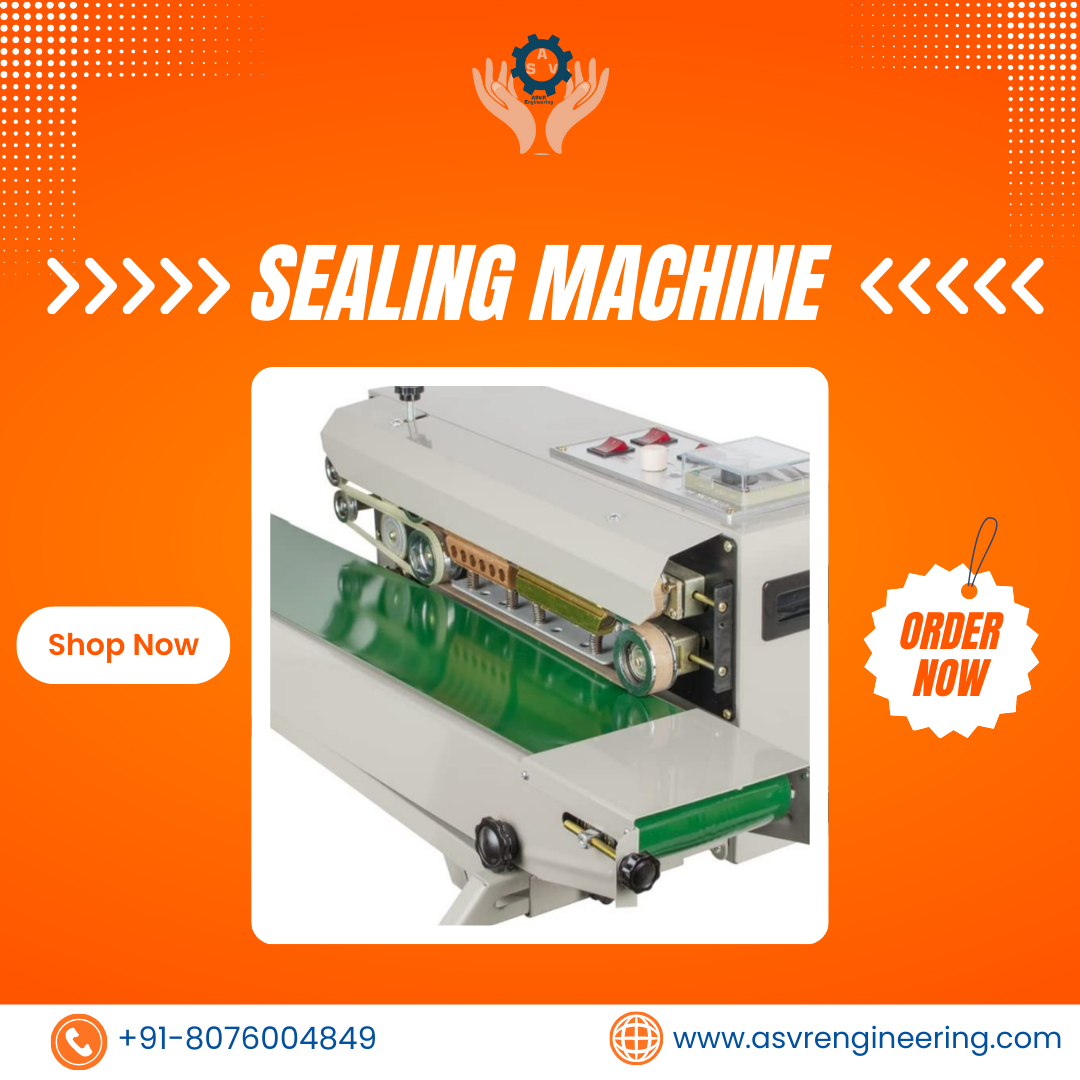

Plastic Sealing Machine

Price: ₹15000

In today’s competitive manufacturing and retail environment, packaging is no longer just about wrapping a product—it is about protection, presentation, shelf life, and brand value. A Plastic Sealing Machine plays a critical role in ensuring products are packed securely, hygienically, and professionally across multiple industries. From small retail outlets to large-scale manufacturing units, plastic sealing machines have become an essential part of modern packaging operations.

At ASVR Engineering, we offer high-quality plastic sealing machines designed to deliver consistent performance, durability, and cost efficiency. Our machines are engineered to handle diverse packaging needs while ensuring strong, leak-proof, and uniform seals every time.

What Is a Plastic Sealing Machine?

A plastic sealing machine is a packaging device used to seal plastic films, pouches, bags, and laminates by applying controlled heat and pressure. These machines are widely used for sealing products such as food items, pharmaceuticals, chemicals, cosmetics, hardware components, and consumer goods.

Depending on the application, plastic sealing machines can seal:

-

Polyethylene (PE)

-

Polypropylene (PP)

-

Laminated films

-

Aluminum foil-laminated pouches

-

Multi-layer packaging materials

The main objective is to protect the product from moisture, dust, air, contamination, and leakage while extending shelf life and improving visual appeal.

Why Plastic Sealing Machines Are Essential for Businesses

In industries where packaging quality directly affects customer trust, plastic sealing machines provide multiple advantages:

1. Product Protection

A proper seal prevents external contaminants and maintains product freshness, especially for food and pharmaceutical items.

2. Professional Packaging

Uniform and neat sealing enhances product appearance, making it more attractive to customers and retailers.

3. Increased Shelf Life

Air-tight sealing reduces oxidation and moisture ingress, helping products last longer.

4. Time & Cost Efficiency

Automated and semi-automatic sealing machines significantly reduce manual labor and packaging time.

5. Reduced Wastage

Accurate heat control minimizes packaging material wastage and rejections.

Types of Plastic Sealing Machines

Different industries require different sealing solutions. Below are the most commonly used types of plastic sealing machines:

Impulse Sealing Machine

Impulse sealers are widely used for low to medium volume packaging. Heat is generated only when the sealing bar is pressed, making them energy efficient and safe to operate. These machines are ideal for sealing PE and PP bags.

