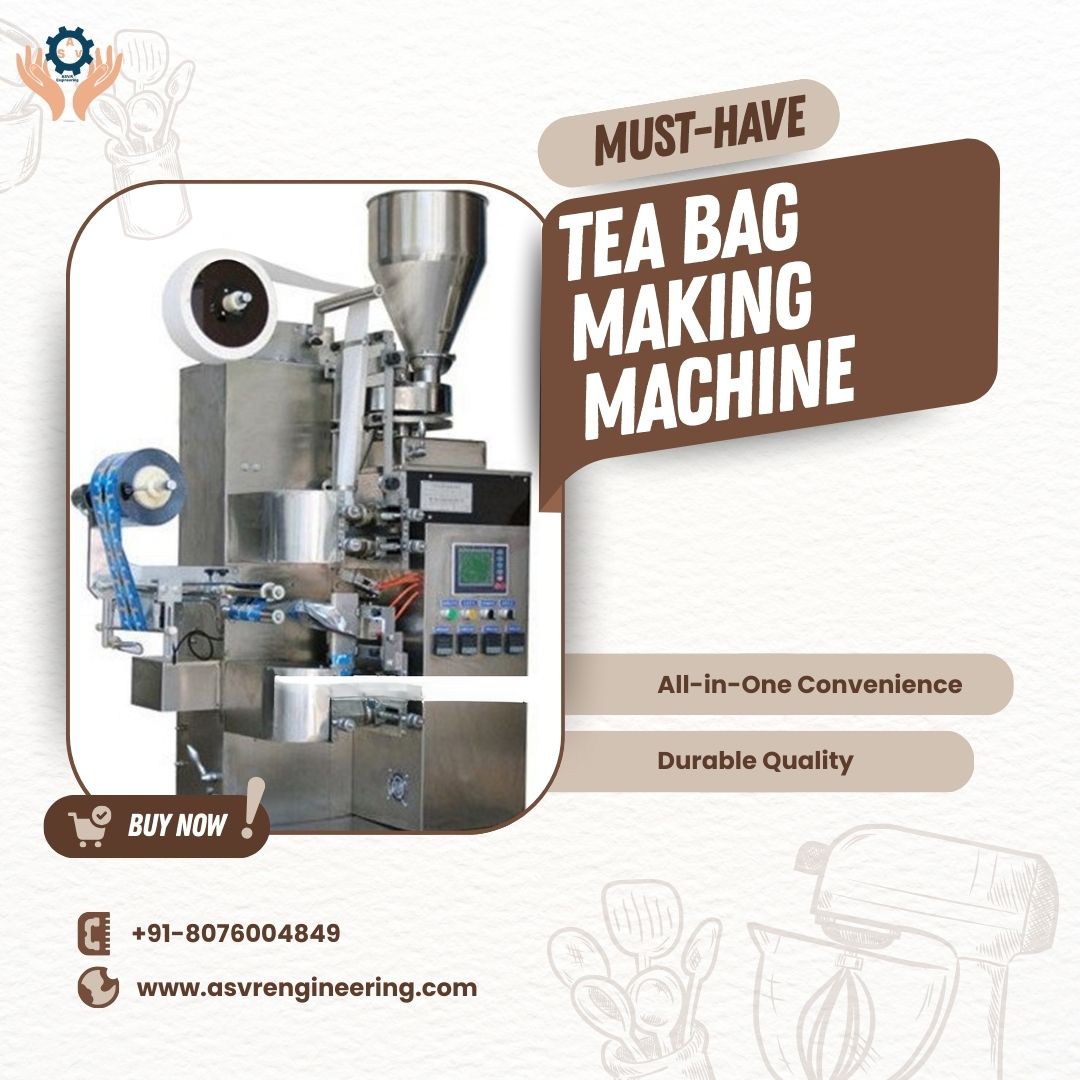

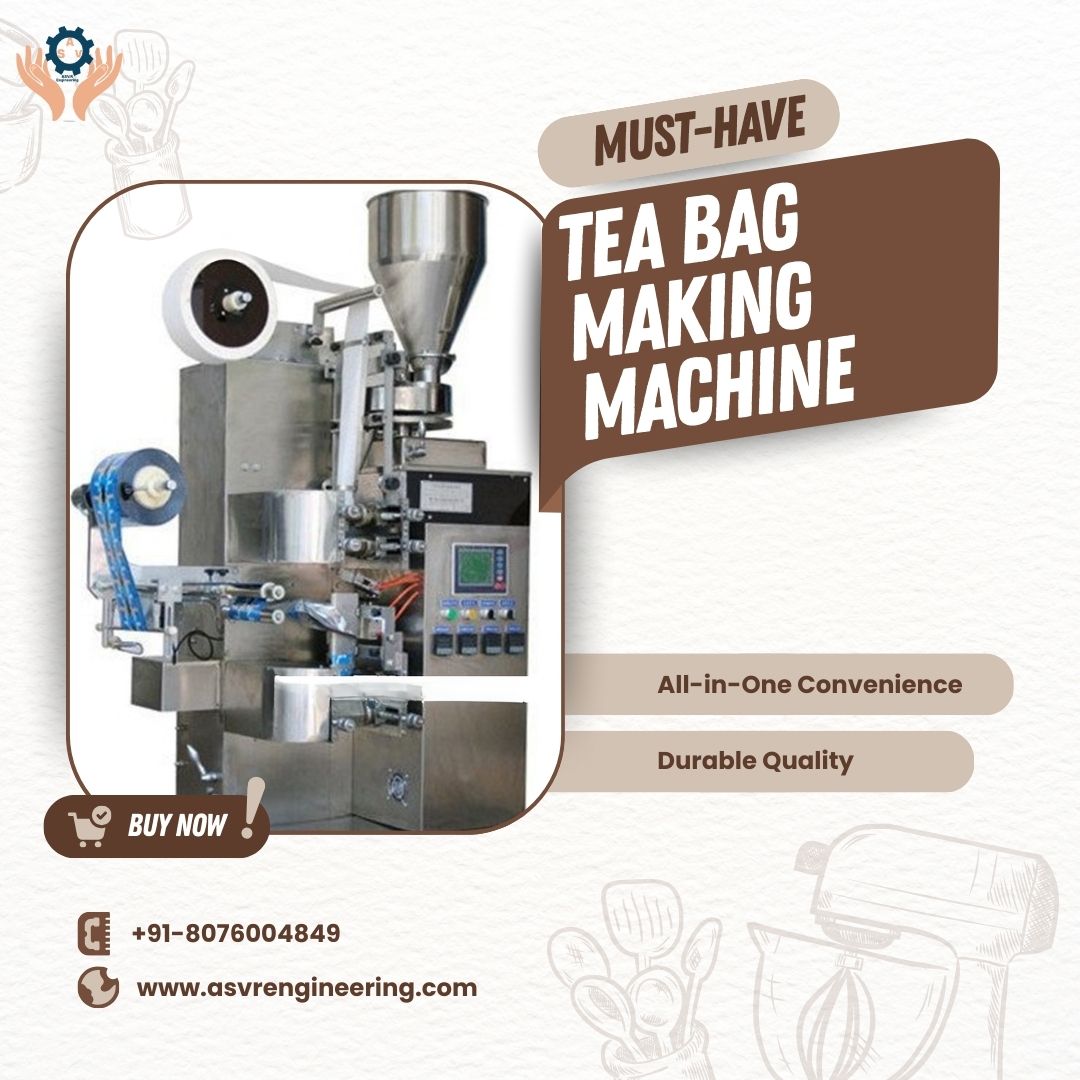

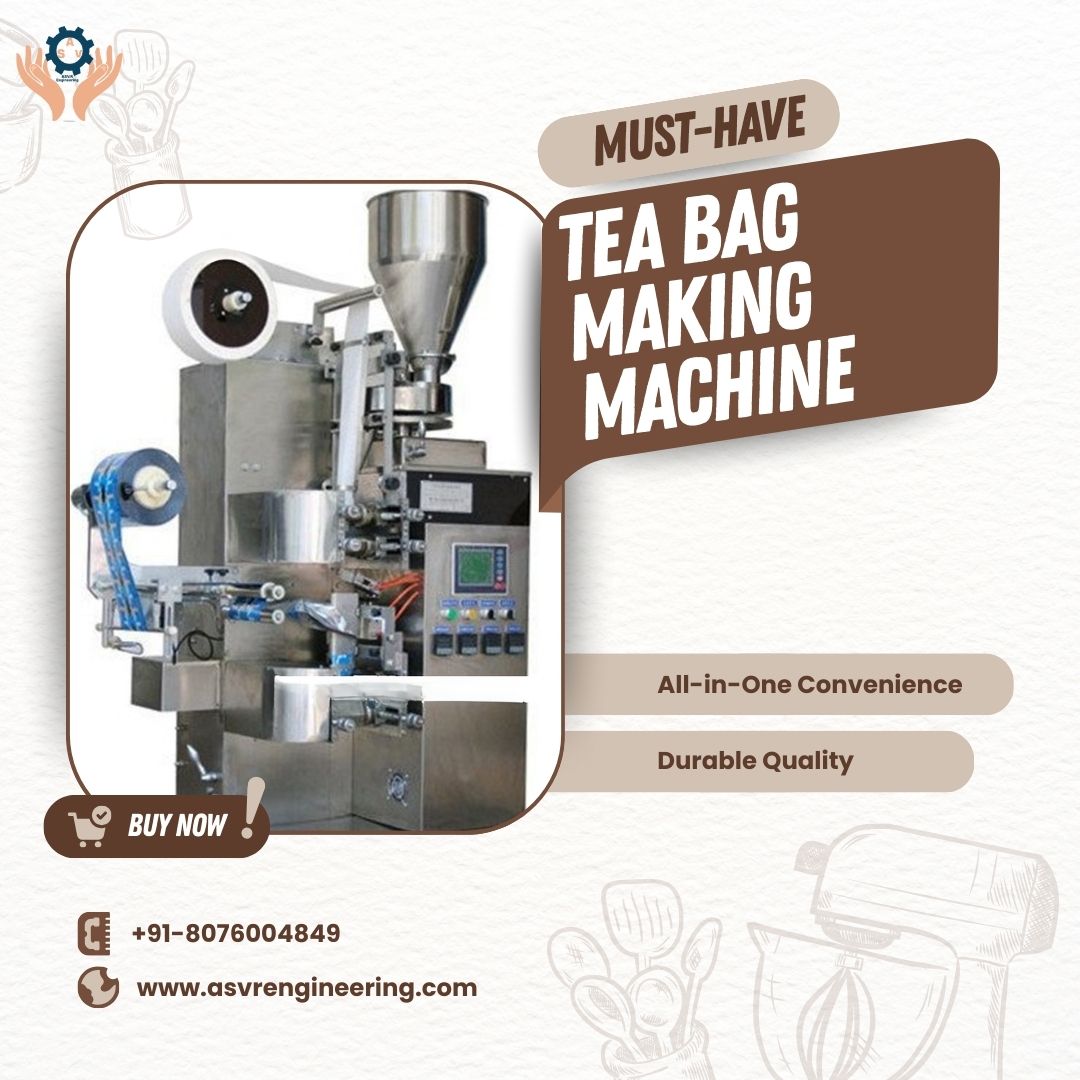

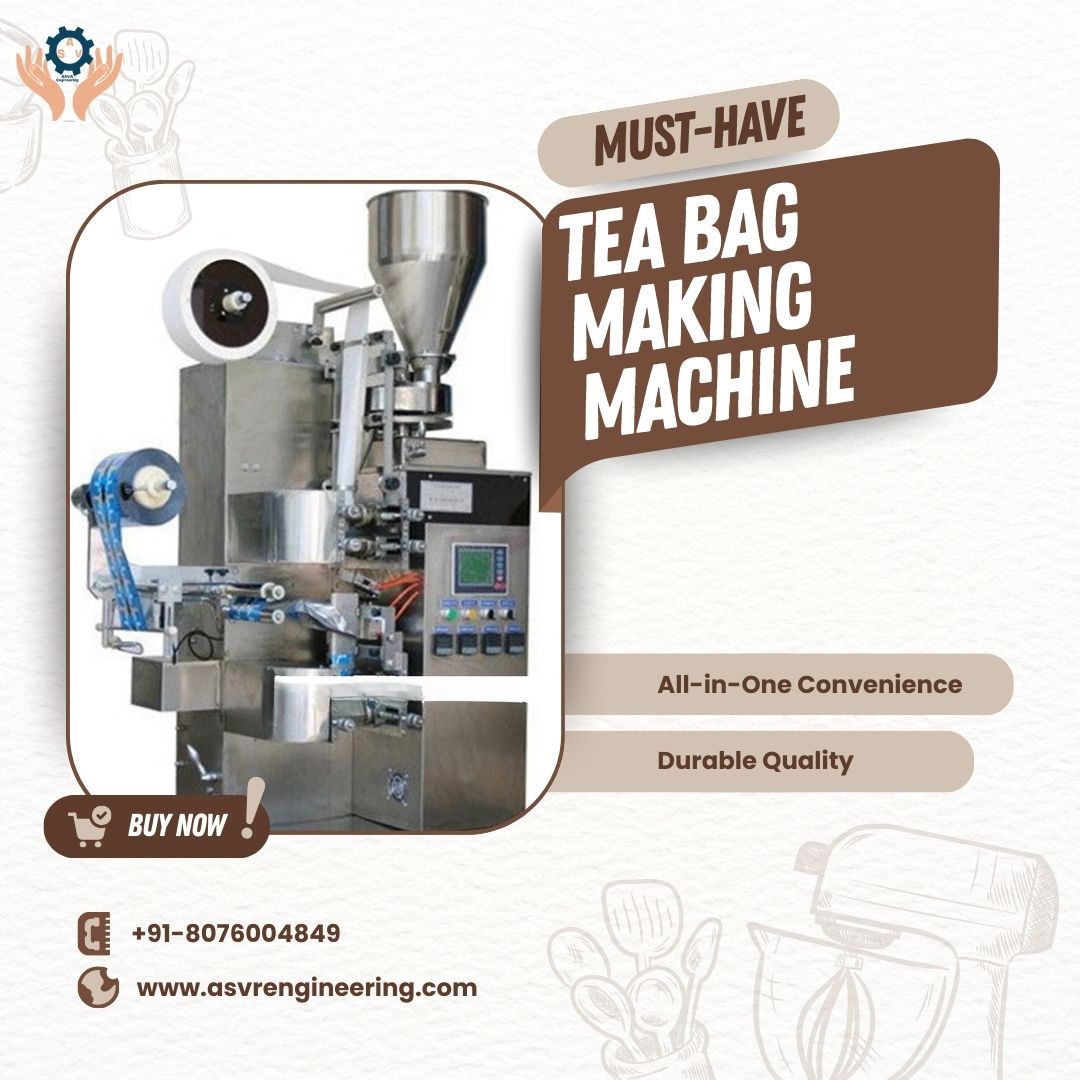

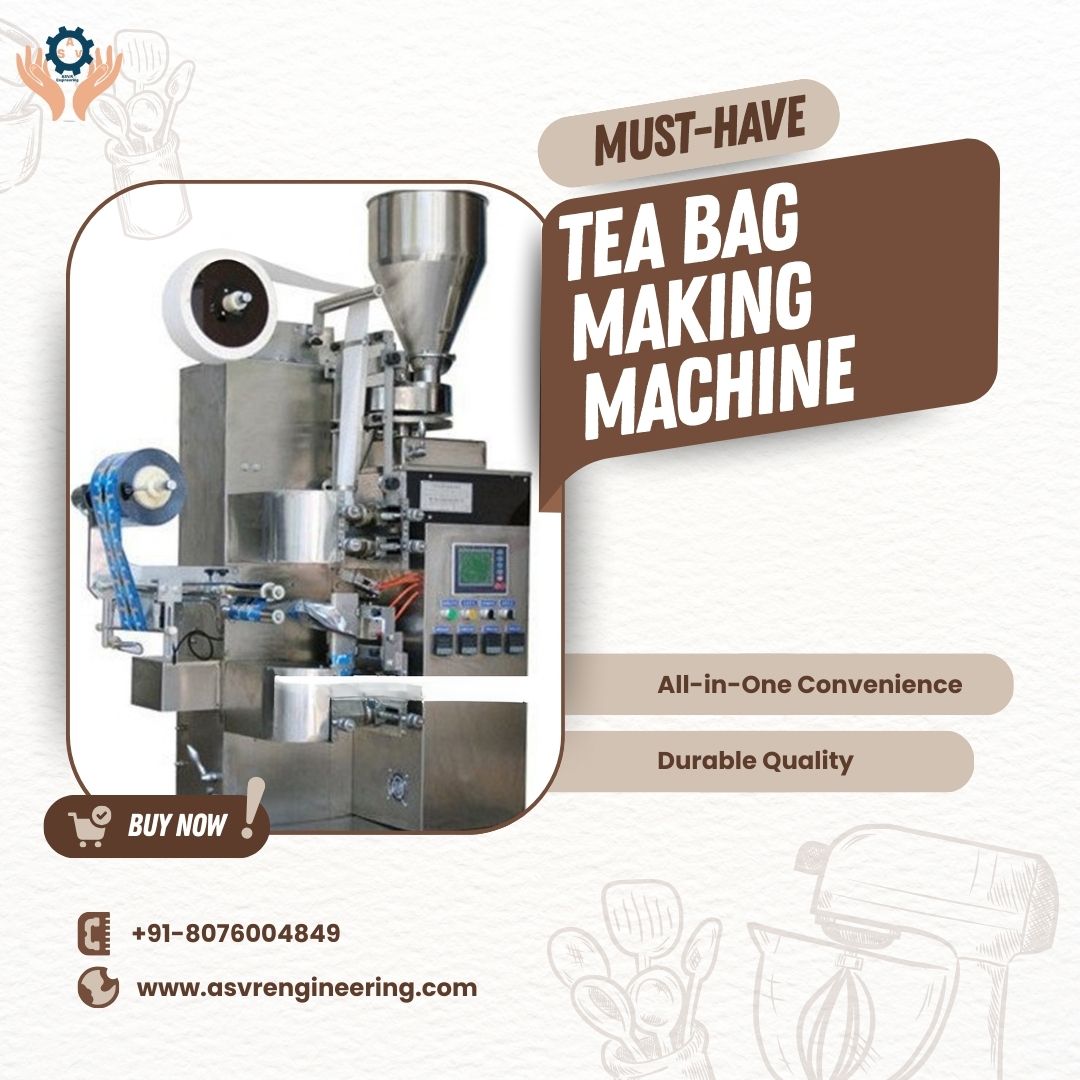

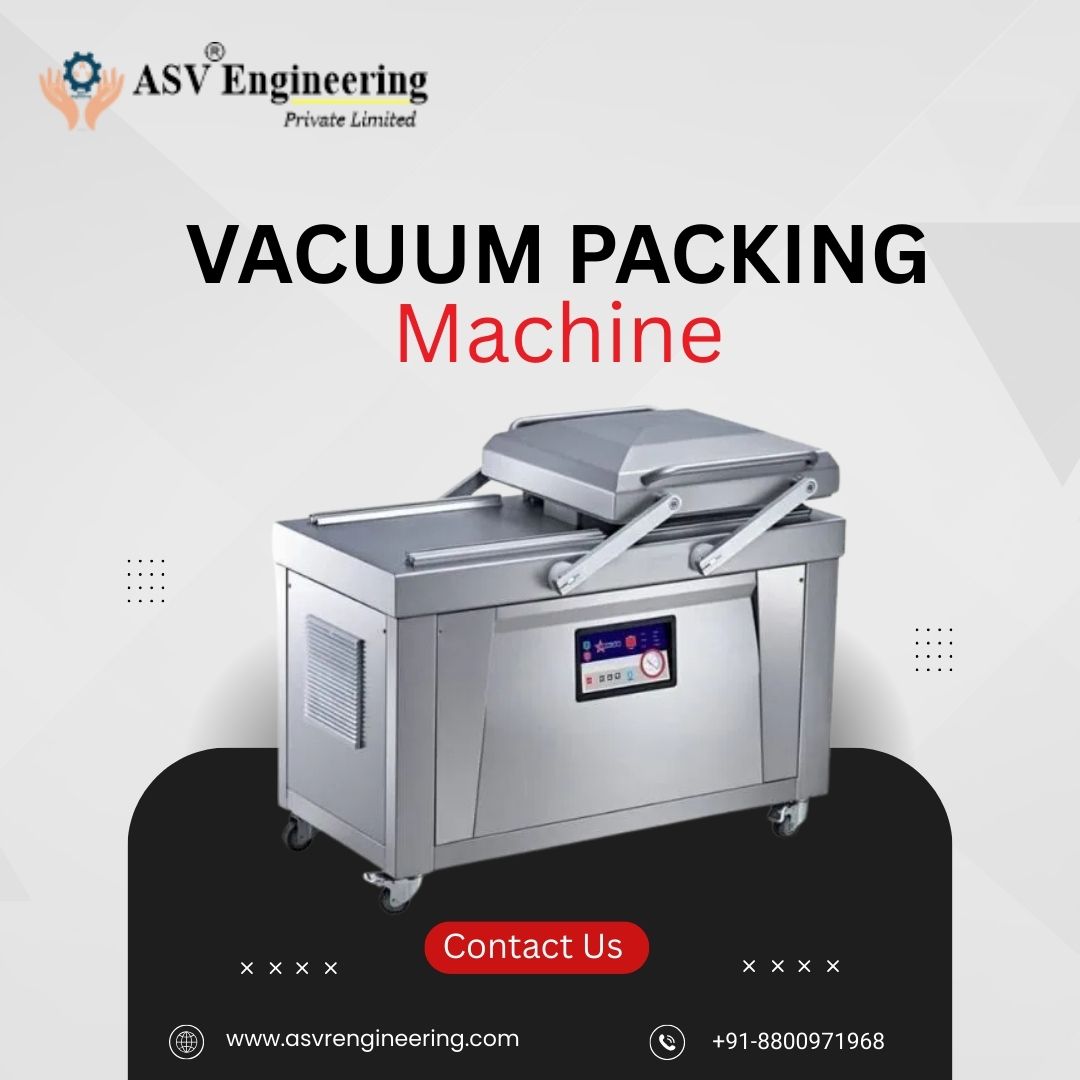

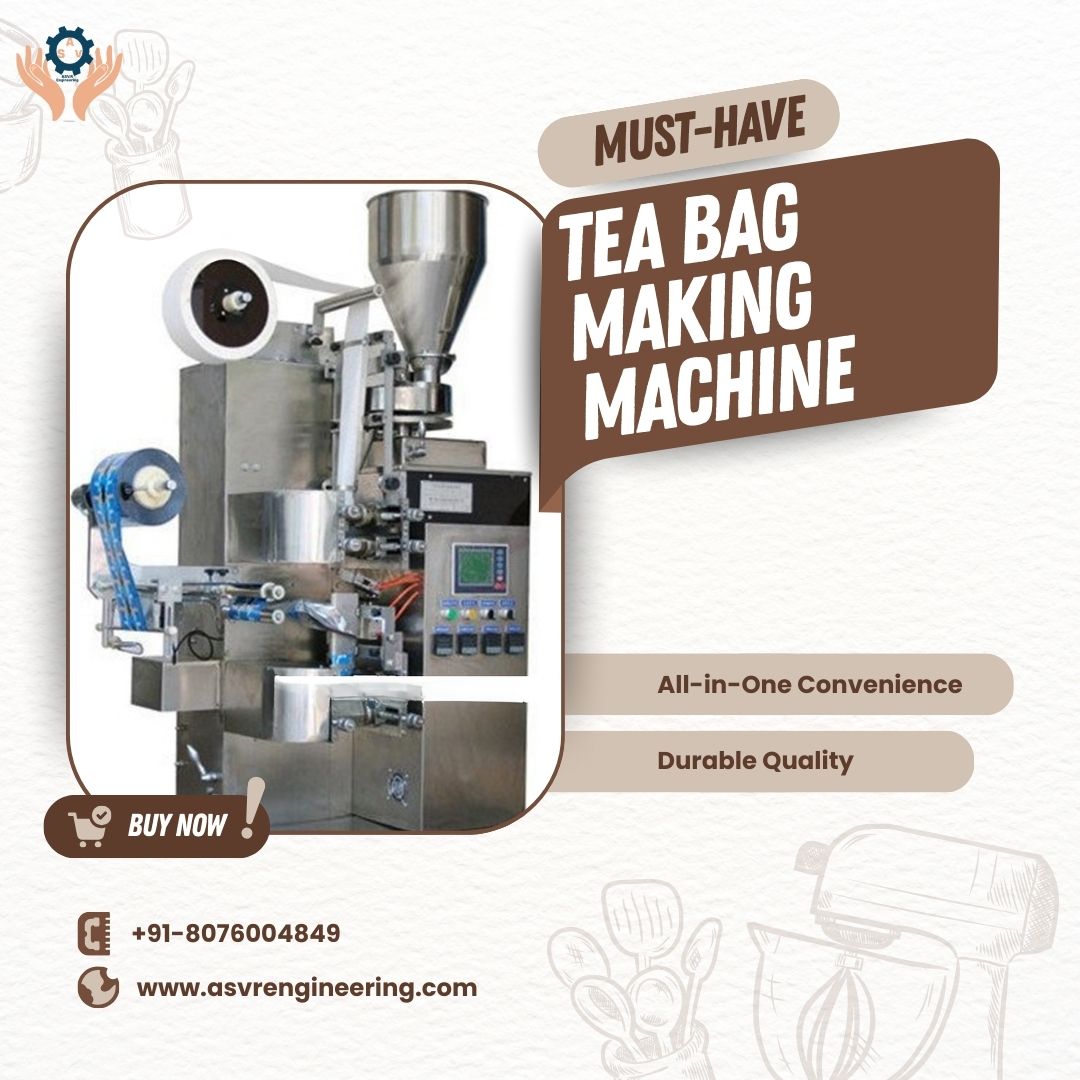

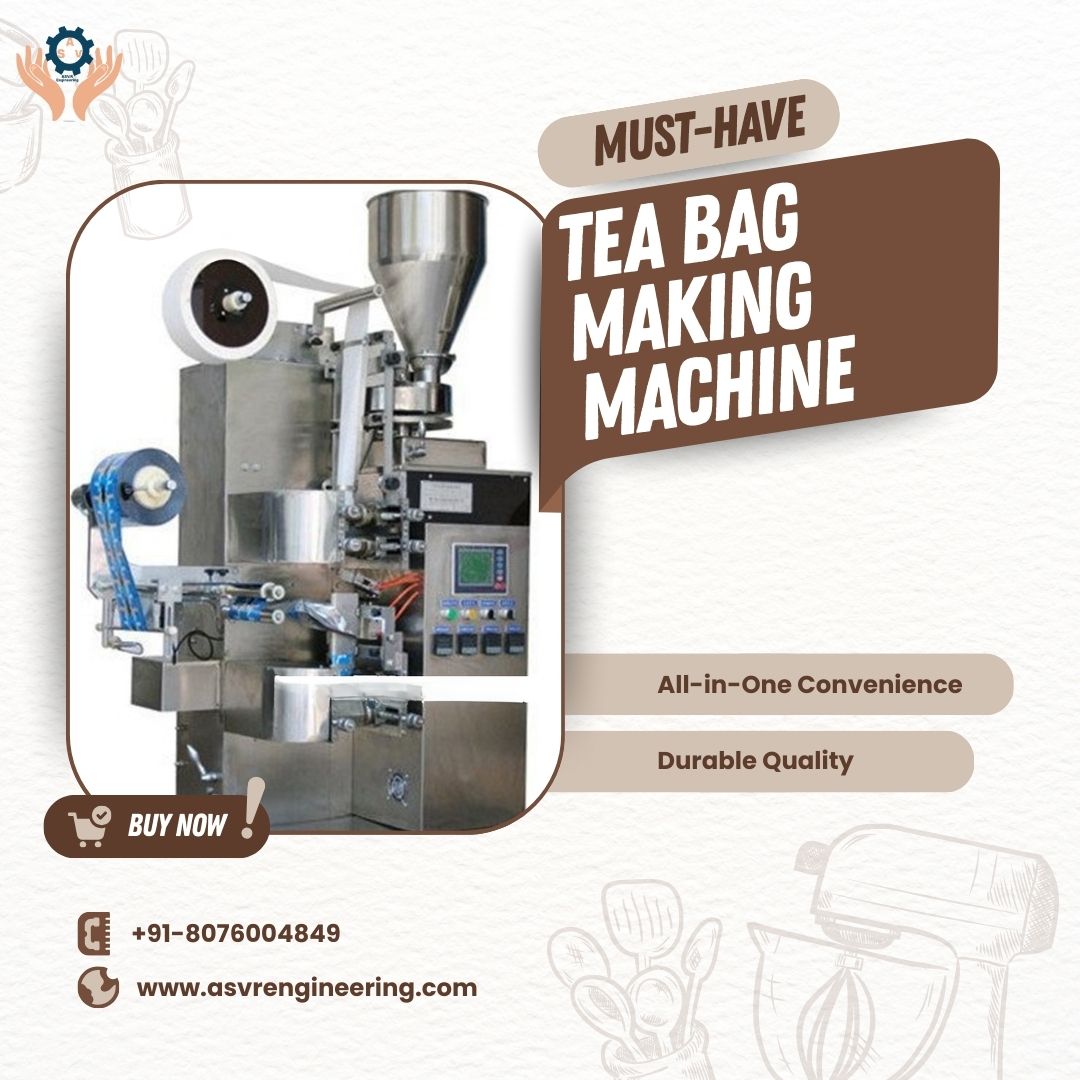

Best Tea Bag Making Machine Manufacturers Offering Advanced Technology & Best Price

Price: ₹47000

Tea is one of the most consumed beverages in the world, and India holds a special place as both a producer and consumer of premium-quality tea. With changing lifestyles, consumers now prefer hygienic, convenient, and well-packed tea products—especially tea bags. This shift has created a massive demand for high-performance tea bag making machines that can deliver consistent quality, speed, and efficiency.

Businesses entering or expanding in the tea packaging segment need reliable machinery that ensures accuracy in filling, strong sealing, minimal wastage, and long-term durability. That’s why choosing the best tea bag making machine manufacturers becomes a critical decision for any tea brand, wholesaler, exporter, or FMCG company.

What Is a Tea Bag Making Machine?

A tea bag making machine is an automated or semi-automatic system designed to produce tea bags by accurately filling tea leaves or herbal blends into filter paper, sealing them securely, attaching threads and tags (if required), and packaging them for commercial distribution.

