Leading Automatic Milk Bag Packaging Machine Distributors Providing Hygienic, Energy-Efficient & Durable Systems

Price: ₹112000

In today’s fast-growing dairy industry, packaging is no longer just a final step—it is a critical process that defines product quality, shelf life, hygiene, and brand trust. As consumer demand for safe, fresh, and well-sealed milk continues to rise, dairy businesses are increasingly shifting towards advanced automation. This is where automatic milk bag packaging machines play a vital role.

As leading automatic milk bag packaging machine distributors, ASVR Engineering delivers high-performance, hygienic, and energy-efficient milk packaging systems designed to meet the evolving needs of modern dairy plants. From small milk collection centers to large-scale milk processing units, our machines ensure consistent output, minimal wastage, and long-term operational reliability.

Understanding Automatic Milk Bag Packaging Machines

An automatic milk bag packaging machine is a fully integrated system that performs milk filling, pouch forming, sealing, and cutting in a single continuous operation. These machines are designed to handle liquid milk efficiently while maintaining strict hygiene standards required by the dairy industry.

Unlike manual or semi-automatic methods, automatic systems eliminate human contact with milk during packaging, significantly reducing contamination risks. This ensures that milk reaches consumers in its purest and safest form.

Modern milk bag packaging machines are compatible with LDPE and other food-grade films and are capable of producing uniform pouches with strong seals, even during high-speed production cycles.

Why Automation Is Essential in Milk Packaging

The dairy sector operates on thin margins and high volumes. Any leakage, spillage, or downtime can lead to financial losses and product spoilage. Automatic milk packaging systems solve these challenges by offering:

-

Consistent pouch weight and size

-

High-speed production with minimal error

-

Reduced labor dependency

-

Improved hygiene and food safety

-

Lower operational costs over time

For distributors, cooperatives, and private dairies, automation ensures scalability and compliance with food safety regulations.

Hygienic Design for Safe Milk Packaging

Hygiene is the backbone of milk processing. Automatic milk bag packaging machines supplied by ASVR Engineering are manufactured using food-grade stainless steel and corrosion-resistant components. Smooth surface finishes prevent bacterial buildup and make cleaning easy.

Key hygiene features include:

-

Enclosed filling systems

-

Leak-proof sealing mechanisms

-

Minimal product exposure

-

Easy-to-clean contact parts

These features help dairy operators meet FSSAI and other regulatory standards while maintaining consumer trust.

Energy-Efficient Technology for Cost Savings

Energy consumption directly impacts profitability, especially in high-volume dairy operations. Modern milk bag packaging machines are engineered to deliver maximum output while consuming minimal power.

Energy-efficient motors, optimized heating elements, and intelligent control panels reduce electricity usage without compromising performance. Over time, this results in substantial savings on operational costs, making these machines a smart long-term investment.

Durability That Supports Continuous Operations

Dairy plants often operate for long hours, sometimes round-the-clock. Equipment durability is therefore non-negotiable. Automatic milk bag packaging machines from ASVR Engineering are built to withstand continuous use in demanding environments.

Heavy-duty frames, precision-engineered components, and robust sealing systems ensure long service life with minimal maintenance. This durability reduces downtime and enhances production efficiency.

Applications Across the Dairy Industry

Automatic milk bag packaging machines are suitable for a wide range of dairy applications, including:

-

Liquid milk packaging (toned, full cream, double toned, skimmed)

-

Flavored milk

-

Butter milk and lassi

-

Dairy beverages

These machines are ideal for:

-

Dairy cooperatives

-

Private milk brands

-

Milk collection centers

-

Large dairy processing plants

Customization Based on Production Needs

Every dairy operation is unique. Production volume, pouch size, and available space vary from plant to plant. ASVR Engineering offers customizable milk packaging solutions tailored to specific requirements.

Customization options include:

-

Output capacity (pouches per minute)

-

Pouch volume variations

-

Single-lane or multi-lane systems

-

Integration with existing dairy lines

This flexibility allows businesses to scale operations smoothly without replacing their entire setup.

User-Friendly Operation and Easy Maintenance

Advanced technology does not have to be complicated. Automatic milk bag packaging machines are designed with operator convenience in mind. Intuitive control panels allow easy parameter adjustments, while automated diagnostics help identify issues quickly.

Routine maintenance is simple, reducing the need for specialized technicians and lowering service costs. This ease of use ensures uninterrupted production and higher workforce efficiency.

Why Choose ASVR Engineering as Your Distributor

As a trusted distributor of automatic milk bag packaging machines, ASVR Engineering focuses on delivering value beyond just machinery. The company emphasizes reliability, transparency, and long-term customer relationships.

Key reasons to choose ASVR Engineering:

-

Proven expertise in packaging machinery

-

High-quality, tested equipment

-

Competitive pricing

-

Prompt technical support

-

Nationwide supply capability

From initial consultation to after-sales service, clients receive end-to-end support for their dairy packaging needs.

Supporting Growth of the Indian Dairy Sector

India is one of the world’s largest milk producers, and the demand for efficient dairy automation continues to grow. Automatic milk bag packaging machines are a crucial part of this growth, enabling dairies to maintain quality while expanding distribution.

By adopting advanced packaging systems, dairy businesses can improve brand image, reduce losses, and meet the rising expectations of modern consumers.

Future-Ready Packaging Solutions

With increasing focus on sustainability, modern milk packaging machines are designed to minimize film wastage and energy consumption. This not only reduces costs but also supports environmentally responsible operations.

Future-ready systems ensure that dairy plants remain competitive, compliant, and efficient in a rapidly evolving market.

Contact ASVR Engineering Today

If you are looking for leading automatic milk bag packaging machine distributors offering hygienic, energy-efficient, and durable systems, ASVR Engineering is your reliable partner.

