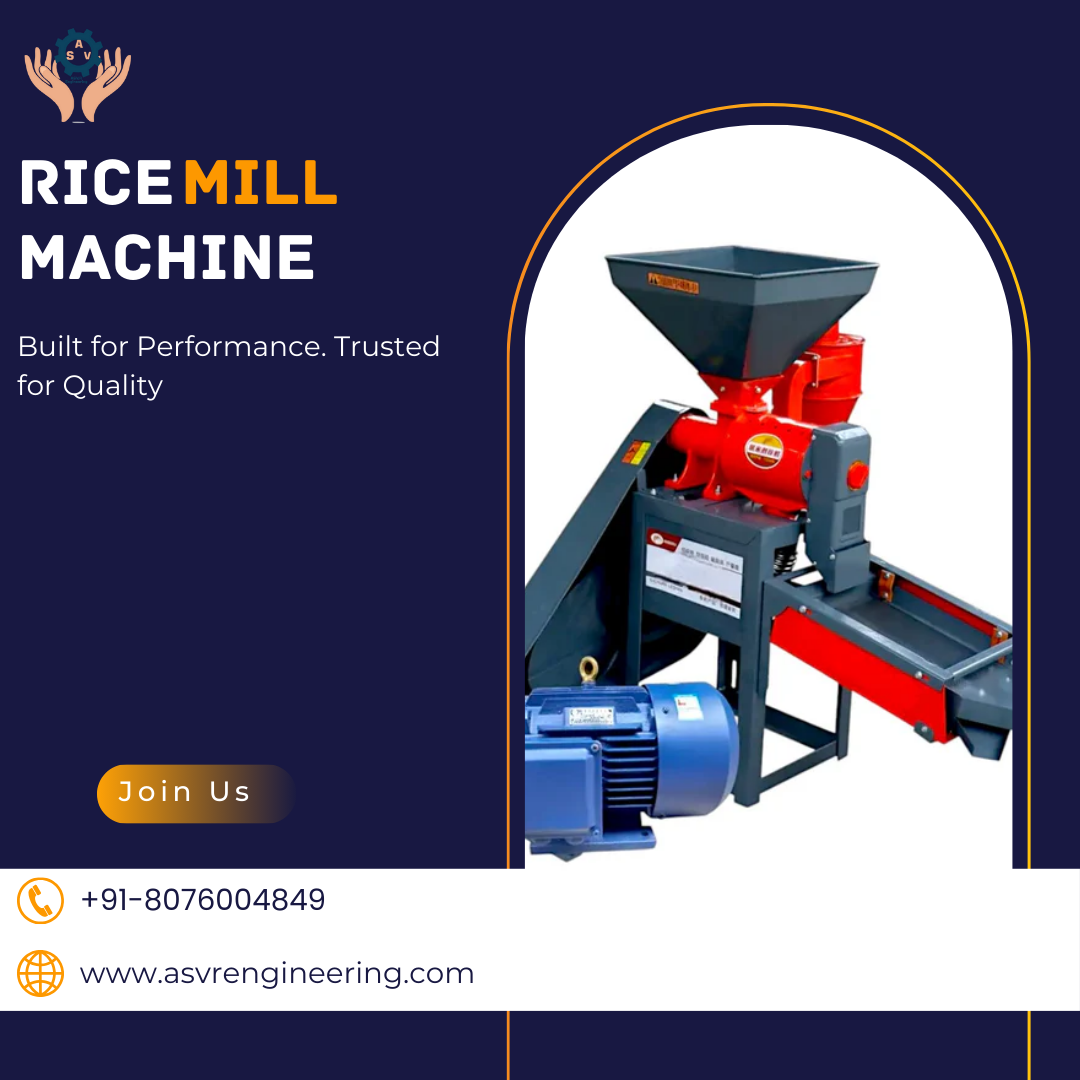

Mini Rice Mill Machine

Price: ₹45000

Rice is one of the most consumed staple foods in India, and its demand continues to rise across domestic and international markets. With increasing consumption, the need for efficient, compact, and affordable rice processing solutions has also grown. A Mini Rice Mill Machine is designed to meet this demand perfectly, especially for small entrepreneurs, farmers, self-help groups, and startups looking to enter the rice milling business with low investment and high returns.

