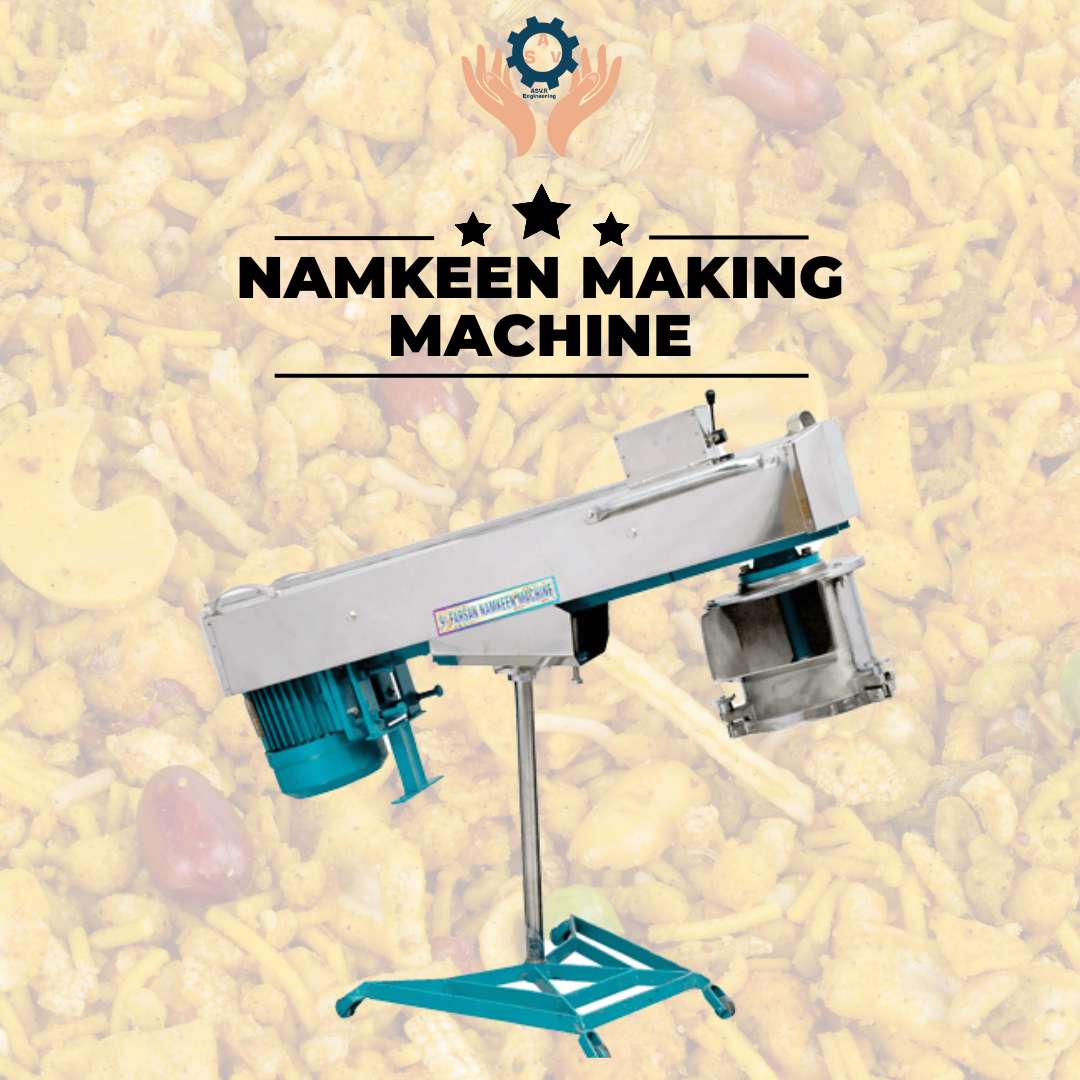

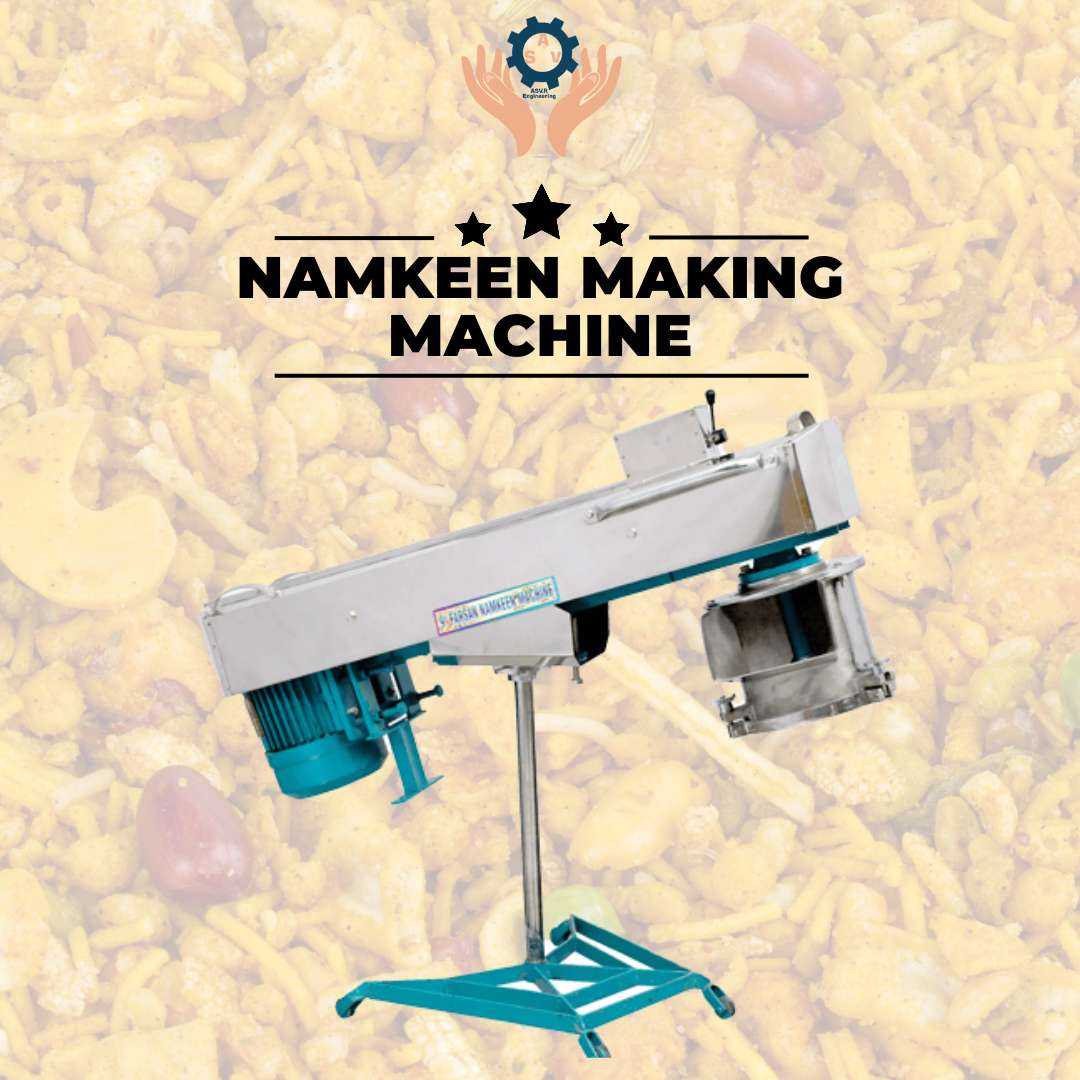

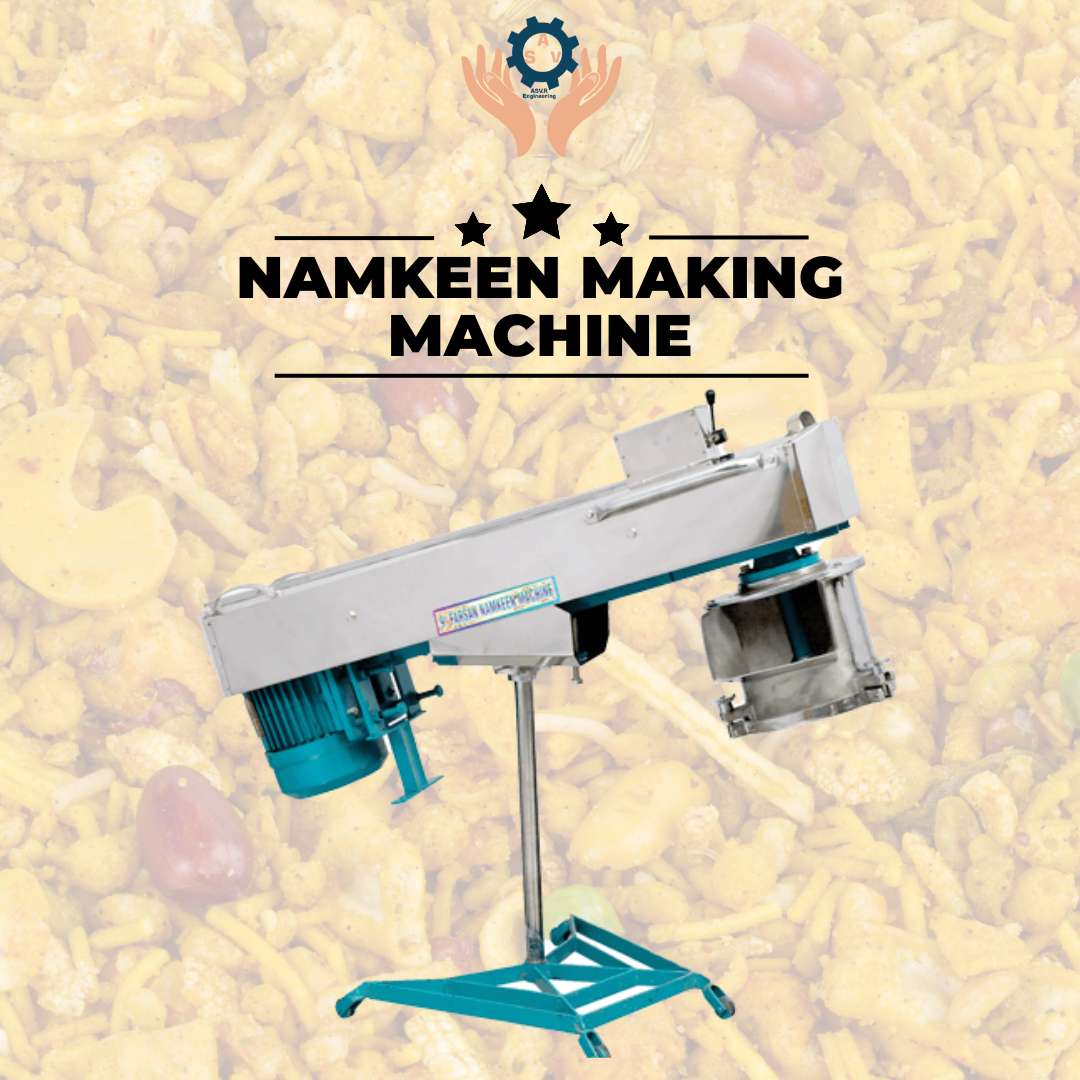

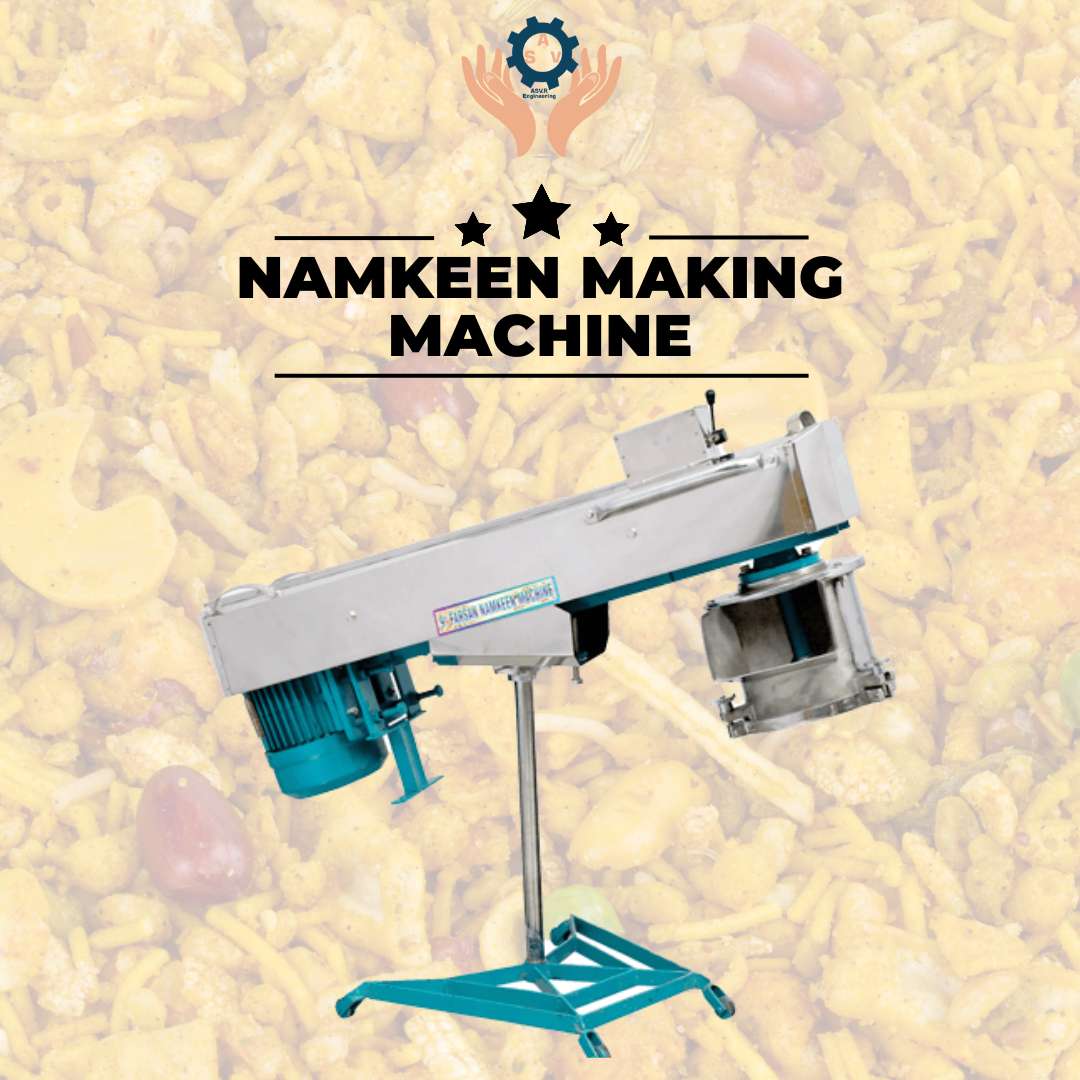

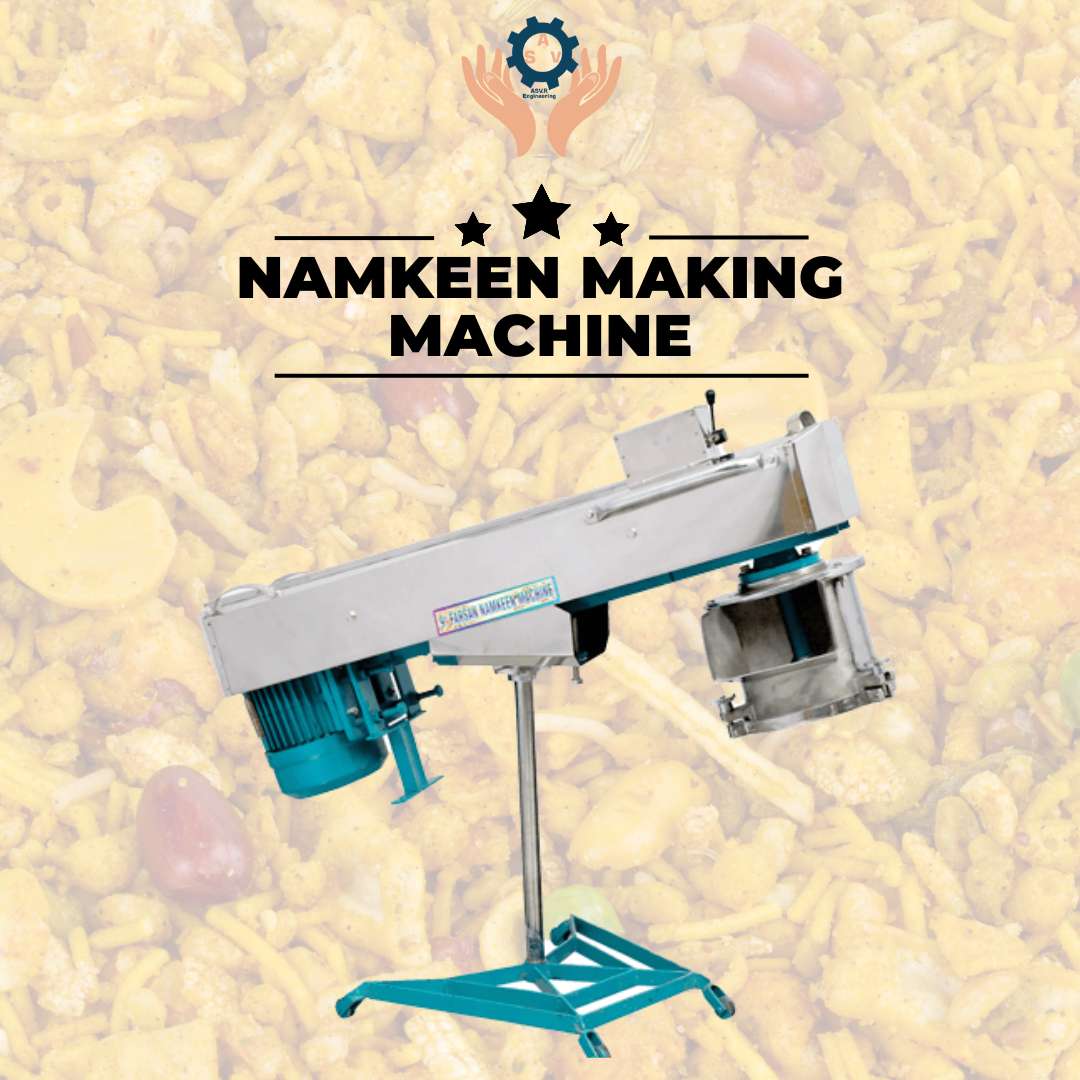

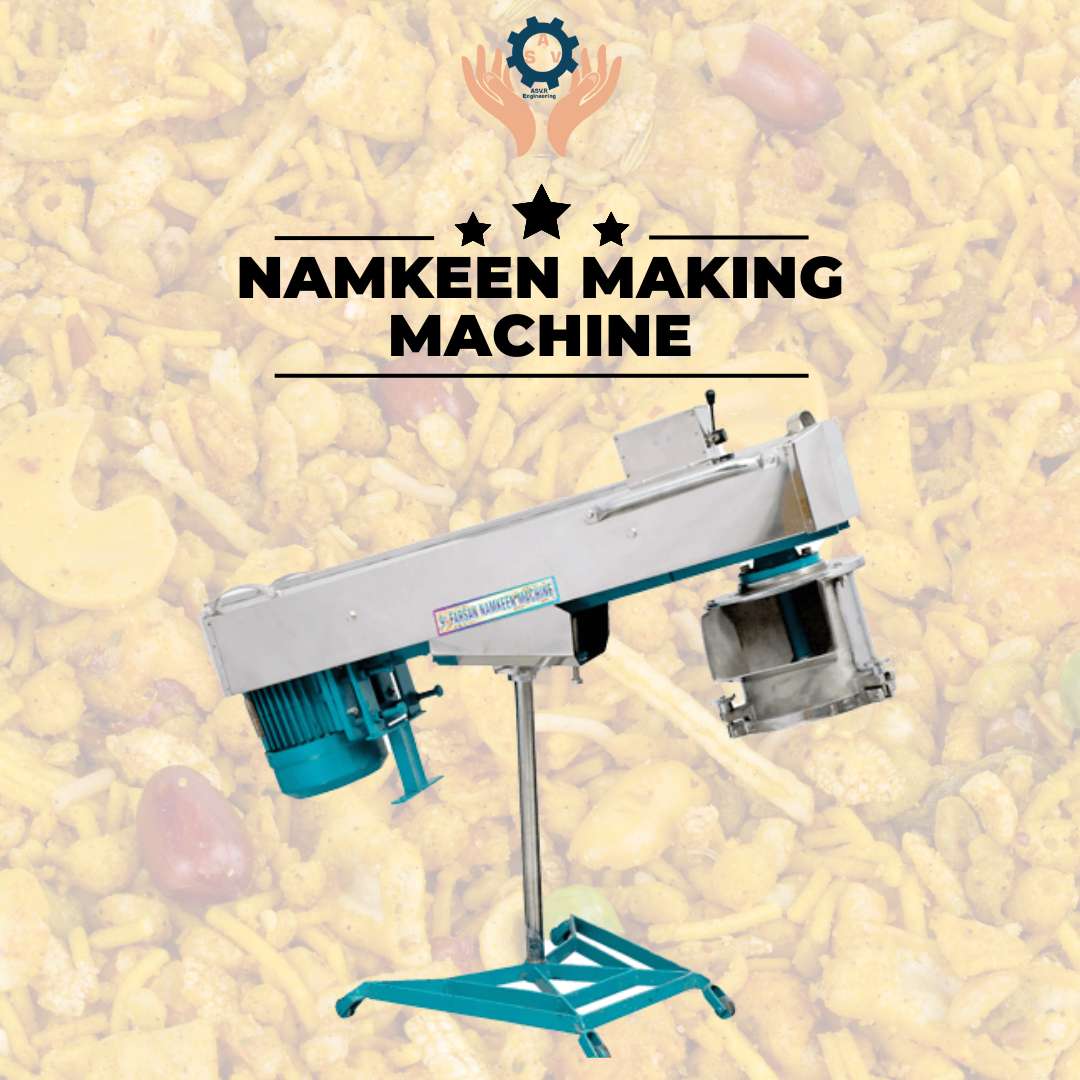

Reliable Automatic Namkeen Making Machine Importers for Small & Large-Scale Snack Manufacturing Units

Price: ₹43000

In India, namkeen is not just a snack—it is a daily habit, a festive essential, and a fast-growing business