Modern machines are capable of producing single-chamber, double-chamber, round, square, or pyramid tea bags, depending on market demand. Advanced models integrate cutting-edge technology for precision control, consistent weight filling, and attractive packaging.

Why Advanced Technology Matters in Tea Bag Manufacturing

When it comes to tea bag production, technology directly affects product quality, operational efficiency, and profitability. Leading tea bag making machine manufacturers focus on innovation to help businesses stay competitive.

Key Benefits of Advanced Technology

-

High-Speed Production: Automatic systems can produce thousands of tea bags per hour, meeting bulk demand effortlessly.

-

Precision Filling: Ensures uniform weight in every tea bag, maintaining taste consistency and brand trust.

-

Strong & Hygienic Sealing: Heat sealing and ultrasonic sealing technologies prevent leakage and contamination.

-

Reduced Material Wastage: Optimized paper usage and minimal tea loss save raw material costs.

-

Easy Operation & Maintenance: User-friendly control panels and robust design reduce downtime.

Types of Tea Bag Making Machines Available

Understanding machine types helps buyers choose the right solution based on their production scale and target market.

1. Automatic Tea Bag Making Machine

Fully automatic machines handle filling, sealing, cutting, tagging, and sometimes even outer envelope packing. Ideal for large-scale commercial production.

2. Double Chamber Tea Bag Machine

Popular in premium markets, double-chamber tea bags allow better infusion and improved flavor release. These machines are widely used by export-oriented brands.

3. Pyramid Tea Bag Machine

Designed for luxury and specialty teas, pyramid-shaped bags provide more space for tea leaves to expand, enhancing aroma and taste.

4. Herbal & Specialty Tea Bag Machine

Specially engineered for herbs, spices, green tea, and flavored blends that require gentle handling and precise dosing.

Features to Look for in the Best Tea Bag Making Machine

Before investing, it’s important to evaluate machine features that ensure long-term value.

-

Stainless Steel Construction: Food-grade SS body ensures hygiene and durability.

-

PLC & Touch Screen Control: Allows easy monitoring and precise adjustments.

-

Flexible Bag Size Options: Supports different tea bag dimensions and styles.

-

High Output Capacity: Matches your current and future production needs.

-

Energy Efficiency: Reduces power consumption and operational costs.

-

After-Sales Support: Quick service and spare availability are crucial for uninterrupted production.

Why Choose Reliable Tea Bag Making Machine Manufacturers

Not all machines deliver the same performance. Trusted manufacturers invest in R&D, quality testing, and customer support to ensure smooth operations.

Advantages of Working with Reputed Manufacturers

-

Proven machine performance with real-world industry experience

-

Customization options based on tea type and packaging style

-

Transparent pricing with no hidden costs

-

Technical training and installation support

-

Long machine life with consistent output quality

Choosing a reputed supplier minimizes risk and ensures your investment delivers returns for years.

Best Price with No Compromise on Quality

Price is an important factor, especially for startups and medium-scale manufacturers. However, the lowest price does not always mean the best deal. The best tea bag making machine manufacturers strike the right balance between affordability and quality.

High-quality machines reduce breakdowns, improve output efficiency, and save maintenance costs in the long run. Competitive pricing combined with advanced technology ensures faster ROI and sustainable growth.

Applications of Tea Bag Making Machines

Tea bag machines are widely used across multiple segments:

-

Tea processing units

-

FMCG and packaged food companies

-

Herbal and ayurvedic product manufacturers

-

Export-oriented tea brands

-

Private label tea startups

-

Hotels, cafes, and institutional suppliers

Whether producing black tea, green tea, herbal infusions, or flavored blends, the right machine supports diverse applications.