Applications: Retail shops, food packing units, e-commerce packaging, medical supplies.

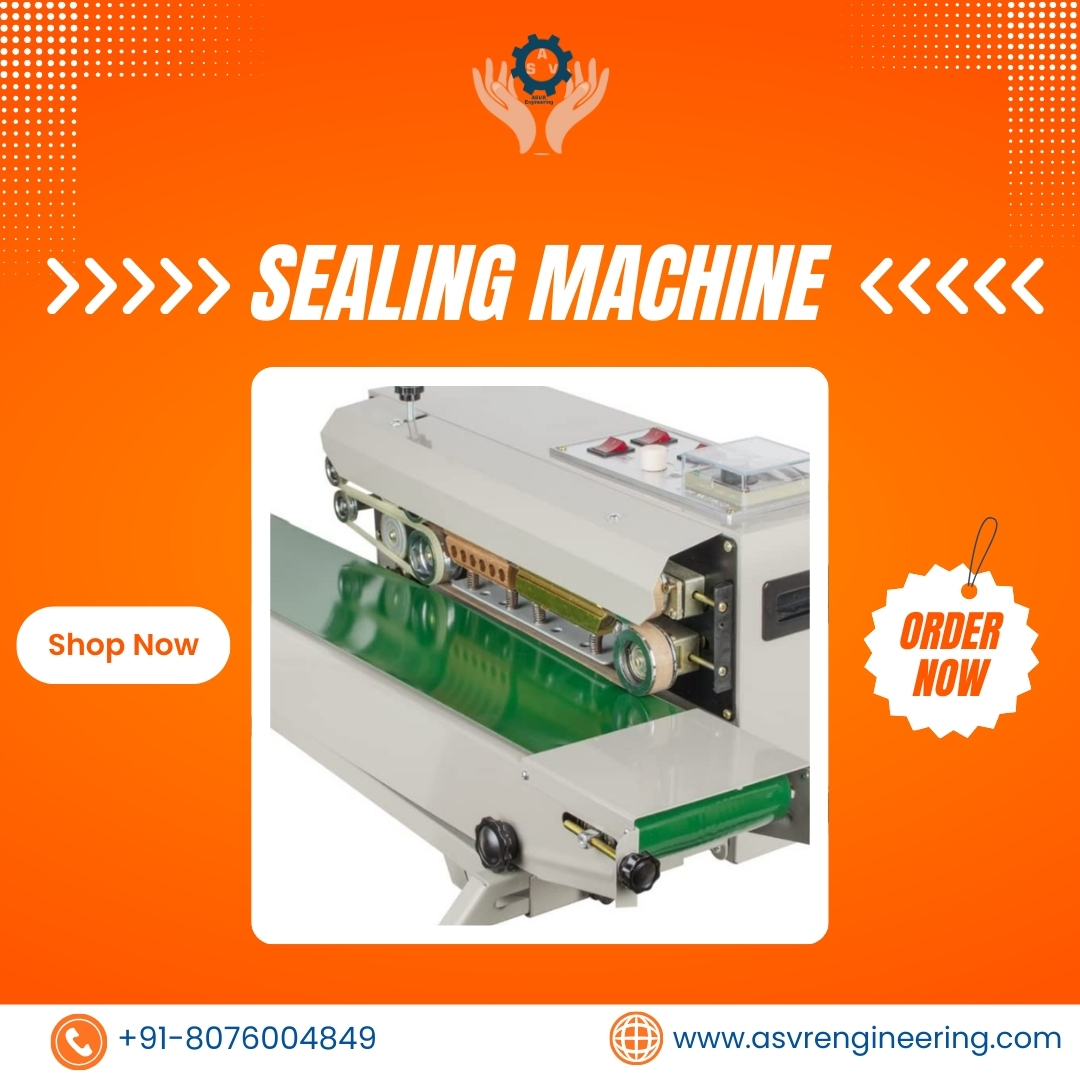

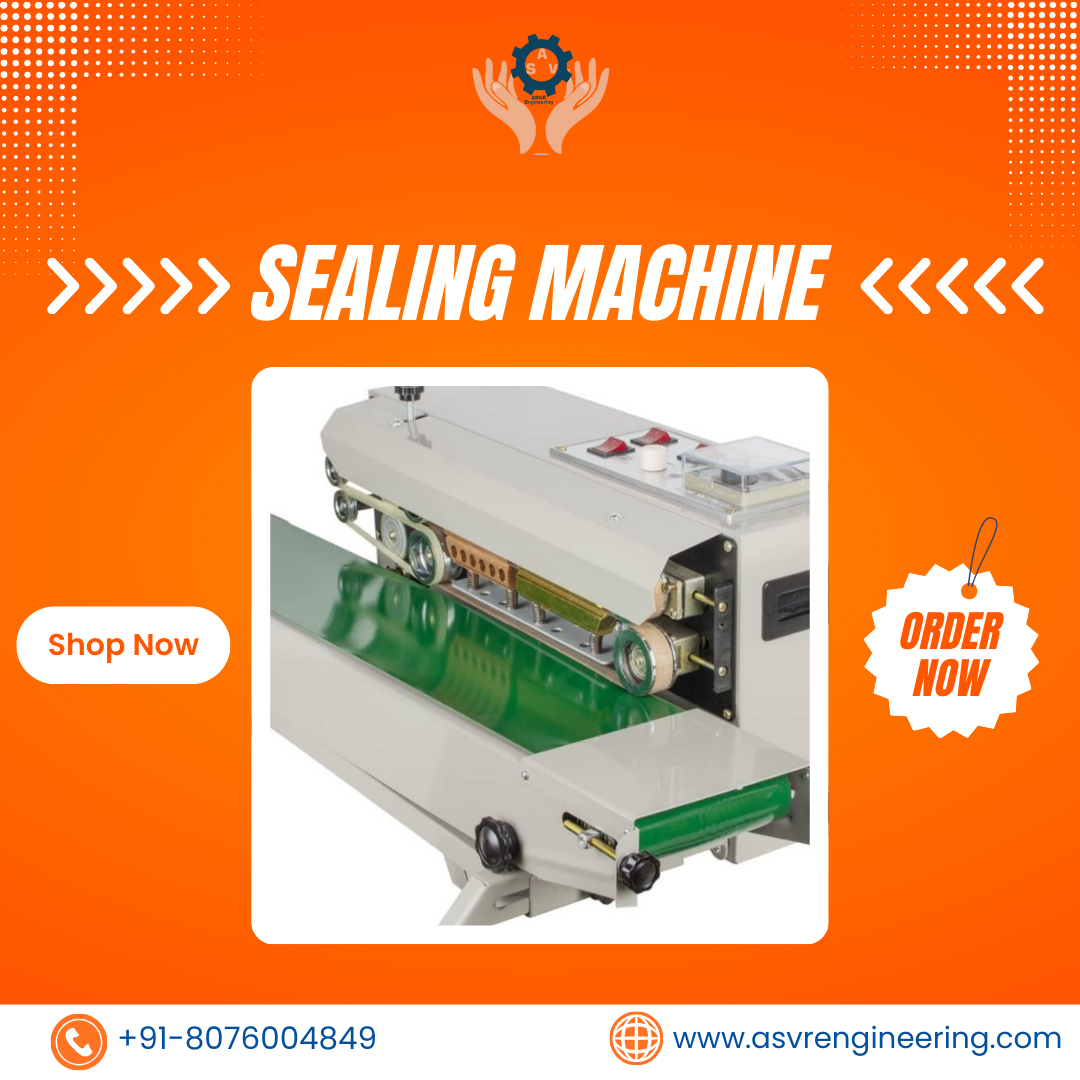

Continuous Band Sealing Machine

Continuous band sealers are designed for high-speed and high-volume packaging operations. Bags are fed continuously through the machine, making them ideal for production lines.

Applications: Food processing industries, chemical packaging, fertilizer packing, pharmaceutical companies.

Foot Operated Plastic Sealer

Foot sealers allow hands-free operation, providing better control and higher productivity. They are suitable for sealing thicker plastic bags and larger pouches.

Applications: Industrial packaging, hardware items, bulk products.

Hand Operated Plastic Sealing Machine

These compact machines are ideal for small businesses and startups. They are easy to operate, lightweight, and cost-effective.

Applications: Kirana stores, bakeries, small manufacturing units.

