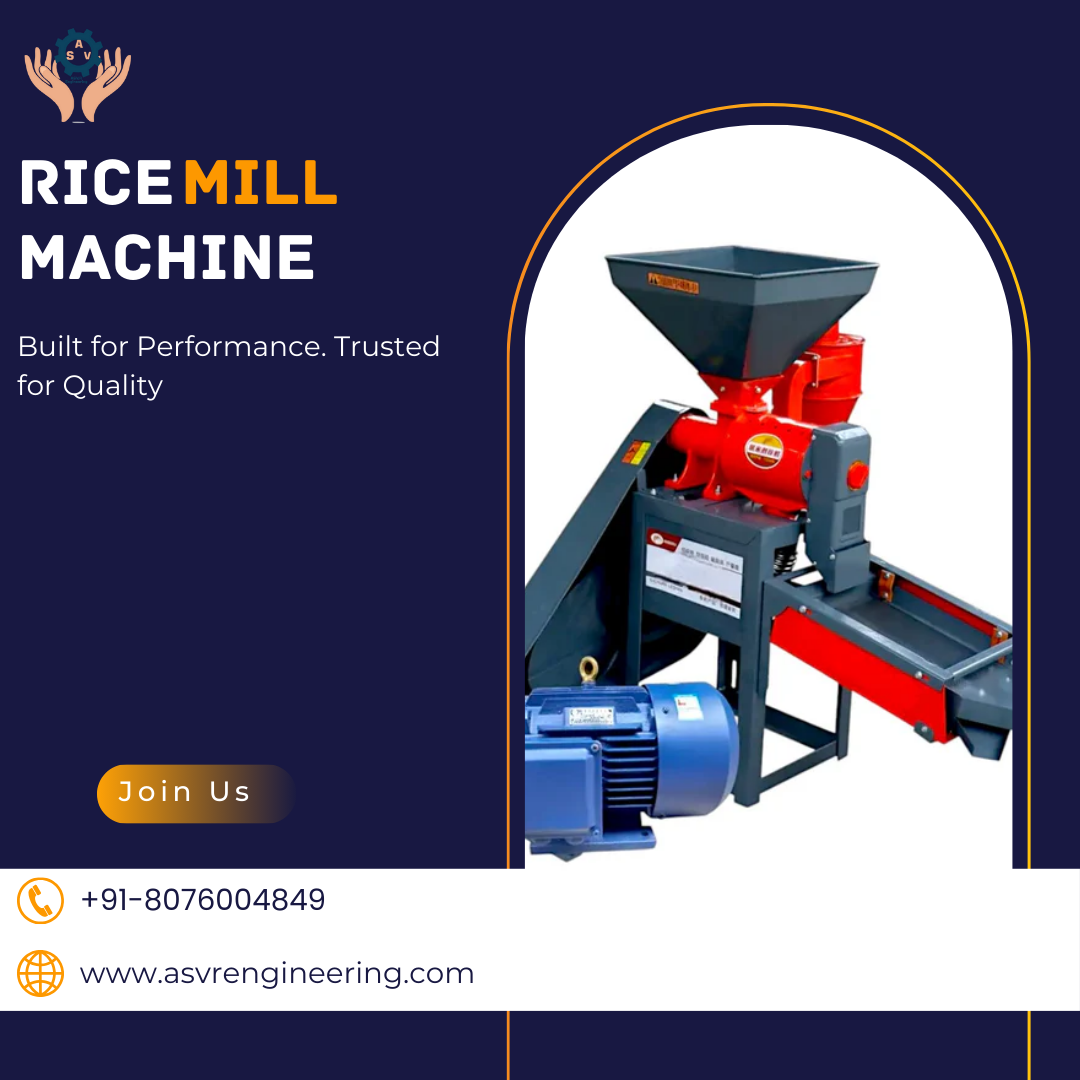

Trusted Rice Puffing Machine Manufacturers in India for Automatic & Semi-Automatic Solutions

Price: ₹107000

India is one of the largest producers and consumers of rice-based snacks in the world. Among these, puffed rice (murmura) holds a special place due to its affordability, nutritional value, and widespread consumption across urban and rural markets. From street vendors to packaged food brands, the demand for high-quality puffed rice continues to grow every year. To meet this rising demand, food processors need reliable, efficient, and long-lasting rice puffing machines.