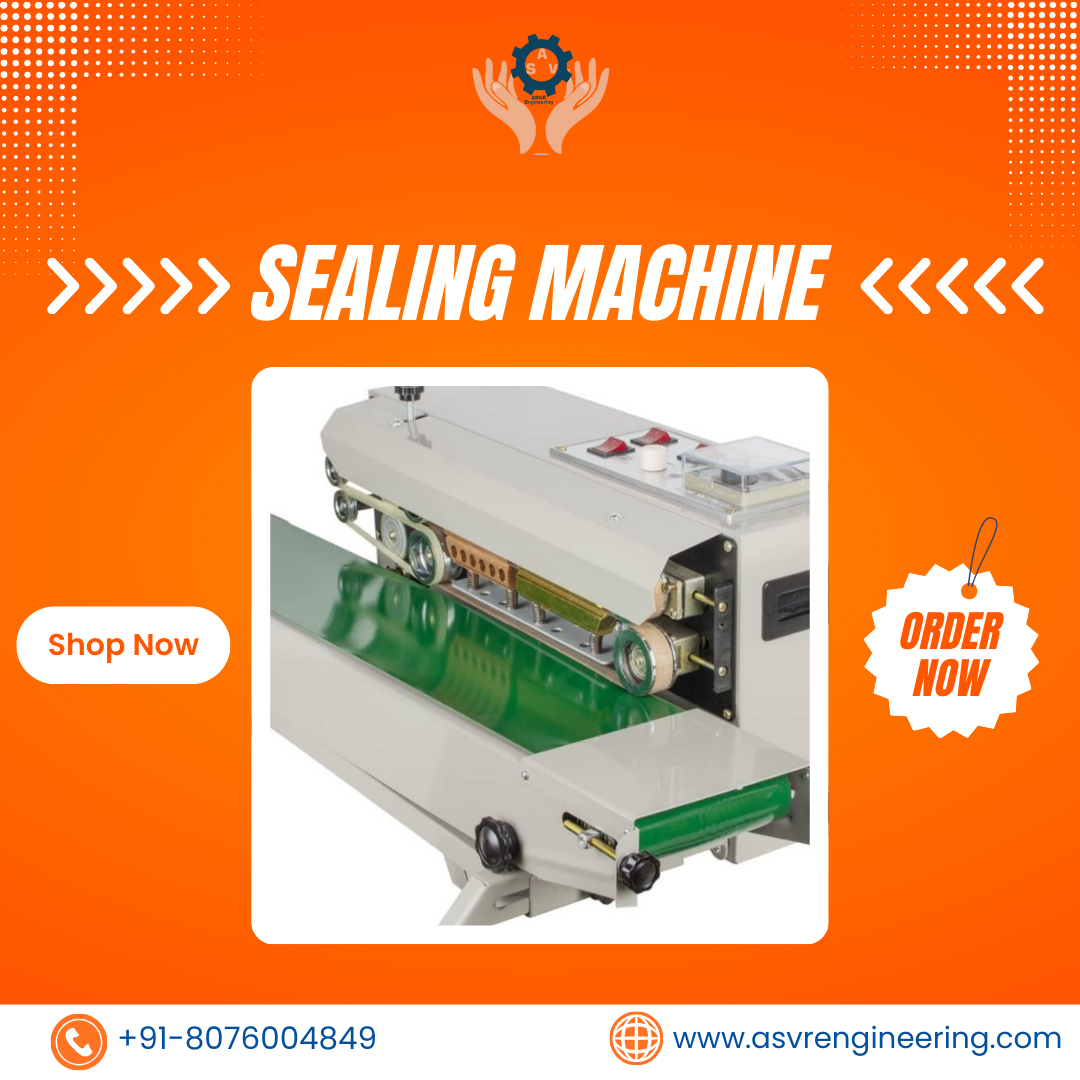

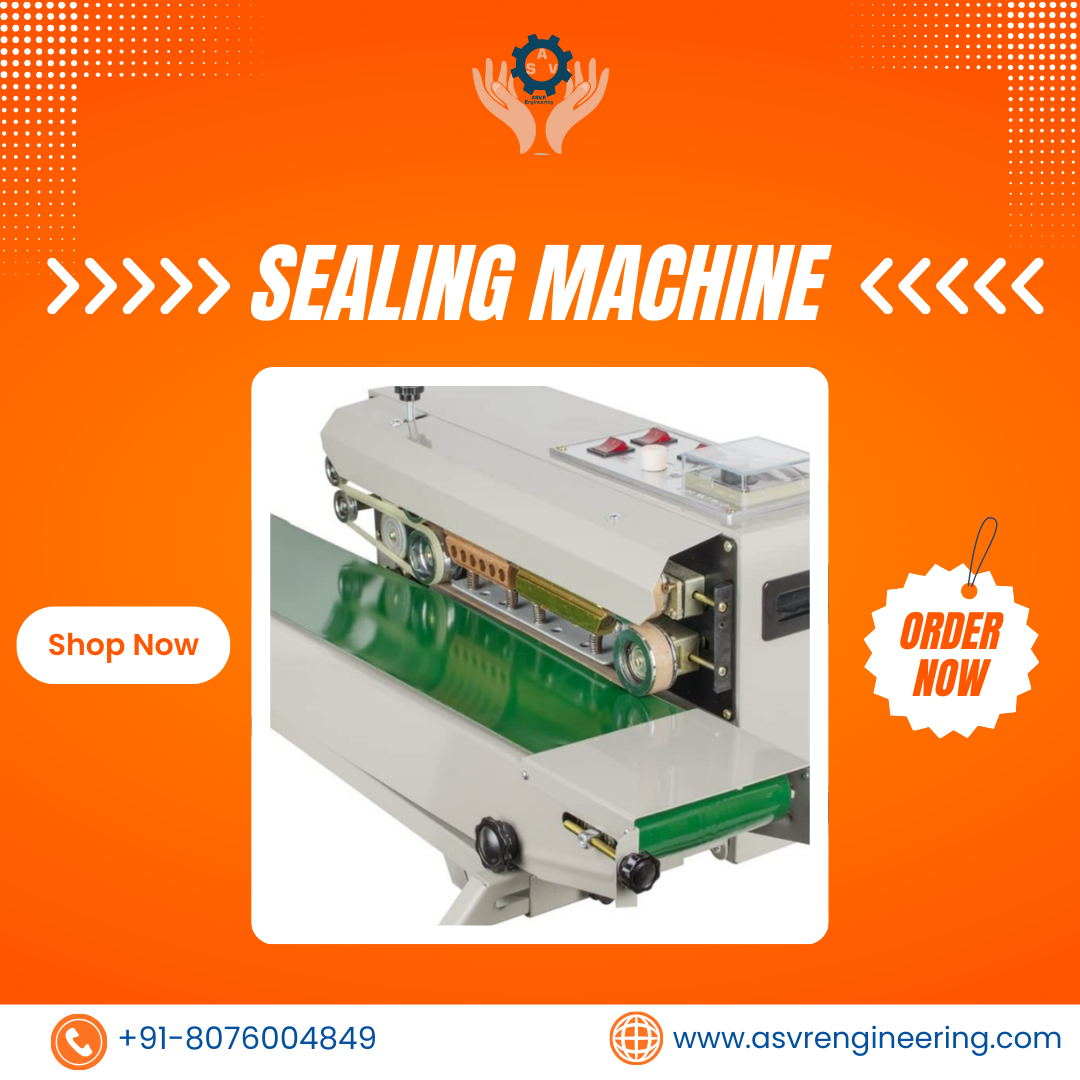

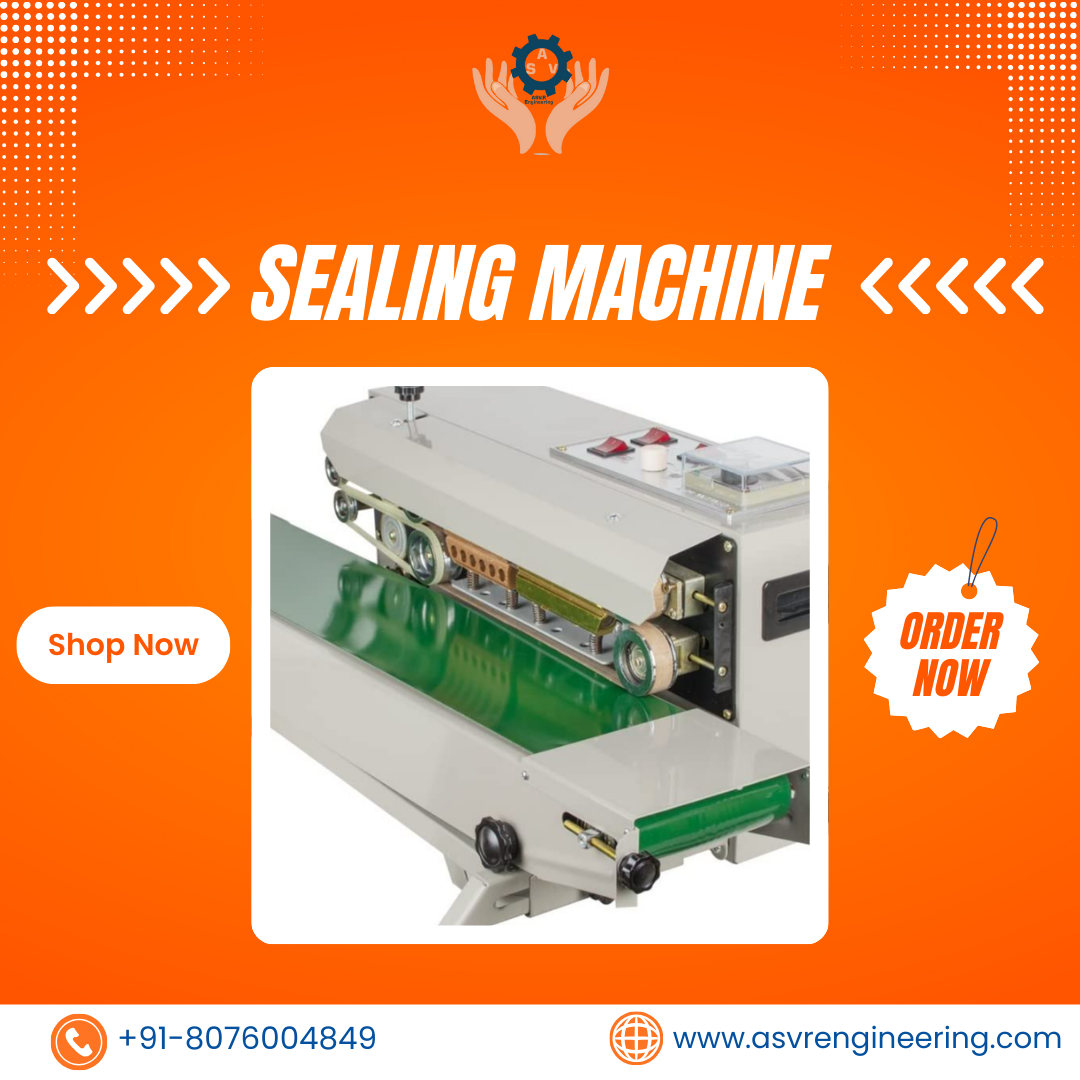

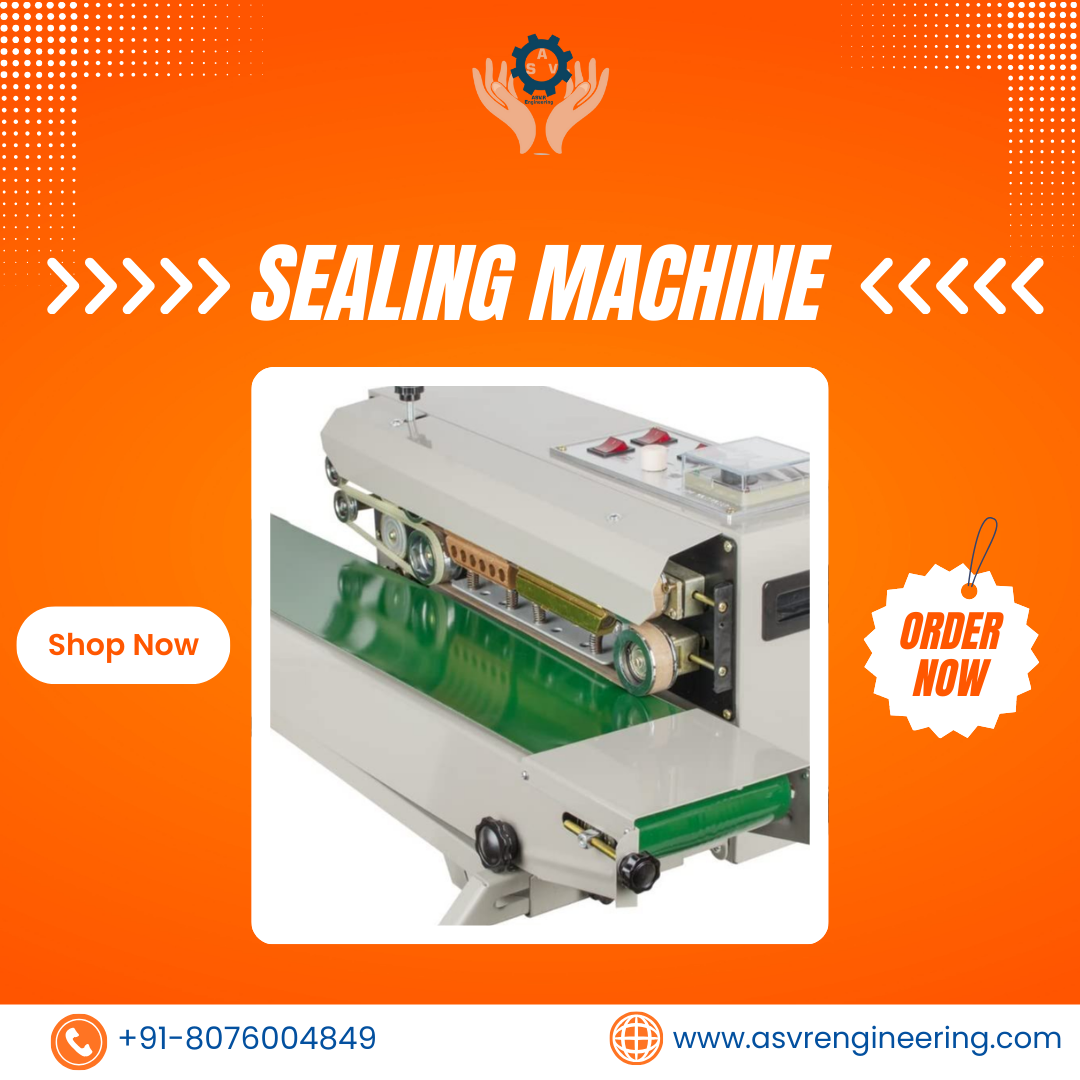

Why ASVR Engineering Is a Trusted Name

ASVR Engineering is known for delivering robust, technologically advanced, and cost-effective tea bag making machines designed for Indian and international markets. Their machines are built to meet strict quality standards and high production demands.

What Sets Them Apart

-

Advanced manufacturing technology

-

Strong focus on quality and performance

-

Competitive pricing without compromising durability

-

Reliable customer support and technical assistance

-

Solutions suitable for small, medium, and large-scale production

Choosing the Right Tea Bag Making Machine for Your Business

Before finalizing your purchase, consider:

-

Your daily production target

-

Type of tea (CTC, leaf, herbal, flavored)

-

Packaging style preference

-

Available factory space

-

Budget and future expansion plans

Consulting with experienced manufacturers helps you select the most suitable machine that aligns with your business goals.

Future of Tea Bag Packaging Industry

With rising health awareness and premium tea consumption, the tea bag market is expected to grow rapidly. Eco-friendly filter papers, biodegradable packaging, and innovative tea blends are shaping the future.

Manufacturers adopting advanced tea bag making machines will stay ahead by delivering quality, speed, and sustainability—key factors in modern consumer markets.

Conclusion

Investing in a high-quality tea bag making machine is a strategic move for any tea business aiming for growth and brand recognition. The best tea bag making machine manufacturers offering advanced technology & best price provide solutions that combine efficiency, reliability, and affordability.

By choosing a trusted manufacturer, businesses can ensure consistent quality, higher productivity, and long-term profitability in the competitive tea industry.