opportunity. From local kirana stores to national supermarket chains, the demand for hygienically produced, consistent-quality namkeen has increased rapidly. To meet this demand, manufacturers today rely on advanced automation rather than manual or semi-automatic methods. This is where reliable automatic namkeen making machine importers play a crucial role in supporting both emerging entrepreneurs and established snack brands.

At ASVR Engineering, we understand the evolving needs of the Indian snack food industry. By importing and supplying high-performance automatic namkeen making machines, we help manufacturers achieve better productivity, uniform taste, and scalable operations—without compromising on quality or hygiene.

Growing Demand for Automatic Namkeen Making Machines in India

The Indian snack market has witnessed strong growth over the last decade. With changing lifestyles, increasing urbanization, and higher disposable income, ready-to-eat snacks like sev, bhujia, gathiya, boondi, and mixture have become everyday staples. Traditional production methods, while suitable for small volumes, struggle to maintain consistency and hygiene when demand increases.

Automatic namkeen making machines solve these challenges by:

-

Reducing dependency on skilled labor

-

Ensuring uniform shape, size, and texture

-

Increasing production capacity with minimal wastage

-

Maintaining food-grade hygiene standards

For small-scale units, automation offers a clear path to expansion. For large-scale snack manufacturers, it ensures efficiency, repeatability, and cost control.

Why Import Quality Matters in Namkeen Machinery

Not all machines deliver the same results. Imported automatic namkeen making machines are designed using advanced engineering standards and are tested for long-term industrial use. As experienced importers, we focus on machines that offer durability, precision, and adaptability to Indian snack recipes.

Key advantages of imported namkeen machines include:

-

Robust construction with food-grade stainless steel

-

Advanced control systems for consistent output

-

Energy-efficient motors and heating systems

-

Compatibility with multiple namkeen varieties

By sourcing from trusted international manufacturers, we ensure that Indian snack producers receive machinery that performs reliably even under continuous operation.

