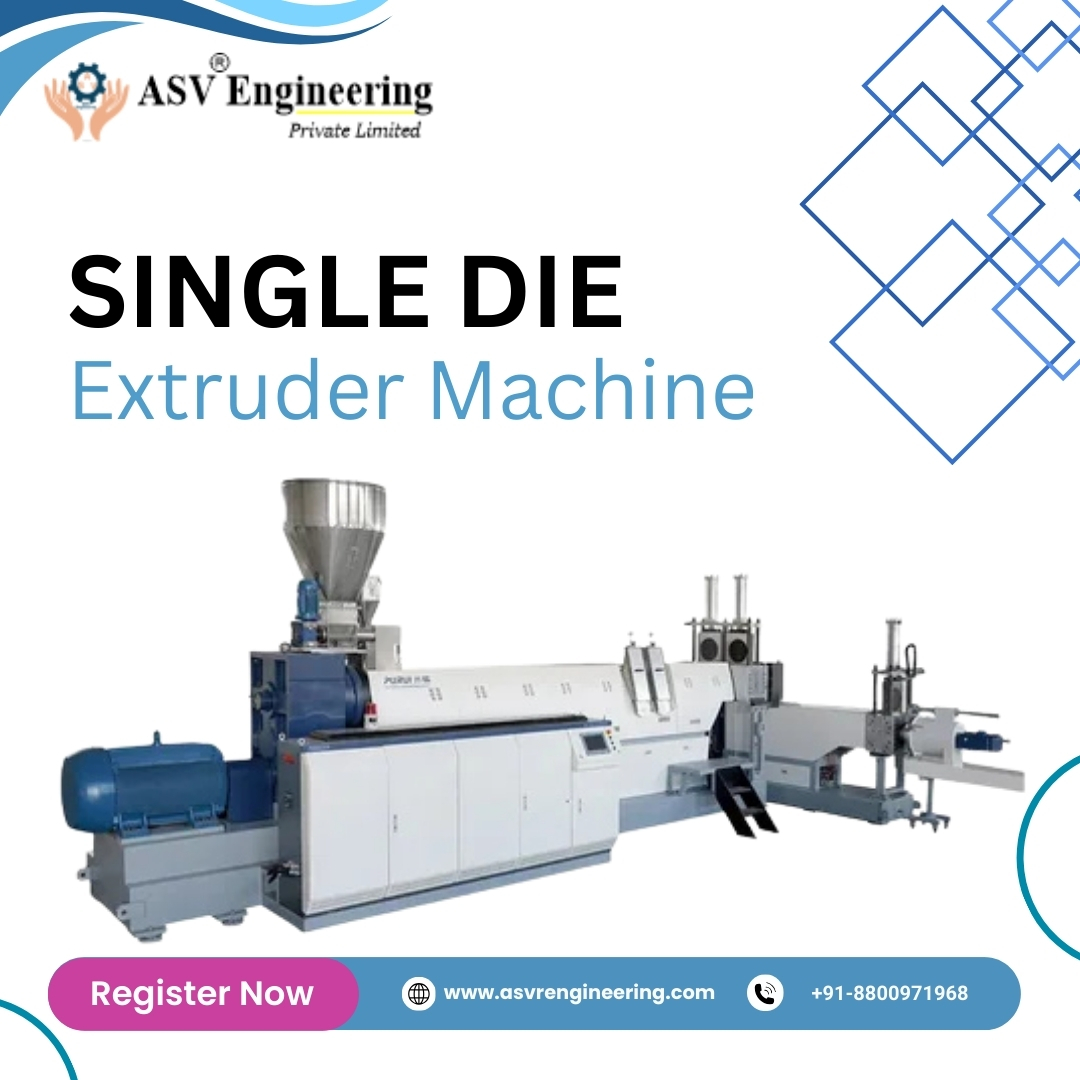

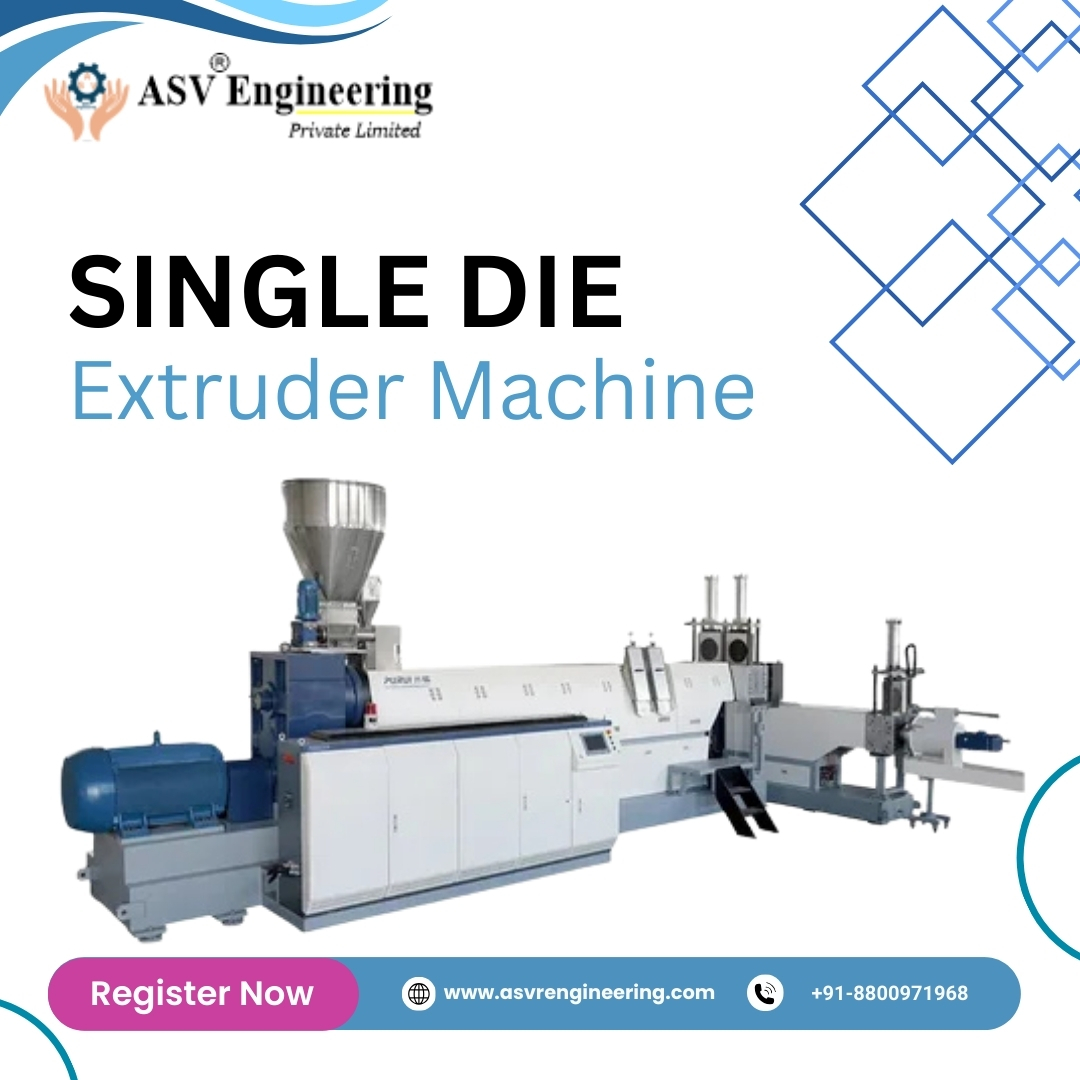

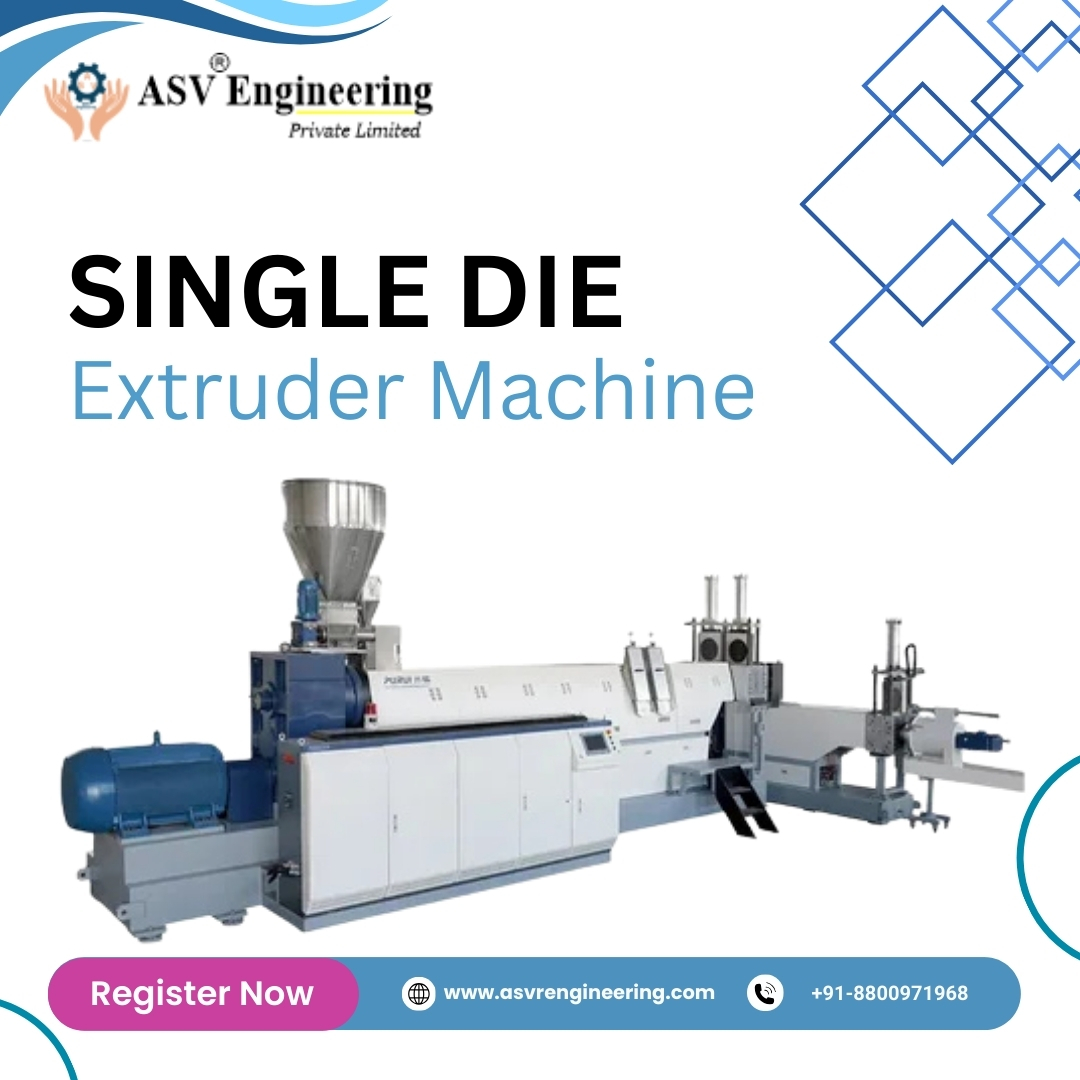

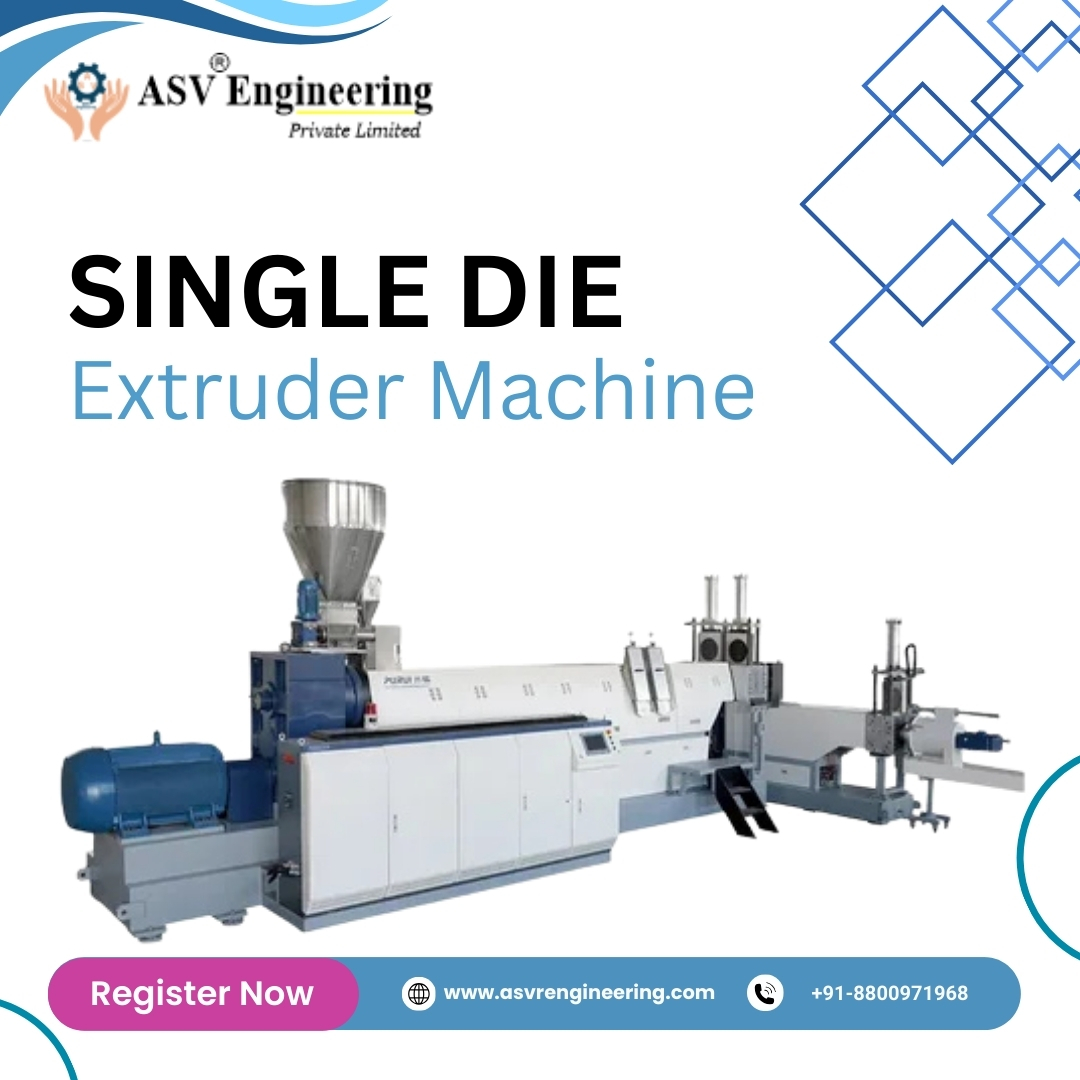

Puff Extruder Machine

Price: ₹450000

In today’s fast-growing food processing industry, demand for hygienic, uniform, and high-output snack production equipment is increasing rapidly. Among the most essential machines used in snack manufacturing is the Puff Extruder Machine. This advanced food processing equipment is widely used for producing puffed snacks, cereals, corn puffs, kurkure-type snacks, pellets, and various extruded food products with consistent texture and taste.

At ASVR Engineering, we design and manufacture high-quality puff extruder machines that meet modern production requirements. Our machines are engineered to deliver excellent performance, low maintenance, and long service life, making them ideal for small-scale units as well as large industrial food processing plants.

What Is a Puff Extruder Machine?

A puff extruder machine is a specialized food processing machine that uses heat, pressure, and mechanical shear to expand raw ingredients into puffed or expanded snack products. Ingredients such as corn grits, rice flour, wheat flour, or mixed cereals are fed into the extruder, where they are cooked under controlled conditions and forced through a die to create puffed shapes.