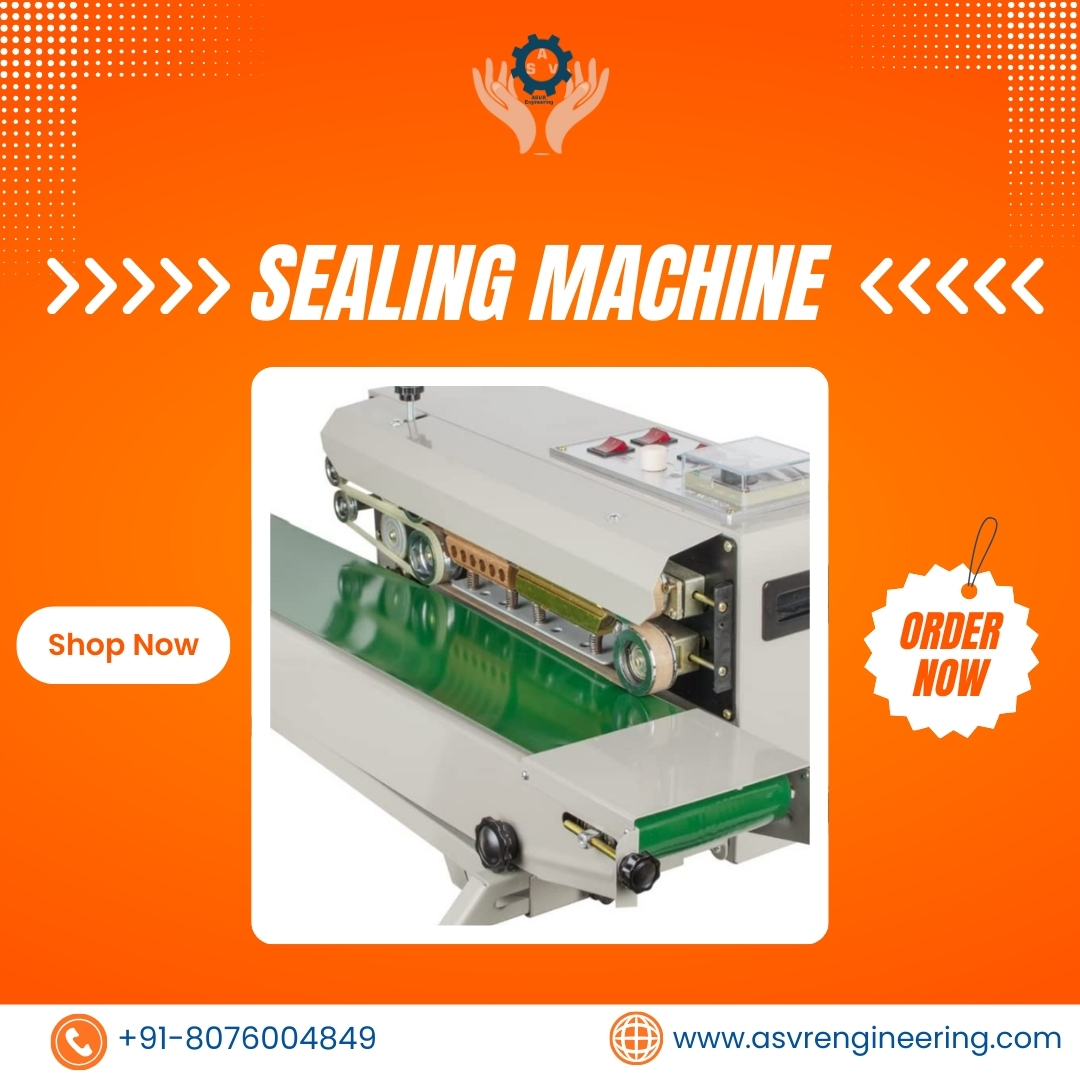

Contact Details

📞 Phone: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now

Related Posts

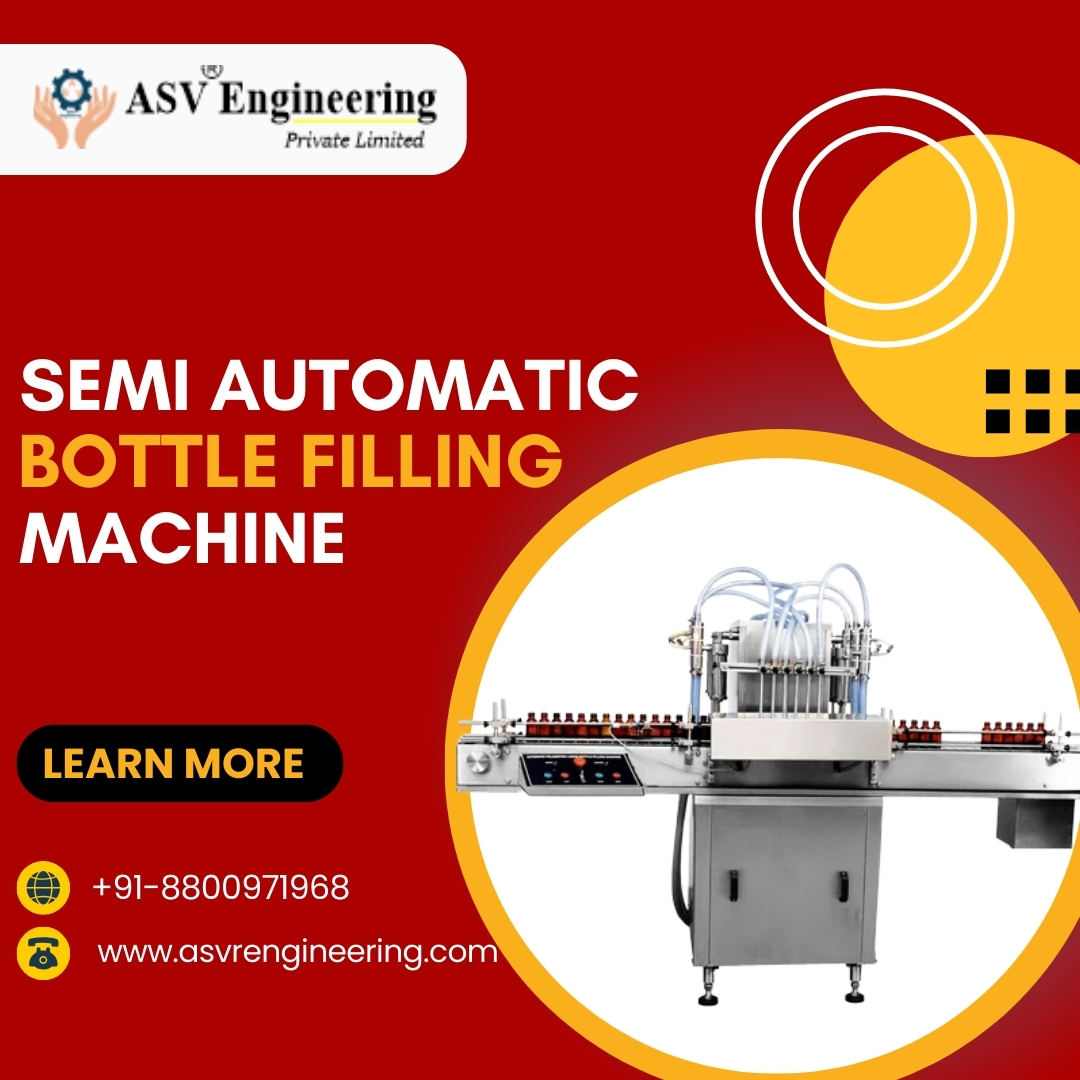

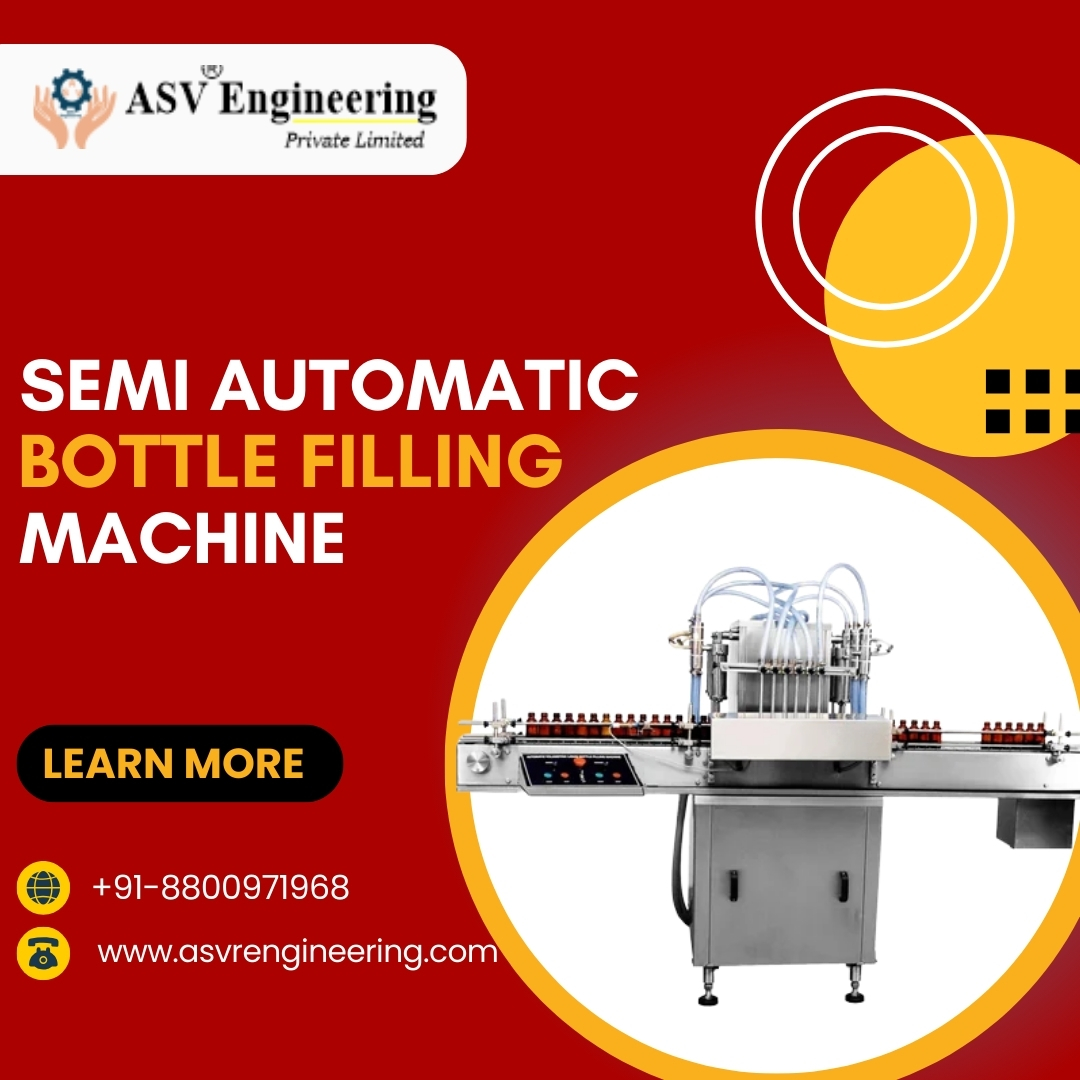

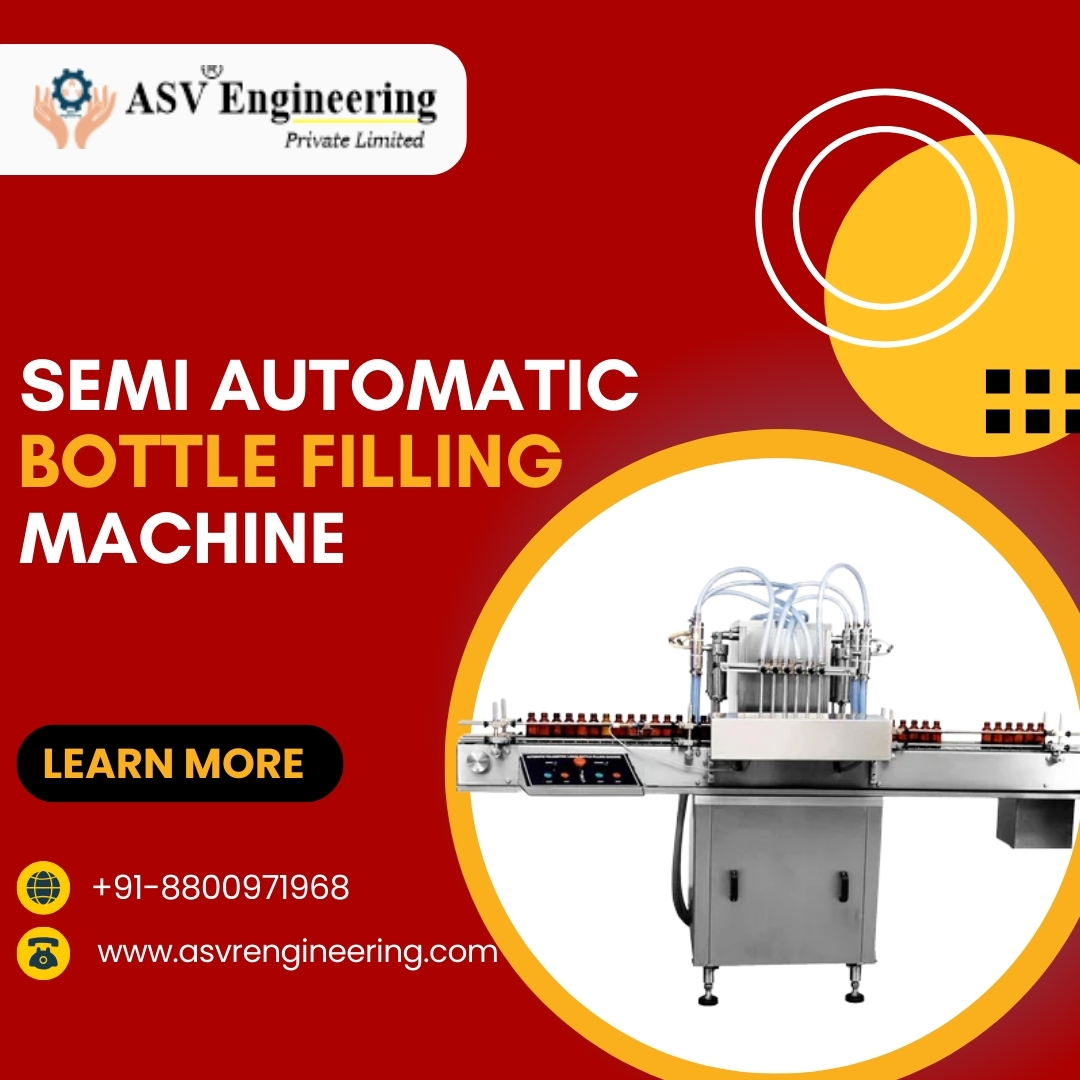

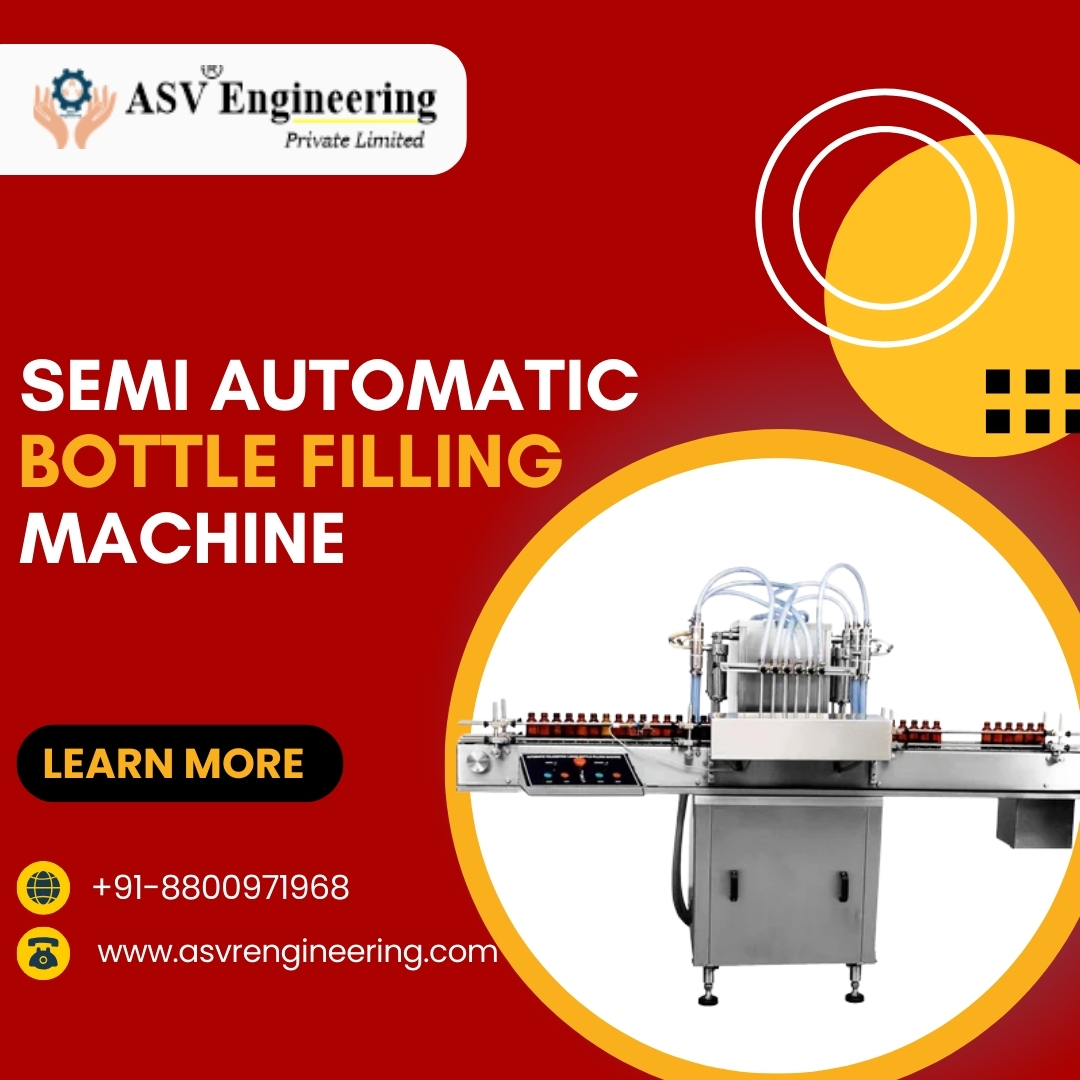

