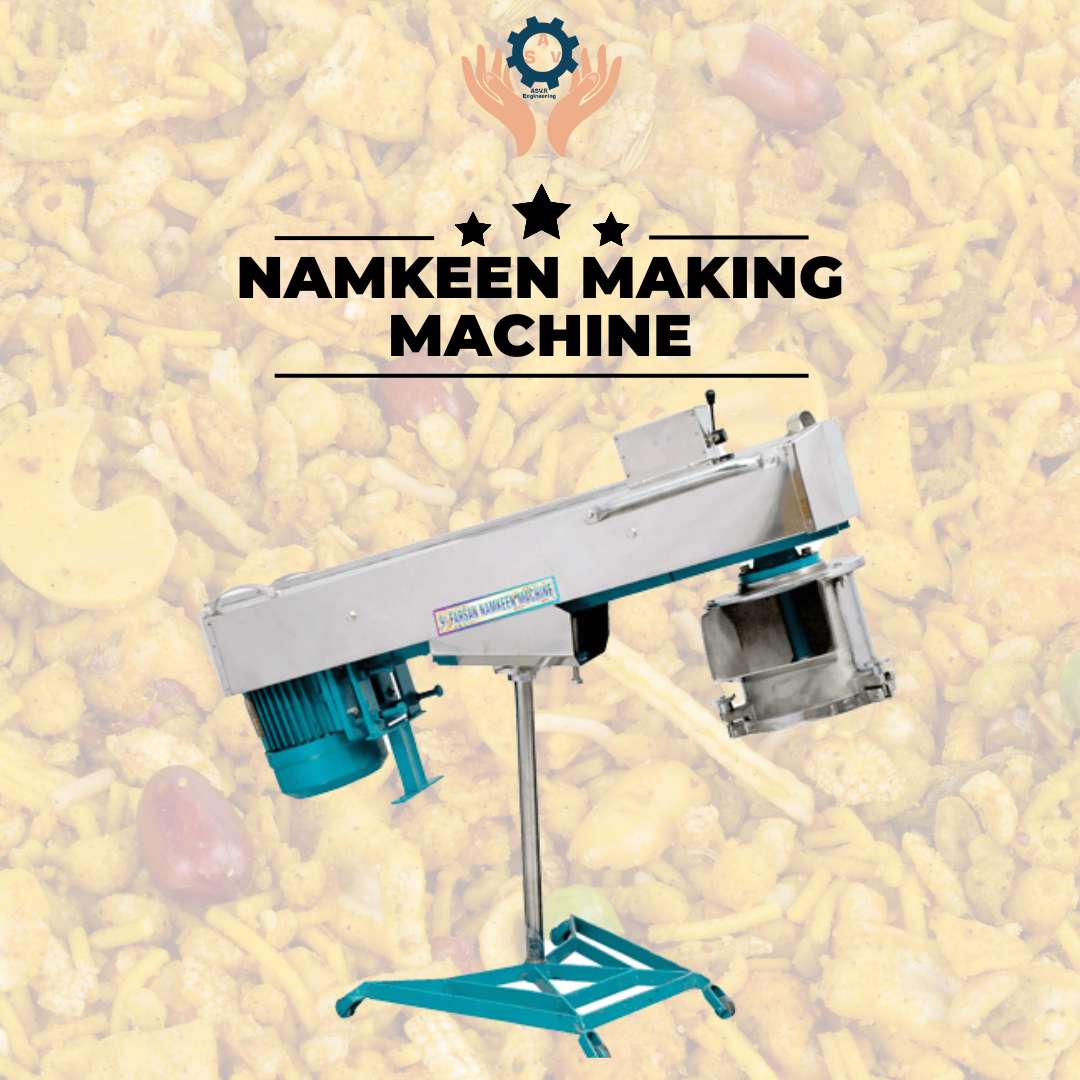

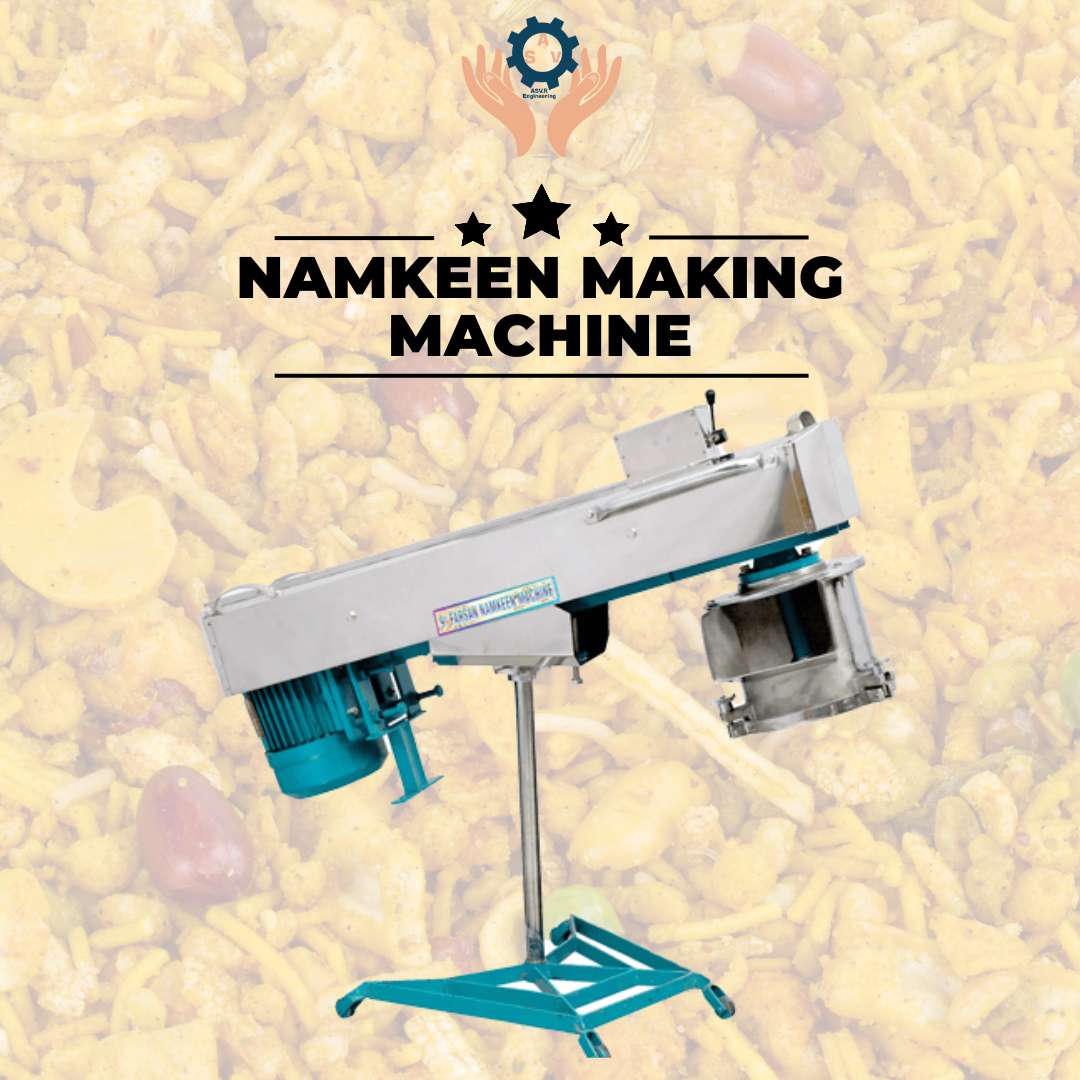

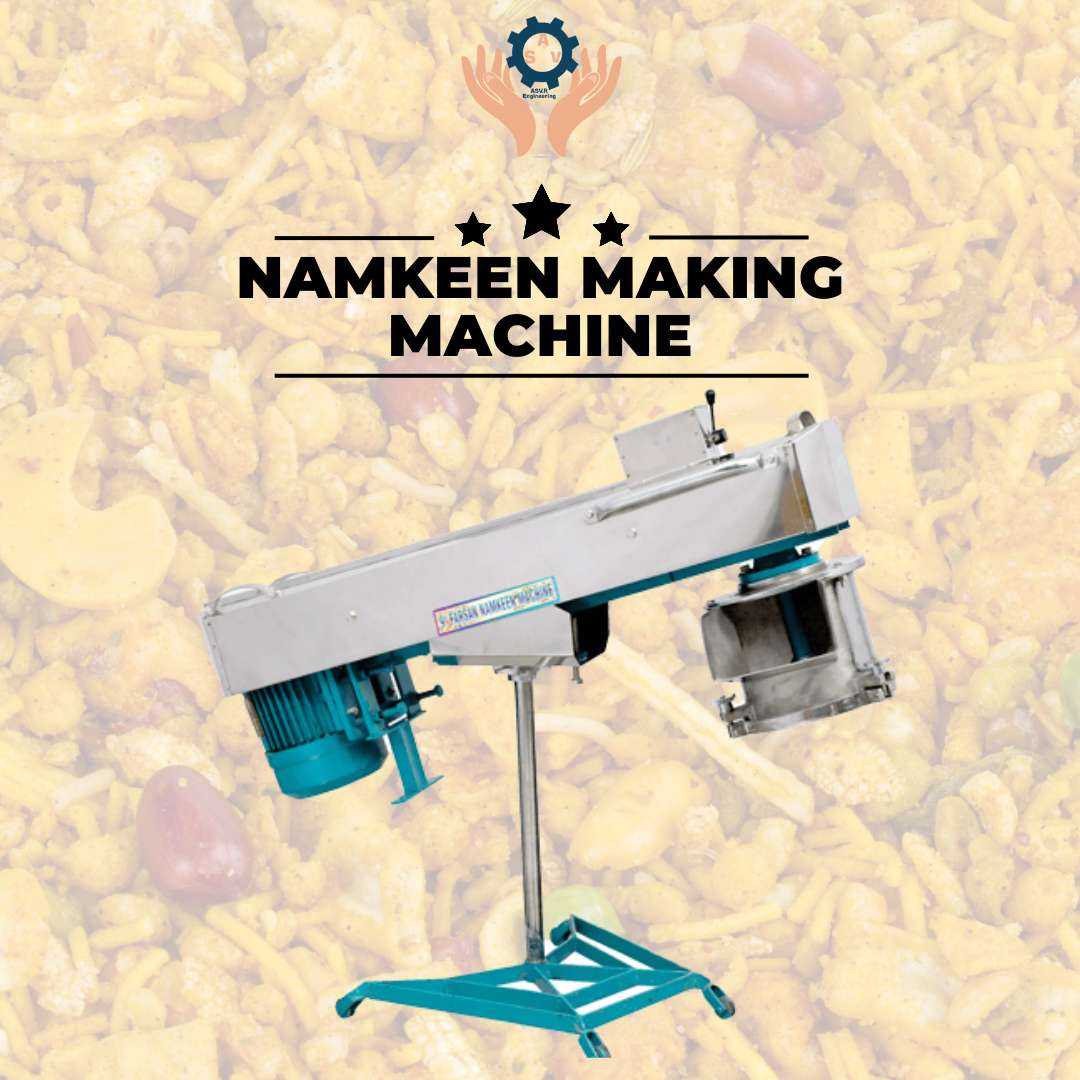

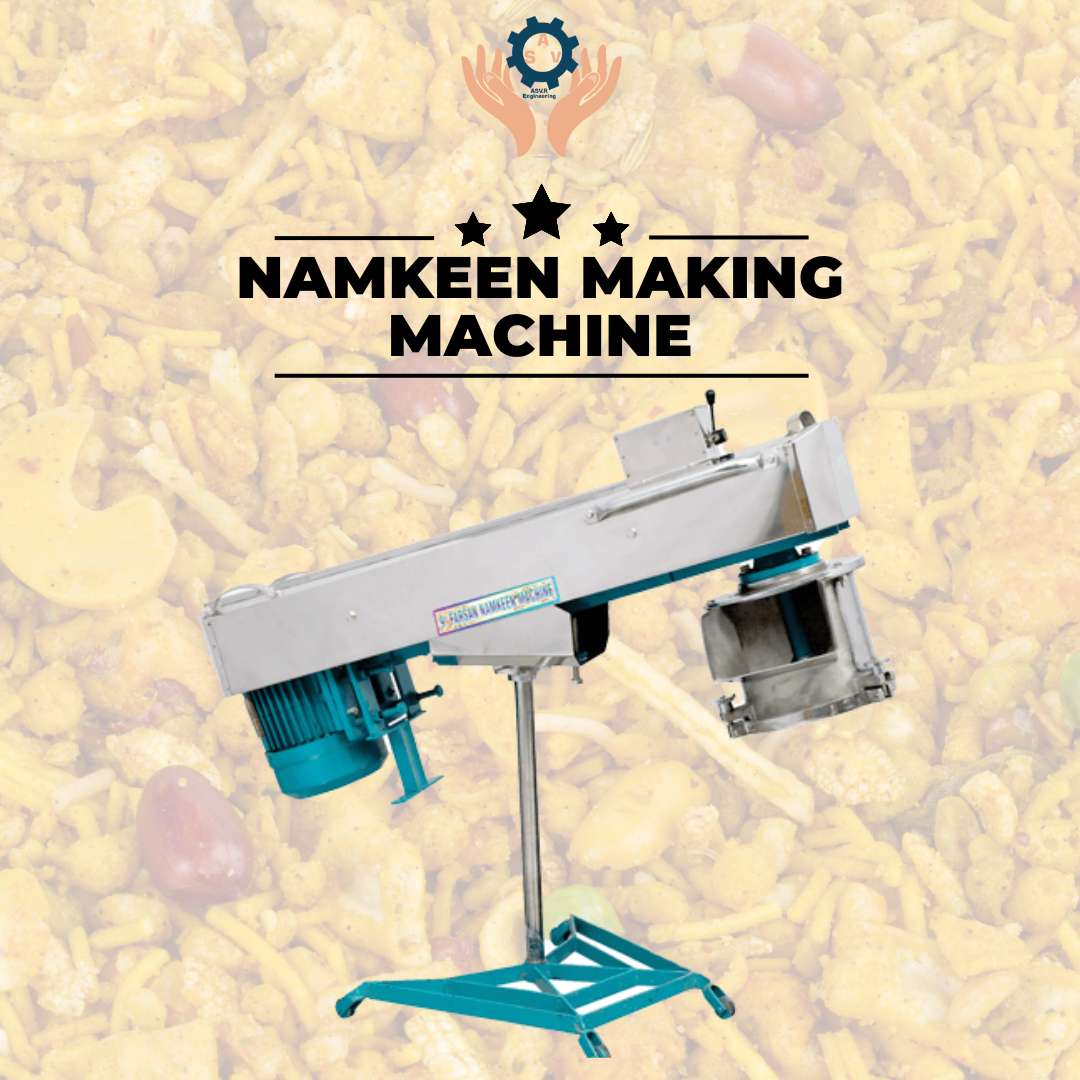

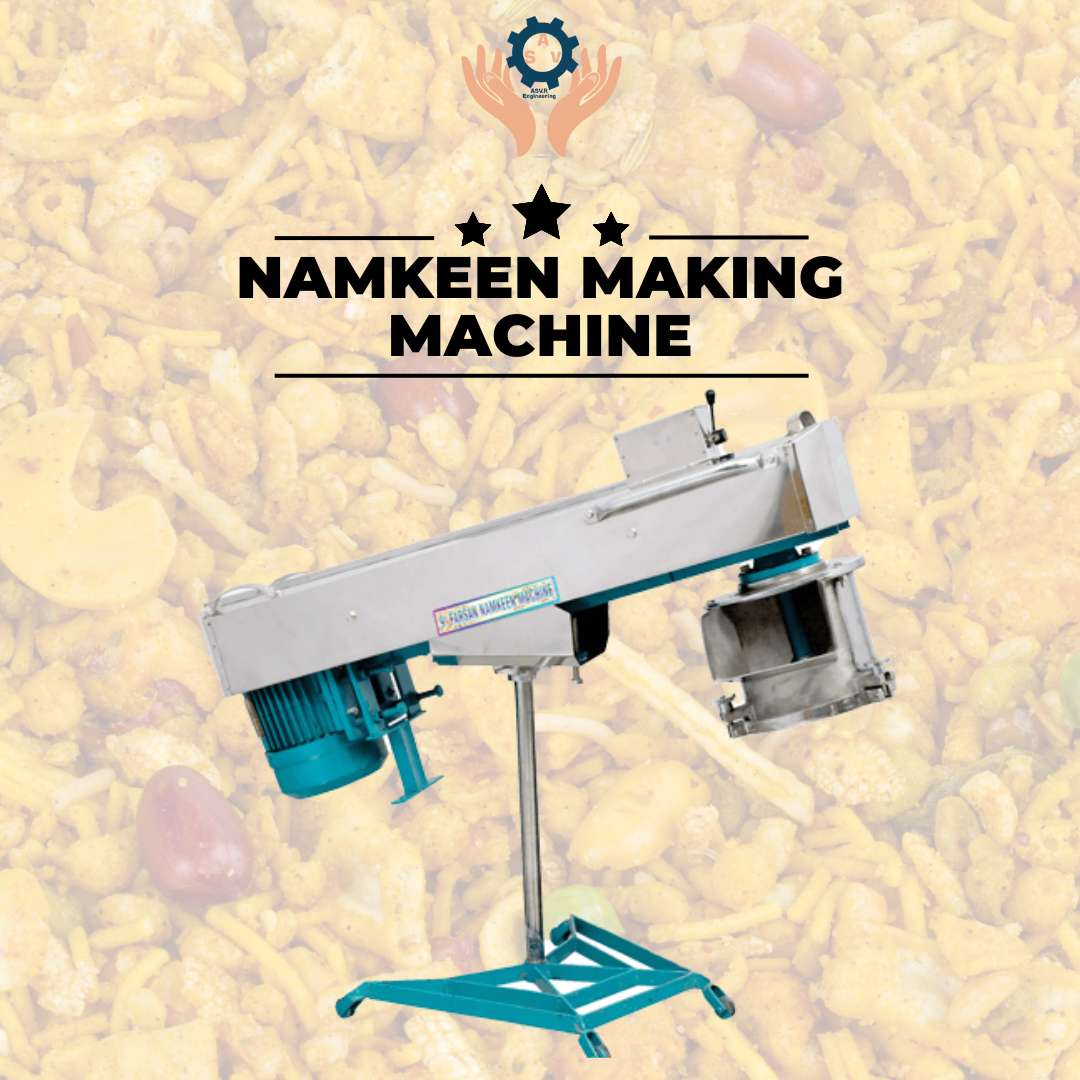

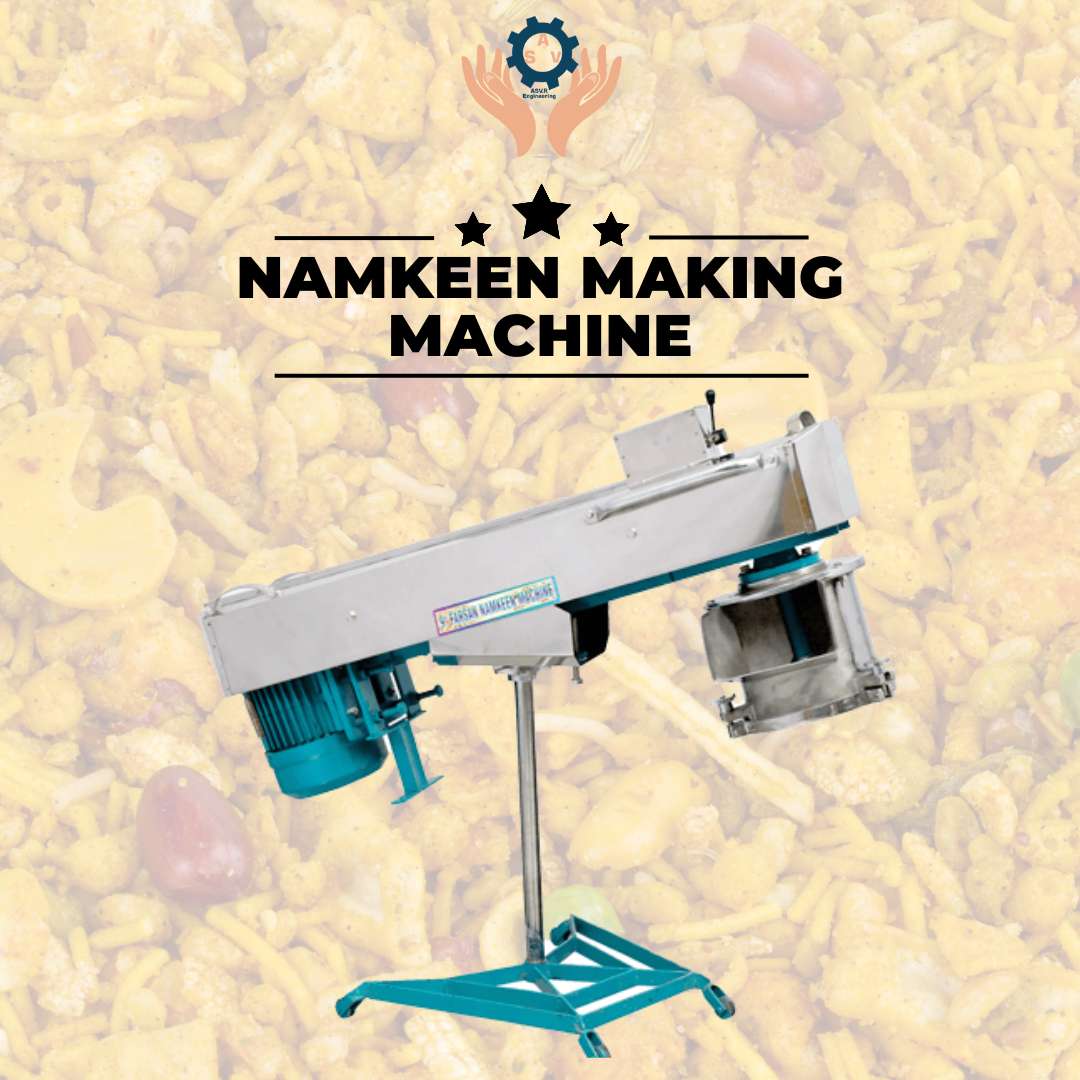

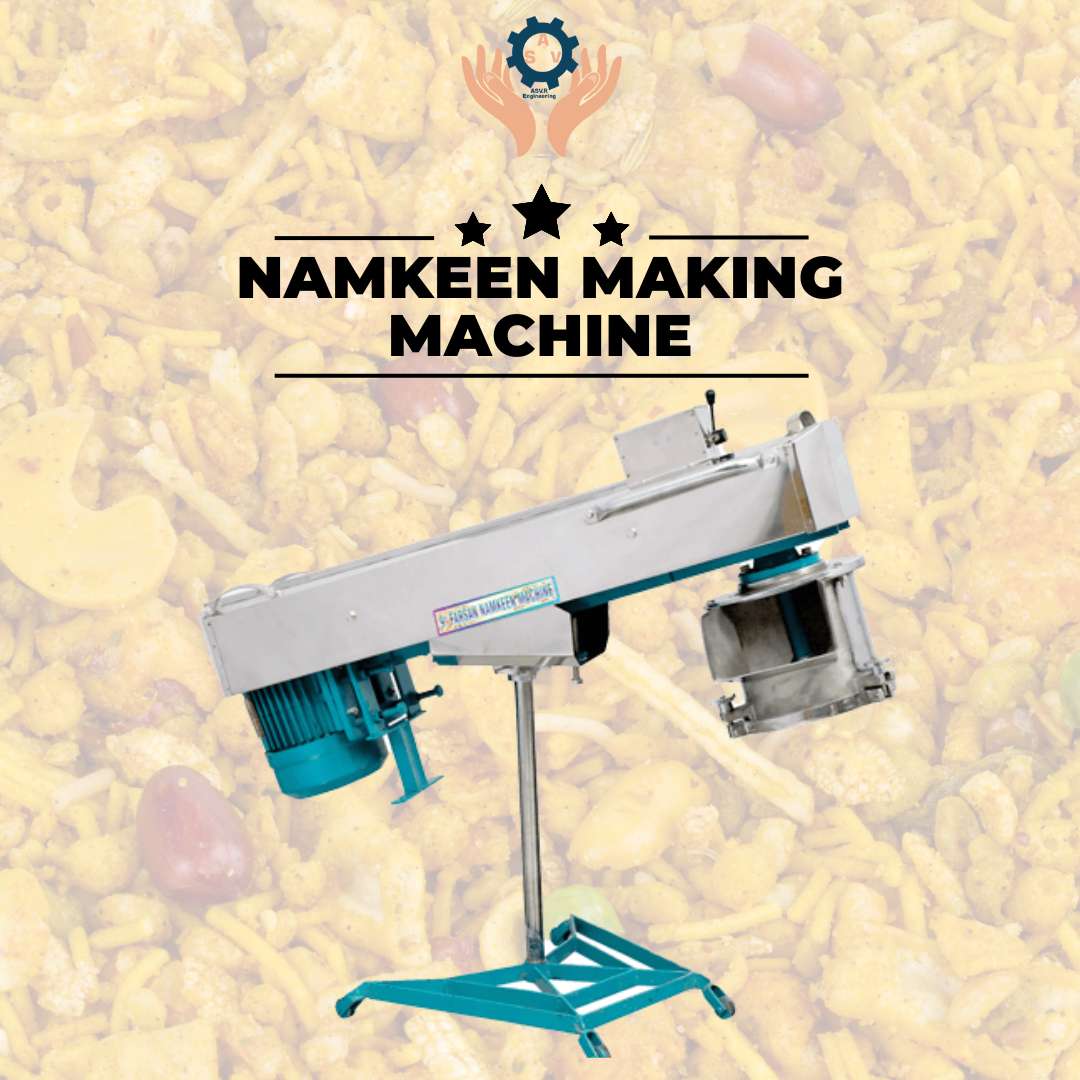

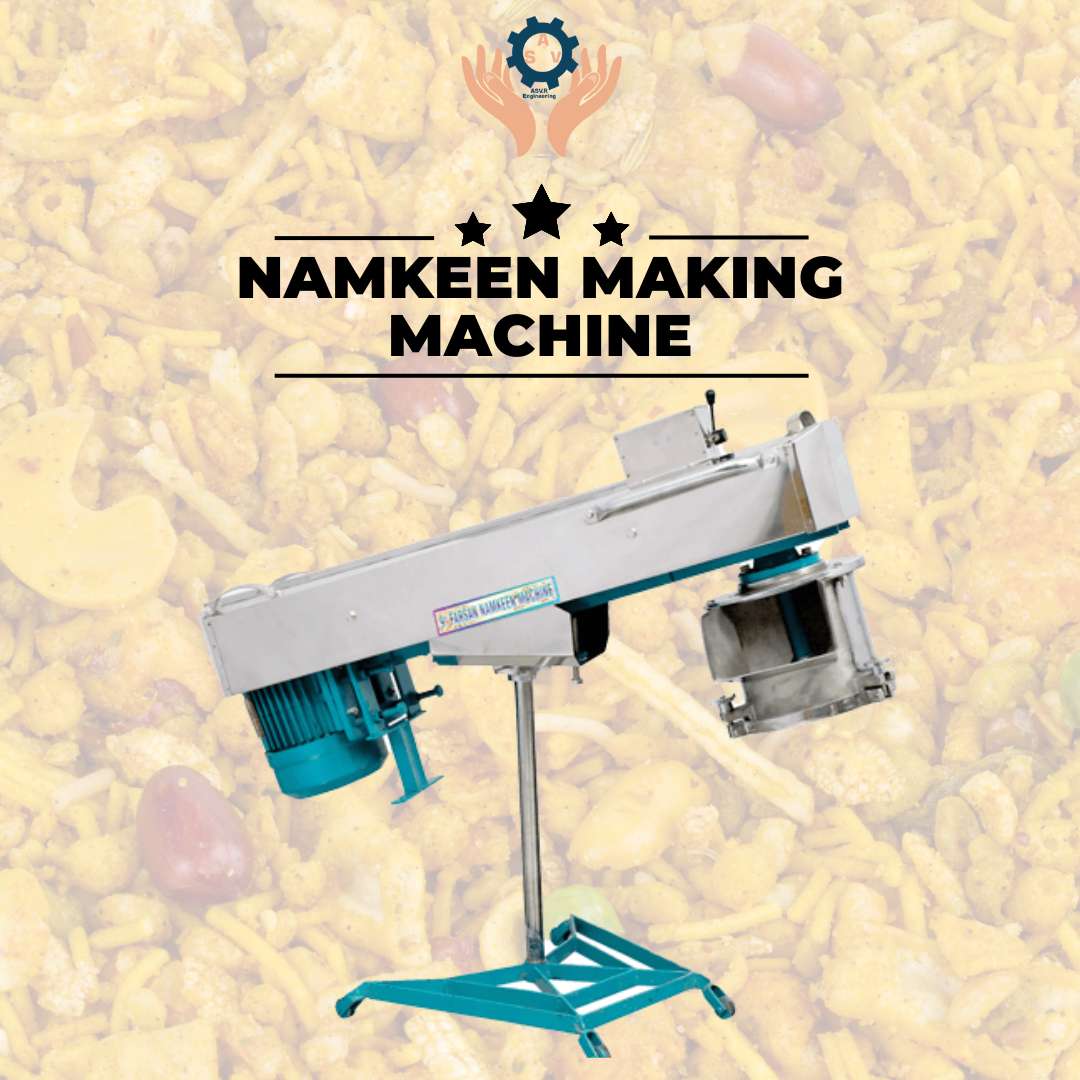

