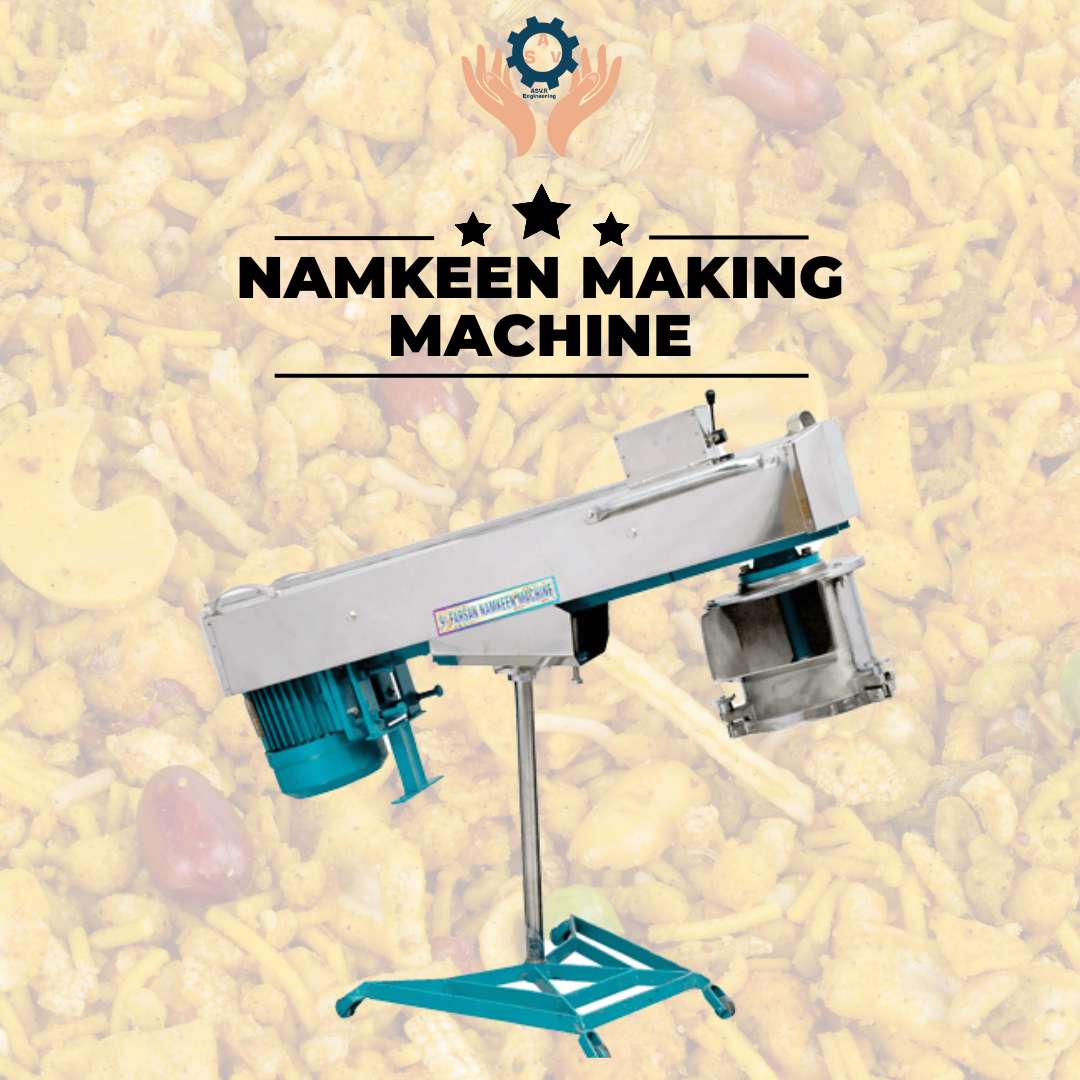