Choosing the right manufacturer is just as important as choosing the right machine. A well-designed rice puffing machine ensures consistent quality, lower production cost, energy efficiency, and long-term business profitability. This is where ASVR Engineering stands out as one of the trusted rice puffing machine manufacturers in India, offering both automatic and semi-automatic solutions designed for Indian production conditions.

Understanding the Rice Puffing Process

Rice puffing is a precise process that involves controlled heating, pressure release, and moisture management. Raw or parboiled rice grains are heated under specific temperature conditions, causing the moisture inside the grain to vaporize rapidly. This expansion results in light, crispy puffed rice.

Modern rice puffing machines are designed to automate this process, ensuring:

-

Uniform puffing

-

Consistent size and texture

-

Minimal breakage

-

Higher yield per batch

Traditional manual methods often lead to uneven quality, higher wastage, and increased labor costs. By investing in a professionally manufactured rice puffing machine, businesses can scale production while maintaining quality standards.

Why Demand for Rice Puffing Machines Is Growing in India

The Indian snack food market has witnessed rapid growth due to changing lifestyles, increased urbanization, and rising demand for ready-to-eat foods. Puffed rice is no longer limited to local consumption; it is now packaged, branded, and exported.

Key factors driving demand include:

-

Growth of small and medium food processing units

-

Expansion of FMCG snack brands

-

Low investment, high return food businesses

-

Increasing preference for hygienic, machine-processed food

As a result, manufacturers who can supply durable, efficient, and scalable rice puffing machines are becoming highly sought after.

Automatic vs Semi-Automatic Rice Puffing Machines

Understanding the difference between automatic and semi-automatic rice puffing machines helps buyers make informed decisions.

Semi-Automatic Rice Puffing Machines

Semi-automatic machines are ideal for:

-

Small to medium-scale production

-

Start-ups entering the puffed rice business

-

Entrepreneurs with limited initial investment

These machines require some manual intervention but still offer significant advantages over traditional methods. They provide better temperature control, uniform puffing, and reduced labor fatigue.

Automatic Rice Puffing Machines

Automatic rice puffing machines are designed for:

-

Large-scale commercial production

-

Continuous operation with minimal manpower

-

Consistent output quality

With automated feeding, heating, puffing, and discharge mechanisms, these machines deliver high output while maintaining hygiene and energy efficiency.

ASVR Engineering offers both options, allowing businesses to scale smoothly as demand increases.

Why ASVR Engineering Is a Trusted Name in Rice Puffing Machines

ASVR Engineering has earned its reputation through engineering precision, quality manufacturing, and customer-centric service. Their machines are built keeping Indian raw materials, operating conditions, and power availability in mind.

Key Strengths of ASVR Engineering

1. Robust Build Quality

Machines are manufactured using high-grade steel and industrial-quality components that ensure durability even in continuous operation.

2. Efficient Heating System

Optimized heating mechanisms reduce fuel or electricity consumption while maintaining consistent puffing quality.

3. Custom-Designed Solutions

Machines can be tailored based on production capacity, space availability, and automation requirements.

4. Low Maintenance Design

Easy access to components ensures quick cleaning and minimal downtime.

5. Consistent Output Quality

Uniform puffing improves product appearance, texture, and shelf life.

Applications of Rice Puffing Machines

Rice puffing machines manufactured by ASVR Engineering are widely used across multiple segments:

-

Small-scale murmura manufacturing units

-

Medium and large food processing plants

-

FMCG snack manufacturing companies

-

Contract food manufacturers

-

Export-oriented food processing businesses

Whether the requirement is local market supply or large-scale commercial production, the machines are designed to adapt seamlessly.

Advantages of Investing in a High-Quality Rice Puffing Machine

Investing in a professionally manufactured rice puffing machine delivers long-term benefits:

-

Higher production efficiency

-

Reduced raw material wastage

-

Improved hygiene standards

-

Lower labor dependency

-

Better profit margins

A reliable machine also reduces breakdown frequency, saving both time and repair costs.

Energy Efficiency and Cost Effectiveness

Energy consumption is a major concern in food processing operations. ASVR Engineering focuses on designing machines that optimize heat usage and minimize energy loss. This directly translates into lower operating costs and improved sustainability.

Efficient machines help businesses remain competitive, especially in price-sensitive markets like India.

Quality Control and Safety Standards

Food safety and hygiene are critical in today’s market. Machines are designed to meet modern food processing standards, ensuring:

-

Safe contact surfaces

-

Easy cleaning and maintenance

-

Reduced contamination risk

This makes the machines suitable for businesses aiming to supply organized retail chains and branded markets.