The extrusion process ensures:

-

Uniform product expansion

-

Consistent shape and texture

-

Better cooking efficiency

-

Enhanced shelf life of snacks

This makes puff extruder machines a preferred choice for snack manufacturers across India and international markets.

Applications of Puff Extruder Machines

Puff extruder machines are versatile and used across a wide range of food processing applications, including:

-

Corn puffs and rings

-

Kurkure-type snacks

-

Breakfast cereals

-

Fryums and pellets

-

Extruded namkeen snacks

-

Animal feed and pet food

-

Health and multigrain snacks

Due to this versatility, investing in a high-quality puff extruder machine significantly improves production flexibility and profitability.

Key Features of Our Puff Extruder Machine

At ASVR Engineering, every puff extruder machine is built with precision engineering and premium-grade materials. Some standout features include:

Robust Construction

Manufactured using high-quality steel and food-grade components, our machines are designed for continuous industrial use.

High Production Efficiency

Optimized screw design and heating system ensure maximum output with minimal raw material wastage.

Uniform Product Quality

Advanced temperature and pressure control help maintain consistent puff size, shape, and texture.

Energy-Efficient Operation

Our machines are designed to reduce power consumption while maintaining high productivity.

Easy Operation & Maintenance

User-friendly controls and accessible components make operation and routine maintenance simple and cost-effective.

Customizable Output

Die and cutter options allow manufacturers to produce different snack shapes and sizes as per market demand.

Manufacturing Process Using Puff Extruder Machine

The puff extruder machine follows a systematic process that ensures high-quality snack production:

-

Raw Material Feeding – Ingredients are fed into the hopper in measured quantities.

-

Mixing & Cooking – Inside the barrel, raw materials are mixed, heated, and cooked under pressure.

-

Extrusion – The cooked mixture is forced through a die, creating expanded or puffed shapes.

-

Cutting – A rotating cutter slices the extruded product to desired length.

-

Drying & Flavoring – Final products are dried and seasoned before packaging.

This controlled process ensures consistent quality, hygiene, and production speed.

Why Choose ASVR Engineering Puff Extruder Machine?

Choosing the right manufacturer is as important as choosing the right machine. ASVR Engineering stands out in the food processing machinery industry due to:

-

Years of manufacturing experience

-

Strict quality control standards

-

Reliable after-sales support

-

Competitive pricing without compromising quality

-

Machines designed as per Indian and international food safety norms

Our puff extruder machines are trusted by snack manufacturers who prioritize durability, performance, and long-term value.

Benefits of Investing in a Puff Extruder Machine

A high-quality puff extruder machine offers several business advantages:

-

Increased production capacity

-

Reduced labor dependency

-

Lower operating costs

-

Consistent product quality

-

Faster return on investment

-

Ability to expand product range easily

Whether you are starting a new snack manufacturing unit or upgrading an existing plant, a puff extruder machine is a smart investment.

Quality & Safety Standards

Food safety is a top priority in snack manufacturing. Our puff extruder machines are built using food-grade materials and comply with standard hygiene requirements. Proper sealing, smooth surfaces, and easy cleaning ensure safe and contamination-free production.

Industries We Serve

Our puff extruder machines are widely used in:

-

Snack food manufacturing units

-

FMCG food processing plants

-

Small and medium-scale food industries

-

Export-oriented snack production units

-

Animal and pet food manufacturers

Customization & Technical Support

At ASVR Engineering, we understand that every manufacturer has unique requirements. That’s why we offer:

-

Customized machine capacity

-

Die and cutter customization

-

Technical guidance during installation

-

Operator training support

-

Prompt after-sales service

Our technical team ensures that your machine operates efficiently from day one.