Unlike large rice mills that require heavy capital, large land areas, and complex operations, a mini rice mill machine offers a simplified yet highly effective way to process paddy into polished rice. It is compact, easy to operate, energy-efficient, and suitable for both rural and semi-urban areas.

At ASVR Engineering, we specialize in manufacturing and supplying robust, reliable, and high-performance mini rice mill machines that deliver consistent quality output and long-term operational benefits.

What Is a Mini Rice Mill Machine?

A mini rice mill machine is a small-scale rice processing unit that converts raw paddy into edible rice through multiple stages such as cleaning, dehusking, separation, whitening, and polishing. Despite its compact size, it performs all essential milling functions with high precision.

These machines are specifically engineered for:

-

Small rice mill owners

-

Farmers processing their own produce

-

Rural entrepreneurs

-

Cooperative societies

-

Startups in agro-processing

The machine can process different varieties of paddy and is suitable for daily use with minimal supervision.

Key Components of a Mini Rice Mill Machine

A standard mini rice mill machine includes several integrated components that ensure smooth and efficient rice processing:

1. Paddy Cleaner

Removes dust, stones, straw, and other impurities from raw paddy, ensuring clean input material.

2. Dehusker (Sheller)

Separates the husk from the paddy grain without damaging the rice kernel.

3. Paddy Separator

Separates un-husked paddy from brown rice for reprocessing, improving recovery rate.

4. Rice Whitener

Removes the bran layer from brown rice to produce white rice of uniform quality.

5. Rice Polisher

Enhances the appearance, shine, and market value of rice.

6. Blower & Aspirator

Efficiently removes husk and bran, keeping the processing area clean.

All these components work together seamlessly in a compact design, making the mini rice mill machine highly productive and reliable.

Advantages of Using a Mini Rice Mill Machine

Low Investment, High Profit

One of the biggest advantages of a mini rice mill machine is its affordability. Compared to large-scale rice mills, the initial investment is much lower, making it ideal for small businesses and new entrepreneurs.

Compact & Space-Saving Design

The machine requires minimal space and can be installed in small workshops or rural settings without the need for large infrastructure.

Easy Operation

Designed with user-friendly controls, the machine can be operated by semi-skilled or trained workers with ease.

Energy Efficient

Consumes less power while delivering excellent output, helping reduce operational costs.

High Rice Recovery

Advanced milling technology ensures minimum breakage and higher yield of whole rice grains.

Low Maintenance

Built with high-quality materials and precision engineering, the machine requires minimal maintenance and offers long service life.

Applications of Mini Rice Mill Machine

-

Small-scale rice milling businesses

-

Farmers processing paddy for personal and local sale

-

Village-level rice processing units

-

Agro-based startups

-

Cooperative and SHG-based enterprises

The flexibility of the mini rice mill machine allows it to adapt to various business models and production capacities.

Why Mini Rice Mill Machine Is Ideal for Farmers

Farmers often sell raw paddy at lower prices due to lack of processing facilities. By installing a mini rice mill machine, farmers can process their own produce and sell finished rice directly to the market, significantly increasing profit margins.

Benefits for farmers include:

-

Better control over product quality

-

Higher income from value addition

-

Reduced dependency on large mills

-

Opportunity for local employment

Mini Rice Mill Machine for Small Business & Startups

If you are planning to start a rice milling business with limited capital, a mini rice mill machine is the perfect solution. With growing demand for locally processed, fresh rice, small mills are gaining popularity.

The business advantages include:

-

Quick return on investment

-

Growing local and regional demand

-

Simple licensing and setup process

-

Scalable operations

Many entrepreneurs start with a mini rice mill and later expand to larger units as demand increases.

Build Quality & Technology

At ASVR Engineering, our mini rice mill machines are manufactured using premium-grade raw materials and advanced production techniques. Each machine undergoes strict quality checks to ensure durability, efficiency, and consistent performance.

Key highlights:

-

Heavy-duty structure

-

Precision-engineered components

-

Smooth operation with low vibration

-

Long-lasting performance

Our focus is on delivering machines that work reliably even under continuous operation.

Installation & Support

We provide complete guidance for installation and setup of the mini rice mill machine. Our technical team ensures that the machine is installed correctly and operates at optimal efficiency.