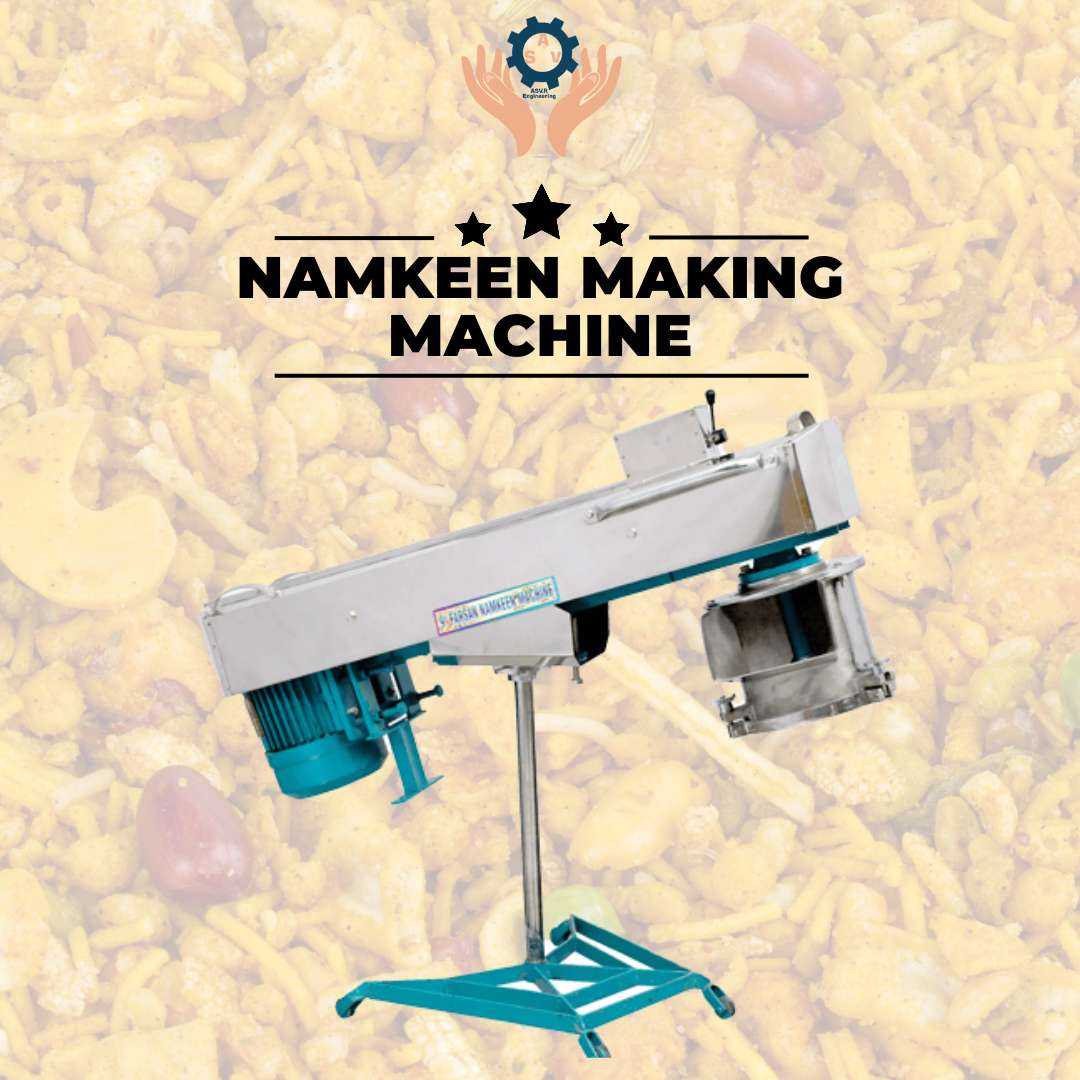

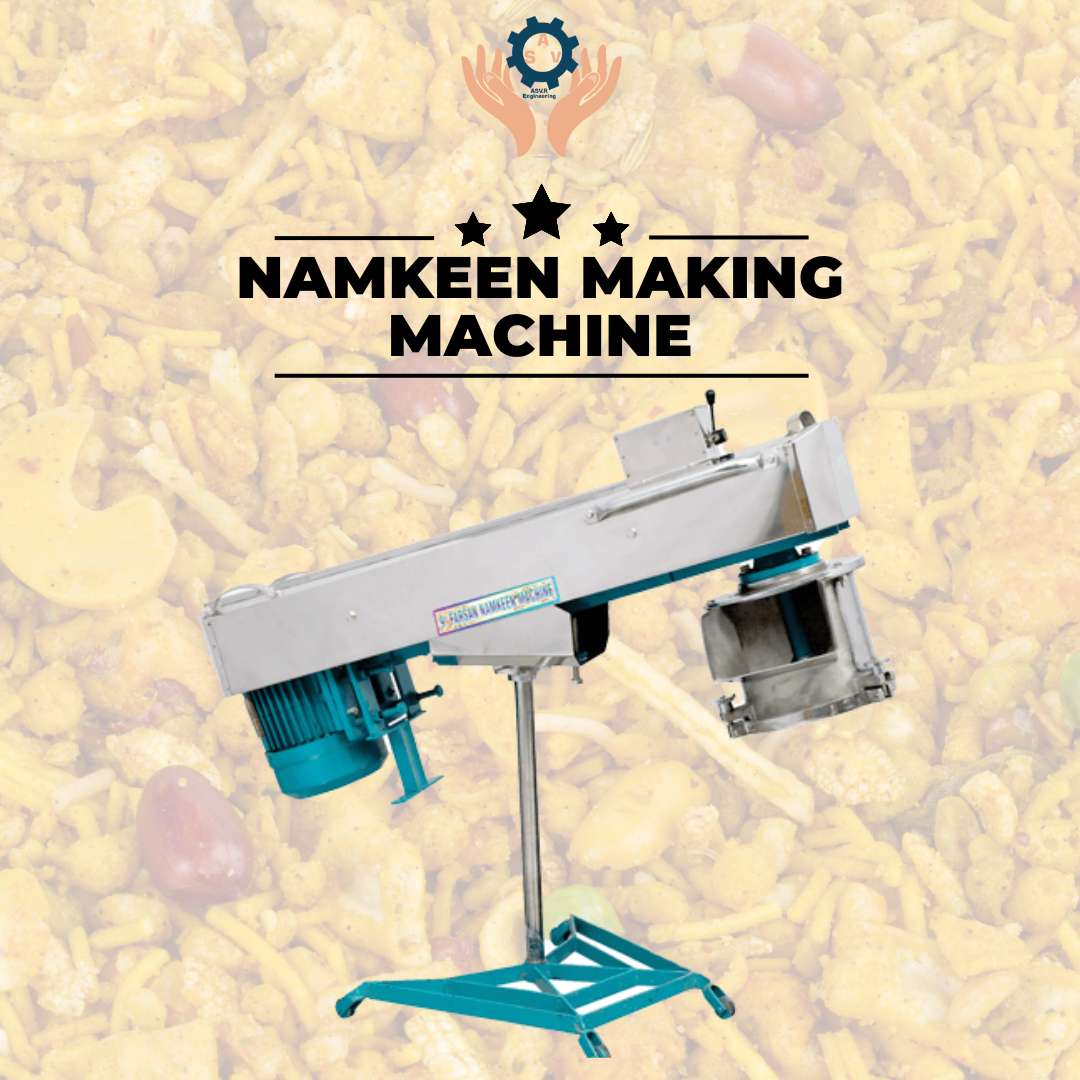