After-Sales Support and Technical Assistance

One of the biggest challenges buyers face is lack of after-sales support. ASVR Engineering provides reliable technical guidance, spare part availability, and maintenance support, ensuring smooth long-term operation.

Prompt support helps businesses avoid prolonged downtime and maintain steady production schedules.

Choosing the Right Rice Puffing Machine Manufacturer

When selecting a manufacturer, buyers should consider:

-

Manufacturing experience

-

Quality of materials used

-

Customization options

-

Technical support availability

-

Proven customer satisfaction

ASVR Engineering fulfills all these criteria, making it a preferred choice among rice puffing machine buyers across India.

Why Indian Manufacturers Are Preferred Globally

Indian rice puffing machine manufacturers are known for offering the perfect balance of quality, affordability, and adaptability. Machines are designed for diverse operating conditions and raw material variations, making them suitable for both domestic and international markets.

ASVR Engineering contributes to this reputation by consistently delivering machines that perform reliably across different production environments.

Conclusion

The growing demand for puffed rice presents a profitable opportunity for food entrepreneurs and manufacturers. However, success in this business depends heavily on the quality and efficiency of the rice puffing machine used.

As one of the trusted rice puffing machine manufacturers in India, ASVR Engineering provides automatic and semi-automatic rice puffing machines that combine performance, durability, and cost efficiency. Their focus on quality engineering, customer support, and practical design makes them a dependable partner for businesses of all sizes.

For entrepreneurs looking to start or scale their puffed rice production, investing in the right machine from a trusted manufacturer is the first step toward long-term success.