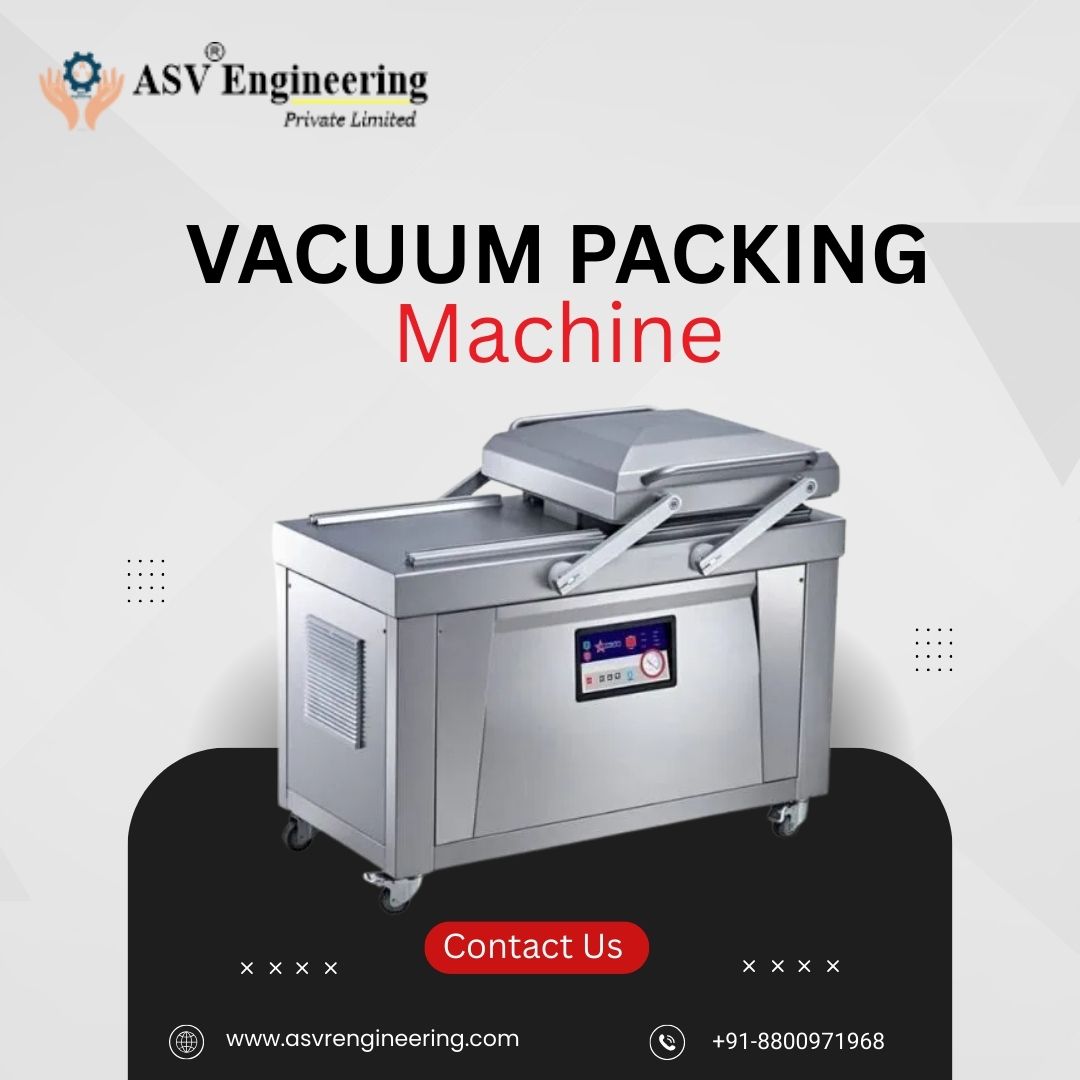

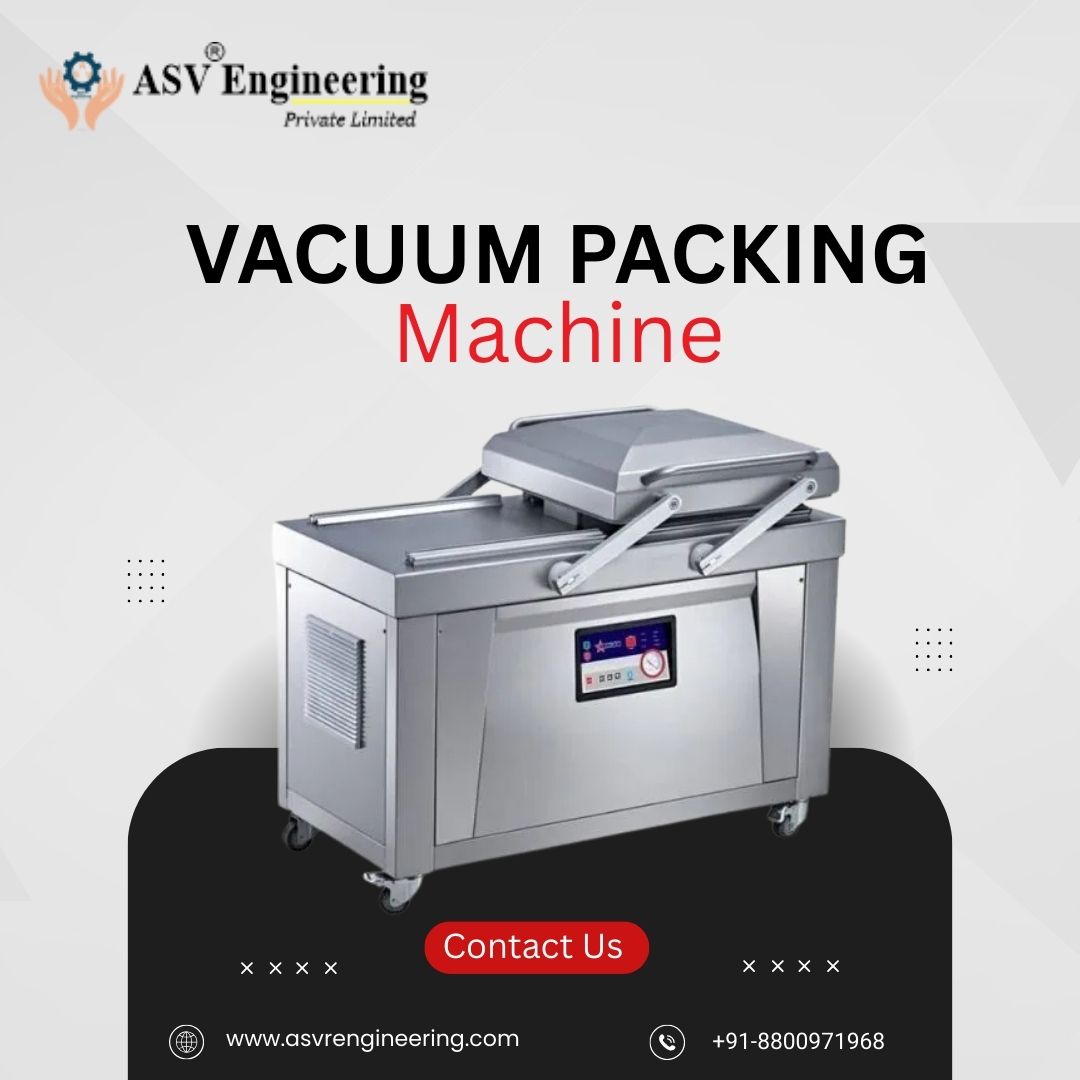

Vacuum Plastic Sealing Machine

Vacuum sealers remove air from the package before sealing, significantly extending product shelf life.

Applications: Frozen food, meat, dairy products, pharmaceuticals.

Industries Using Plastic Sealing Machines

Plastic sealing machines are used across a wide range of industries, including:

-

Food & Beverage Industry – Snacks, grains, spices, sweets, frozen foods

-

Pharmaceutical Industry – Tablets, capsules, medical devices

-

Cosmetics Industry – Creams, powders, personal care products

-

Chemical Industry – Powders, granules, industrial chemicals

-

Agriculture Sector – Seeds, fertilizers, pesticides

-

Retail & E-commerce – Courier bags, product pouches

Key Features of ASVR Engineering Plastic Sealing Machines

Our plastic sealing machines are designed keeping Indian industrial conditions in mind. Key features include:

-

Heavy-duty body with robust construction

-

Uniform heating for strong and consistent seals

-

Adjustable temperature control

-

Energy-efficient operation

-

Easy maintenance and long service life

-

Compatible with multiple plastic materials

-

User-friendly design for safe operation

Each machine undergoes strict quality checks to ensure flawless performance and reliability.

How to Choose the Right Plastic Sealing Machine

Selecting the right sealing machine depends on several factors:

1. Packaging Material

Different plastics require different heat levels. Ensure the machine supports your packaging material.

2. Production Volume

Low volume operations can opt for manual or impulse sealers, while high volume industries should choose continuous or automatic machines.

3. Bag Size & Thickness

Choose a sealing length and heating capacity that matches your packaging dimensions.

4. Industry Requirements

Food and pharma industries may require hygienic and stainless-steel body machines.

5. Budget & ROI

Invest in a machine that balances initial cost with long-term productivity and durability.

Maintenance Tips for Long Machine Life

To ensure optimal performance and long service life, follow these simple maintenance tips:

-

Clean the sealing bar regularly

-

Avoid overheating beyond recommended limits

-

Replace Teflon tape when worn out

-

Keep electrical components dust-free

-

Perform periodic inspections

Regular maintenance not only increases machine life but also ensures consistent sealing quality.

