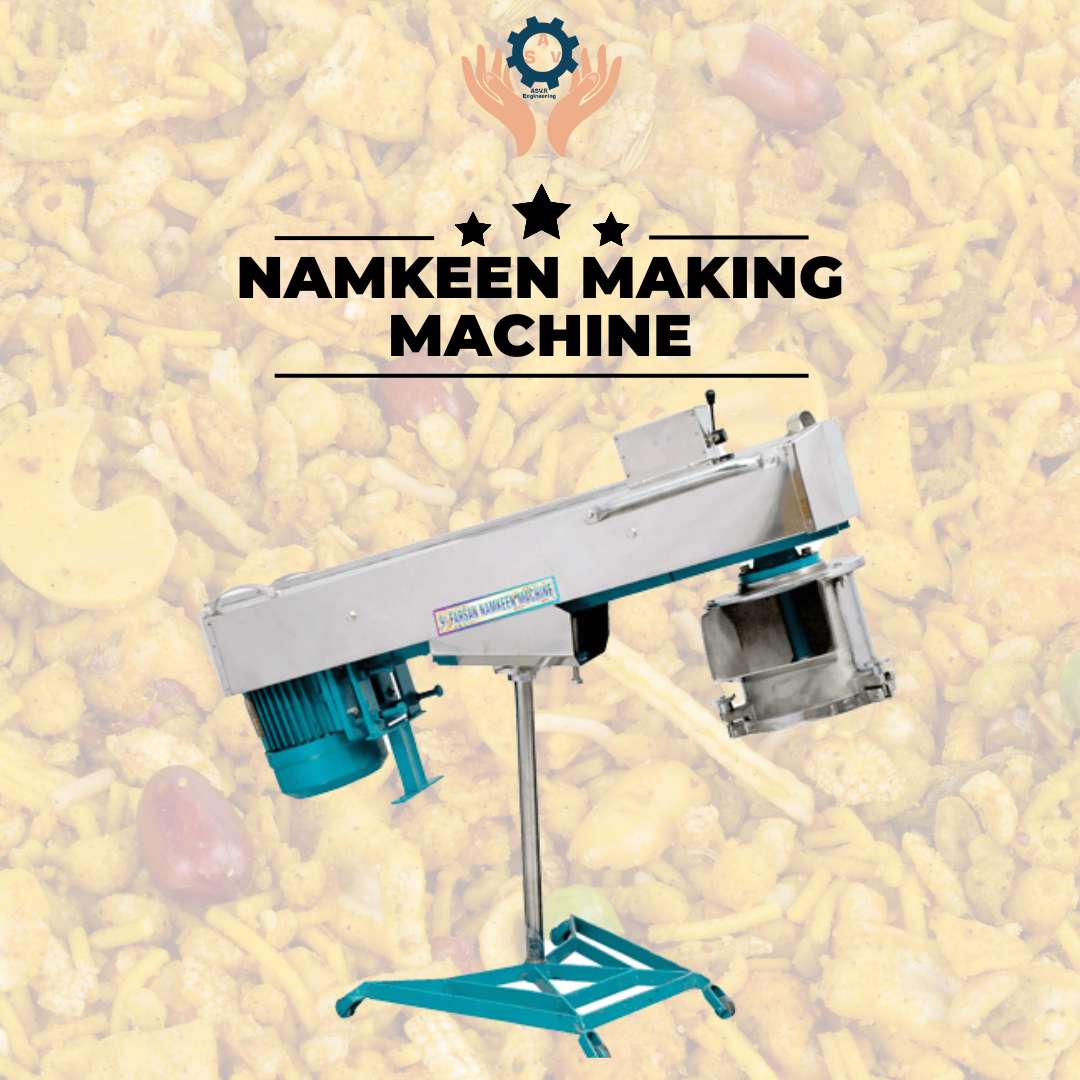

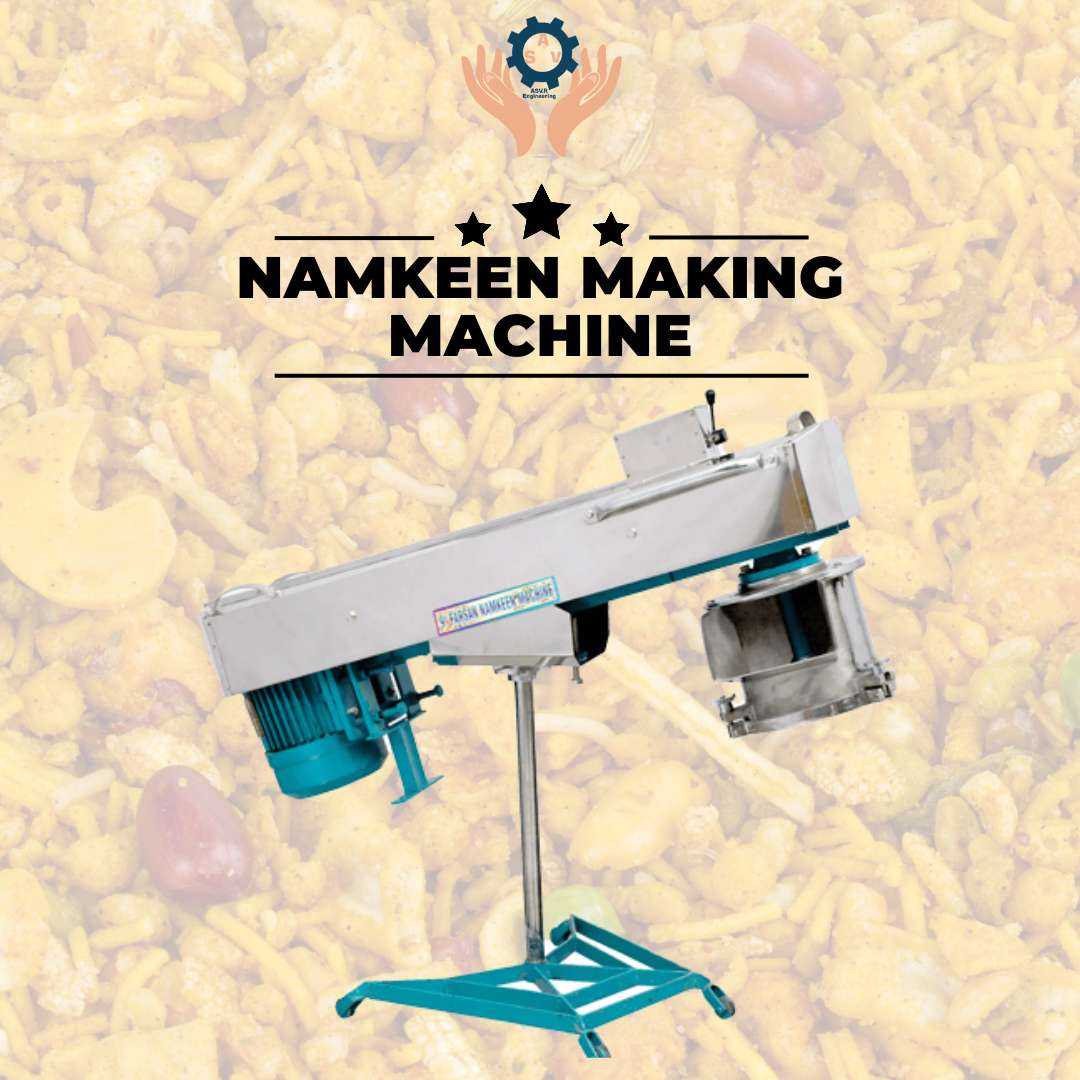

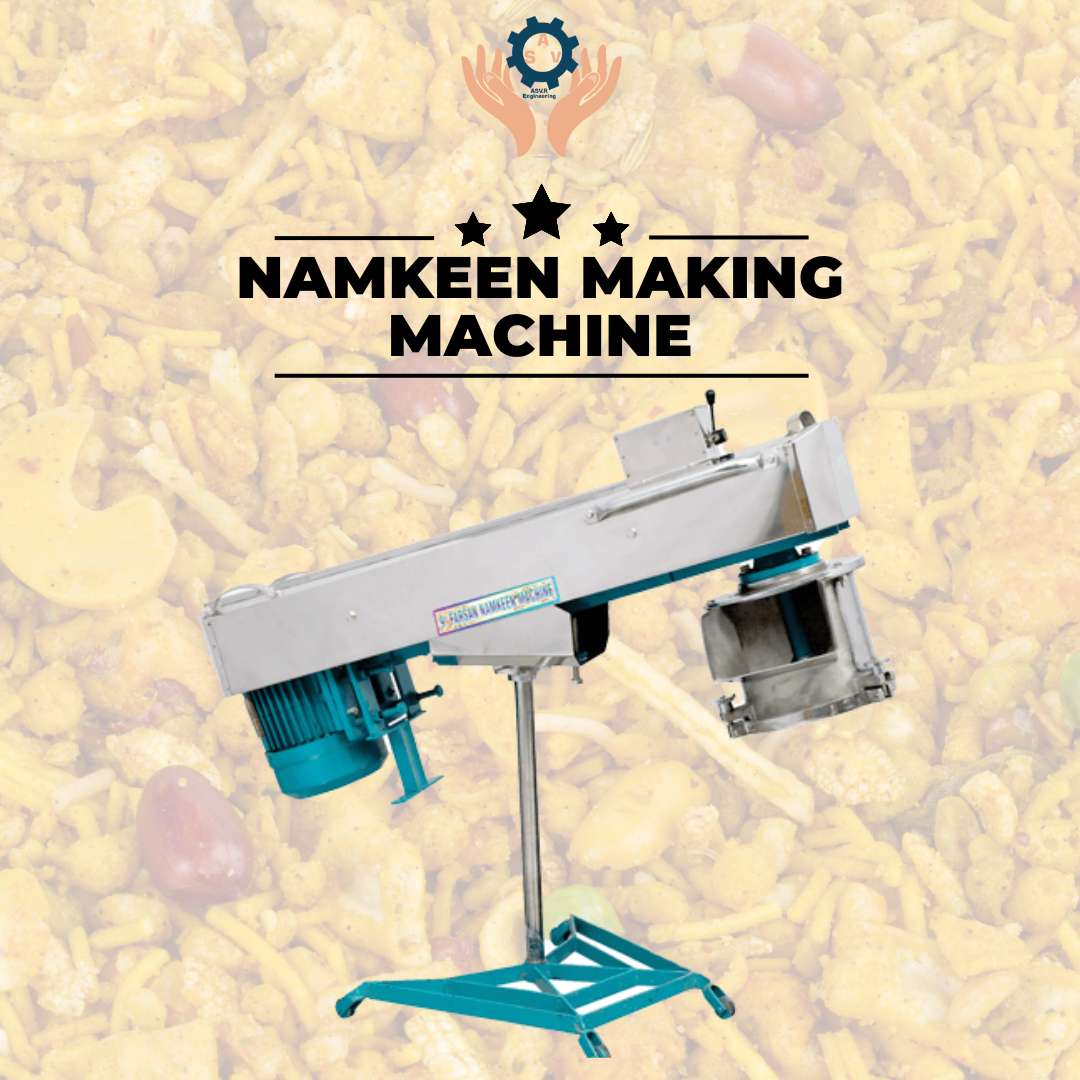

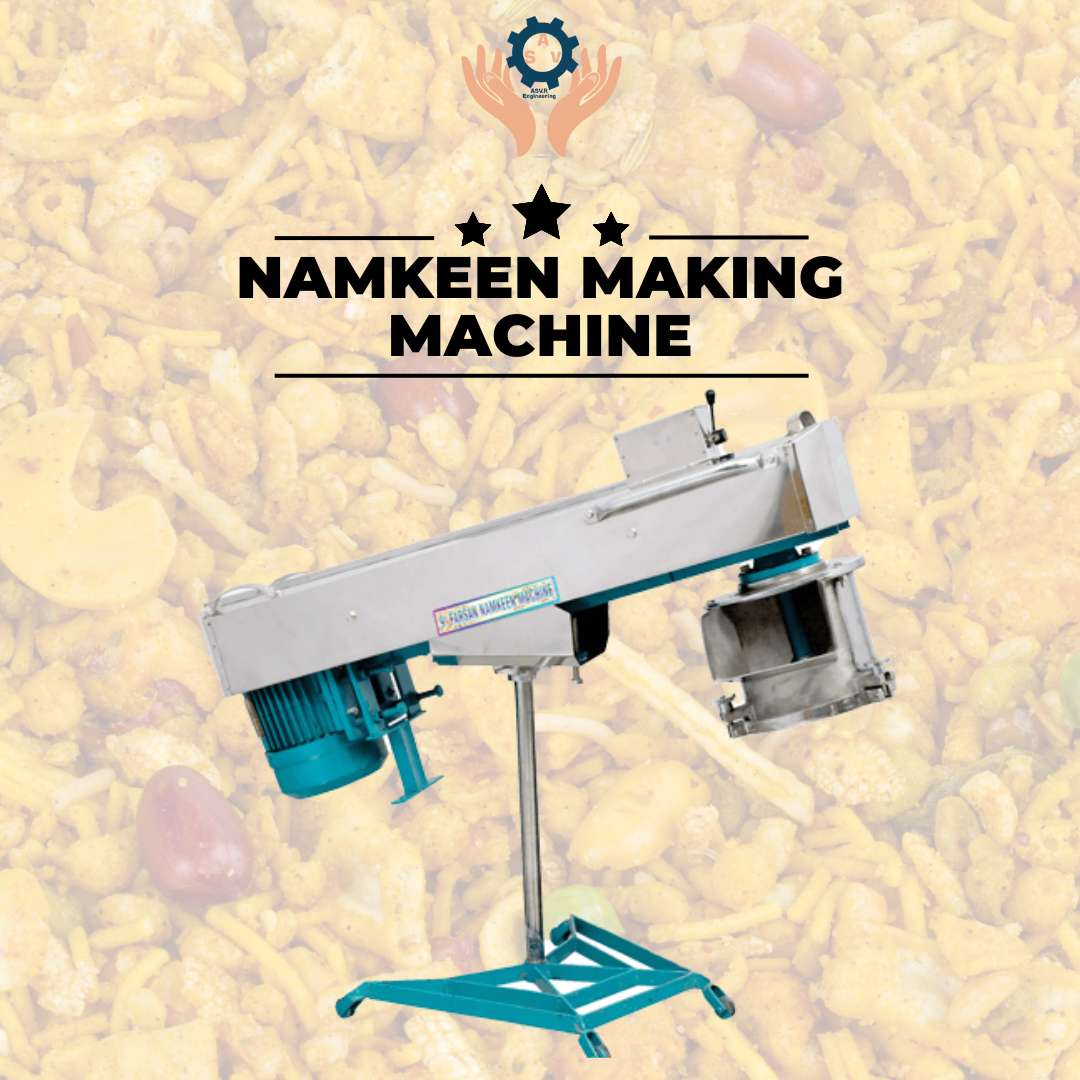

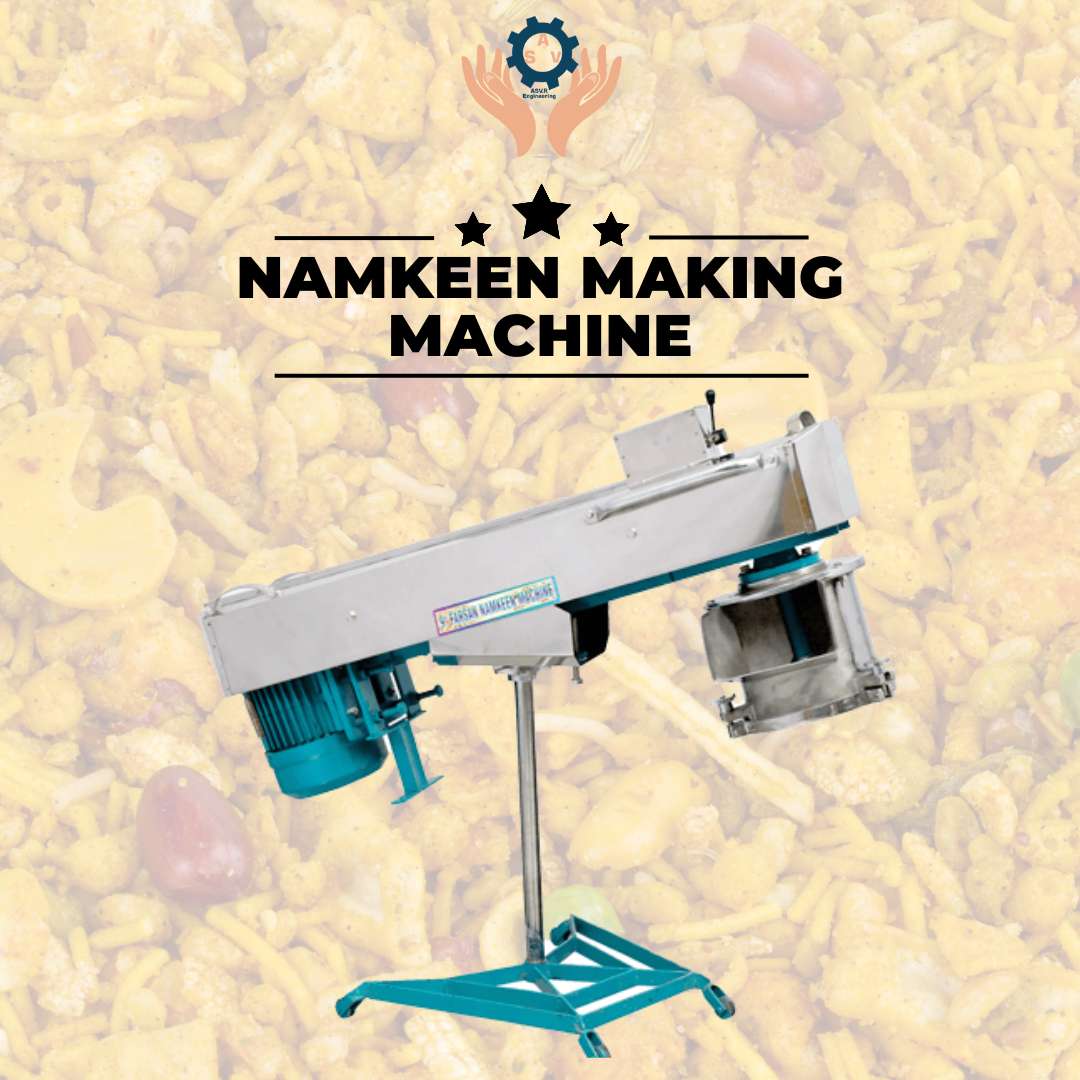

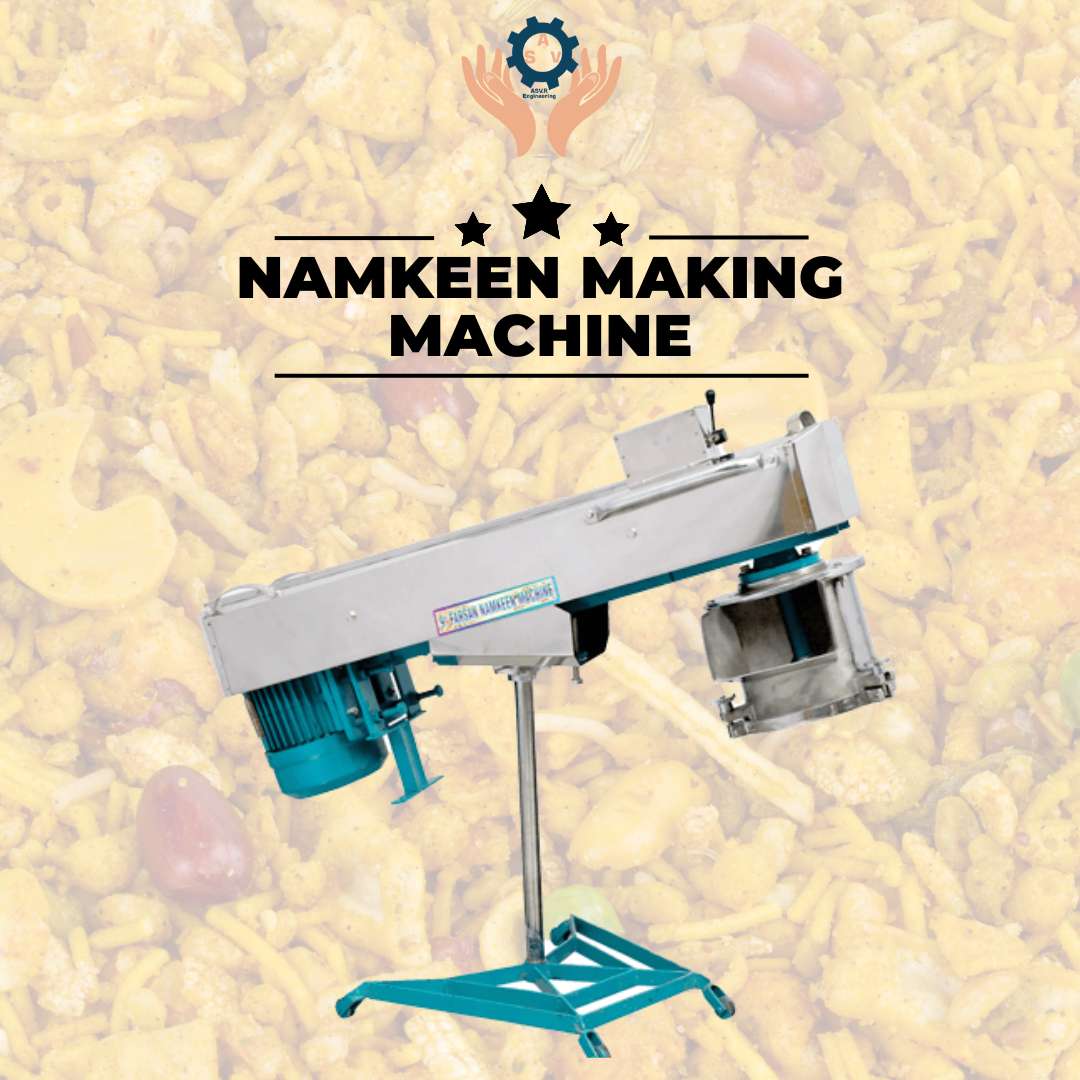

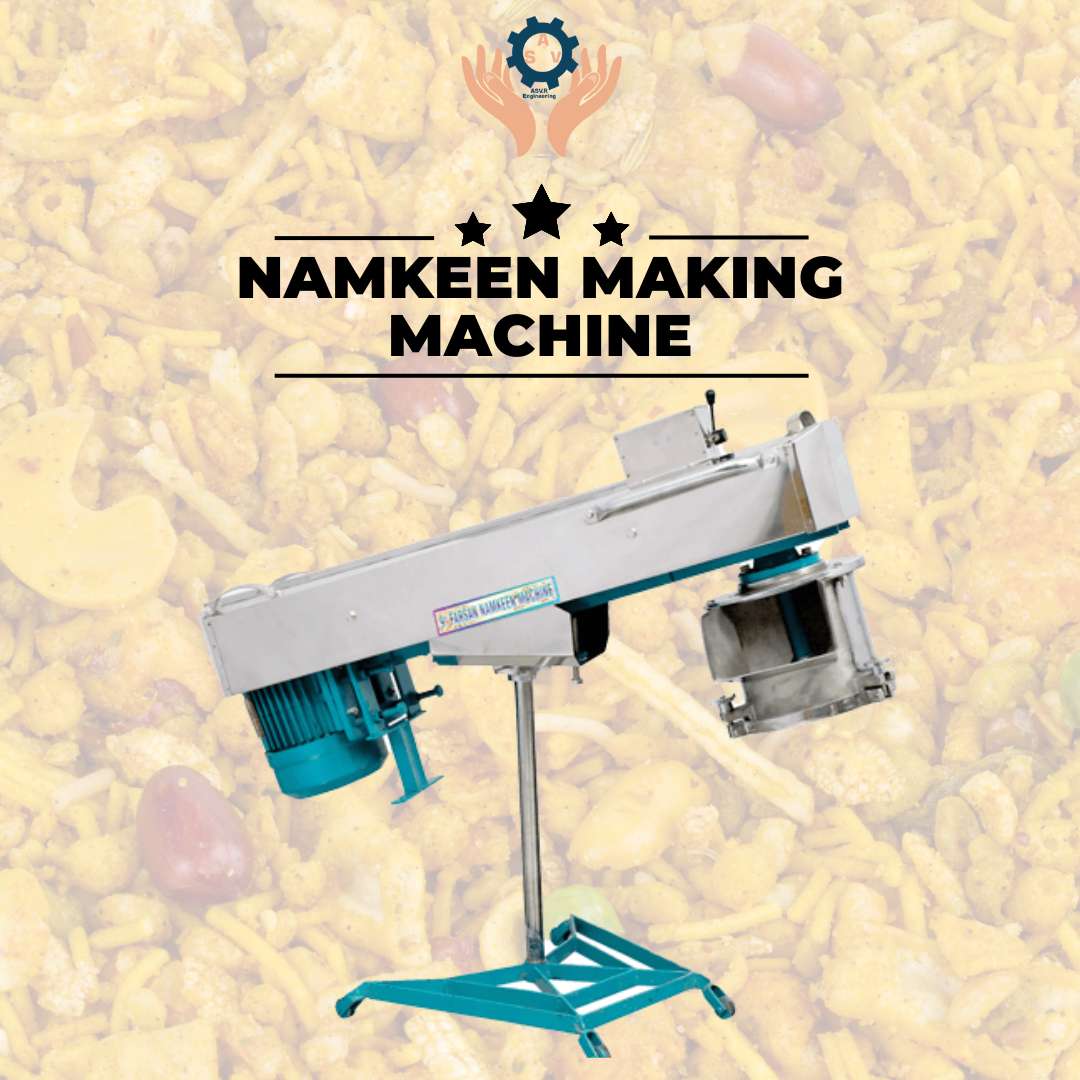

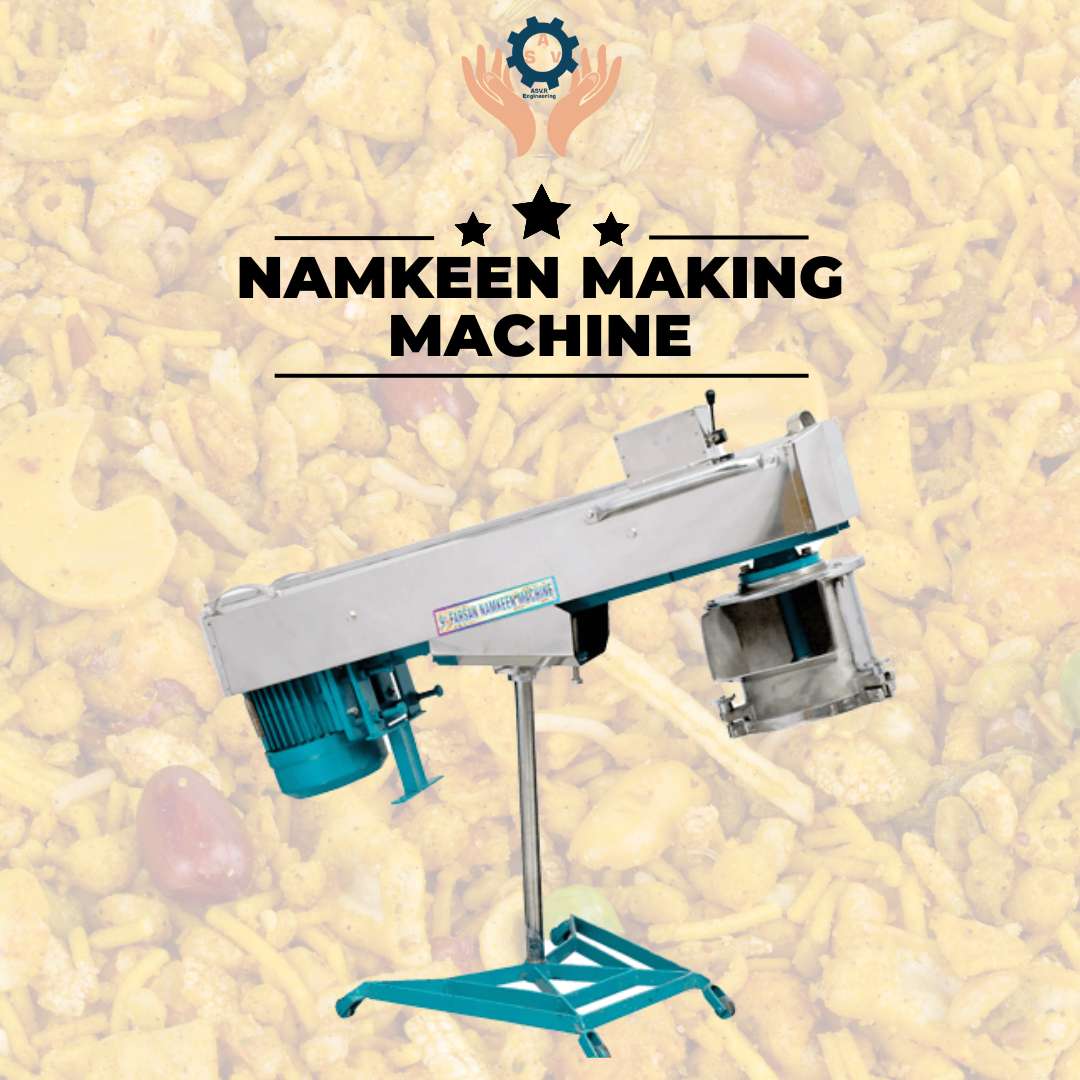

Global Semi Automatic Namkeen Making Machine Exporters Supplying Durable, High-Performance Equipment

Price: ₹37000

Introduction

The namkeen and traditional snack industry has evolved rapidly over the last decade. From small local units to