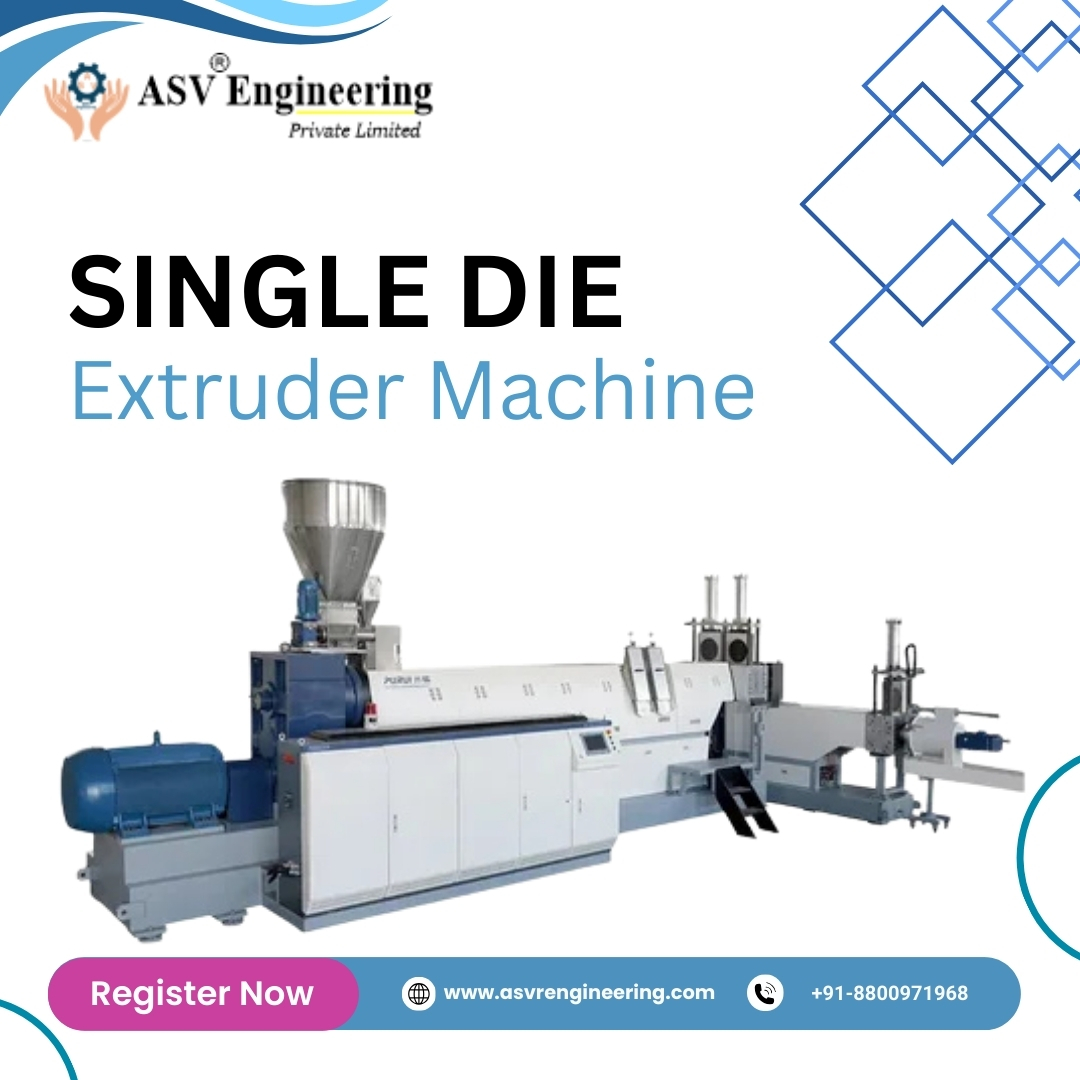

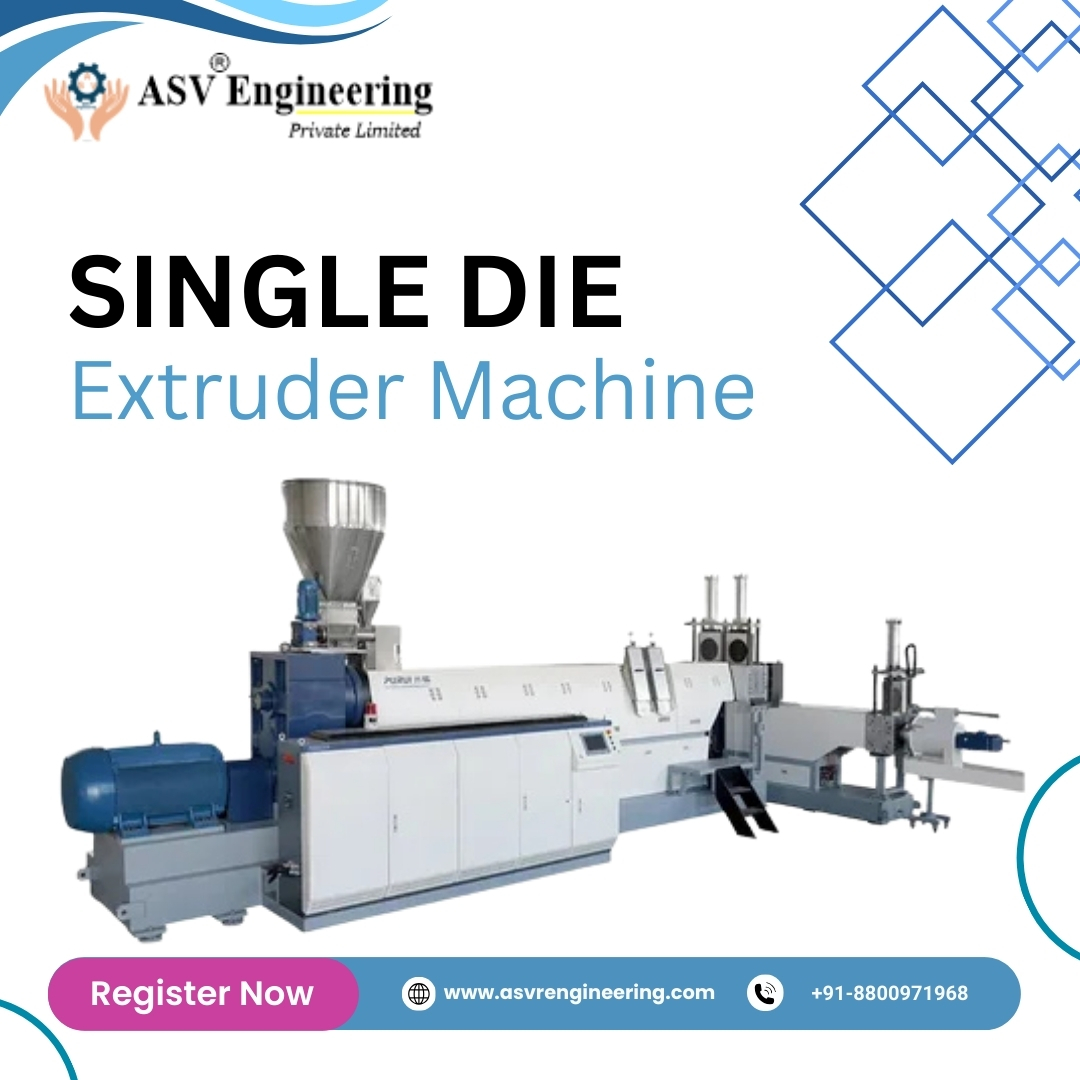

Trusted Puff Extruder Machine Distributors Delivering High-Performance Snack Processing Solutions

Price: ₹450000

In today’s fast-growing snack food industry, manufacturers are constantly looking for reliable machinery that ensures consistent quality, high output, and long-term operational efficiency. Among the most critical equipment in snack manufacturing is the puff extruder machine, which plays a vital role in producing popular products like corn puffs, kurkure-style snacks, rings, balls, and other expanded snacks. When it comes to sourcing dependable machinery, choosing experienced and trustworthy distributors becomes just as important as the machine itself.

ASVR Engineering has emerged as one of the most dependable puff extruder machine distributors, offering robust, high-performance snack processing solutions tailored to the needs of modern food manufacturers. With a strong focus on engineering precision, durability, and customer satisfaction, the company supports snack brands, food processors, and startups across India in building profitable and scalable snack production lines.