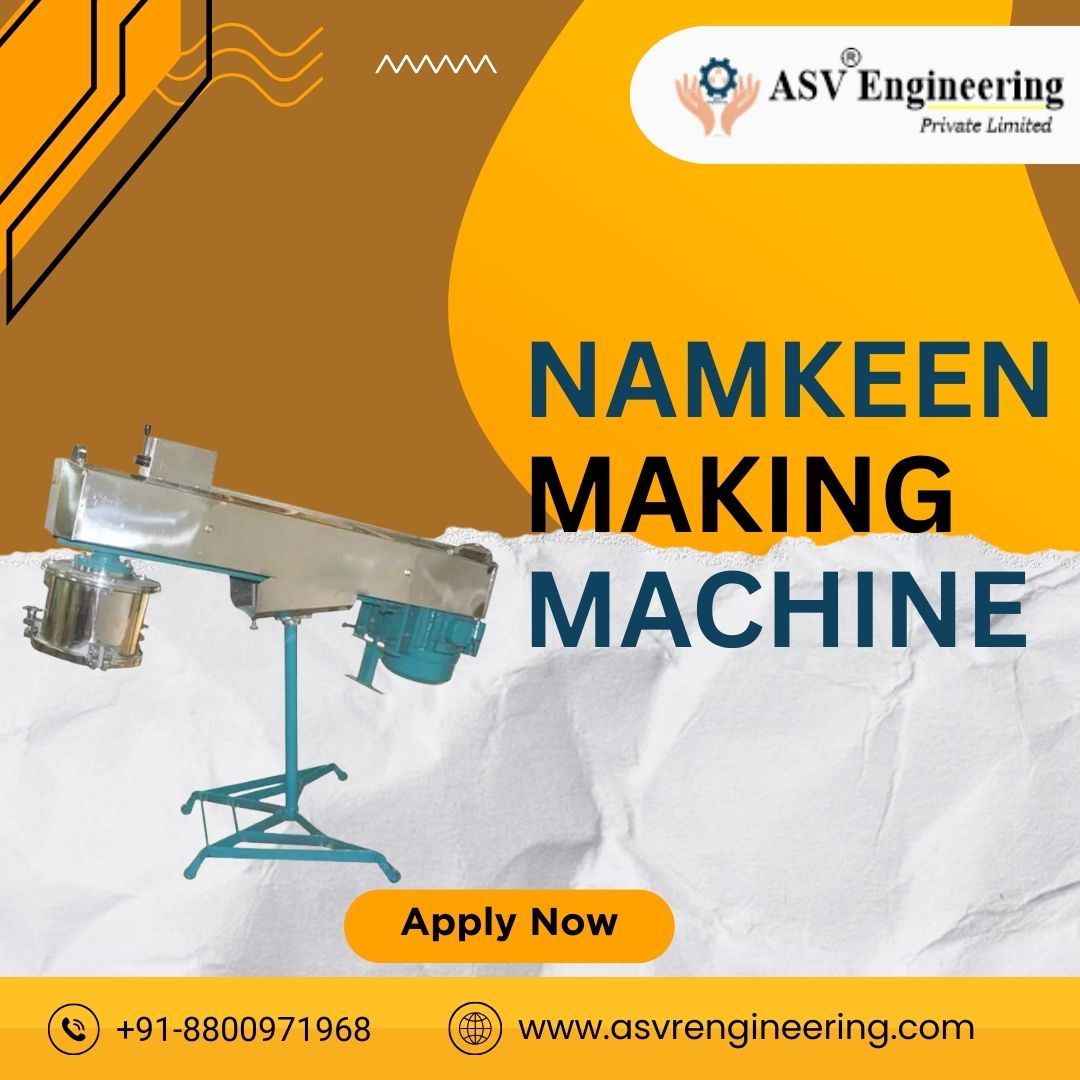

Contact Details

Phone: +91-8076004849, +91-8800971968

Website: https://www.asvrengineering.com

Buy Now