We also offer:

-

Operational training

-

Maintenance guidance

-

Prompt after-sales support

-

Availability of spare parts

Why Choose ASVR Engineering?

Choosing the right manufacturer is as important as choosing the right machine. ASVR Engineering has built a strong reputation in the field of industrial and agro-processing machinery.

What Sets Us Apart:

-

Years of manufacturing expertise

-

Customizable machine options

-

Competitive pricing

-

Strong customer support

-

Pan-India supply capability

Our machines are trusted by hundreds of clients across India for their performance and reliability.

Market Demand & Business Potential

Rice consumption in India continues to grow due to population increase and food security needs. This creates a steady and reliable market for rice milling businesses. Mini rice mill machines enable small players to enter this market with confidence.

With proper planning, sourcing of paddy, and local marketing, a mini rice mill business can become a sustainable and profitable venture.

Environment-Friendly Milling

Modern mini rice mill machines are designed to minimize waste and energy consumption. By-products like husk and bran can be reused as cattle feed, fuel, or raw material for other industries, making the process more sustainable and eco-friendly.

Contact ASVR Engineering

If you are looking for a reliable, efficient, and affordable Mini Rice Mill Machine, ASVR Engineering is your trusted partner.

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Our team will be happy to guide you with the right machine based on your capacity, budget, and business goals.