Understanding Puff Extruder Machines and Their Importance

A puff extruder machine is designed to process raw ingredients such as maize grits, rice flour, wheat flour, or multigrain blends into expanded, crunchy snack products. Through a controlled process of heat, pressure, and mechanical shear, the extruder transforms simple raw materials into ready-to-shape, ready-to-flavor snack bases.

The demand for puffed snacks continues to rise due to changing lifestyles, urbanization, and increasing preference for ready-to-eat foods. To meet this demand, manufacturers need machines that deliver:

-

Uniform expansion and texture

-

Consistent output quality

-

Energy-efficient operation

-

Low wastage and easy maintenance

This is where a reliable distributor with deep technical knowledge and after-sales support makes a real difference.

Why ASVR Engineering is a Trusted Name in Puff Extruder Distribution

ASVR Engineering has built its reputation on a foundation of engineering excellence, ethical business practices, and customer-centric solutions. As trusted puff extruder machine distributors, they understand that every snack manufacturer has unique requirements—whether it’s a small-scale startup or a large commercial production unit.

Their approach goes beyond simply supplying machines. They focus on delivering complete snack processing solutions, helping clients select the right capacity, configuration, and automation level to maximize return on investment.

High-Performance Puff Extruder Machines for Diverse Snack Applications

The puff extruder machines distributed by ASVR Engineering are suitable for a wide range of snack products, including:

-

Corn puffs and curls

-

Kurkure-type extruded snacks

-

Rings, balls, and tube-shaped snacks

-

Multigrain and protein-enriched snacks

-

Custom-designed innovative snack shapes

Each machine is engineered to maintain precise control over temperature, moisture, and pressure, ensuring consistent puffing, superior taste, and appealing texture in every batch.

Advanced Engineering for Consistent Output

One of the biggest challenges in snack production is maintaining uniform quality throughout long production runs. ASVR Engineering addresses this through machines that feature:

-

Heavy-duty screws and barrels made from wear-resistant alloys

-

Precision-designed die heads for uniform shaping

-

Stable drive systems for continuous operation

-

Optimized heating zones for controlled expansion

These features help manufacturers achieve stable output, reduced downtime, and longer machine life, even under demanding production schedules.

Energy Efficiency and Cost-Effective Operation

Energy consumption is a major operational cost in food processing plants. The puff extruder machines supplied by ASVR Engineering are designed with energy efficiency in mind, ensuring optimal power usage without compromising performance.

Efficient motor systems, balanced mechanical design, and smooth material flow reduce unnecessary energy loss. This translates into lower electricity bills, reduced production costs, and improved profit margins—a critical advantage in competitive snack markets.

Customization to Match Your Business Goals

No two snack businesses are the same. Recognizing this, ASVR Engineering offers customized puff extruder solutions based on:

-

Desired production capacity

-

Raw material type and formulation

-

Product shapes and sizes

-

Level of automation required

-

Available plant space

Whether you are launching a new snack brand or expanding an existing production line, their team works closely with you to design a solution that aligns with your long-term growth plans.

Hygienic Design and Food Safety Compliance

Food safety is non-negotiable in the snack industry. Puff extruder machines distributed by ASVR Engineering are built following strict hygiene standards, with:

-

Food-grade stainless steel contact parts

-

Smooth surfaces for easy cleaning

-

Minimal material residue zones

-

Compliance with standard food processing norms

This ensures safer production, easier audits, and greater confidence when supplying products to distributors, retailers, and institutional buyers.

Reliable After-Sales Support and Technical Guidance

One of the key reasons manufacturers trust ASVR Engineering is their strong after-sales support system. Machine performance does not end at installation—it requires regular guidance, maintenance, and technical assistance.

Clients benefit from:

-

Installation and commissioning support

-

Operator training for smooth machine handling

-

Quick response to technical queries

-

Availability of genuine spare parts

This commitment helps manufacturers minimize downtime and maintain uninterrupted production.

Supporting Startups and Established Manufacturers Alike

ASVR Engineering works with a diverse client base, including:

-

First-time snack manufacturing startups

-

Medium-scale food processing units

-

Large commercial snack producers

-

Private label and contract manufacturers

Their ability to scale solutions according to budget and production needs makes them a preferred partner for businesses at every stage.