Why Choose ASVR Engineering for Plastic Sealing Machines?

ASVR Engineering is a trusted name in packaging machinery solutions. Our commitment to quality, innovation, and customer satisfaction sets us apart.

What makes us different:

-

Industry-proven machinery

-

Competitive pricing

-

Reliable after-sales support

-

Customized solutions as per client needs

-

Pan-India supply capability

We understand that every business has unique packaging requirements, and our team works closely with clients to deliver the right solution.

Applications in Small, Medium & Large Businesses

Whether you are a startup or an established manufacturing unit, plastic sealing machines from ASVR Engineering help streamline packaging operations, reduce costs, and improve output efficiency. From sealing a few dozen packets a day to thousands per hour, we have solutions for every scale of operation.

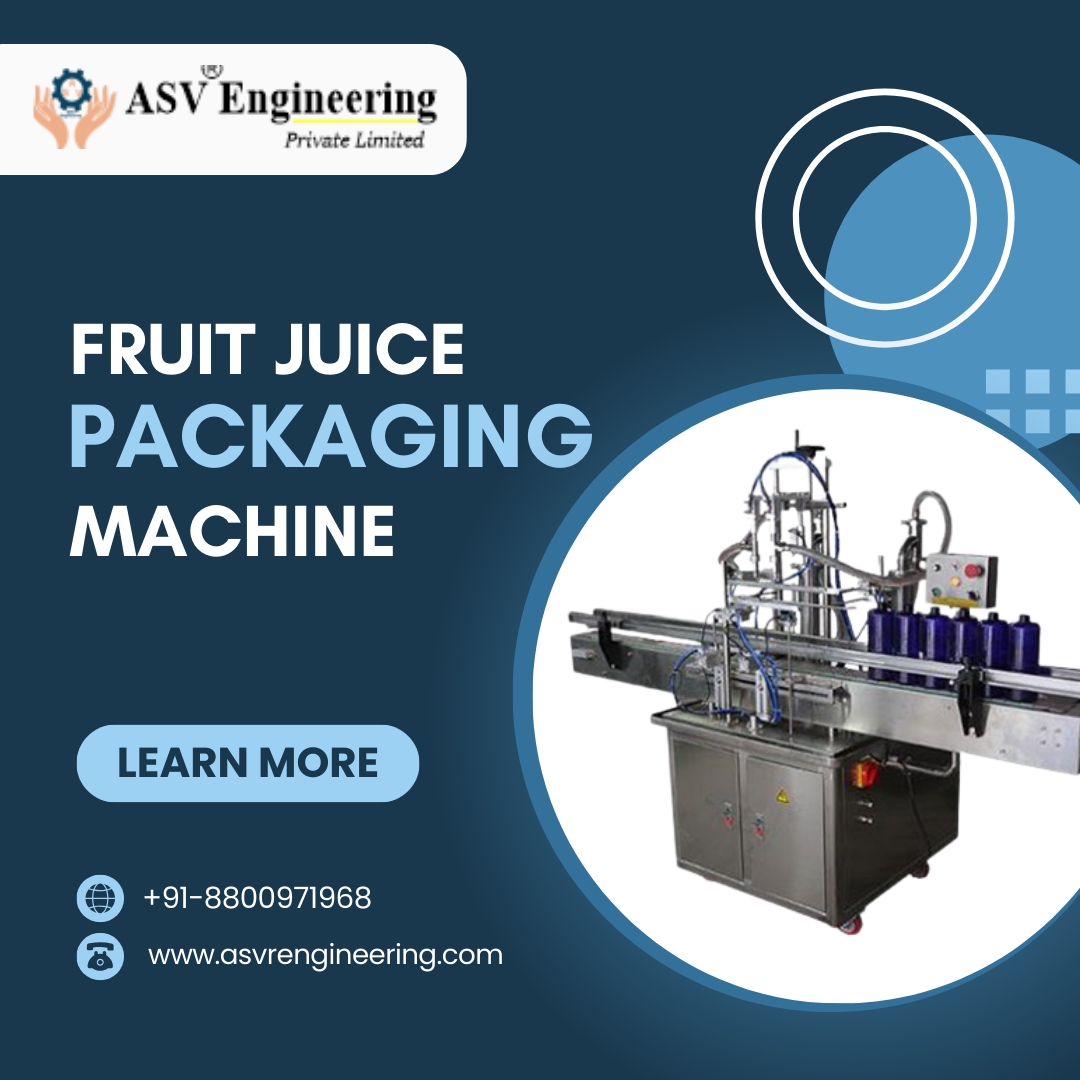

Contact Us for the Best Plastic Sealing Machine Solutions

If you are looking for a reliable, durable, and high-performance plastic sealing machine, get in touch with us today.

📞 Contact Numbers: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

Our experts are always ready to guide you in choosing the right machine for your business needs.

