines?

1. Versatility

Our machines are engineered to handle all product types—free-flowing powders, sticky pastes, viscous liquids, and hard granules—with minimal changeover time.

2. Precision Filling

We integrate auger fillers, piston fillers, cup fillers, or multi-head weighers based on product consistency for accurate dosing.

3. Strong Sealing Performance

Whether you're packaging sauces, flour, or fertilizer, our temperature-controlled sealing systems ensure airtight and tamper-proof pouches.

4. User-Friendly Operation

Touchscreen HMI, programmable settings, and real-time monitoring simplify the operation even for non-technical staff.

5. Durability & Hygiene

Machines are built with corrosion-resistant, food-grade stainless steel—ideal for long-lasting and hygienic production lines.

Industries We Serve

-

Food & Beverage: Spices, pulses, tea, snacks, oil, sauces, flour

-

Pharmaceutical: ORS, tablets, powders, syrups

-

Chemicals & Agro: Fertilizers, seeds, pesticides

-

Personal Care: Shampoo, gels, creams

-

Homecare: Detergents, toilet cleaners, floor cleaners

Popular Machine Configurations

| Model | Product Type | Filling System | Speed (approx.) |

|---|---|---|---|

| Auger-based Pouch Machine | Powder (spices, milk) | Servo Auger Filler | 30–60 pouches/min |

| Piston Filler Pouch Machine | Liquids (oil, juice) | Piston Pump | 30–50 pouches/min |

| Cup Filler Pouch Machine | Granules (tea, sugar) | Volumetric Cup | 40–80 pouches/min |

| Multihead Weigher Machine | Snacks, chips | 10-14 Head Weighers | 60–100 pouches/min |

Customizations Available

-

Multi-lane filling

-

Dust collection system

-

Pneumatic sealing options

-

Servo-driven indexers

-

Printed film registration systems

-

Date, batch, and MRP coders

-

Adjustable pouch length

Client Testimonial

Mr. Ajay Verma – FMCG Entrepreneur, Delhi

"We chose ASVR Engineering for their all-in-one pouch packaging machine. It packs everything from masalas to hair oil. Easy to operate, very little downtime, and great after-sales support."

Installation & Support

We offer complete on-site installation, commissioning, and operator training. Our support team provides prompt maintenance and spare parts anywhere in India.

-

1-year warranty

-

AMC (Annual Maintenance Contract) options

-

Remote and on-site diagnostics

-

Technical phone/email support

Frequently Asked Questions (FAQs)

Q1: Can one machine handle multiple products?

Yes. With interchangeable fillers and adjustable settings, you can package different products using one machine.

Q2: What power supply is required?

Machines typically run on 220V/415V, 50Hz, 3-phase power. Single-phase models are available for small-scale use.

Q3: What is the delivery time?

Standard models ship within 15–30 days depending on configuration.

Q4: Do you offer export models?

Yes, we supply machines with export-grade packaging, manuals, and CE-compliant features.

How to Get a Quote

-

Call us at 8800971968

-

Share your product, output requirement, and pouch size

-

Our engineers will suggest the best machine model

-

Receive a custom quote with tech specs and price

Contact Us

ASVR Engineering Pvt Ltd

Phone: 8800971968

Website: https://asvrengineering.com

Email: (insert your email)

Address: (insert full address)

Conclusion

If you're seeking a robust, efficient, and all-purpose pouch filling and sealing machine, look no further than ASVR Engineering Pvt Ltd. Our machines are built for precision, productivity, and versatility, making them ideal for businesses across India.

Call now at 8800971968 or visit https://asvrengineering.com to get a quote and take your packaging operations to the next level.

Buy Now

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)