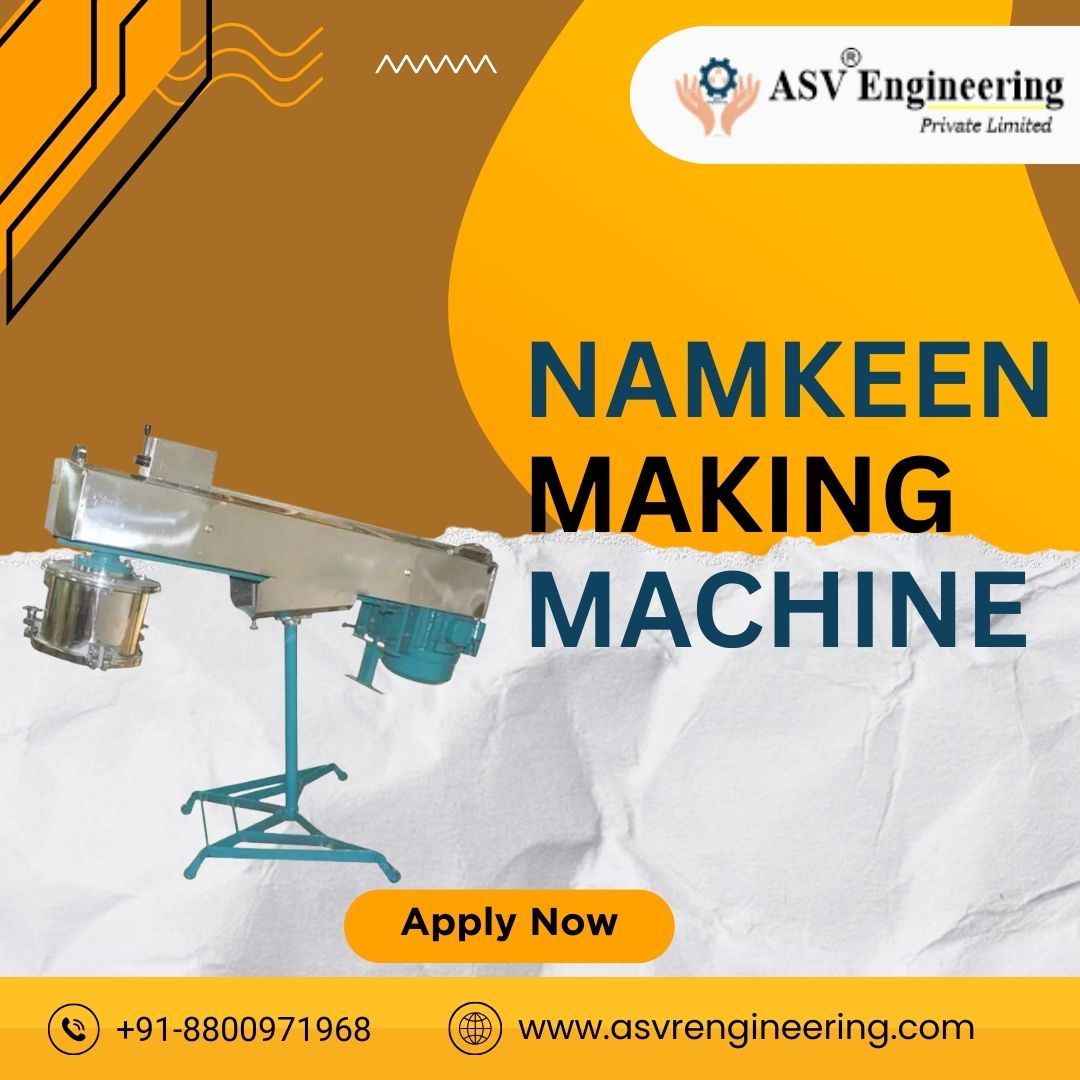

Contact ASVR Engineering

If you are looking for a reliable, durable, and high-performance Puff Extruder Machine, connect with ASVR Engineering today.

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Our team will help you choose the right puff extruder machine tailored to your production needs and budget.