Buy Now

Related Posts

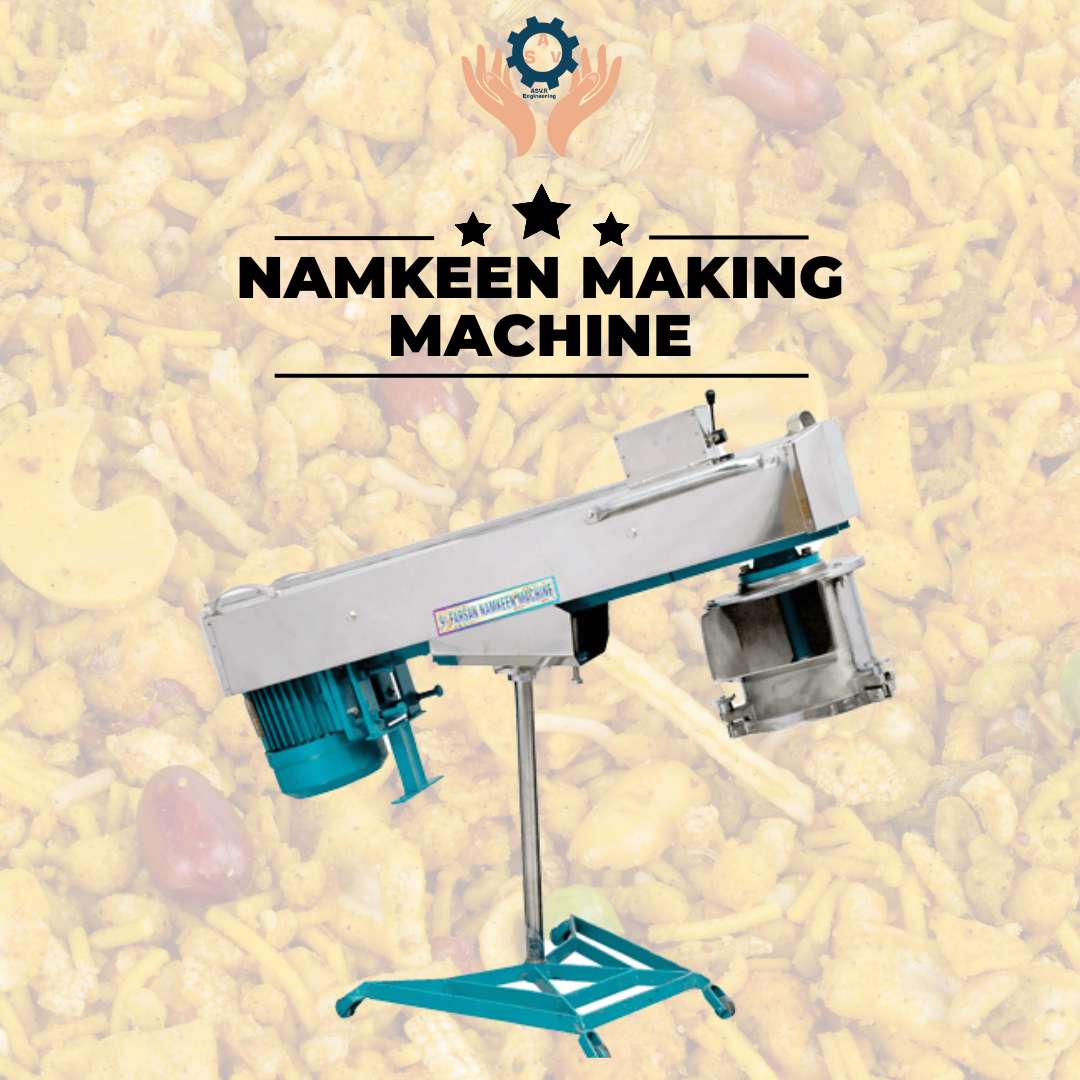

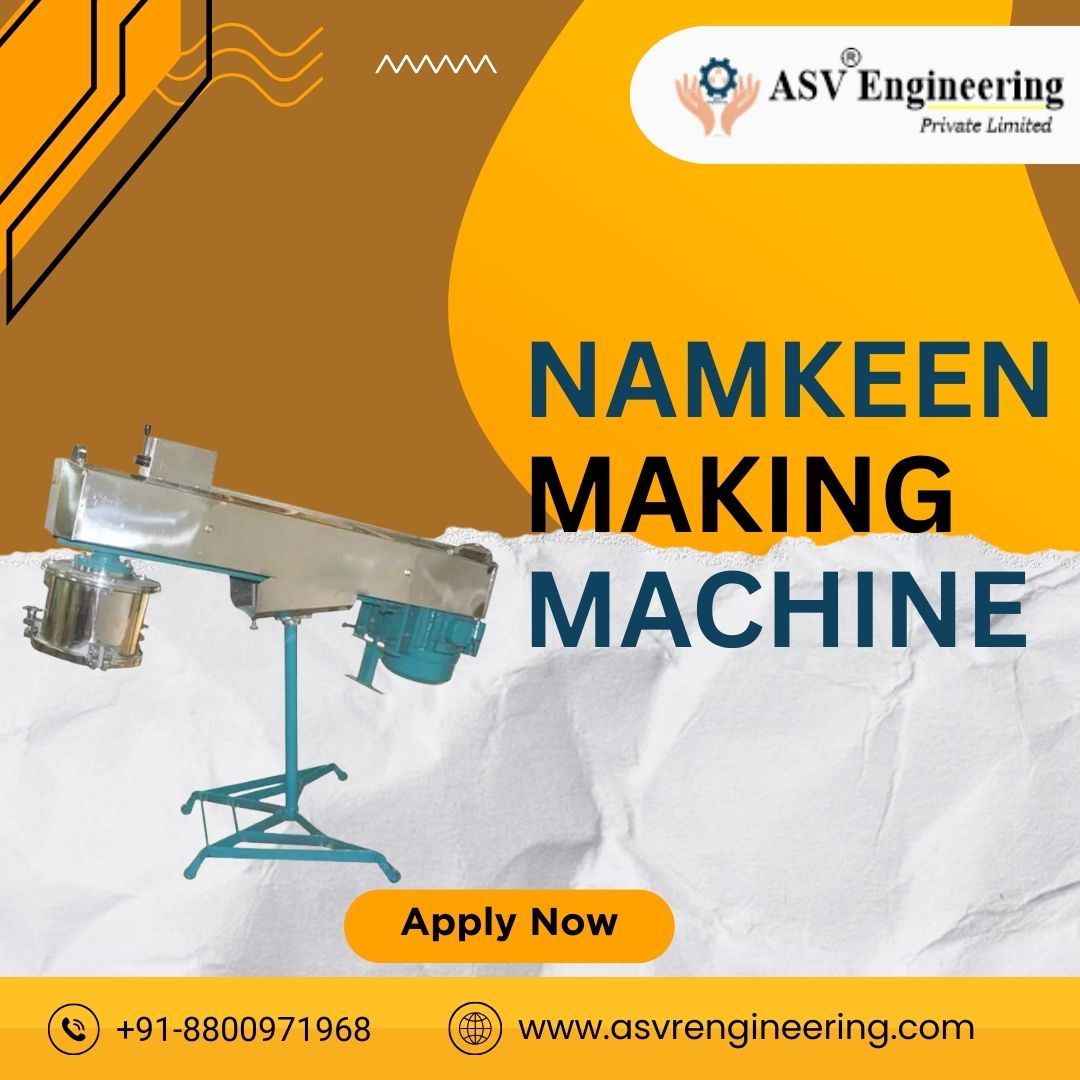