Complete Automatic Namkeen Production Line Solutions

A modern namkeen manufacturing unit is more than just a single machine. It is a complete production line working in synchronization. As reliable automatic namkeen making machine importers, we provide integrated solutions that cover the entire process.

Typical components include:

-

Dough mixing and feeding system

-

Namkeen forming or extrusion machine

-

Continuous fryer with temperature control

-

Oil filtration and recycling system

-

Cooling conveyor

-

Seasoning and mixing drum

-

Packing machine integration support

This end-to-end approach helps manufacturers streamline operations, reduce handling time, and maintain product consistency from batch to batch.

Solutions for Small-Scale Snack Manufacturing Units

Many first-generation entrepreneurs hesitate to invest in automation, assuming it is suitable only for large factories. In reality, compact automatic namkeen making machines are ideal for small and medium units aiming to grow steadily.

Benefits for small-scale units include:

-

Lower manpower requirement

-

Faster return on investment

-

Easy operation and maintenance

-

Scope for gradual capacity expansion

With proper guidance, small manufacturers can start with a basic automatic setup and later upgrade as demand grows. Our team assists in selecting machines that align with current production goals and future plans.

High-Capacity Machines for Large-Scale Namkeen Producers

Large snack manufacturing units operate in a highly competitive environment where consistency, speed, and hygiene are critical. Automatic namkeen making machines designed for large-scale operations can produce hundreds of kilograms per hour with minimal downtime.

These machines are suitable for:

-

National and regional snack brands

-

Export-oriented namkeen manufacturers

-

Contract manufacturing units

-

Institutional snack suppliers

By importing heavy-duty machines with advanced automation, we help large-scale producers maintain quality standards while meeting high-volume requirements.

Focus on Hygiene, Safety, and Compliance

Food safety regulations are becoming stricter across India. Automatic namkeen making machines imported and supplied by us are designed to meet international food processing norms. Stainless steel contact parts, enclosed frying systems, and easy-to-clean designs ensure hygienic production.

Additional safety features include:

-

Temperature and oil level controls

-

Emergency stop systems

-

Overload protection

-

Safe electrical and control panels

These features not only protect the product but also ensure operator safety and regulatory compliance.

Energy Efficiency and Cost Optimization

Energy consumption plays a significant role in snack manufacturing costs. Modern automatic namkeen making machines are designed for optimal fuel and power efficiency. Improved insulation, efficient burners, and advanced motors reduce operating expenses without affecting output quality.

Over time, this efficiency translates into:

-

Lower per-unit production cost

-

Reduced oil and raw material wastage

-

Improved profitability

This makes automation a smart long-term investment rather than a short-term expense.

After-Sales Support and Technical Guidance

Importing quality machinery is only part of the solution. Proper installation, training, and after-sales support are equally important. We provide complete technical assistance to ensure smooth commissioning and operation of automatic namkeen making machines.

Our support includes:

-

Installation supervision

-

Operator training

-

Maintenance guidance

-

Availability of spares and service support

This hands-on approach helps manufacturers run their plants with confidence and minimal downtime.

Why Choose ASVR Engineering as Your Machine Import Partner

Choosing the right importer can make a significant difference in your production success. At ASVR Engineering, our focus is on long-term partnerships rather than one-time sales.

What sets us apart:

-

Proven experience in industrial food processing machinery

-

Carefully selected imported machines

-

Transparent technical consultation

-

Commitment to customer satisfaction

Whether you are starting a new namkeen manufacturing unit or upgrading an existing plant, our team ensures that you receive the right solution for your specific needs.

Empowering the Future of Snack Manufacturing

The future of namkeen manufacturing lies in automation, consistency, and smart production planning. With the right machines and the right import partner, manufacturers can scale their businesses, meet market demand, and maintain product quality across regions.

As reliable automatic namkeen making machine importers, we take pride in supporting India’s snack industry—helping small entrepreneurs grow into established brands and enabling large manufacturers to operate more efficiently.

Contact Details

Company: ASVR Engineering

Phone: +91-8076004849, +91-8800971968

Website: https://www.asvrengineering.com

Buy Now

Related Posts

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)