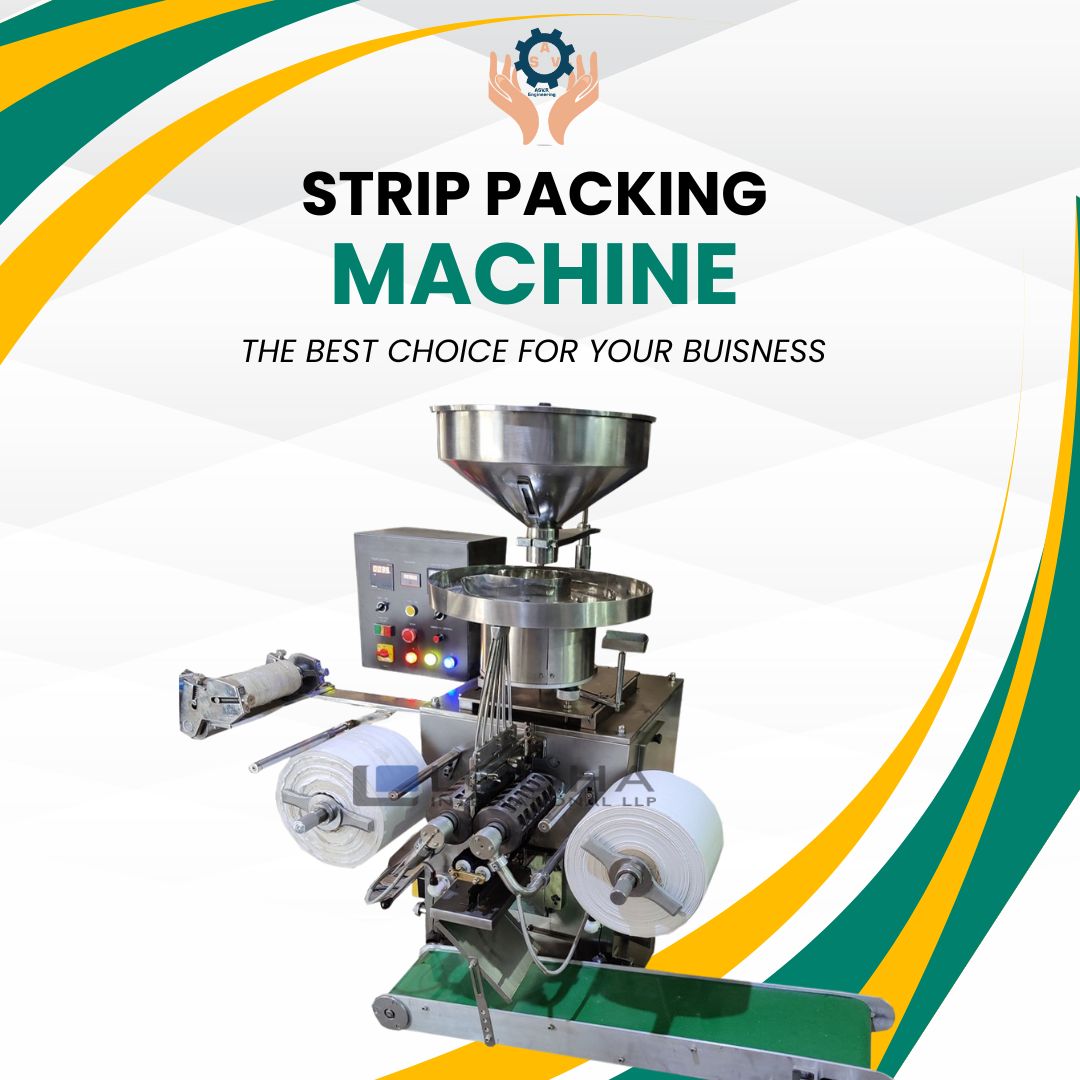

Leading Automatic Bottle Filling Machine Manufacturers for High-Speed Industrial Packaging Solutions

Trusted Automatic Milk Bag Packaging Machine Distributors for Dairy Plants, Milk Booths & FMCG Units

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)