Buy Now

Related Posts

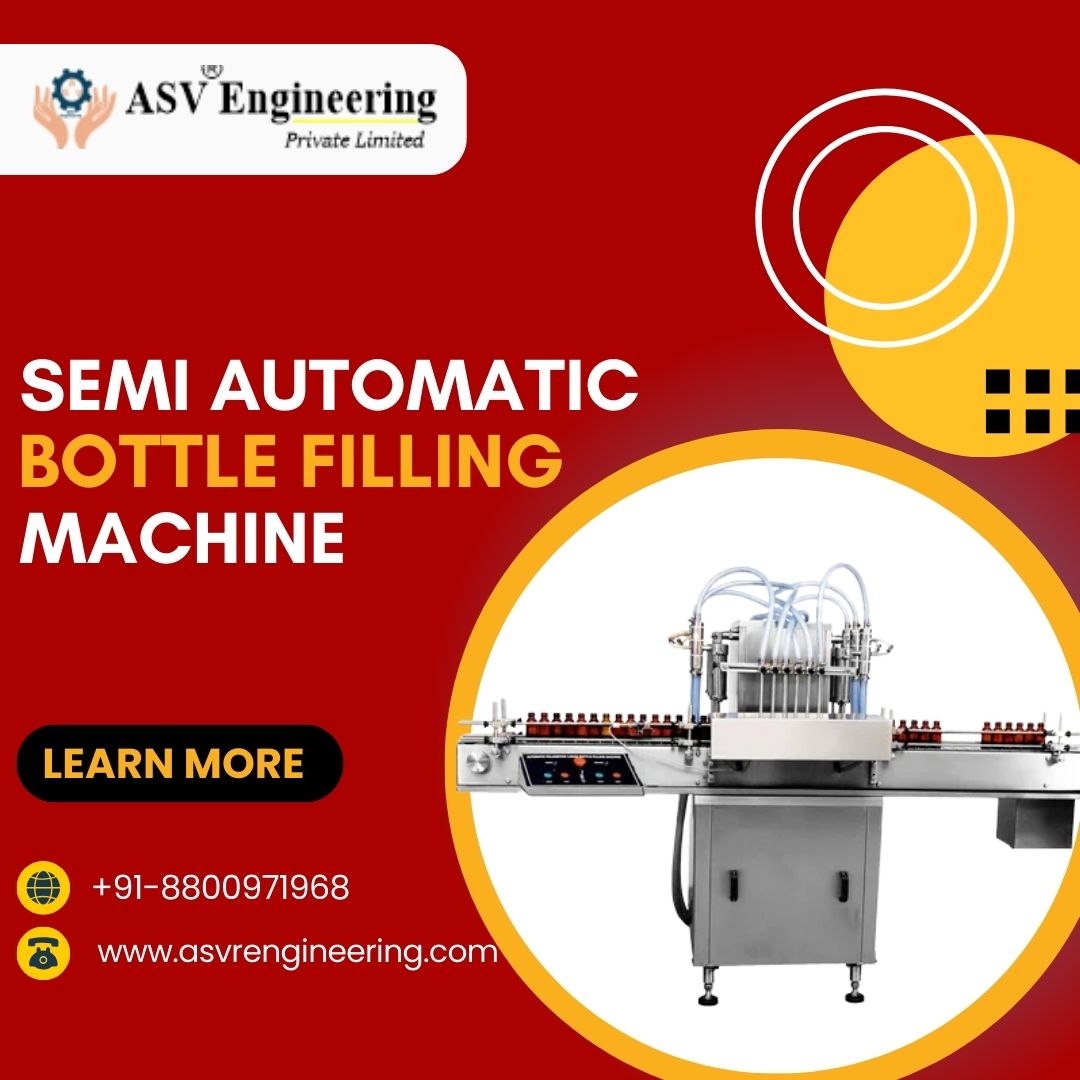

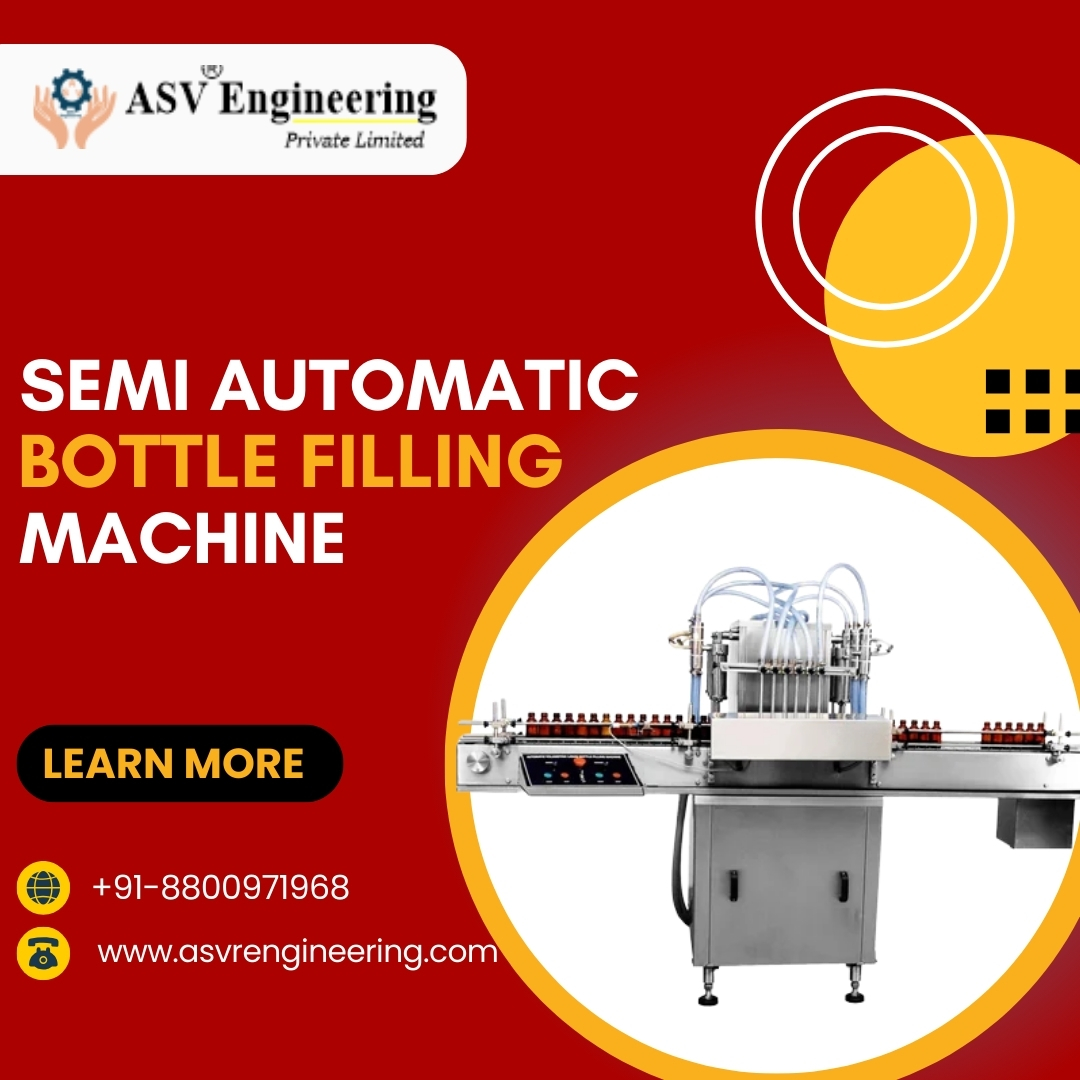

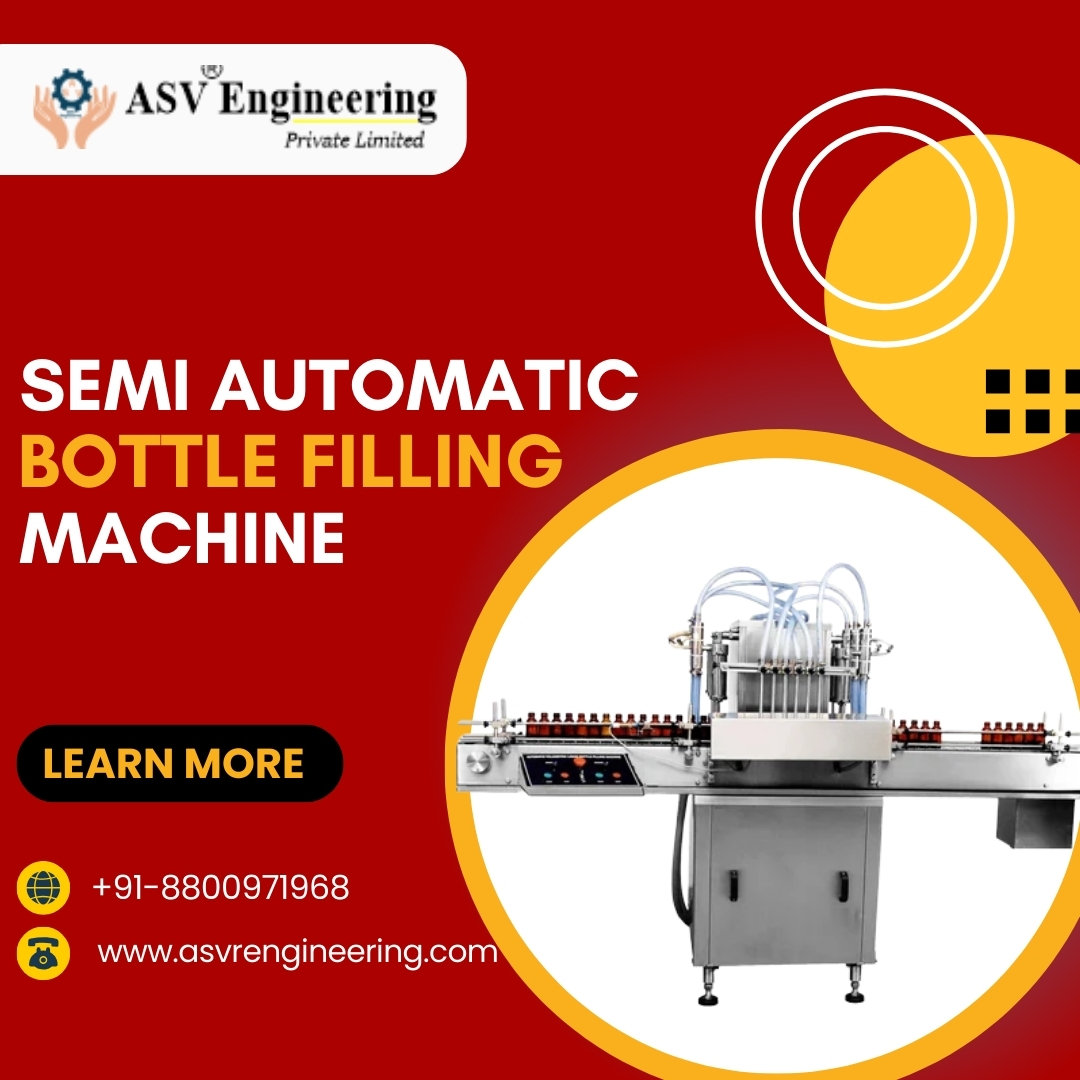

