Automatic FFS Packaging Machine Importers | High-Speed Form Fill Seal Systems for Industrial Packaging

Introduction

In today’s competitive manufacturing environment, packaging is no longer just the final step of production—it is a critical function that directly impacts product safety, shelf life, logistics efficiency, and brand perception. Across industries such as food processing, pharmaceuticals, chemicals, agriculture, FMCG, and consumer goods, manufacturers are rapidly shifting from manual or semi-automatic packing methods to Automatic Form Fill Seal (FFS) Packaging Machines. These advanced systems deliver speed, precision, hygiene, and consistency at a scale that manual packaging simply cannot match.

As trusted Automatic FFS Packaging Machine Importers, ASVR Engineering plays a vital role in bridging global packaging technology with Indian industrial requirements. We bring internationally proven, high-performance FFS systems designed to meet modern production challenges while ensuring reliability, efficiency, and long-term operational value.

This comprehensive guide explains what Automatic FFS Packaging Machines are, how they work, their industrial benefits, applications, and why ASVR Engineering is the preferred partner for businesses seeking high-speed, future-ready packaging solutions.

What Is an Automatic FFS Packaging Machine?

An Automatic Form Fill Seal Packaging Machine is an integrated packaging system that forms a package from a flat roll of packaging film, fills it with product, and seals it—automatically, in a continuous process. Unlike pre-made pouch systems, FFS machines create packaging on demand, offering superior efficiency, reduced material cost, and greater design flexibility.

Key Stages of the FFS Process

-

Forming

Packaging film is unwound from a roll and shaped into a pouch or bag using forming collars or molds. -

Filling

The product—powder, granule, liquid, or solid—is accurately dispensed into the formed package. -

Sealing

The package is heat-sealed to ensure leak-proof, tamper-resistant, and hygienic closure. -

Cutting & Discharge

Finished packs are cut and discharged for secondary packaging or direct distribution.

This streamlined process enables manufacturers to achieve high output with minimal manual intervention.