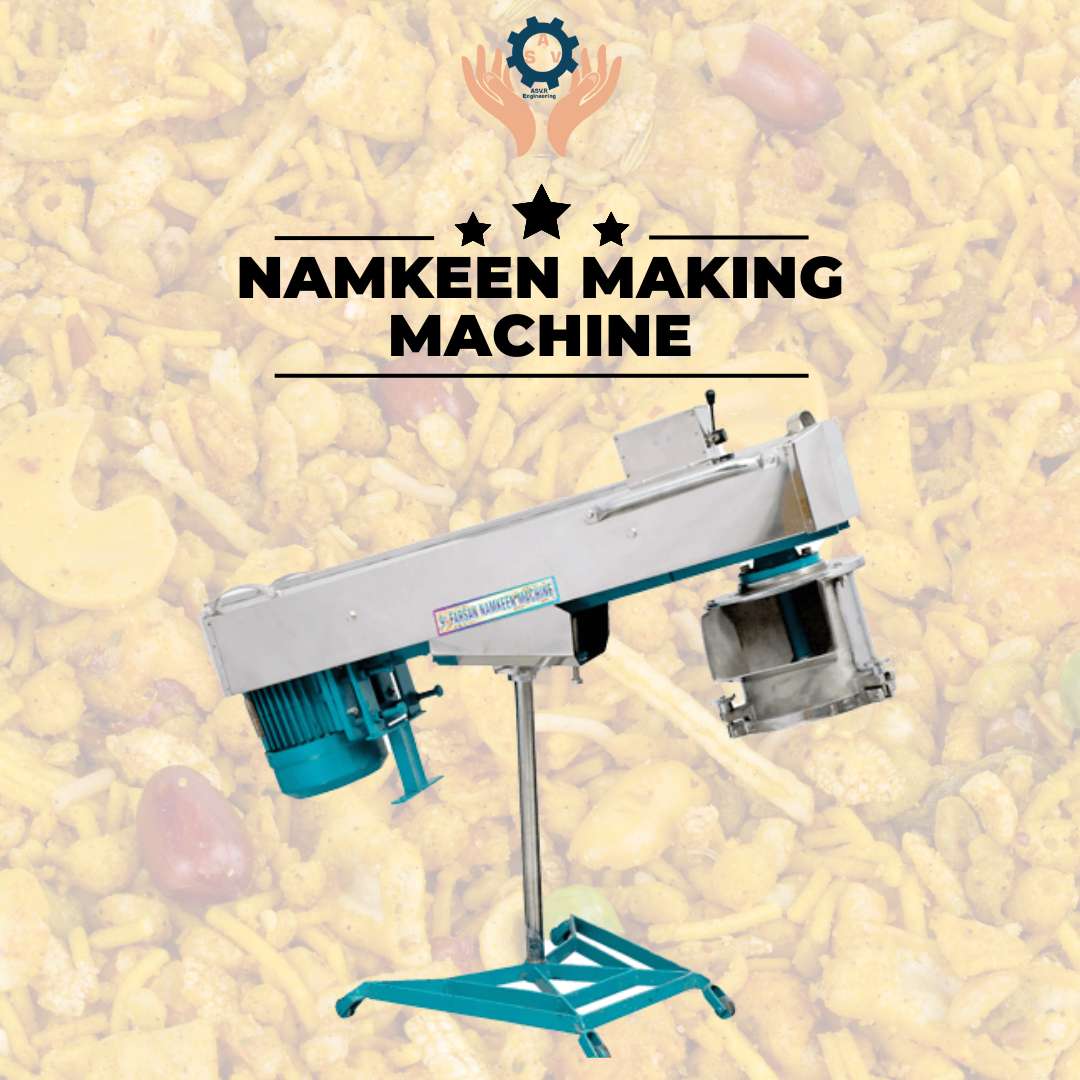

Leading Automatic Namkeen Making Machine Exporters | Fully Automatic Snack Processing Solutions

Price: ₹45500

The demand for Indian namkeen and traditional savory snacks has expanded far beyond domestic markets. From South Asia and the Middle East to Africa, Europe, and North America, consumers now seek authentic taste combined with consistent quality and hygienic processing. This global demand has accelerated the need for fully automatic namkeen making machines that deliver speed, uniformity, and food safety at scale.

As leading automatic namkeen making machine exporters, ASVR Engineering provides advanced, reliable, and production-ready snack processing solutions designed for modern manufacturers. Our machines help businesses move from manual or semi-automatic operations to fully automated production lines that increase output, reduce wastage, and ensure repeatable taste and texture.

Why Automation is Essential in Namkeen Manufacturing

Traditional namkeen preparation relies heavily on skilled labor and manual supervision. While this approach works at a small scale, it becomes inefficient and inconsistent when production volumes increase. Automation addresses these challenges by introducing precision, control, and scalability into every stage of the process.

Fully automatic namkeen making machines ensure:

-

Uniform product quality across batches

-

Higher production capacity with minimal manpower

-

Improved hygiene through enclosed, food-grade systems

-

Lower operational costs over the long term

-

Consistent taste, texture, and appearance

For exporters and large-scale snack manufacturers, automation is no longer optional—it is a necessity.