Boosting Snack Business Profitability

Investing in a high-quality puff extruder machine is not just about production—it’s about profitability. With consistent quality, reduced wastage, and efficient operations, manufacturers can:

-

Launch multiple snack variants using the same base machine

-

Maintain consistent taste and texture across batches

-

Reduce manual intervention and labor costs

-

Expand into new markets with confidence

ASVR Engineering ensures that each machine contributes directly to business growth and brand reliability.

Why Distributors Matter More Than Ever

In the competitive machinery market, the role of distributors is often underestimated. A trusted distributor like ASVR Engineering adds value by offering:

-

Honest technical advice

-

Transparent pricing

-

Proven machinery solutions

-

Long-term partnership mindset

This approach helps clients avoid costly mistakes and ensures that the selected machine truly fits their production goals.

Commitment to Quality and Long-Term Performance

Every puff extruder machine supplied through ASVR Engineering undergoes strict quality checks. From component selection to final testing, the focus remains on delivering machines that perform reliably year after year.

This dedication to quality has helped the company build long-standing relationships with clients who continue to upgrade and expand their snack production lines with confidence.

Conclusion: Your Reliable Partner in Snack Processing Solutions

When it comes to choosing trusted puff extruder machine distributors delivering high-performance snack processing solutions, ASVR Engineering stands out for its technical expertise, customer-focused approach, and commitment to long-term value. Their machines are designed not just to produce snacks, but to support sustainable business growth in a competitive food processing industry.

For manufacturers seeking reliability, efficiency, and expert guidance, ASVR Engineering remains a name they can depend on.