Types of Automatic FFS Packaging Machines

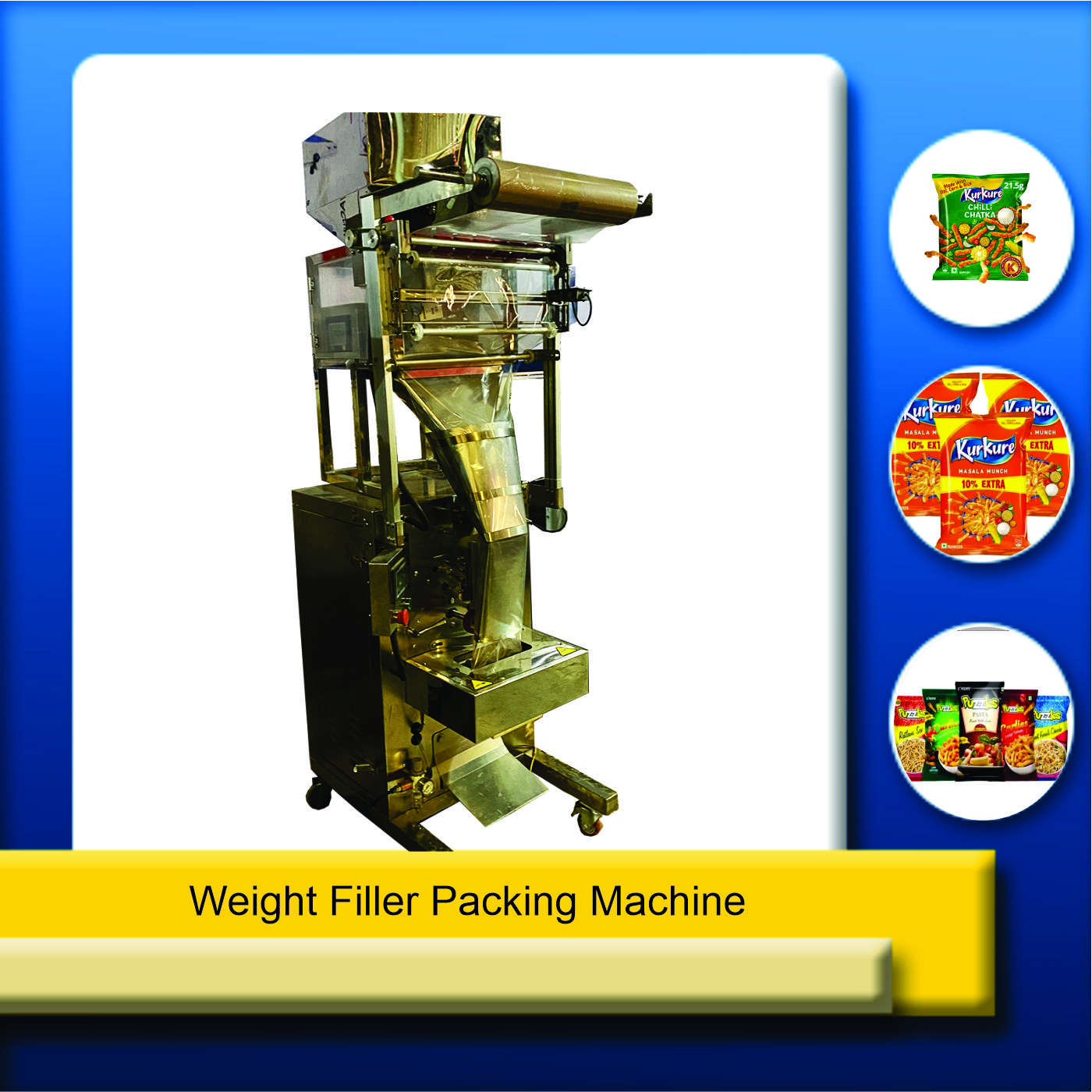

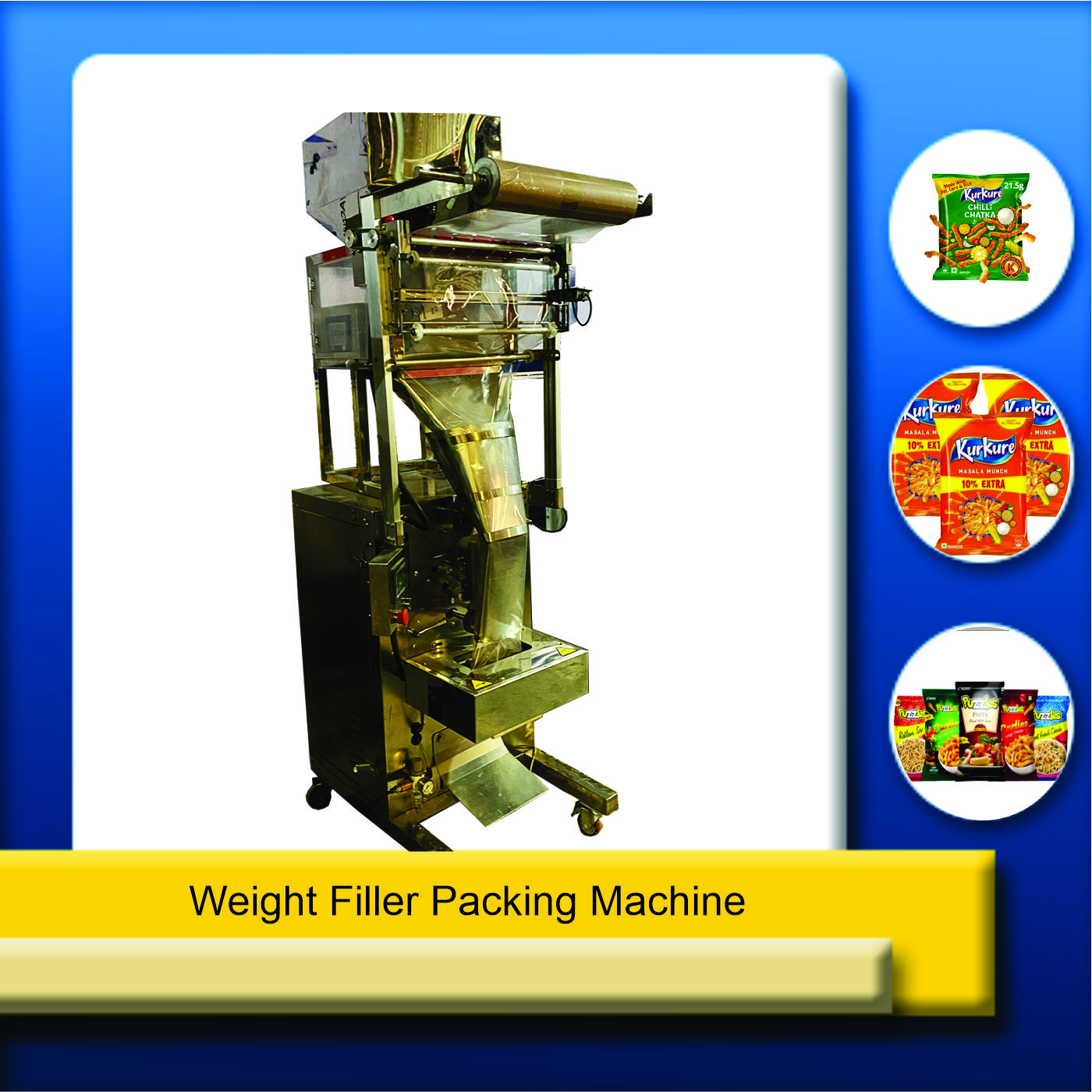

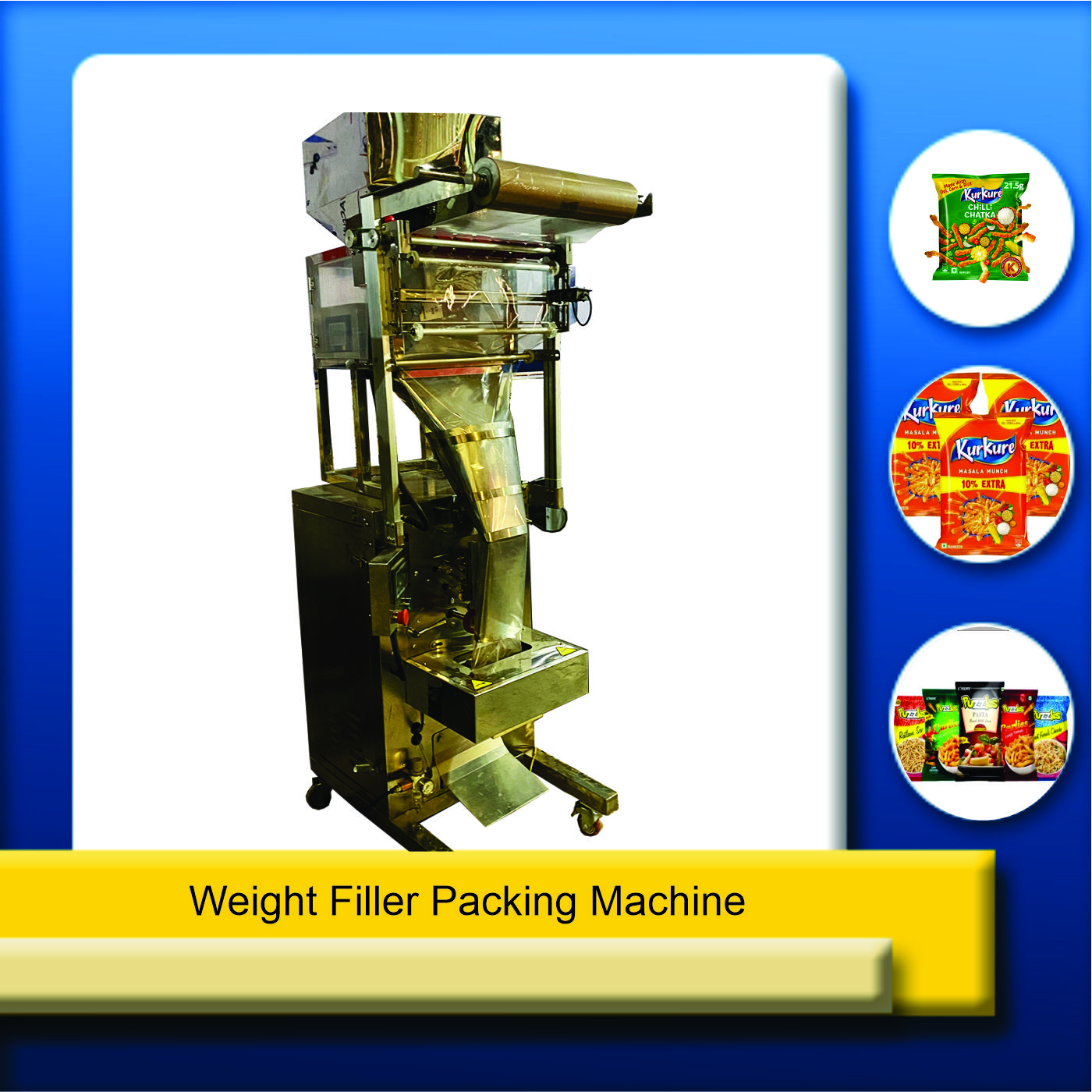

Vertical Form Fill Seal (VFFS) Machines

VFFS machines are widely used for packing free-flowing and semi-free-flowing products such as grains, snacks, sugar, detergent powder, spices, pulses, and fertilizers. The product is dropped vertically into the pouch, making these machines ideal for high-speed operations.