Complete Fully Automatic Namkeen Processing Solutions

ASVR Engineering offers end-to-end namkeen processing solutions, customized to suit different snack varieties and production capacities. Each component is engineered to work seamlessly as part of a continuous production line.

1. Dough Preparation & Mixing System

The process begins with precision dough mixing using high-capacity mixers made from food-grade stainless steel. Automated controls ensure accurate water-to-flour ratios, uniform blending of ingredients, and consistent dough texture.

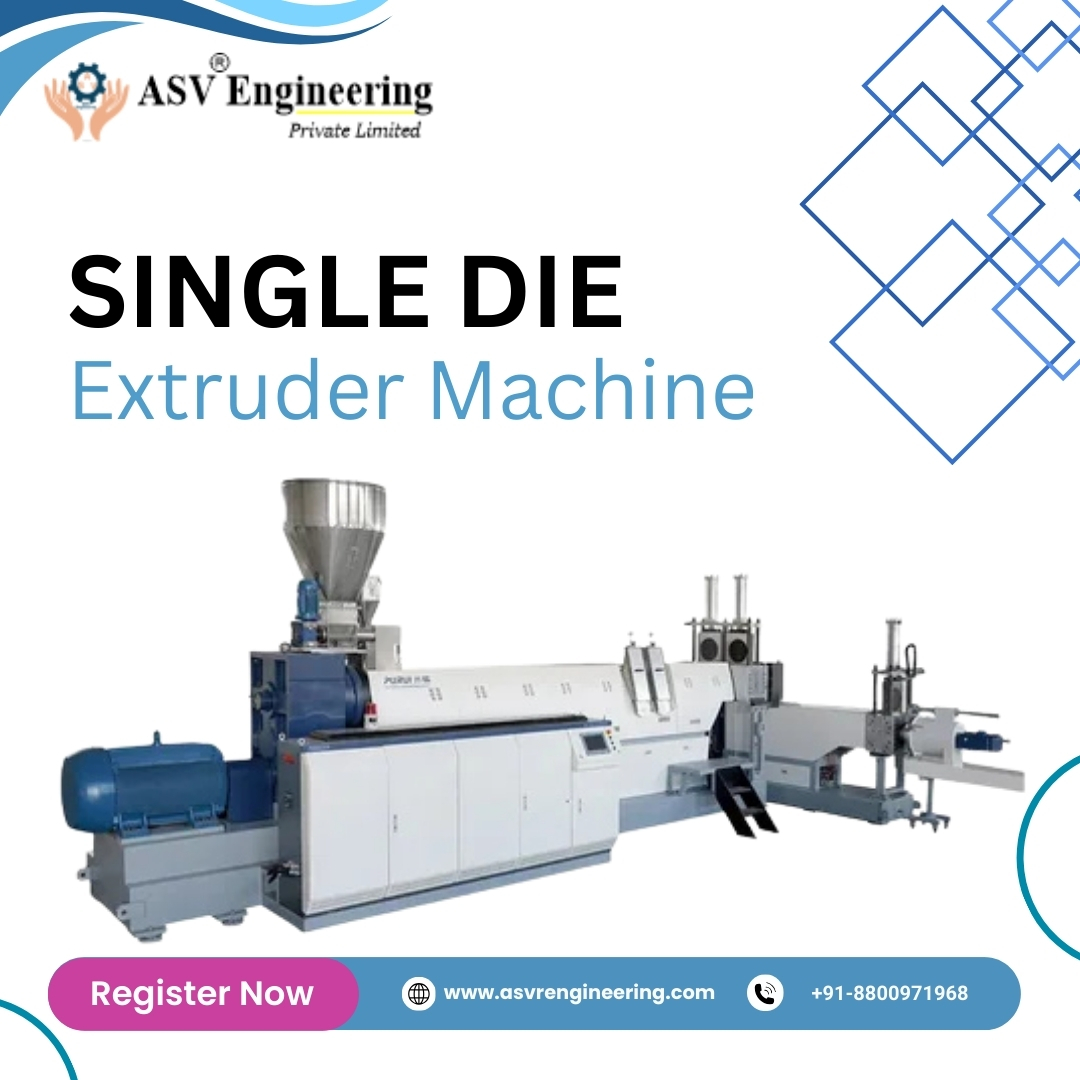

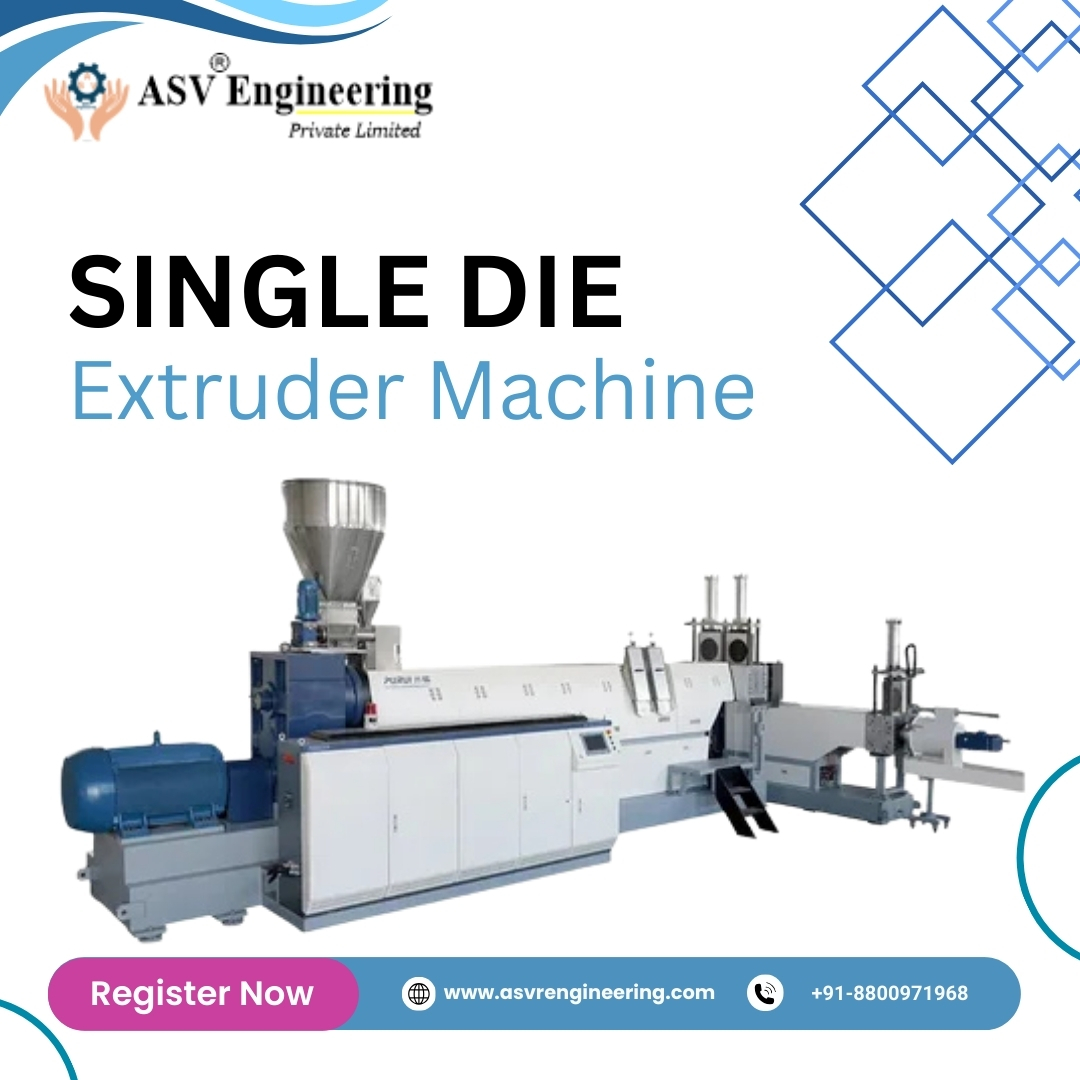

2. Extrusion & Shaping Machine

Automatic extruders shape the dough into various namkeen forms such as sev, bhujia, gathiya, papdi, or custom regional snacks. Interchangeable dies allow manufacturers to diversify their product range without investing in multiple machines.

3. Continuous Frying System

The heart of the namkeen line is the continuous namkeen fryer, designed for temperature stability and even frying. Automated oil circulation, filtration, and heating systems ensure:

-

Uniform golden color

-

Reduced oil absorption

-

Longer oil life

-

Energy efficiency

4. De-Oiling & Cooling Conveyor

After frying, excess oil is removed using vibration or centrifugal de-oiling systems. Cooling conveyors then stabilize the product, preserving crunchiness and preparing it for seasoning.

5. Automatic Seasoning & Flavor Coating

Advanced seasoning drums evenly coat namkeen with spices, salt, or customized flavor blends. Adjustable rotation speed and spray systems ensure consistent taste in every bite.

6. Optional Packing Integration

For manufacturers seeking a complete turnkey solution, the namkeen line can be integrated with automatic weighing and packaging machines, enabling ready-to-market output.

Key Features of Our Automatic Namkeen Making Machines

Our machines are designed to meet international food processing standards while offering flexibility for regional snack variations.

-

Food-grade stainless steel construction

-

PLC-based control panels for easy operation

-

Energy-efficient motors and burners

-

Modular design for future expansion

-

Low maintenance and long service life

-

Customizable capacity from small to large-scale plants

These features make our systems ideal for both emerging snack brands and established exporters.

Global Export Expertise You Can Trust

As experienced namkeen making machine exporters, ASVR Engineering understands the technical, logistical, and compliance requirements of international markets. Our machines are supplied with:

-

Export-ready packaging

-

Detailed operation manuals