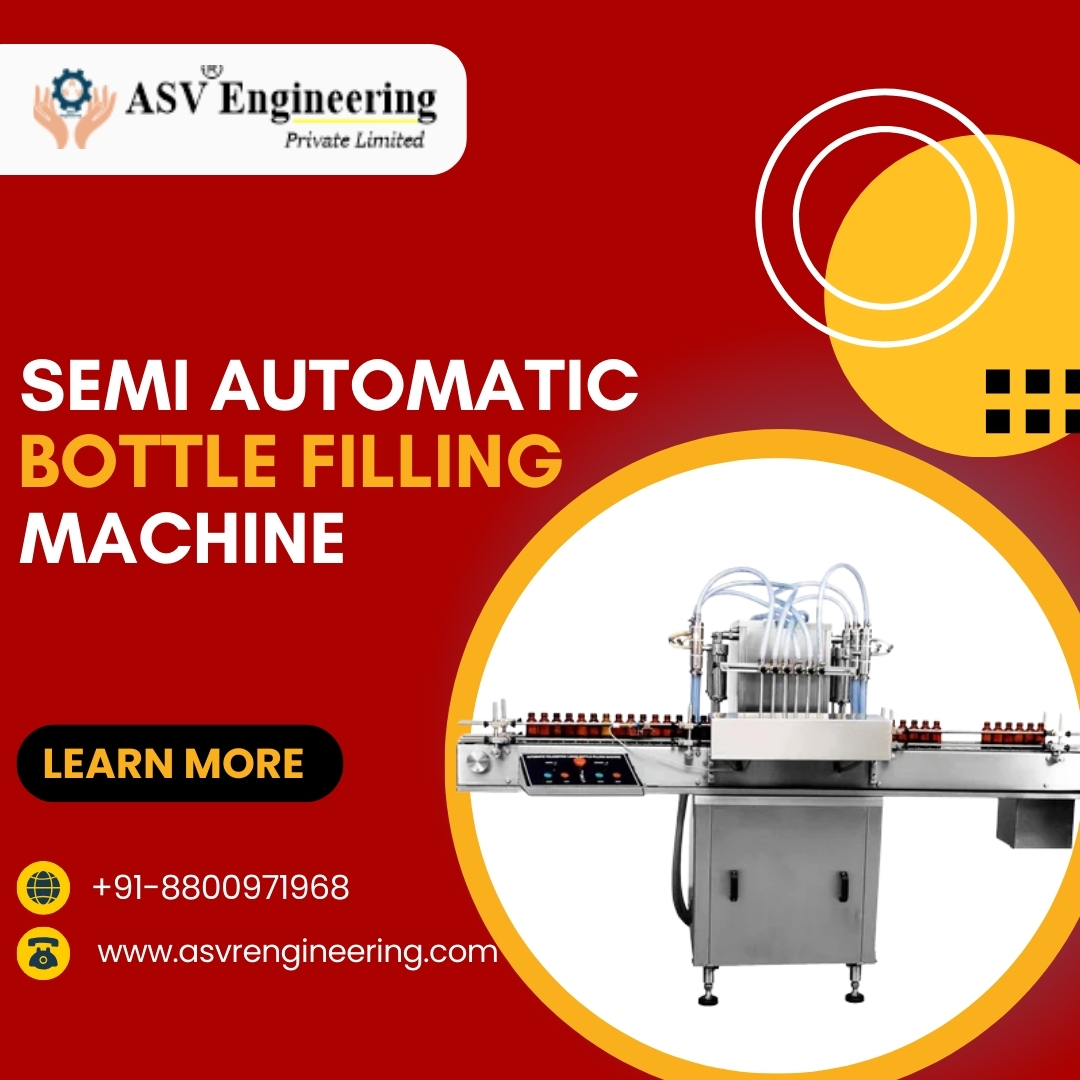

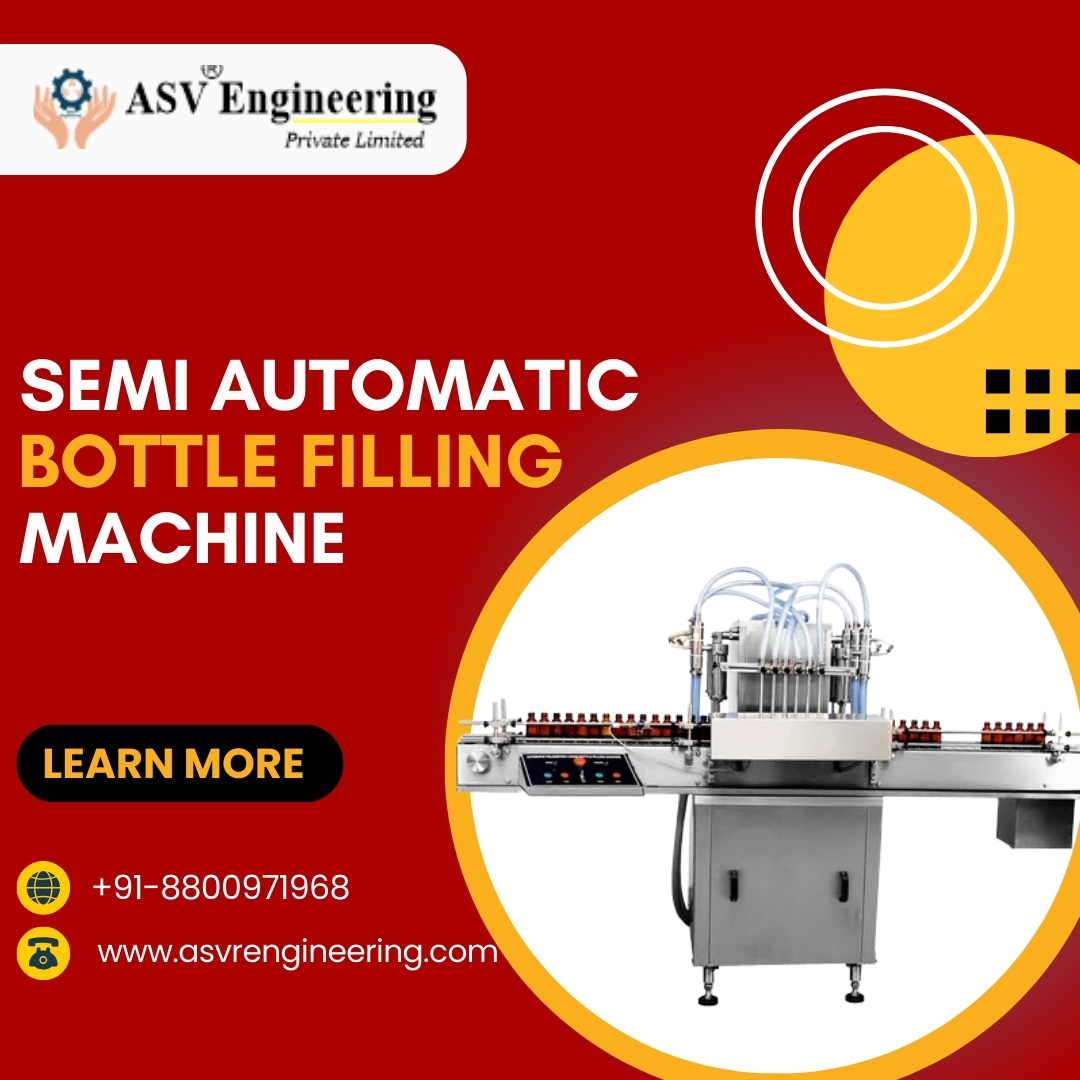

Leading Automatic Bottle Filling Machine Manufacturers for High-Speed Industrial Packaging Solutions

Trusted Automatic Milk Bag Packaging Machine Distributors for Dairy Plants, Milk Booths & FMCG Units

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)