Buy Now

Related Posts

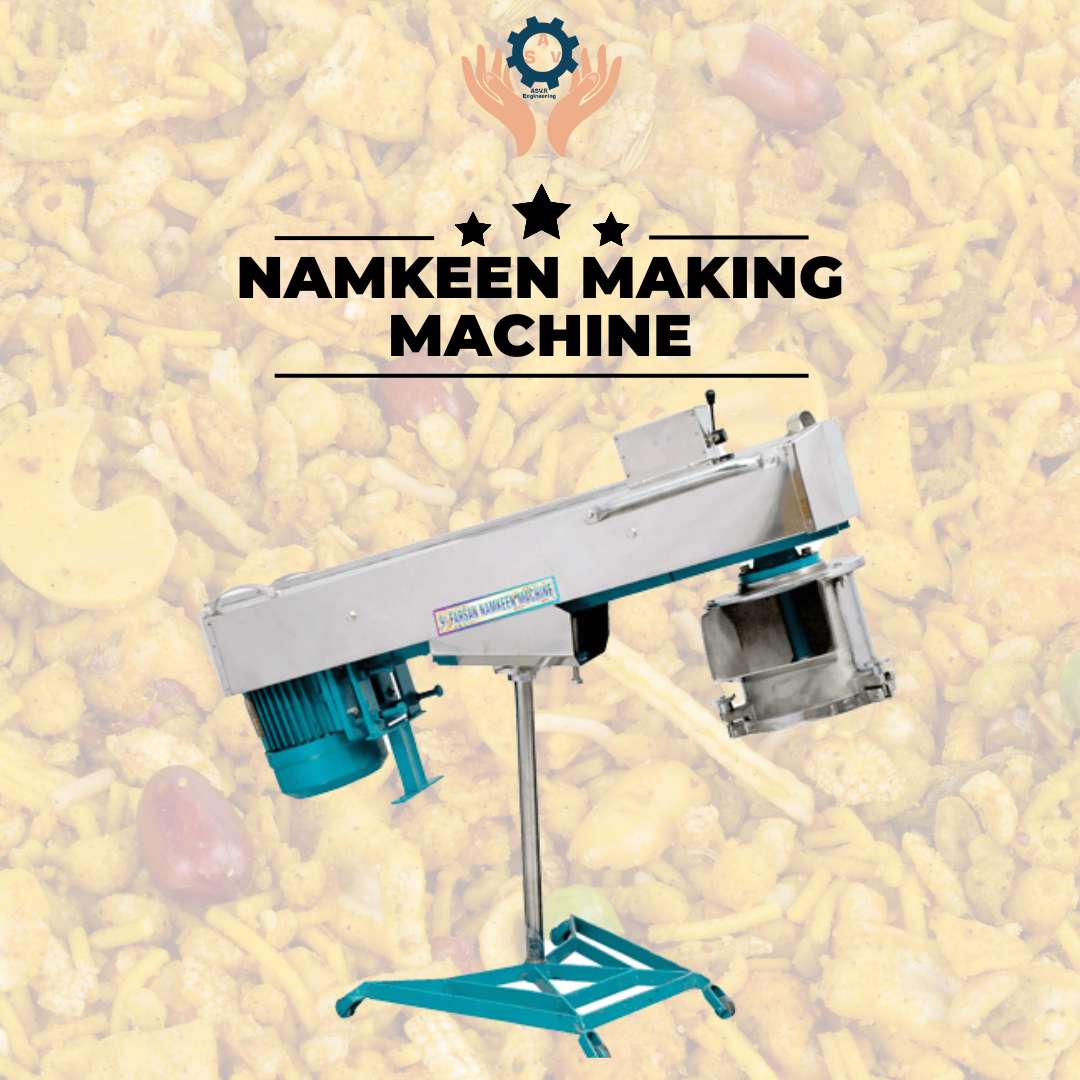

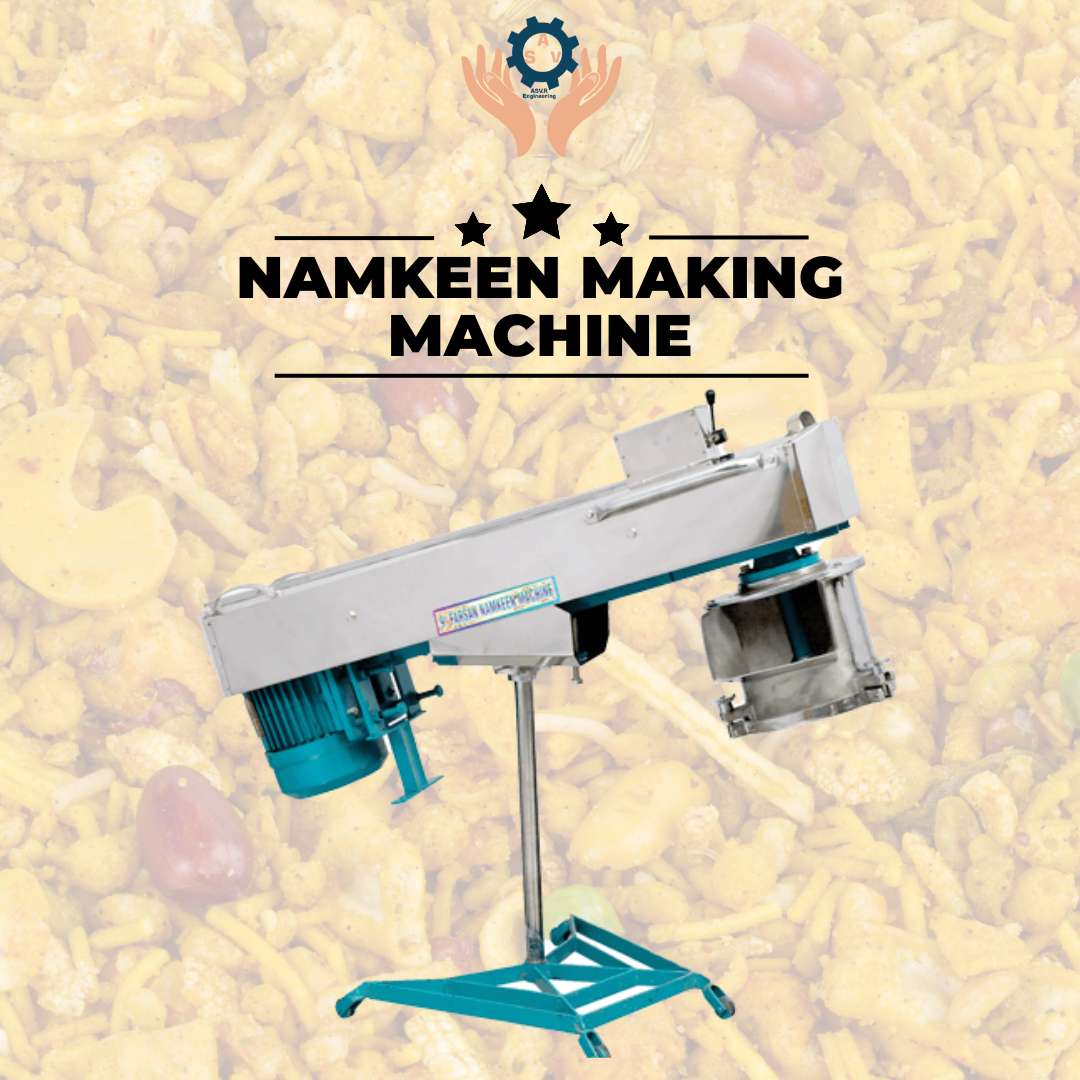