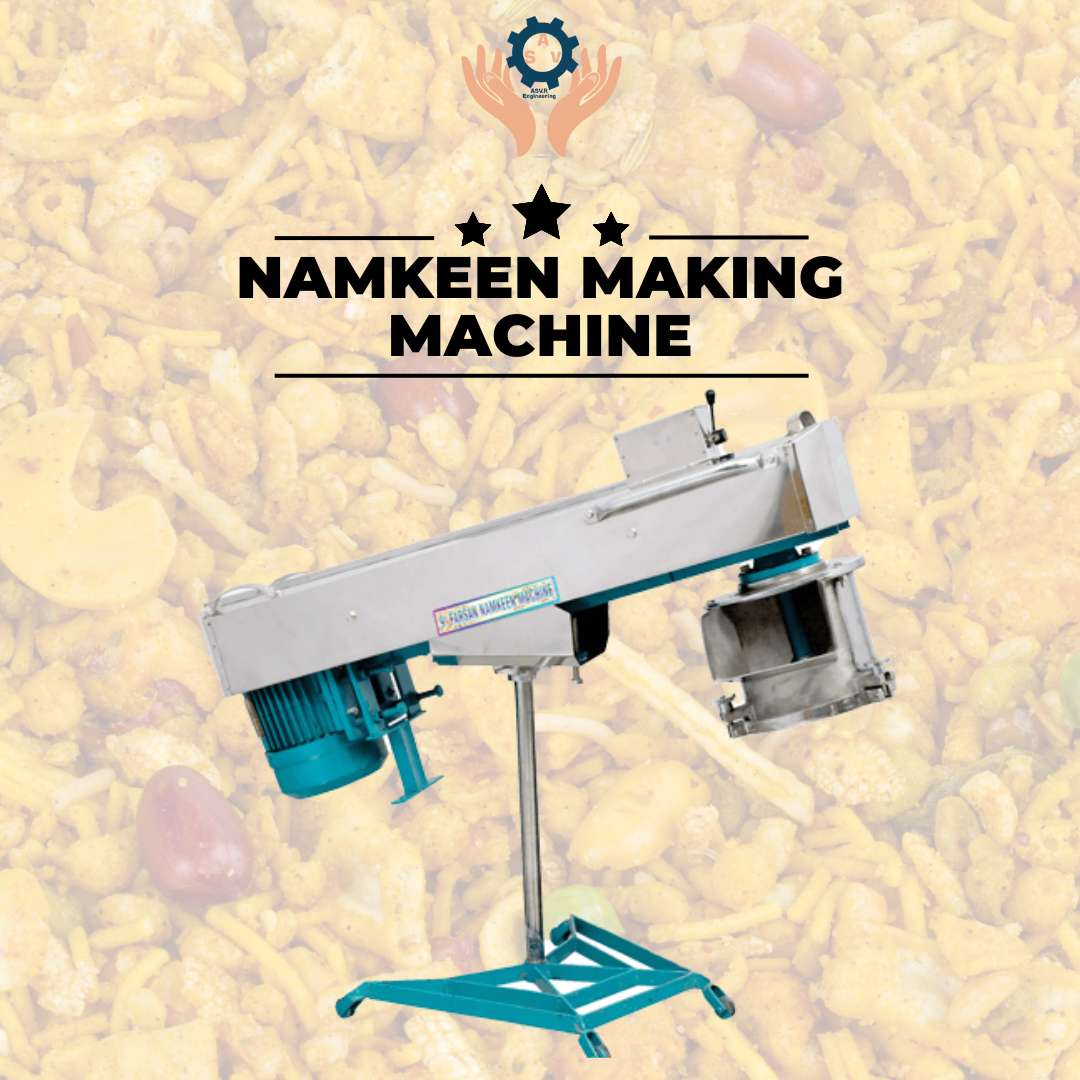