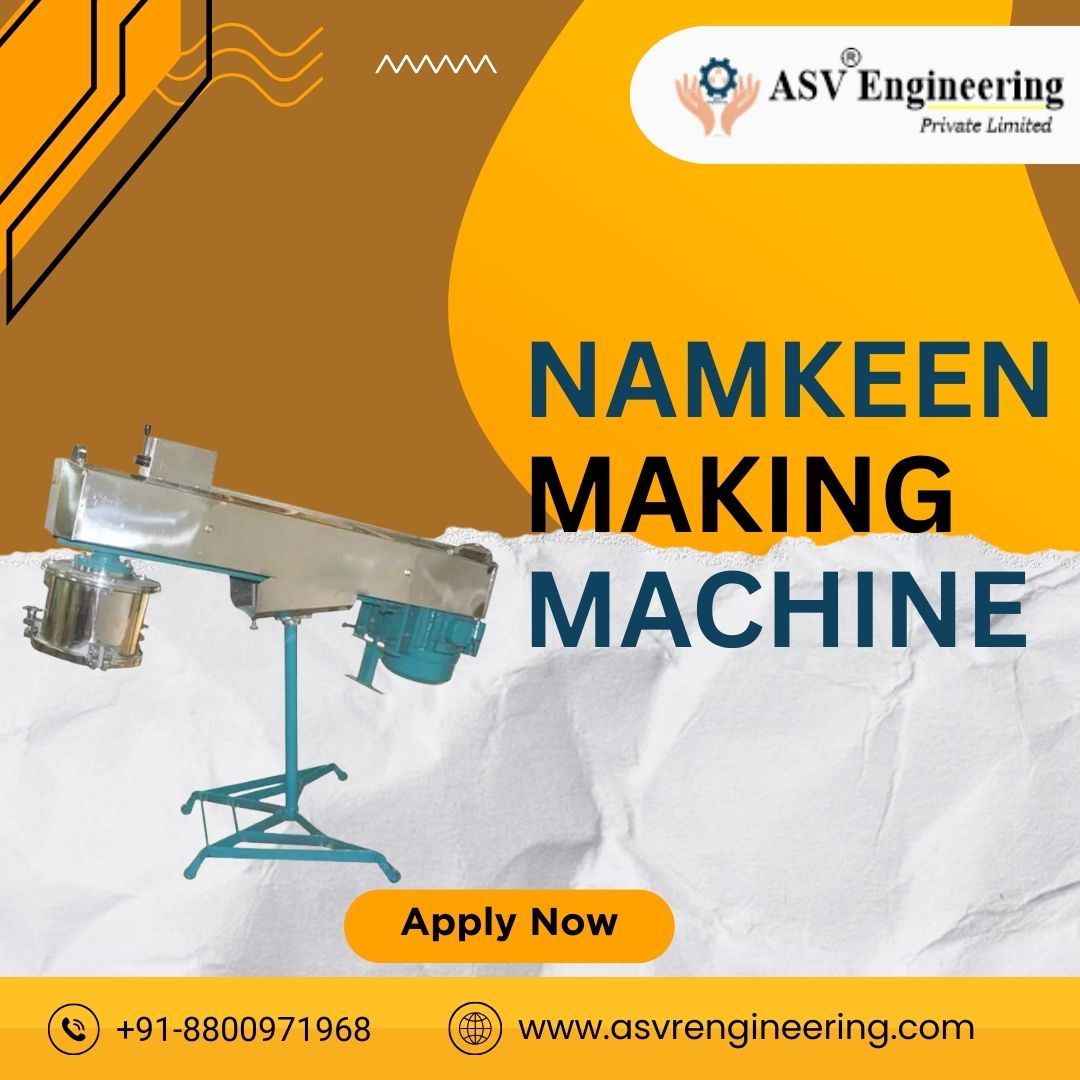

Company Details

Company Name: ASVR Engineering

Contact Numbers: +91-8076004849, +91-8800971968