Related Posts

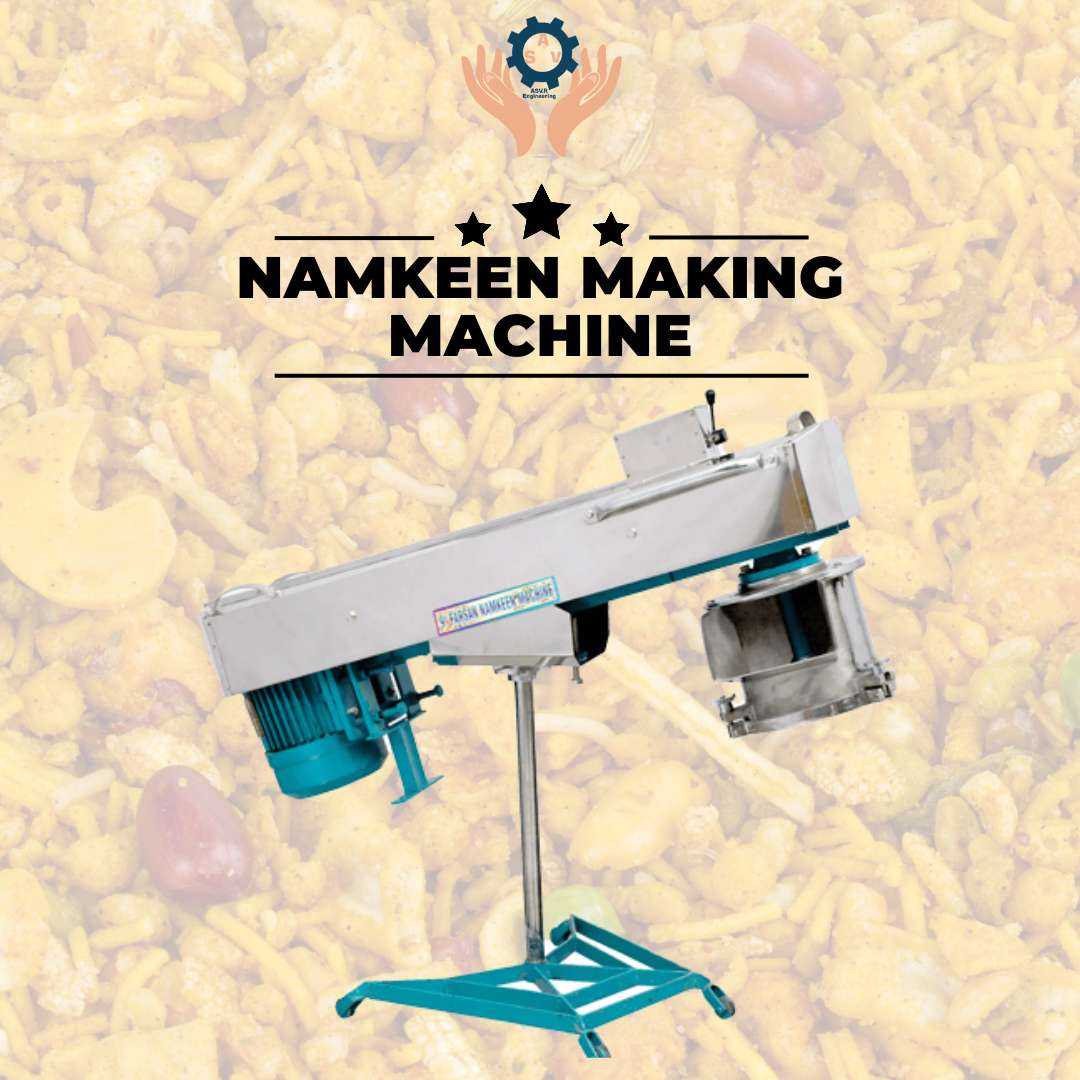

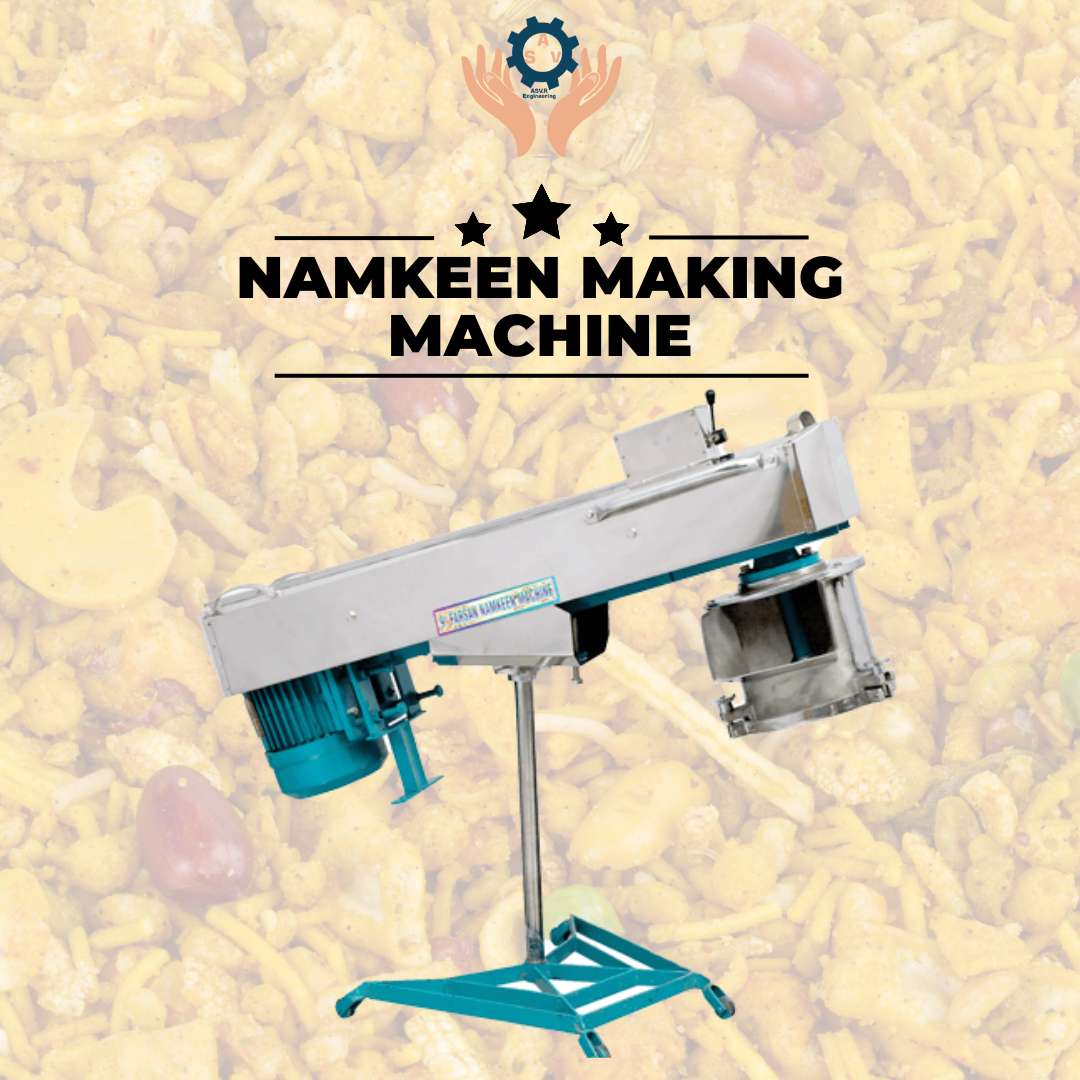

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)