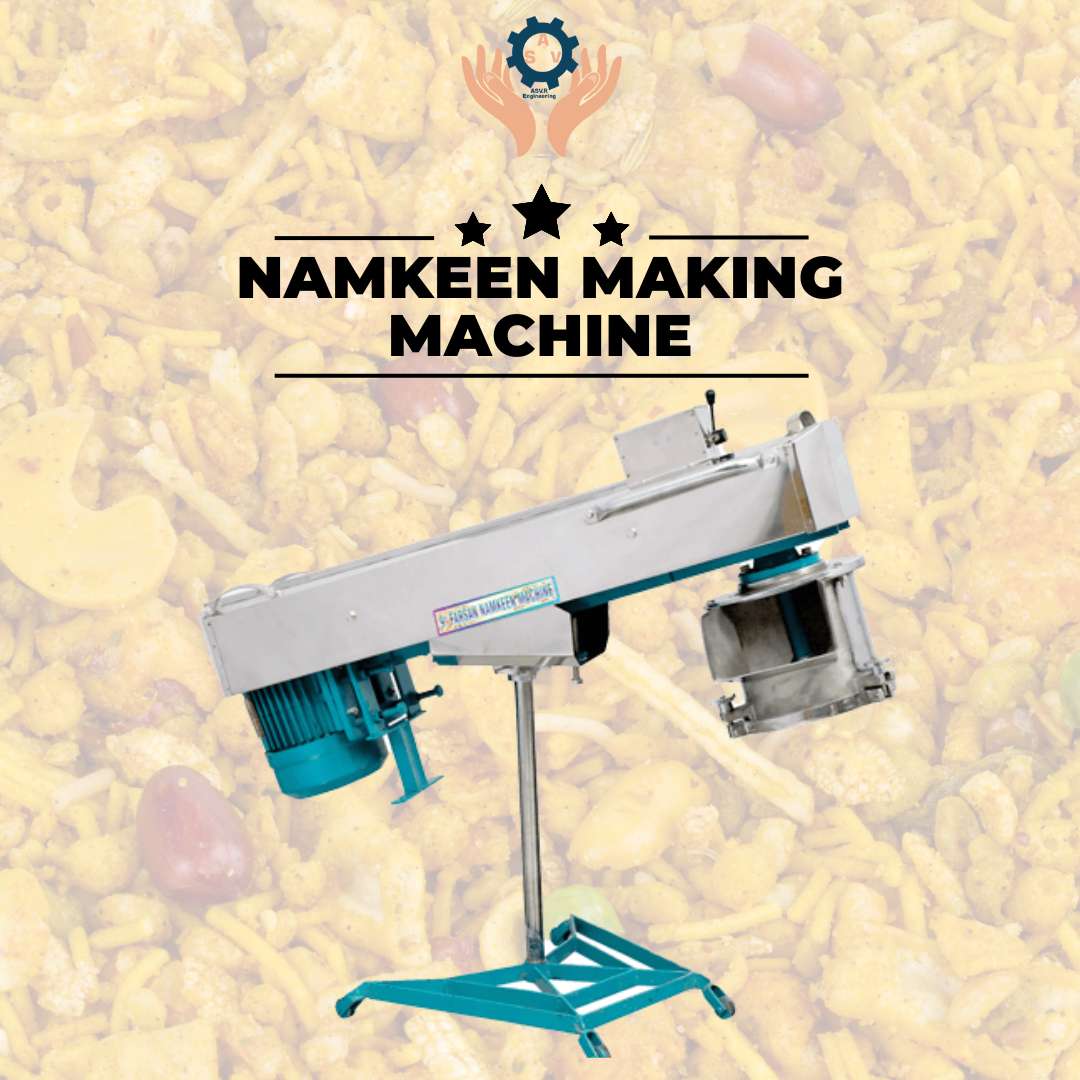

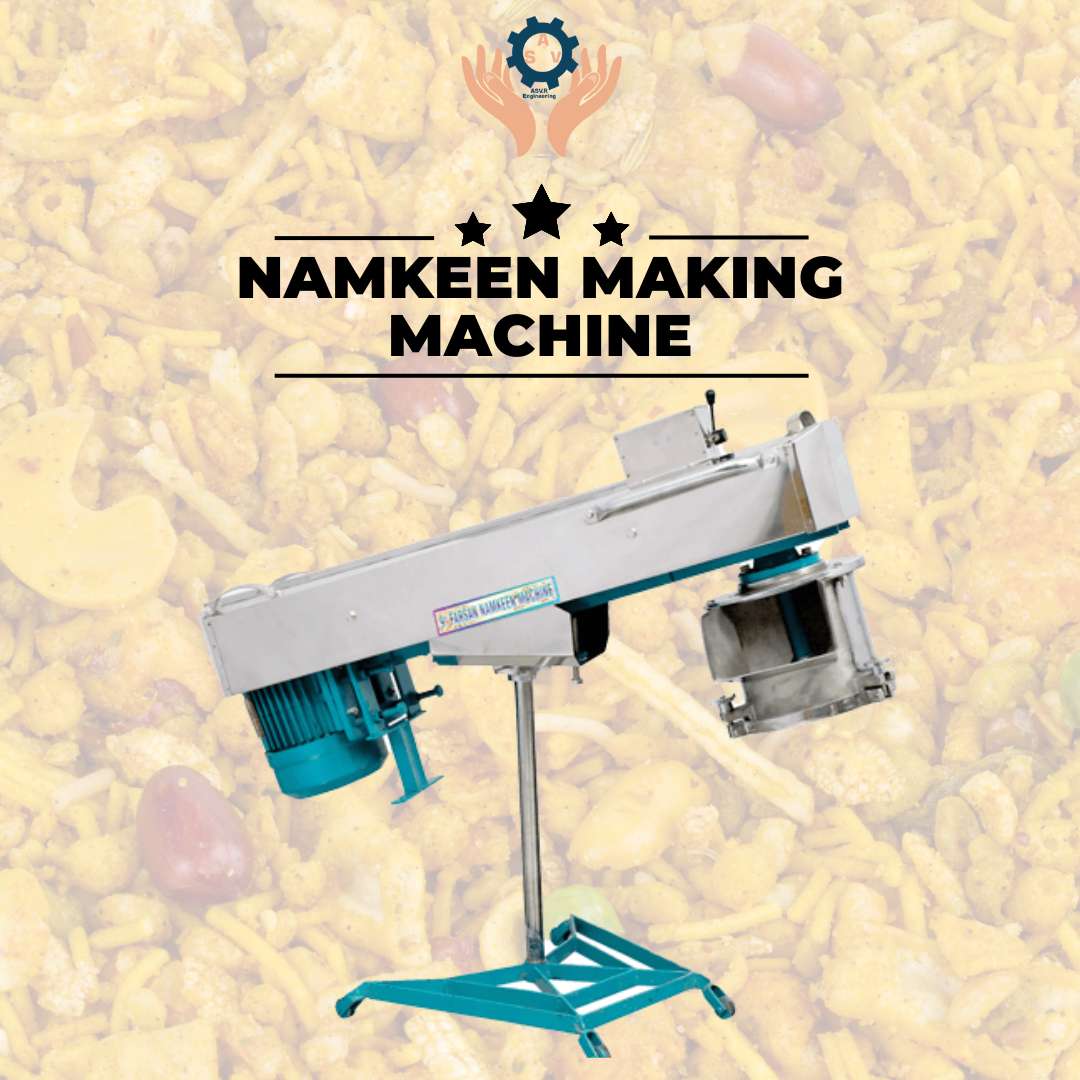