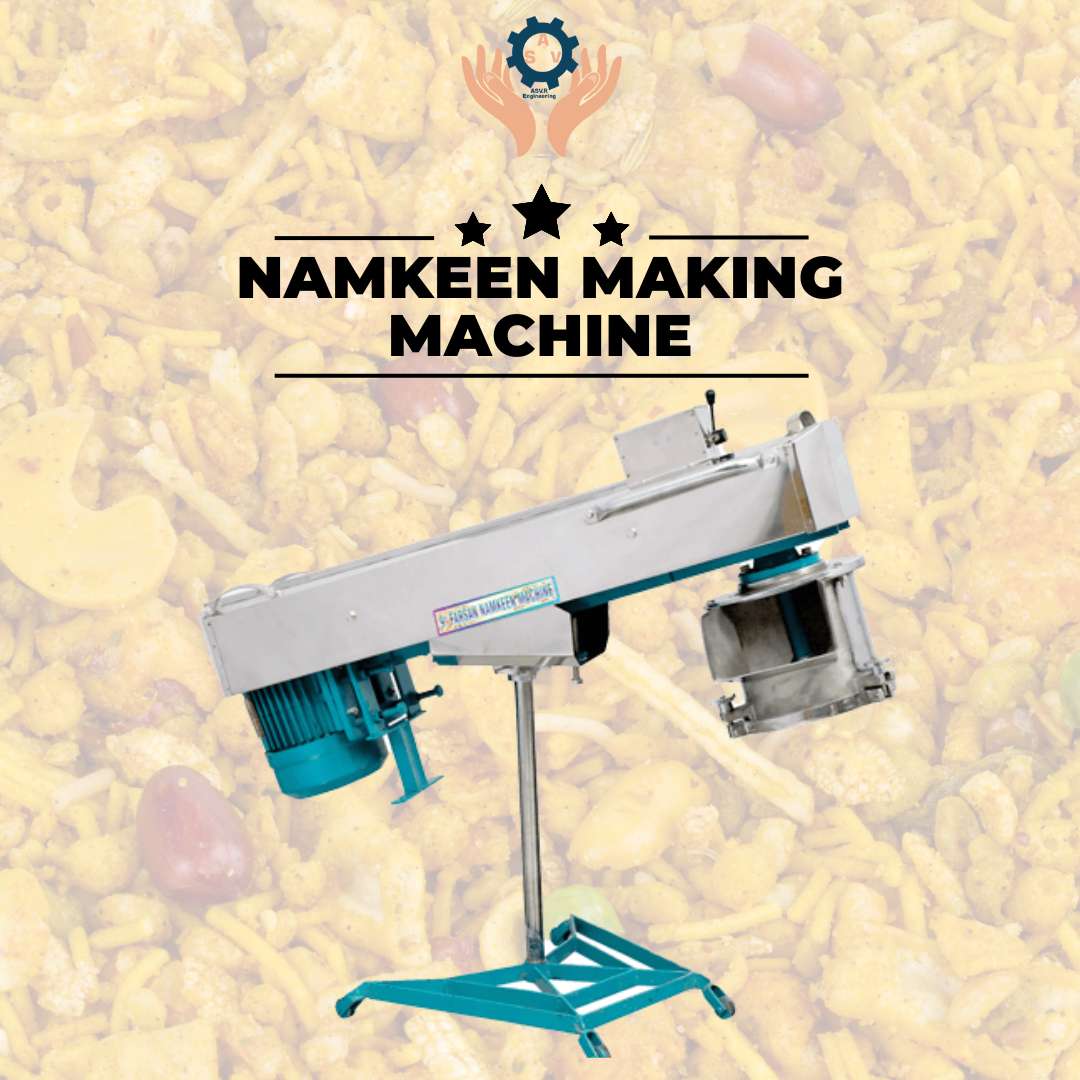

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)