Website: https://www.asvrengineering.com

Buy Now

Related Posts

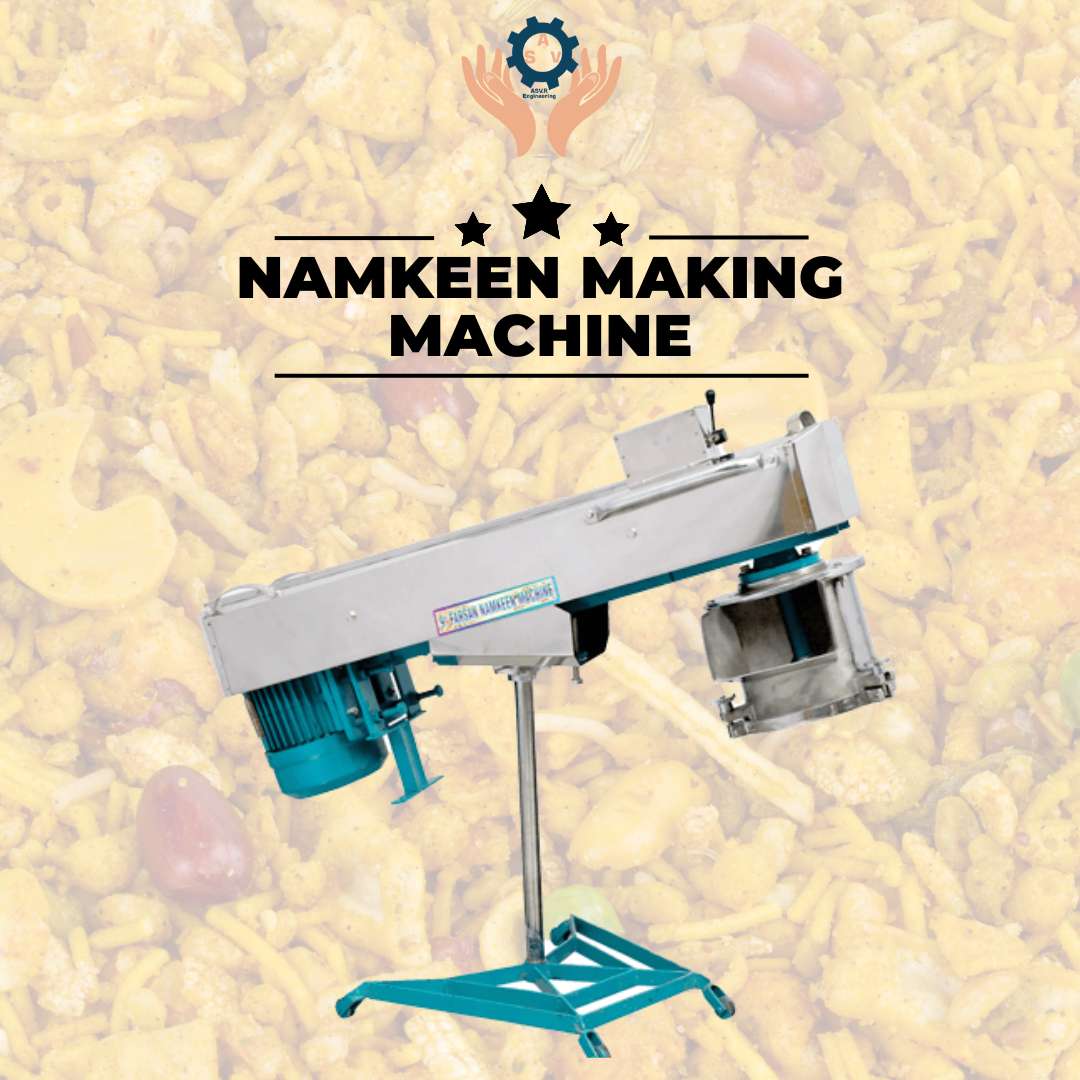