📞 Contact Numbers:

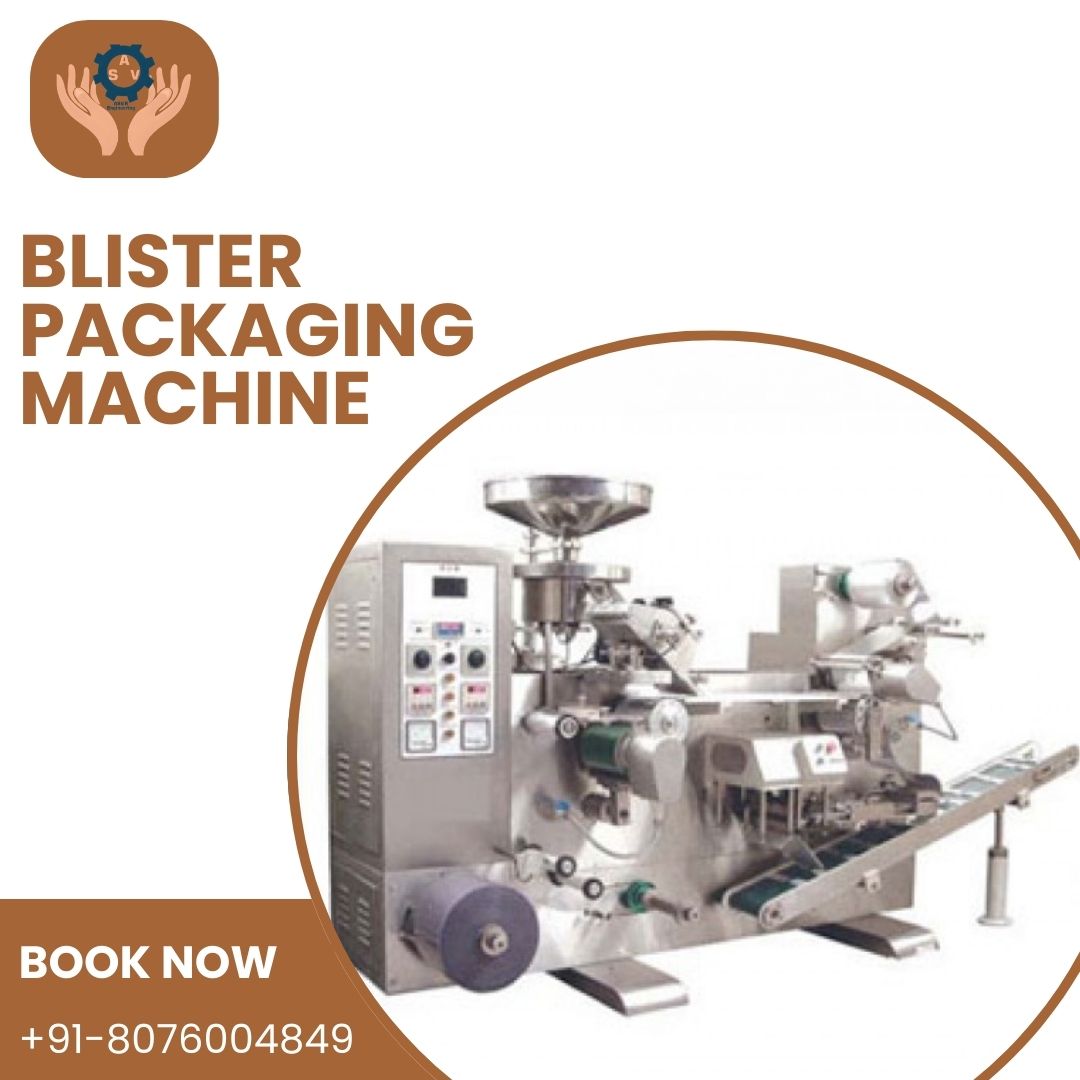

+91-8076004849

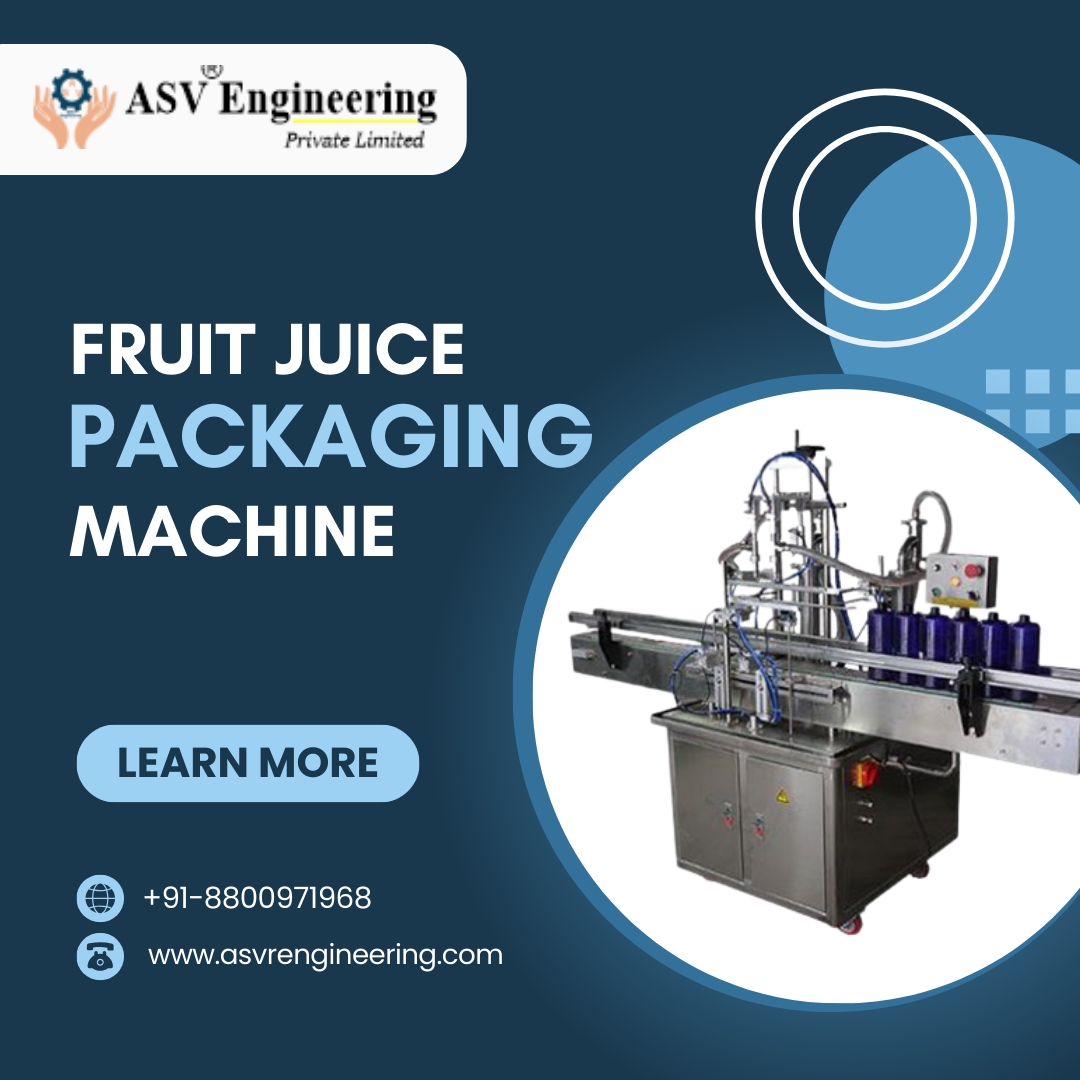

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Invest in advanced milk packaging technology and take your dairy operations to the next level with trusted solutions designed for performance, hygiene, and long-term success.