large-scale export-oriented food processing plants, manufacturers today require machines that are reliable, hygienic, cost-effective, and easy to operate. In this competitive environment, choosing the right machinery partner becomes just as important as choosing the right recipe. ASVR Engineering has emerged as a trusted name among global buyers by supplying semi automatic namkeen making machines that combine durability, performance, and consistent output.

As global semi automatic namkeen making machine exporters, ASVR Engineering focuses on delivering equipment that supports both growing startups and established snack manufacturers. Their machines are designed with practical industry needs in mind—simple operation, robust construction, and the flexibility to produce a wide range of namkeen varieties such as sev, bhujia, gathiya, dal namkeen, and other regional snacks.

Understanding Semi Automatic Namkeen Making Machines

Semi automatic namkeen making machines are ideal for businesses that want to scale production without investing in fully automated systems. These machines strike a balance between manual control and mechanical efficiency. Operators can manage ingredients, shaping, frying, and seasoning with precision, while the machine ensures uniformity and speed.

Unlike fully manual setups, semi automatic systems significantly reduce labor dependency and production errors. At the same time, they are easier to maintain and more affordable than fully automatic plants, making them a preferred choice for exporters, medium-scale manufacturers, and entrepreneurs entering international markets.

Why Global Buyers Prefer Semi Automatic Namkeen Equipment

International buyers look for machines that can adapt to different working environments, voltage standards, and product preferences. Semi automatic namkeen machines from ASVR Engineering are designed to meet these global expectations.

Key reasons global buyers prefer these machines include:

-

Consistent Quality Output: Uniform shape, size, and texture of namkeen products.

-

Operational Simplicity: Easy to train operators with minimal technical background.

-

Lower Power Consumption: Optimized motors and components reduce electricity costs.

-

Versatile Production: Capability to produce multiple namkeen varieties using the same setup.