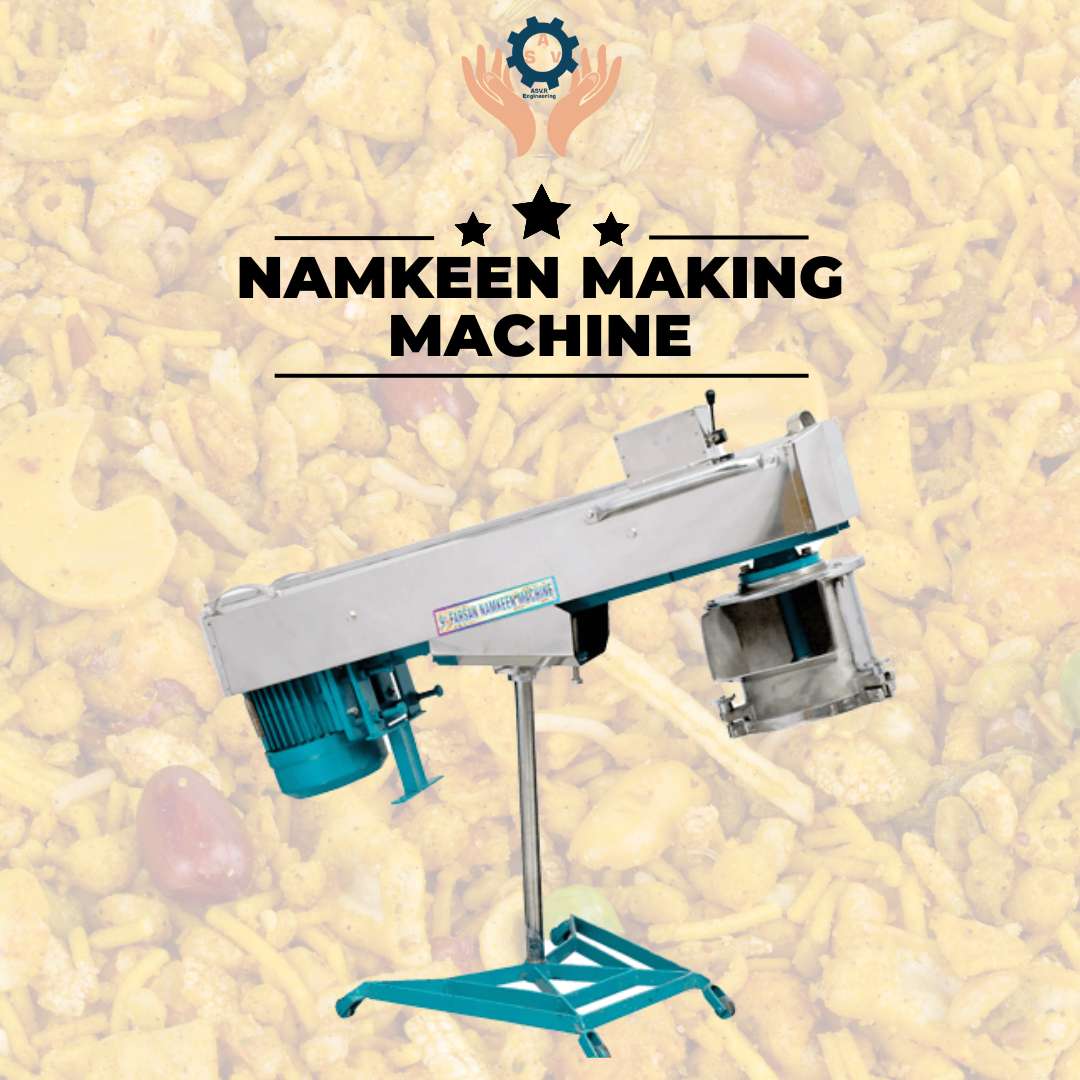

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)