Buy Now

Related Posts

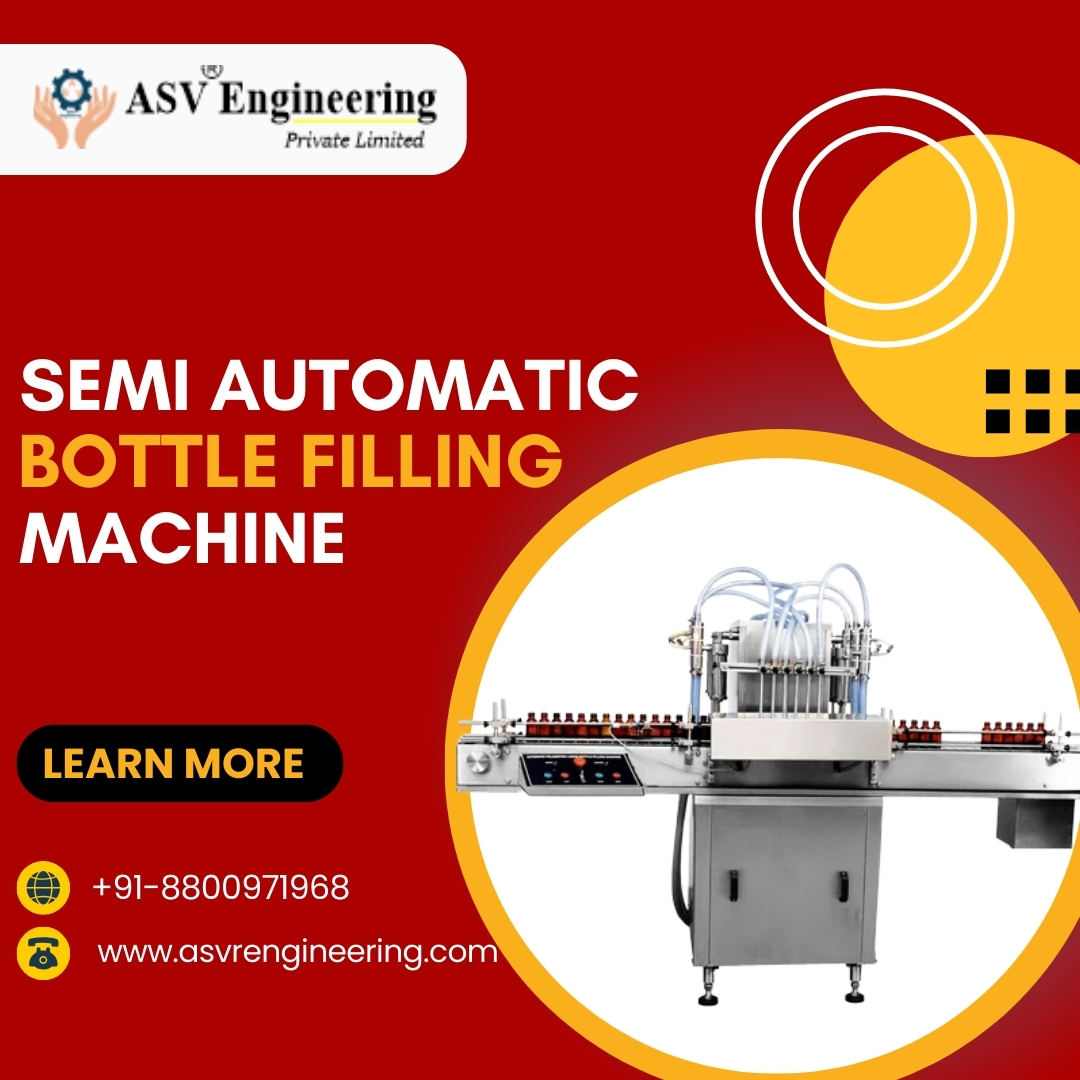

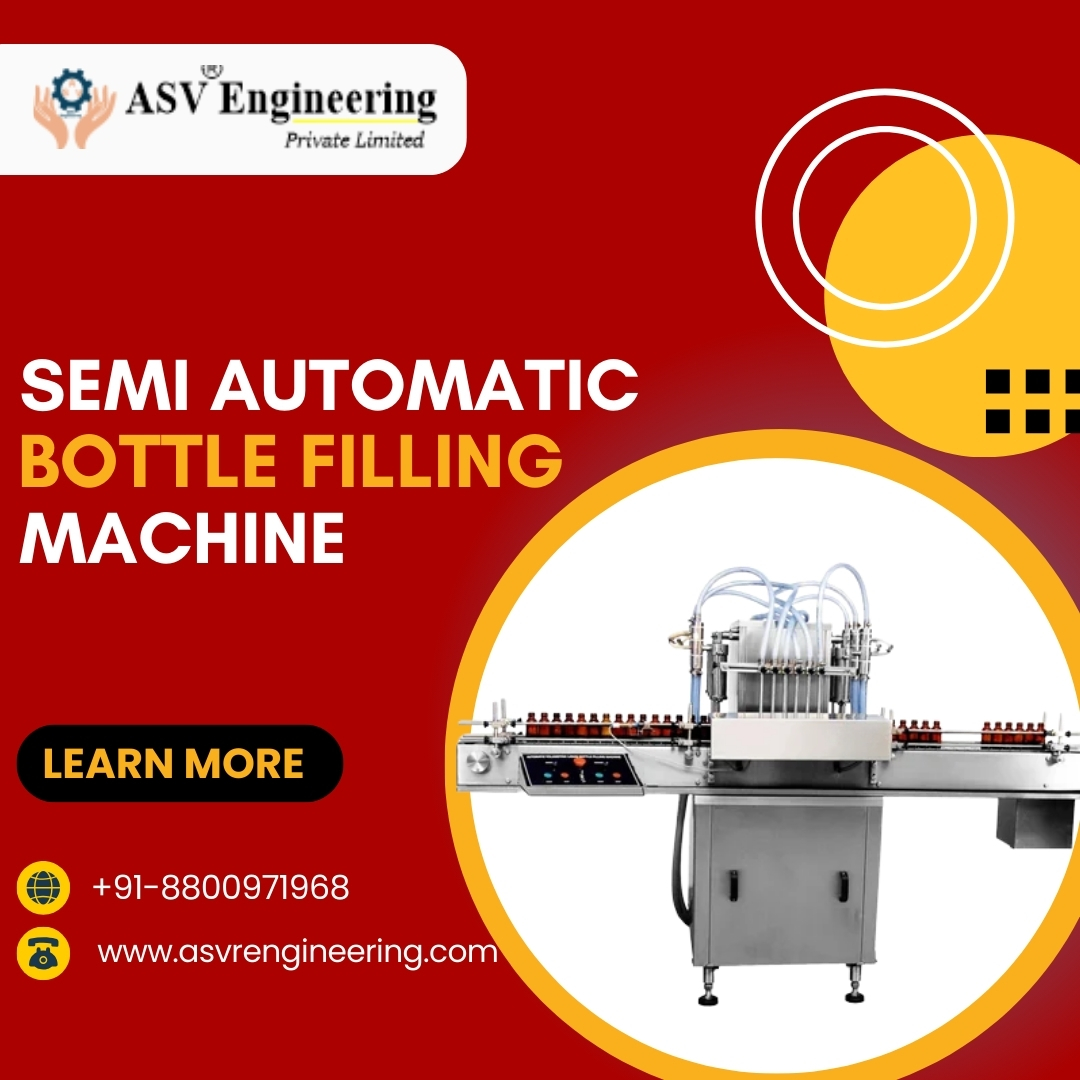