-

Remote technical support

-

On-site installation guidance (where applicable)

We have successfully supported clients across multiple countries, helping them establish efficient snack production facilities that meet local regulations and consumer expectations.

Applications Across the Snack Industry

Our fully automatic namkeen processing solutions are suitable for a wide range of snack products, including:

-

Sev and bhujia

-

Gathiya and farsan

-

Spicy mixtures and blends

-

Regional traditional namkeen

-

Customized export-focused snack variants

This versatility allows manufacturers to respond quickly to changing market trends and consumer preferences.

Hygiene, Safety & Quality Compliance

Food safety is critical in snack manufacturing, especially for export markets. Our machines are built with hygiene-first engineering:

-

Smooth, easy-to-clean surfaces

-

Minimal human contact during processing

-

Compliance-ready design for food safety norms

This ensures safer production environments and higher consumer confidence.

Why Choose ASVR Engineering for Namkeen Machines

Choosing the right machinery partner is as important as choosing the right recipe. ASVR Engineering stands out because of:

-

Proven expertise in snack processing machinery

-

Focus on automation and innovation

-

Custom-built solutions for diverse markets

-

Reliable after-sales support

-

Competitive pricing with export-quality standards

Our goal is not just to sell machines, but to help clients build sustainable and profitable snack manufacturing businesses.

Support, Installation & After-Sales Service

We believe long-term relationships are built on dependable support. From pre-sales consultation to post-installation assistance, our team ensures smooth project execution. Clients receive:

-

Layout planning support

-

Operator training

-

Maintenance guidance

-

Spare parts availability

This commitment ensures uninterrupted production and peace of mind.

Conclusion: Powering the Future of Namkeen Manufacturing

The global snack industry is evolving rapidly, and manufacturers who embrace automation gain a clear competitive advantage. With fully automatic namkeen making machines from ASVR Engineering, businesses can achieve higher efficiency, superior product quality, and scalable growth.

Whether you are launching a new namkeen brand or expanding an existing export operation, our fully automatic snack processing solutions provide the technology, reliability, and support you need to succeed in international markets.

Contact Information

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Buy Now

Related Posts

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)