-

Export-Ready Design: Machines built as per international hygiene and safety standards.

ASVR Engineering: A Trusted Name in Namkeen Machinery Exports

ASVR Engineering has built its reputation by focusing on engineering precision and long-term performance. As global semi automatic namkeen making machine exporters, the company supplies machines that are tested for durability under continuous production conditions.

Every machine is developed using high-grade raw materials, ensuring resistance to heat, oil, and long operating hours. Their engineering team continuously improves designs based on real-world feedback from clients across domestic and international markets.

Key Features of Semi Automatic Namkeen Making Machines

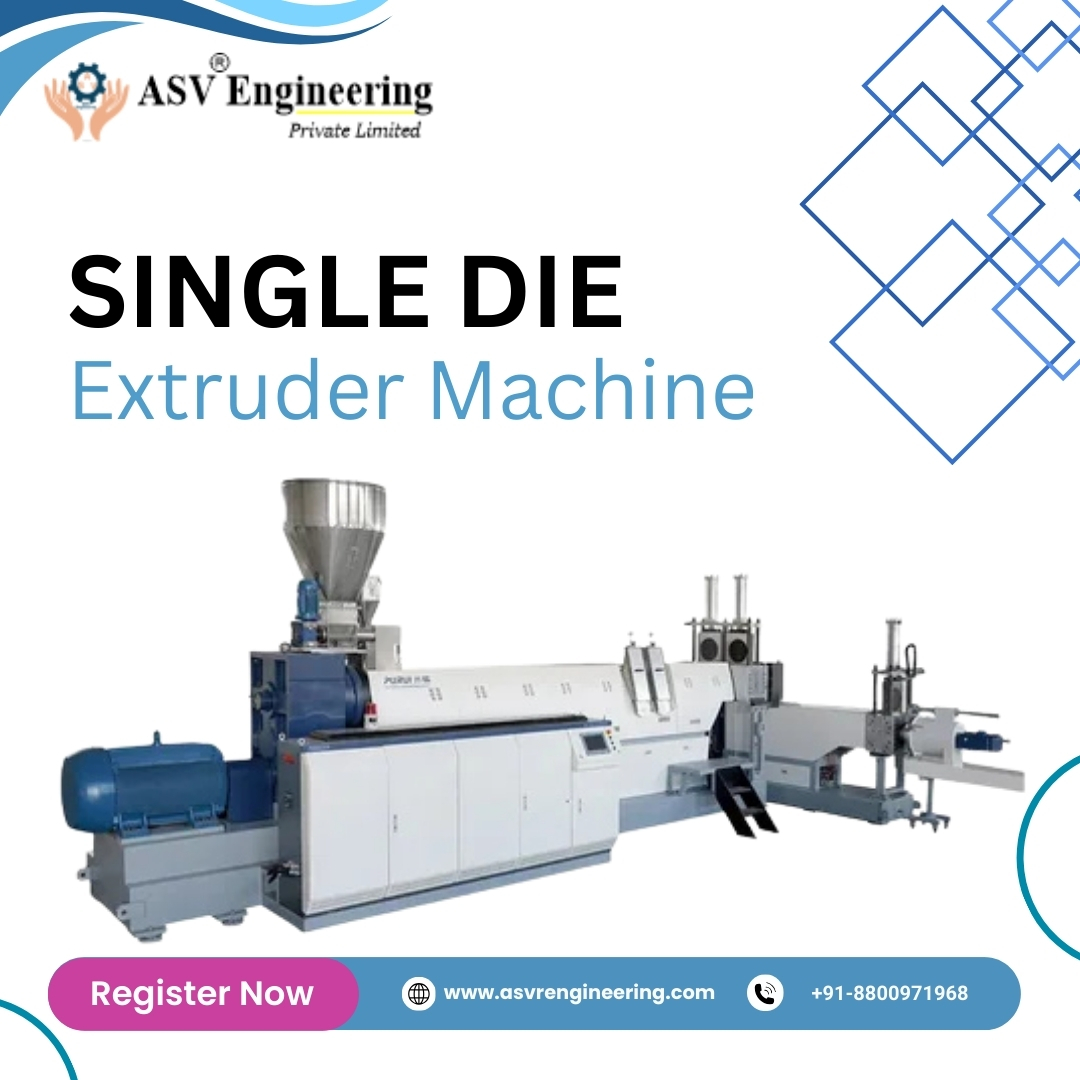

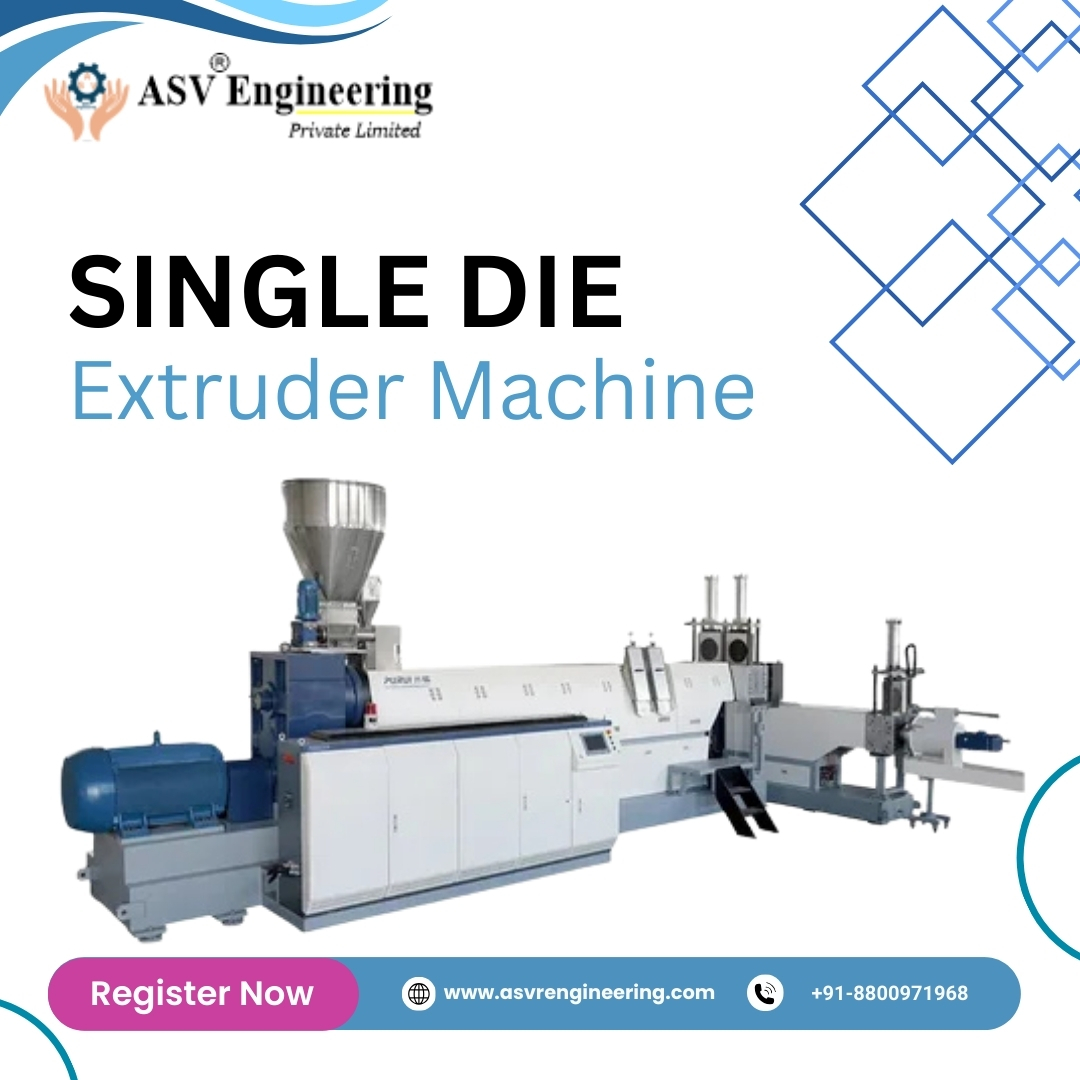

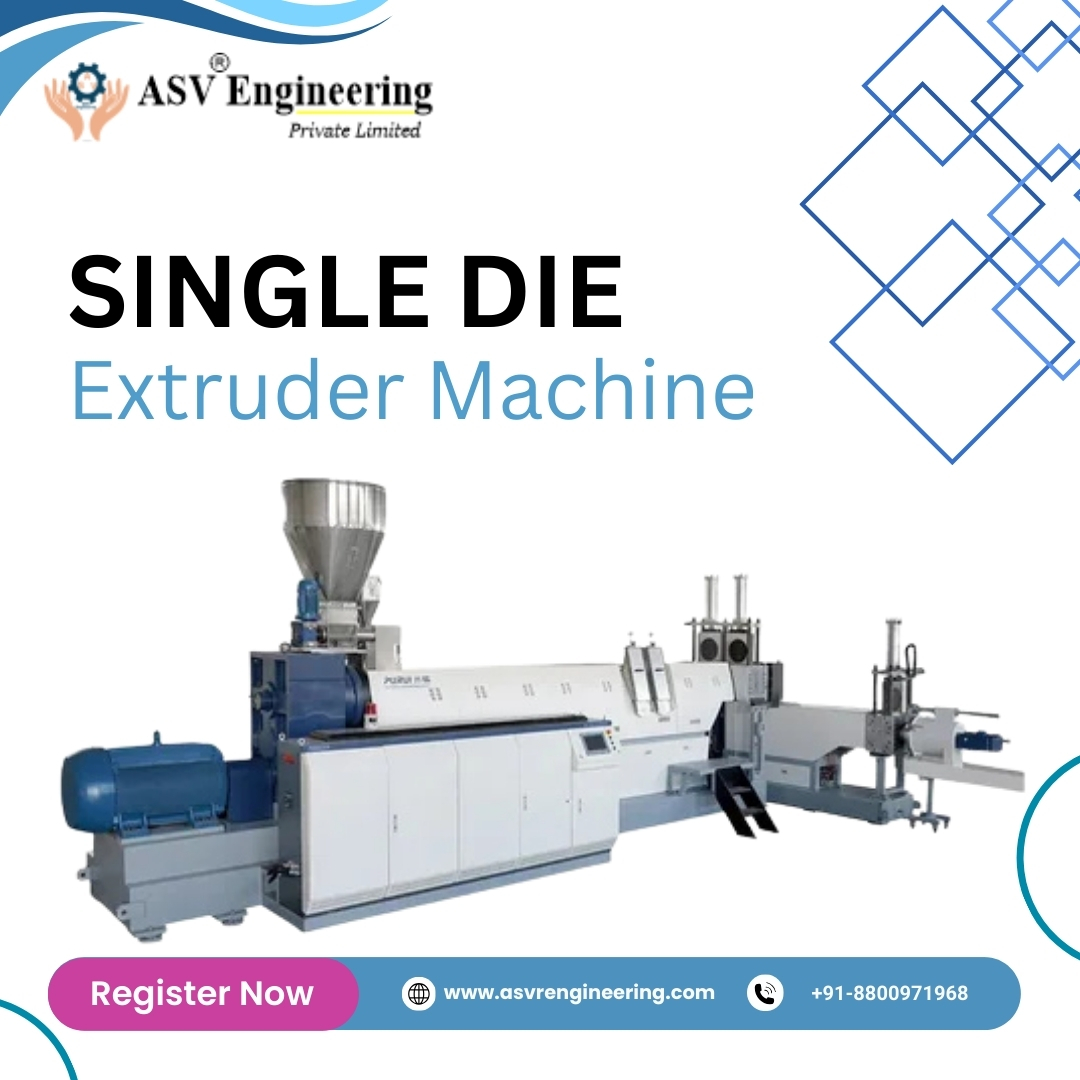

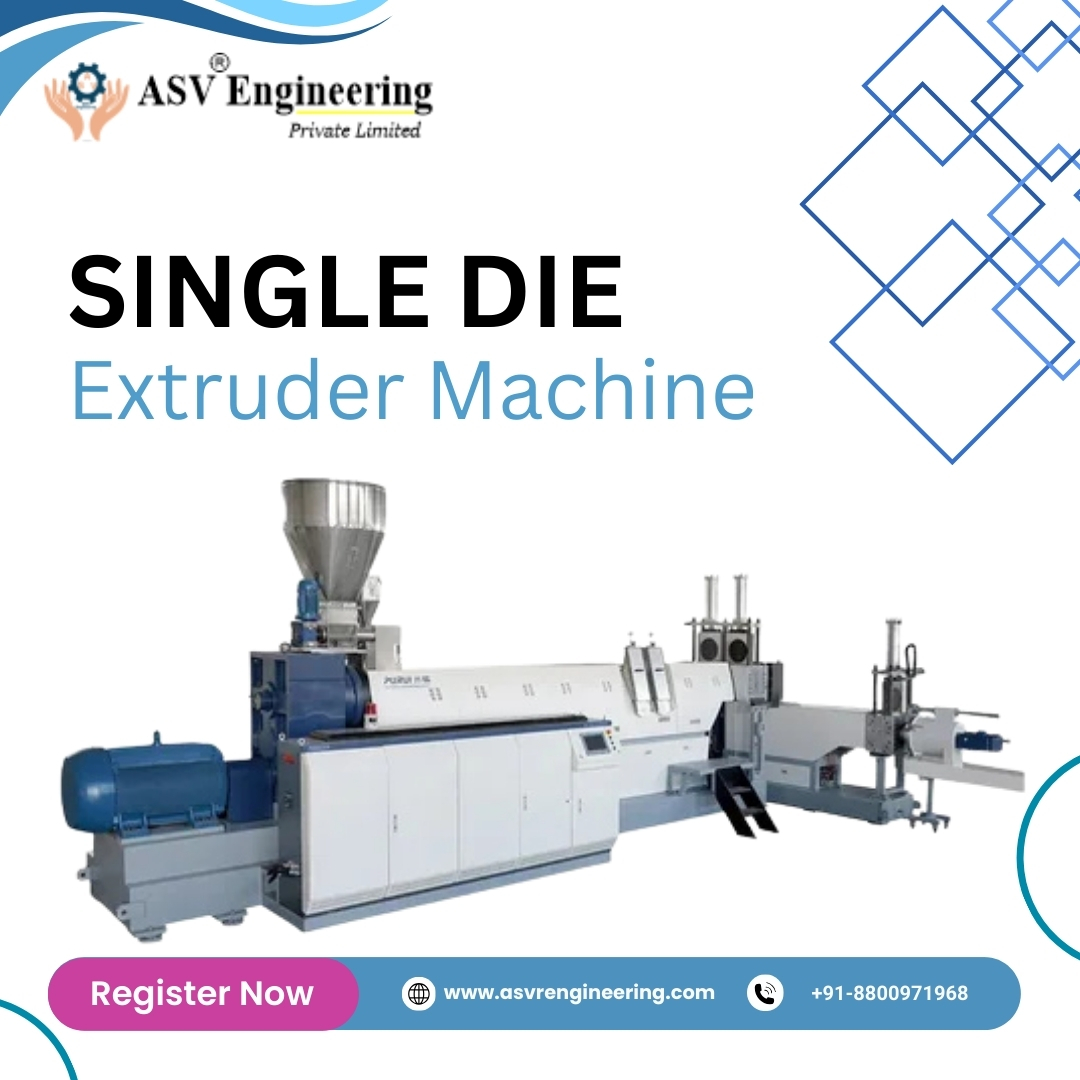

1. Robust Construction

Machines are fabricated using heavy-duty mild steel or food-grade stainless steel, ensuring long service life and easy cleaning.

2. Precision Engineering

Die plates, extruders, and cutting systems are designed to deliver consistent namkeen shapes and thickness.

3. User-Friendly Operation

Control panels and mechanical systems are simple, reducing downtime and operator fatigue.

4. High Production Efficiency

Optimized output capacity helps manufacturers meet bulk orders without compromising quality.

5. Easy Maintenance

Standardized spare parts and accessible components simplify servicing and reduce long-term costs.

Export-Quality Manufacturing Standards

When supplying machinery to international markets, quality compliance is critical. ASVR Engineering follows strict manufacturing and inspection processes to ensure export readiness.

-

Food Safety Compliance: Use of food-grade materials in contact areas.