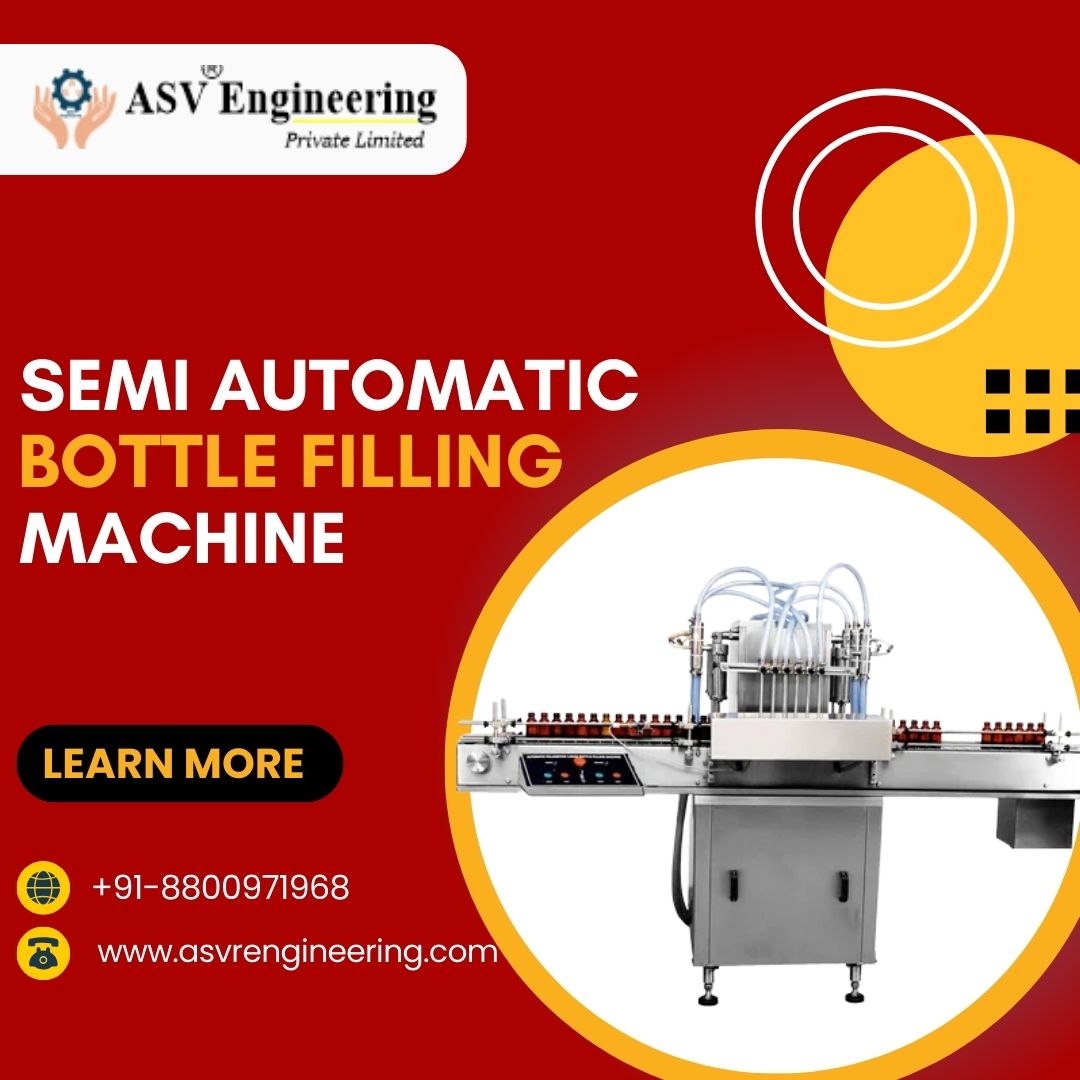

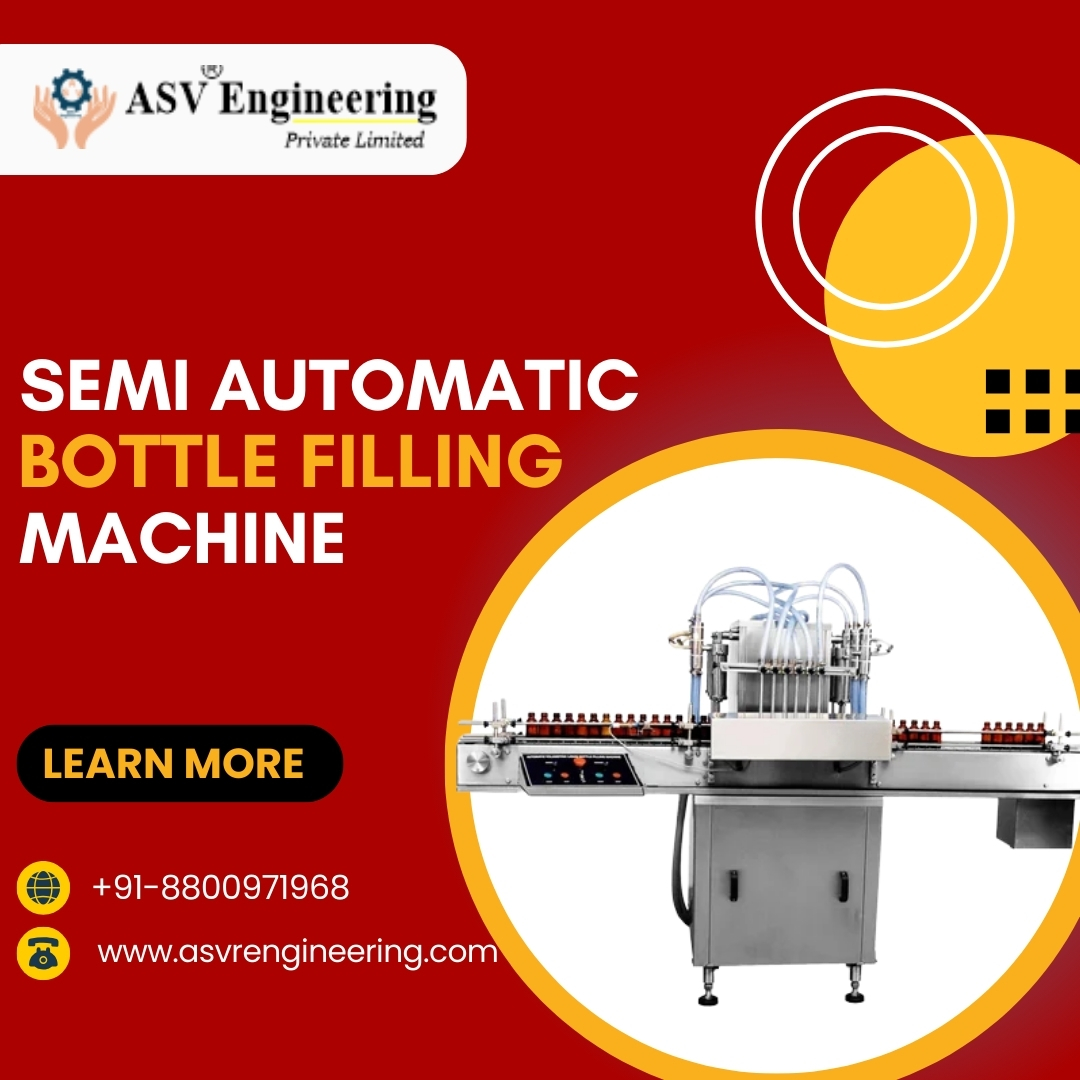

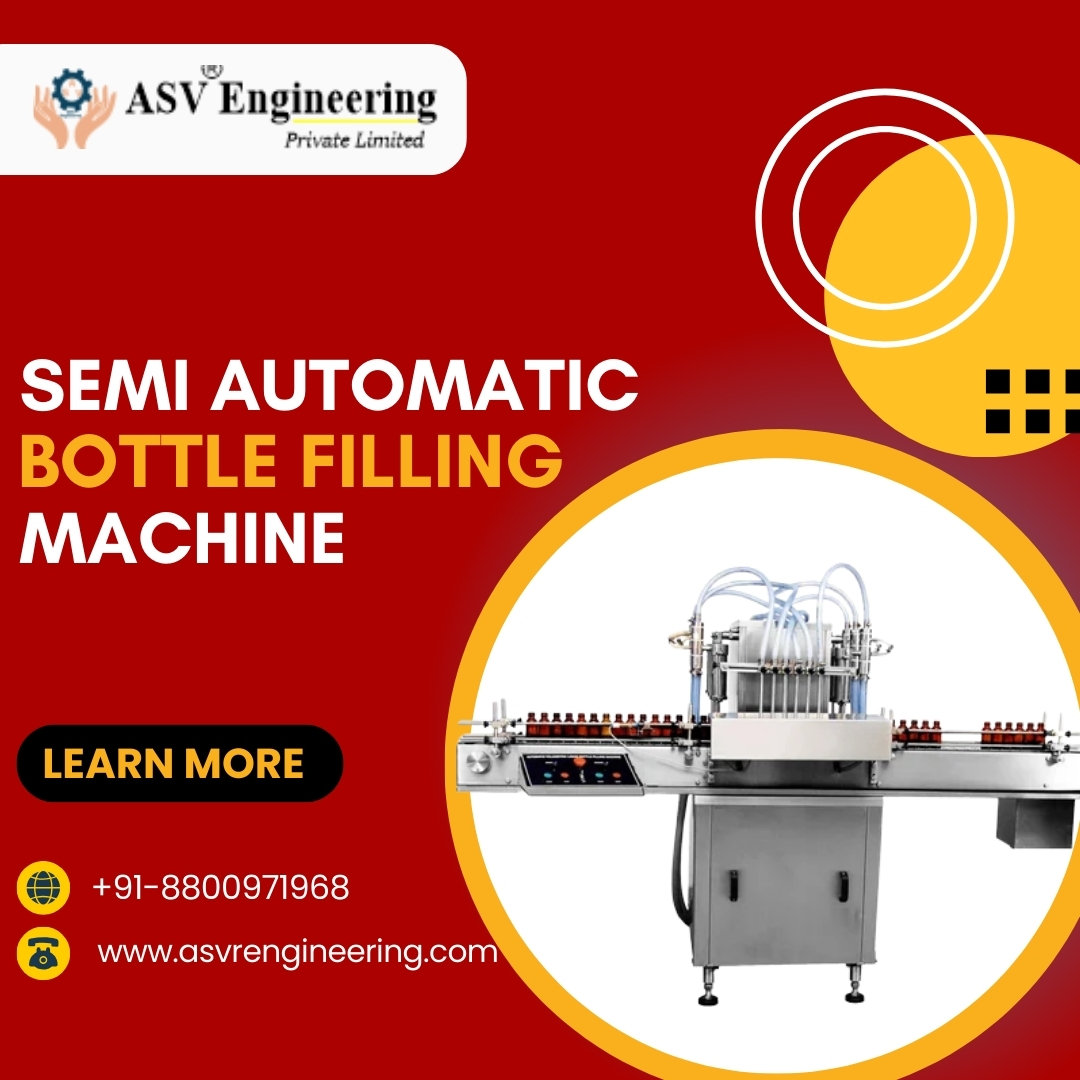