Horizontal Form Fill Seal (HFFS) Machines

HFFS machines are suitable for solid, fragile, or irregularly shaped products such as biscuits, soap bars, medical devices, chocolates, and hardware items. They offer excellent product presentation and are ideal where pack aesthetics matter.

Specialized FFS Systems

-

Liquid and paste FFS machines for oils, sauces, milk, and chemicals

-

Multi-lane FFS machines for extremely high output

-

Stick pack and sachet machines for single-serve packaging

As experienced importers, ASVR Engineering supplies all these variants based on application-specific needs.

Why Industries Prefer Automatic FFS Packaging Systems

1. High-Speed Production

Modern FFS machines can produce hundreds of packs per minute, significantly increasing throughput and meeting large-scale demand without compromising quality.

2. Cost Efficiency

Using roll film instead of pre-made pouches reduces packaging material cost. Automation also lowers labor expenses and minimizes product wastage.

3. Consistent Quality & Accuracy

Advanced sensors, PLC controls, and servo-driven systems ensure precise filling, consistent sealing, and uniform pack appearance.

4. Enhanced Hygiene & Safety

FFS systems are designed for minimal human contact, making them ideal for food and pharmaceutical industries where hygiene standards are critical.

5. Flexible Packaging Options

Manufacturers can easily switch between pouch sizes, shapes, and materials, allowing faster adaptation to market trends.

Industrial Applications of Automatic FFS Packaging Machines

Automatic FFS systems are used across a wide range of industries:

Food & Beverage Industry

-

Snacks, chips, namkeen

-

Rice, wheat, flour, pulses

-

Sugar, salt, spices

-

Milk powder, coffee, tea

-

Sauces, oils, and liquid products

Pharmaceutical & Healthcare

-

Tablets, capsules, powders

-

Medical disposables

-

Nutraceutical products

Chemical & Industrial Goods

-

Detergent powder and liquid

-

Industrial chemicals

-

Adhesives and lubricants

Agriculture & Animal Feed

-

Seeds, grains, fertilizers

-

Cattle feed and supplements

FMCG & Consumer Products

-

Soap bars, shampoos, cosmetics

-

Personal care products

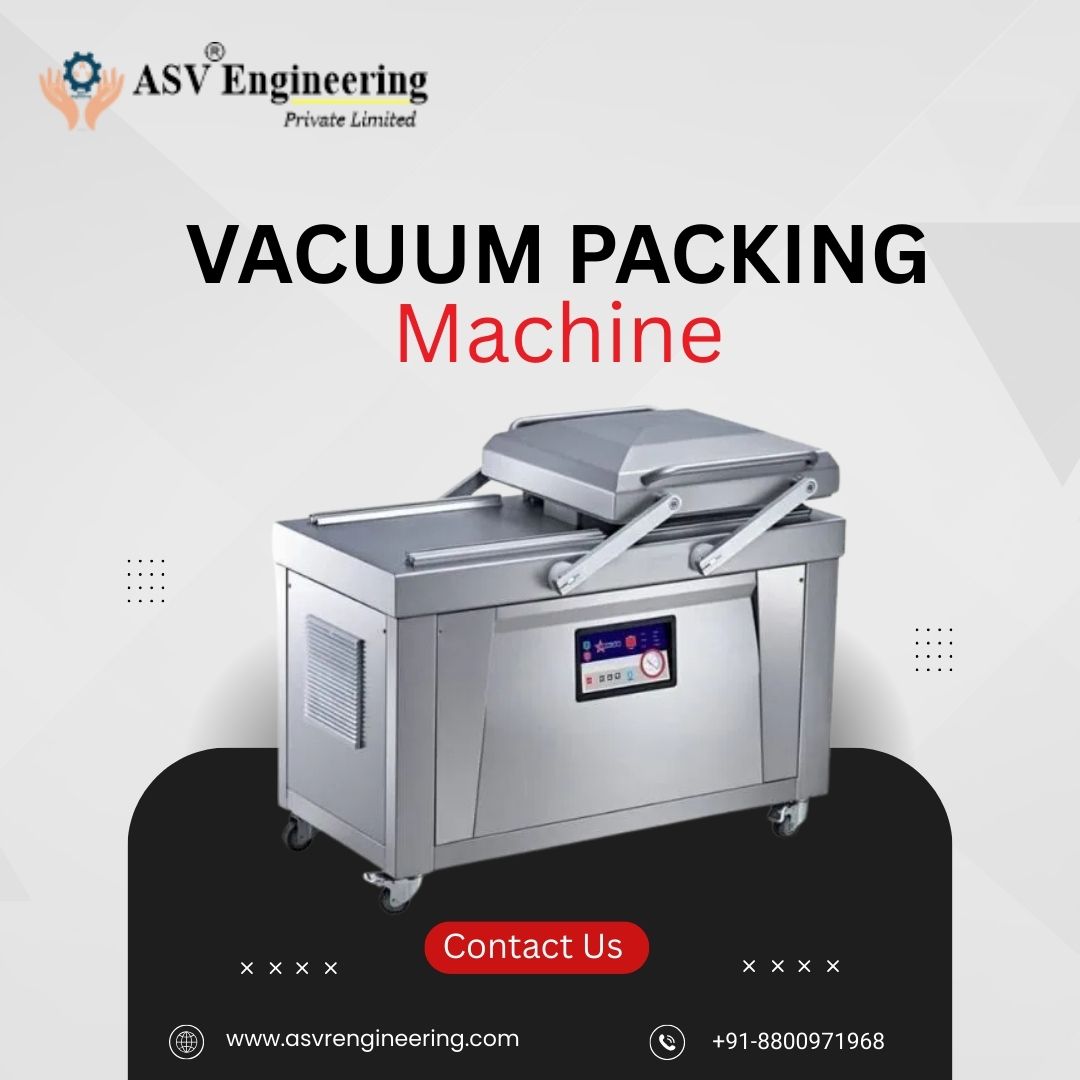

Role of ASVR Engineering as Automatic FFS Packaging Machine Importers

Choosing the right importer is as important as choosing the right machine. At ASVR Engineering, we go beyond simply supplying equipment—we deliver complete packaging solutions.

Global Technology, Local Expertise

We partner with internationally reputed manufacturers to import advanced FFS machines that meet global performance standards while ensuring suitability for Indian operating conditions.

Application-Based Machine Selection

Every industry and product has unique packaging requirements. Our technical team carefully evaluates:

-

Product characteristics

-

Desired output speed

-

Packaging material

-

Budget and scalability

This ensures you receive a machine perfectly aligned with your production goals.

Quality Assurance & Compliance

All imported machines undergo strict quality checks and comply with relevant industrial and safety standards, including food-grade and pharmaceutical norms where required.

Installation, Training & Support

Our services include:

-

On-site installation and commissioning

-

Operator and maintenance training

-

Ongoing technical support and spare parts availability

Key Features of High-Speed FFS Packaging Machines We Import

-

Robust stainless steel construction

-

PLC-based intelligent control systems

-

Servo-driven motors for precision

-

Multi-head weighers and auger fillers

-

Touchscreen HMI panels

-

Energy-efficient design

-

Low maintenance and long service life

These features ensure reliable performance even in continuous, high-volume production environments.

Advantages of Partnering with ASVR Engineering

Trusted Industry Experience

With years of experience in industrial machinery supply, ASVR Engineering understands real-world production challenges and offers practical, result-oriented solutions.

Transparent Pricing

We believe in honest, competitive pricing with no hidden costs, helping businesses plan investments confidently.

End-to-End Solutions

From consultation and machine selection to after-sales service, we manage the complete lifecycle of your packaging system.

Strong After-Sales Network

Our responsive support team ensures minimal downtime and maximum operational efficiency for your packaging line.

Future of Industrial Packaging with FFS Technology

The future of packaging lies in automation, smart manufacturing, and sustainability. Automatic FFS Packaging Machines are evolving with:

-

IoT-enabled monitoring

-

Predictive maintenance systems

-

Eco-friendly packaging materials compatibility

-

Higher speeds with lower energy consumption

By investing in advanced FFS systems today, manufacturers stay ahead of competition and future-proof their operations.

Conclusion

Automatic FFS Packaging Machines are no longer a luxury—they are a necessity for industries aiming to scale efficiently, maintain quality, and stay competitive. As reliable Automatic FFS Packaging Machine Importers, ASVR Engineering brings world-class Form Fill Seal systems to Indian manufacturers, empowering them with speed, precision, and performance.

If you are planning to upgrade your packaging line or set up a new automated facility, ASVR Engineering is your trusted partner for high-speed, durable, and cost-effective FFS packaging solutions.

📞 Contact Numbers: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now

(14).jpg)

(14).jpg)

(14).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

.png)

.png)

.png)

(6).jpg)

.png)

(6).jpg)