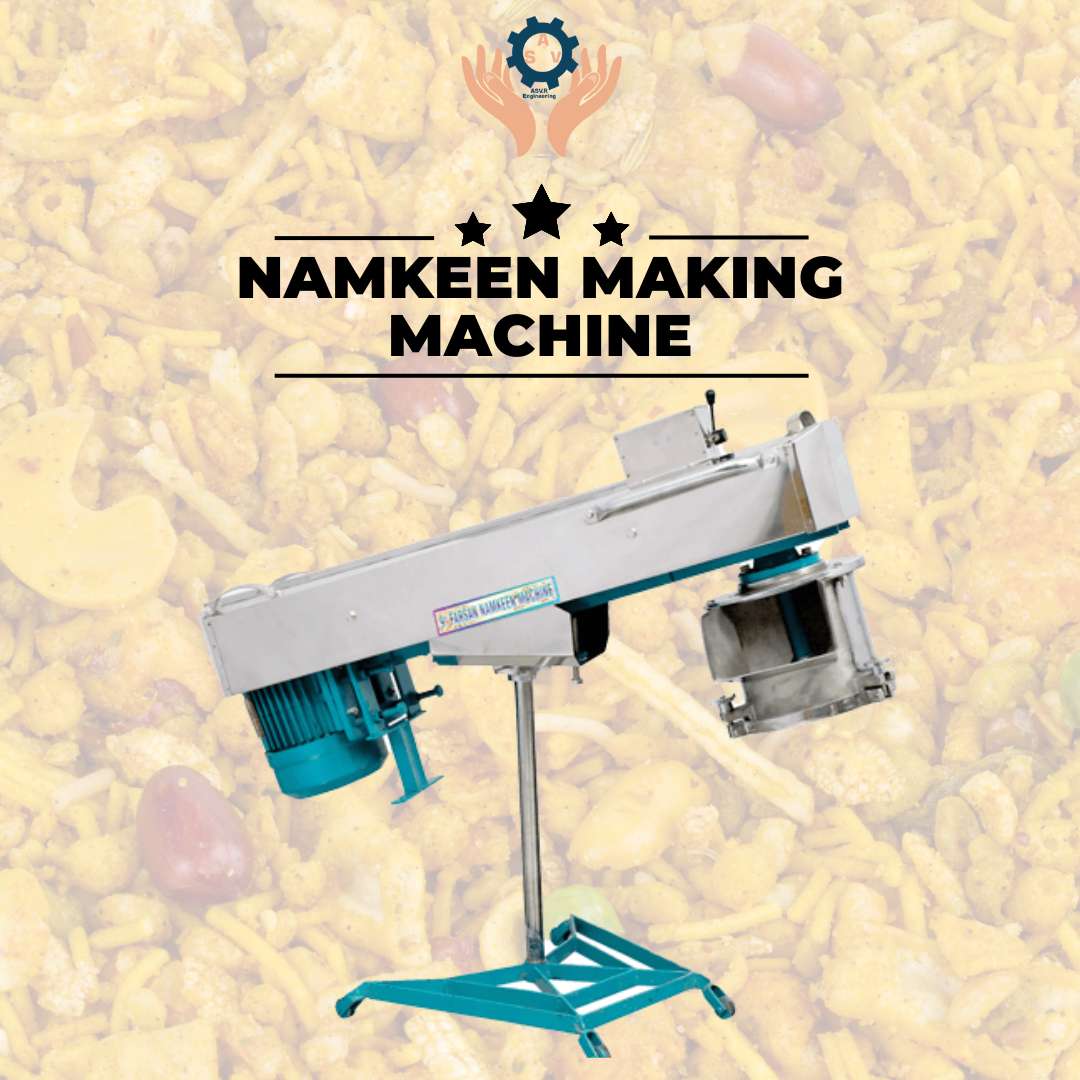

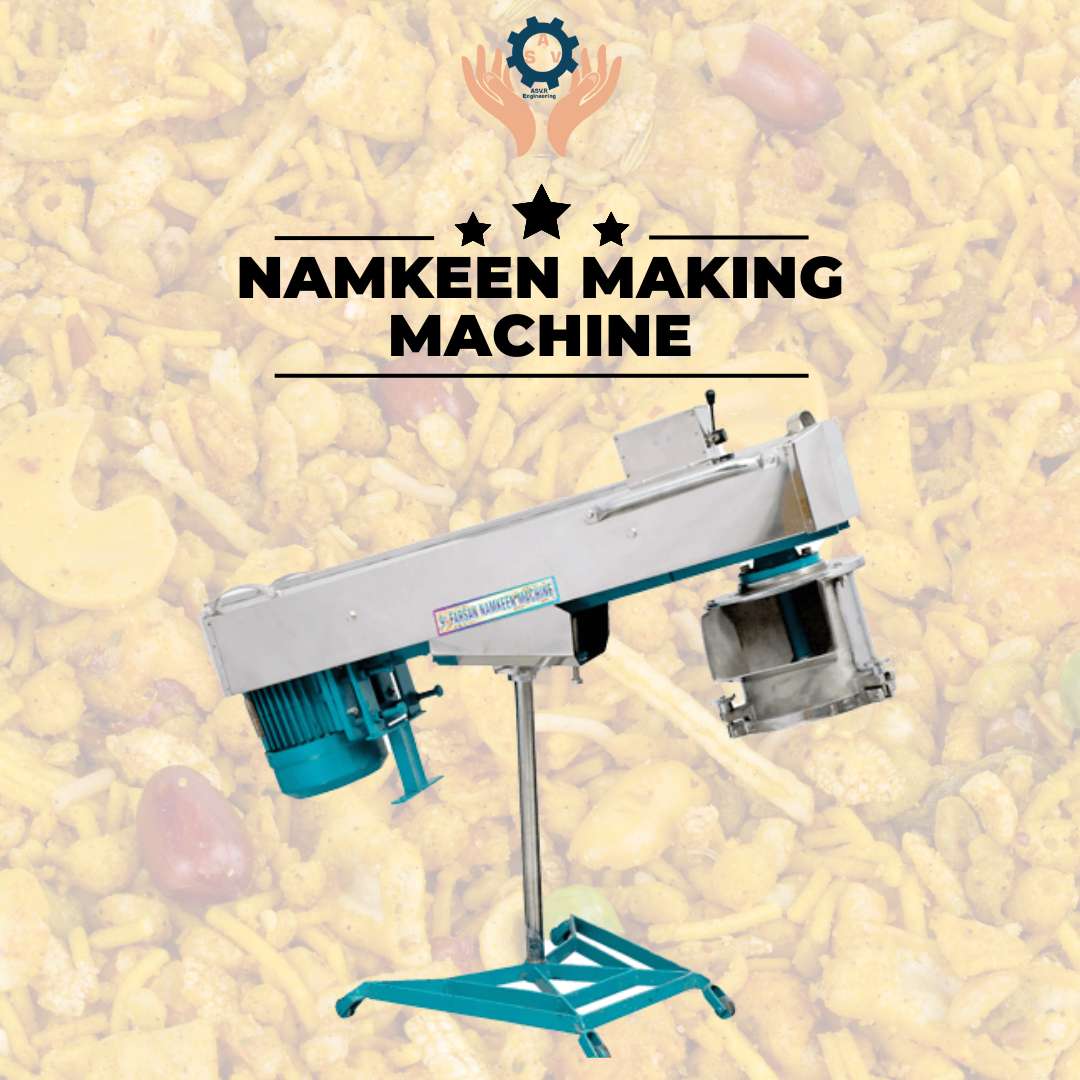

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)