-

Precision Testing: Machines undergo trial runs before dispatch.

-

Secure Packaging: Export-grade packaging to prevent transit damage.

-

Technical Documentation: User manuals and operational guidance provided for overseas clients.

These standards help buyers confidently install and operate machines in different countries without facing regulatory or performance issues.

Applications Across the Global Snack Industry

Semi automatic namkeen making machines supplied by ASVR Engineering are widely used in:

-

Small and medium snack manufacturing units

-

Export-oriented food processing plants

-

Regional namkeen brands expanding internationally

-

Contract manufacturing facilities

-

Traditional snack producers modernizing operations

The flexibility of these machines makes them suitable for adapting traditional Indian namkeen recipes to international taste preferences.

Benefits for Export-Oriented Businesses

For businesses targeting global markets, machinery reliability directly impacts brand reputation. ASVR Engineering’s machines help exporters achieve:

-

Stable Production Cycles: Reduced breakdowns and consistent daily output

-

Uniform Product Quality: Essential for meeting international buyer expectations

-

Cost Optimization: Lower maintenance and operational expenses

-

Scalability: Easy integration with additional equipment as demand grows

These advantages make semi automatic namkeen machines a smart long-term investment.

Customization and Technical Support

ASVR Engineering understands that no two businesses are exactly alike. That’s why they offer customization options based on production capacity, space availability, and specific namkeen types.

In addition, the company provides strong technical support, including:

-

Pre-dispatch testing and demonstration

-

Installation guidance