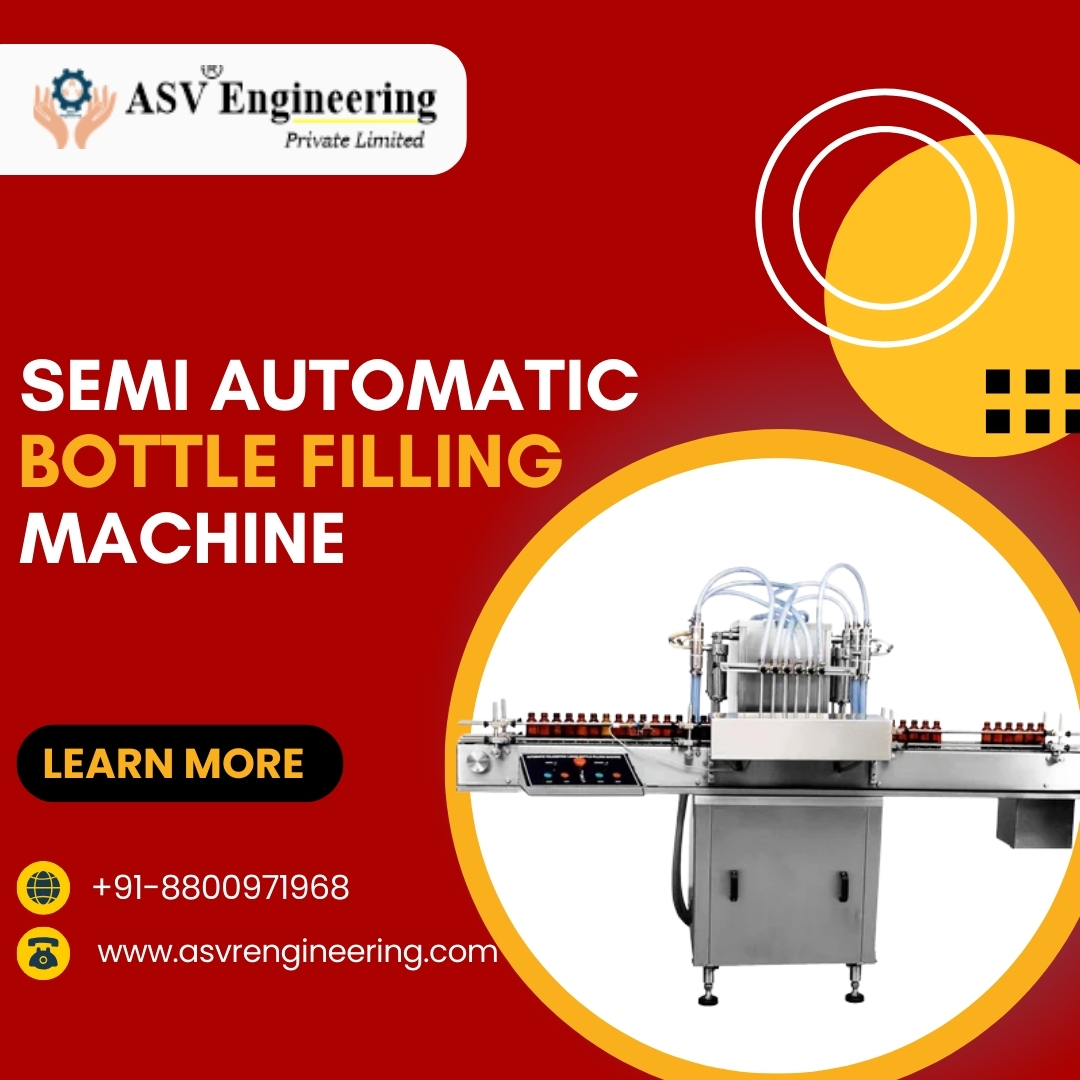

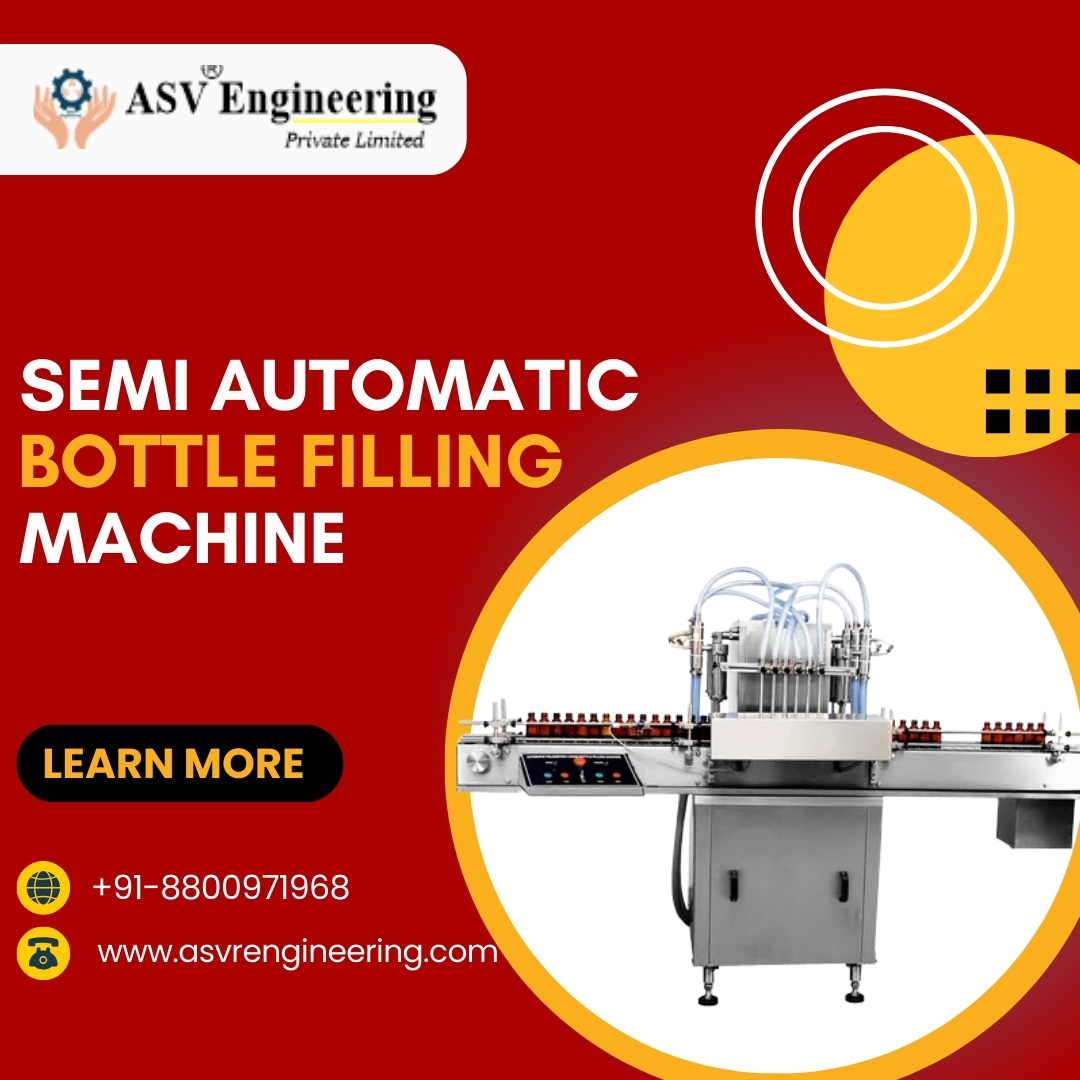

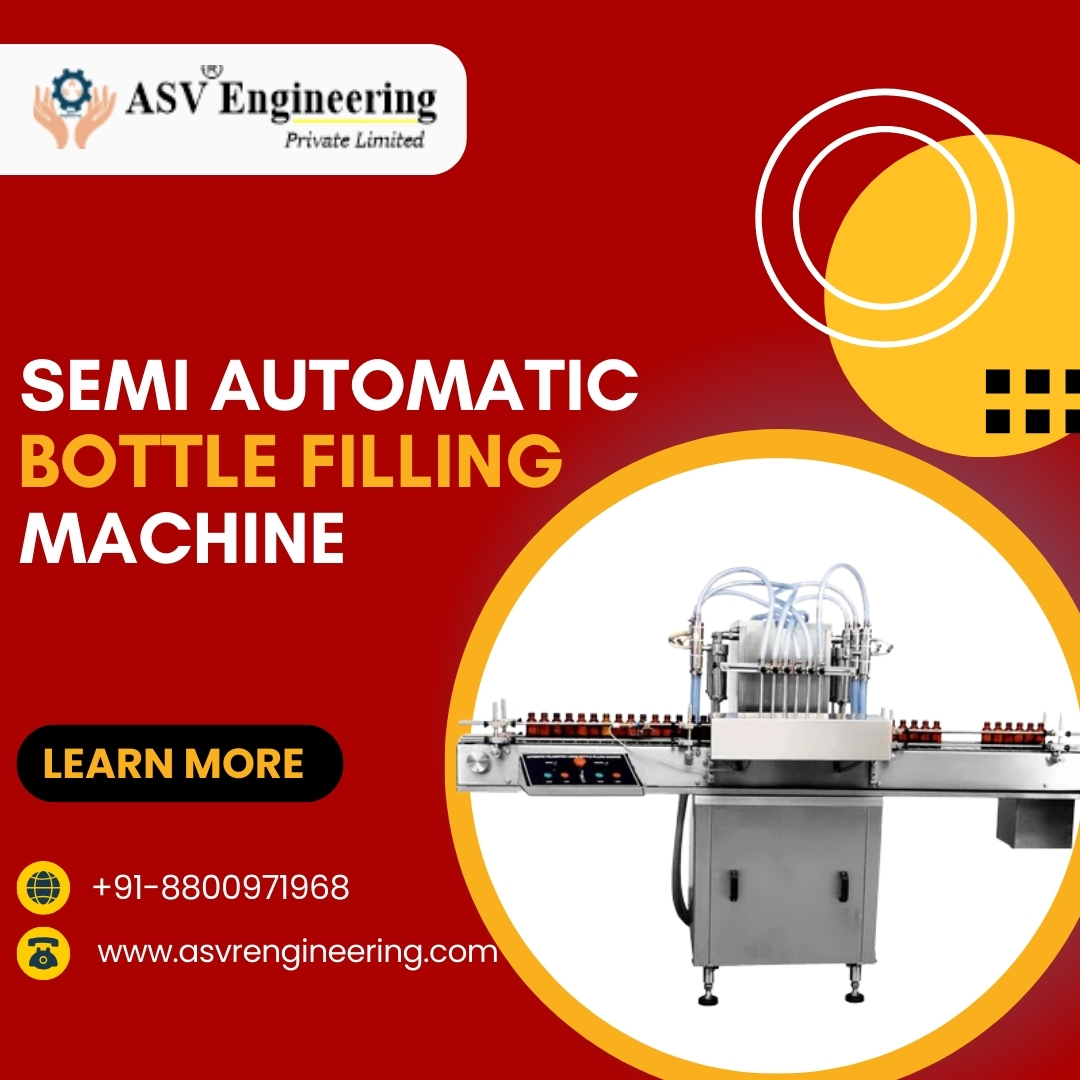

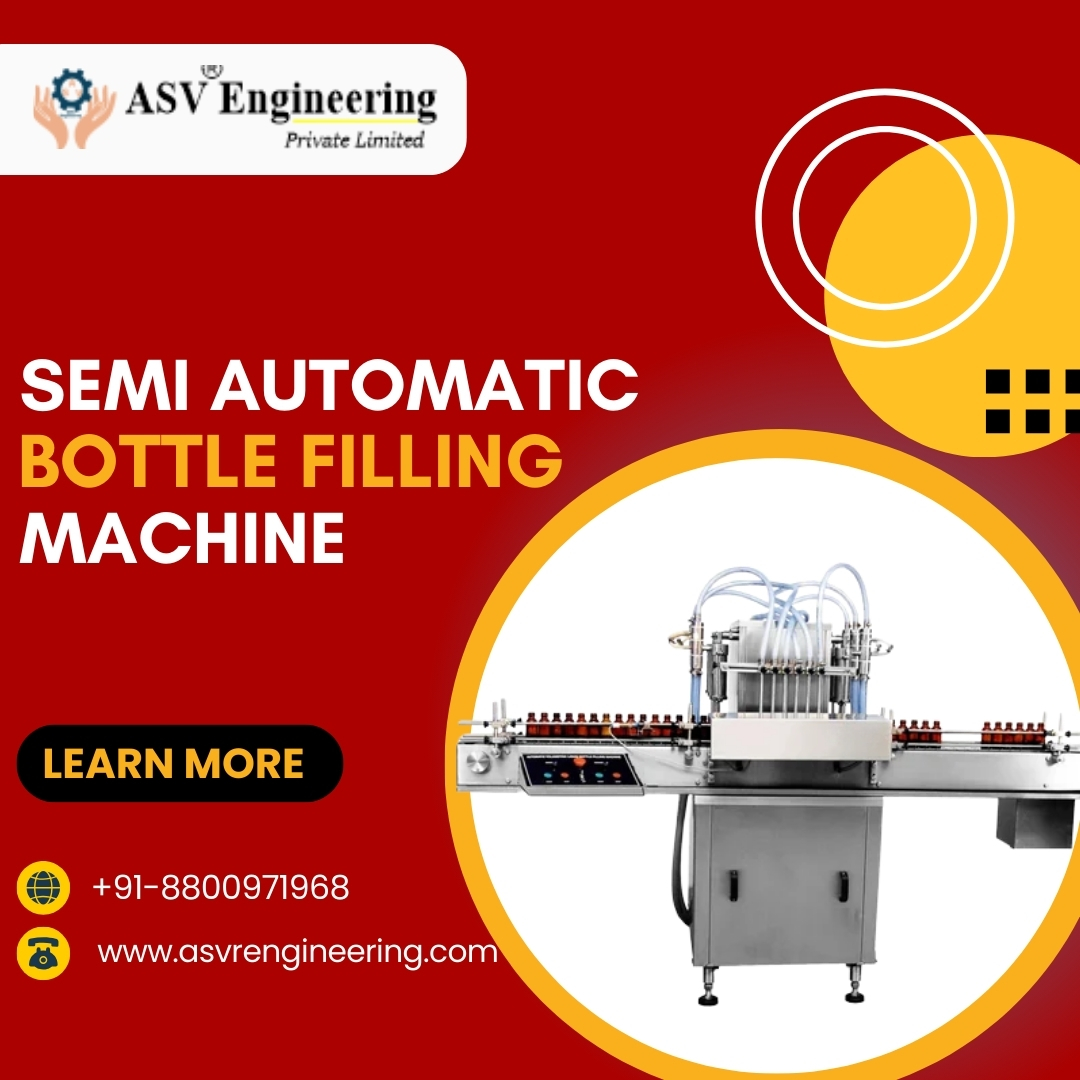

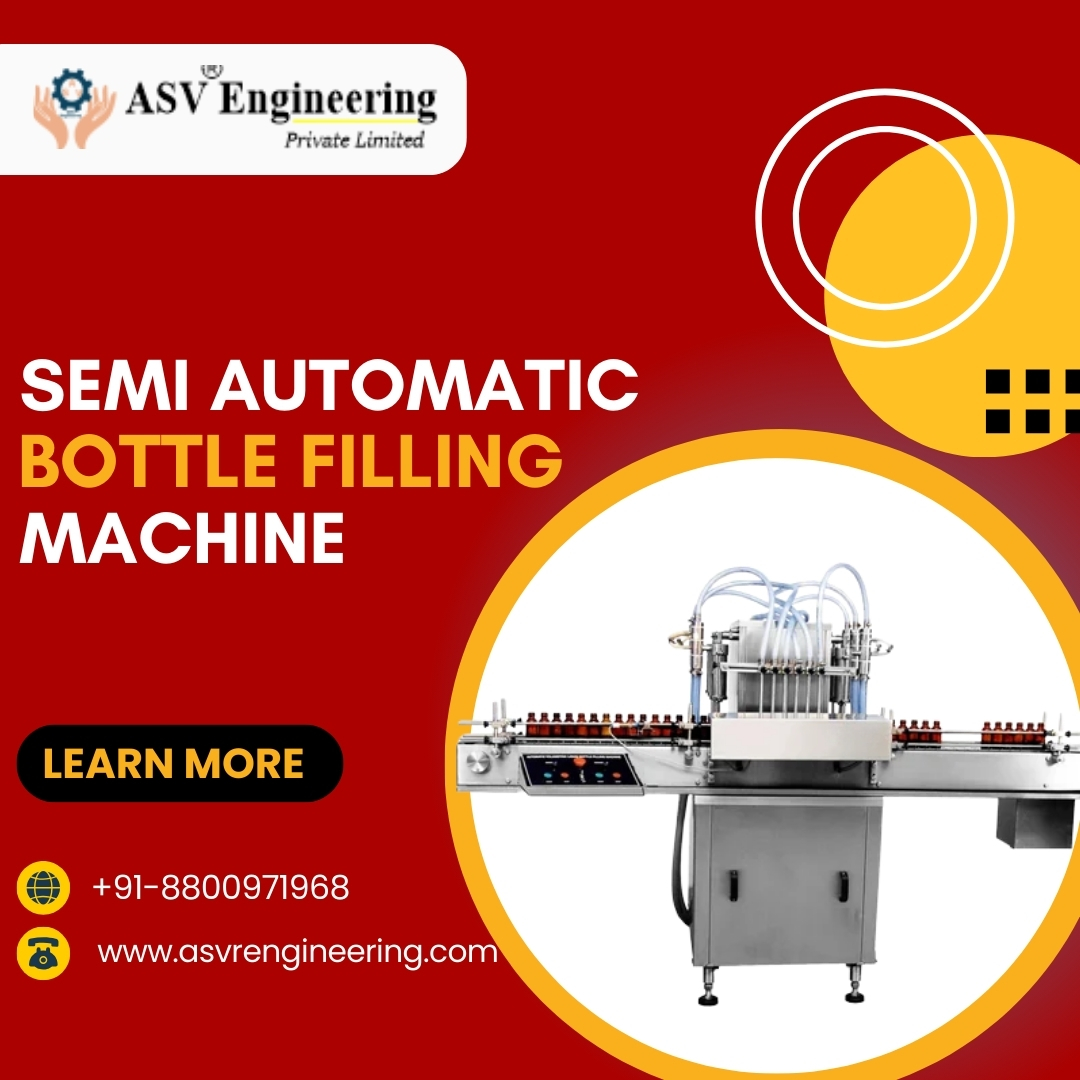

Leading Automatic Bottle Filling Machine Manufacturers for High-Speed Industrial Packaging Solutions

Trusted Automatic Milk Bag Packaging Machine Distributors for Dairy Plants, Milk Booths & FMCG Units

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

(14).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)