-

Operational training

-

After-sales support and spare parts availability

This commitment to customer success strengthens long-term partnerships with global clients.

Sustainability and Energy Efficiency

Modern food processing demands not just performance but also sustainability. ASVR Engineering integrates energy-efficient motors and optimized designs to minimize power consumption. Reduced oil wastage and efficient frying systems further support environmentally responsible production.

Why Choose ASVR Engineering as Your Export Partner

Choosing the right exporter is about more than just price. It is about reliability, service, and long-term value. ASVR Engineering stands out because of:

-

Proven experience in snack food machinery

-

Export-focused manufacturing approach

-

Transparent communication and documentation

-

Competitive pricing without quality compromise

-

Dedicated customer support

These strengths position the company as a preferred global semi automatic namkeen making machine exporter.

Conclusion

The global demand for namkeen and traditional snacks continues to rise, creating immense opportunities for manufacturers and exporters. Success in this market depends heavily on reliable machinery that delivers consistent quality and performance. ASVR Engineering meets these demands by supplying durable, high-performance semi automatic namkeen making machines designed for export markets.

For businesses looking to expand production, improve efficiency, and maintain international quality standards, partnering with ASVR Engineering is a strategic step toward sustainable growth.

Company Details

Company Name: ASVR Engineering

Contact Numbers: +91-8076004849, +91-8800971968

Website: https://www.asvrengineering.com

Buy Now

Related Posts

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)