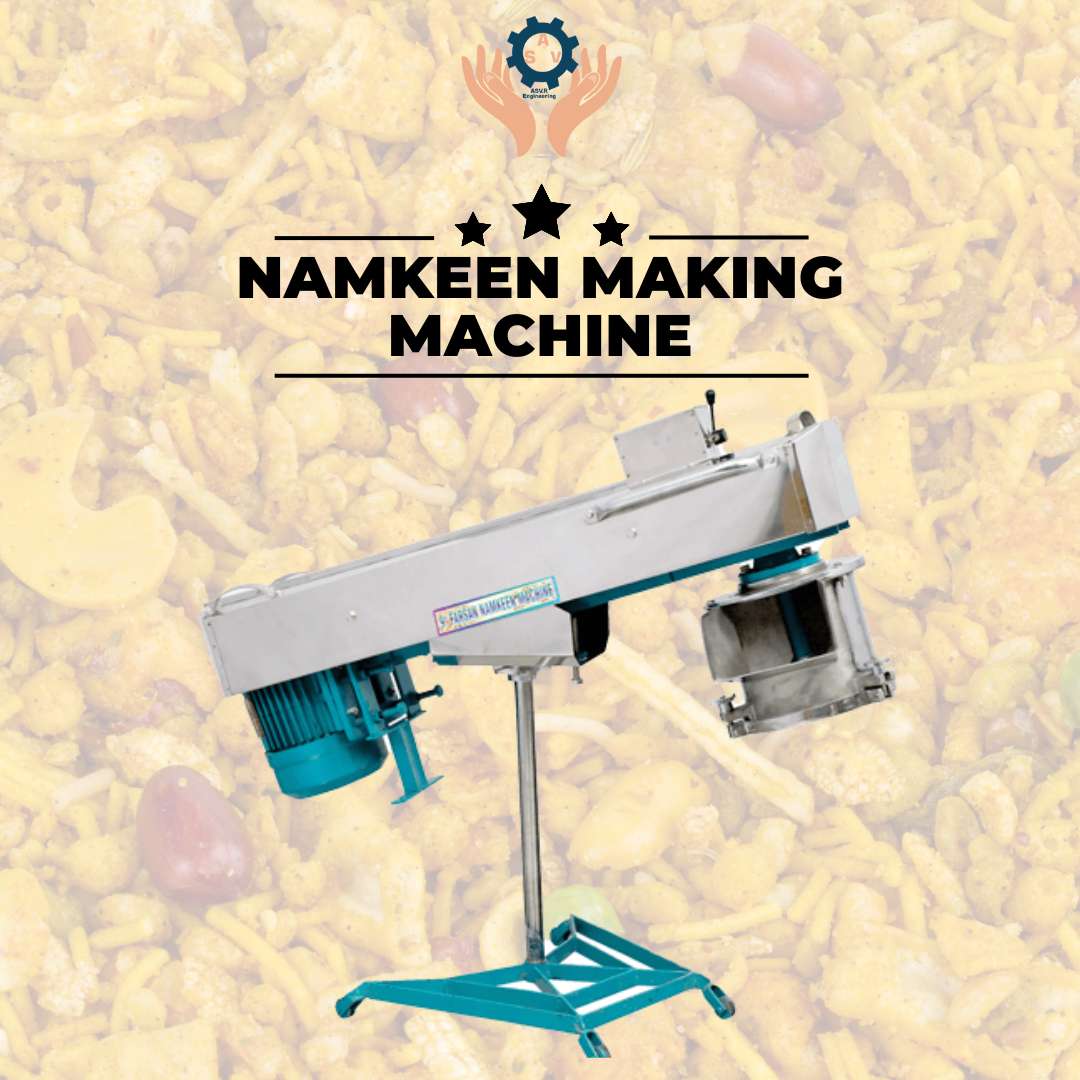

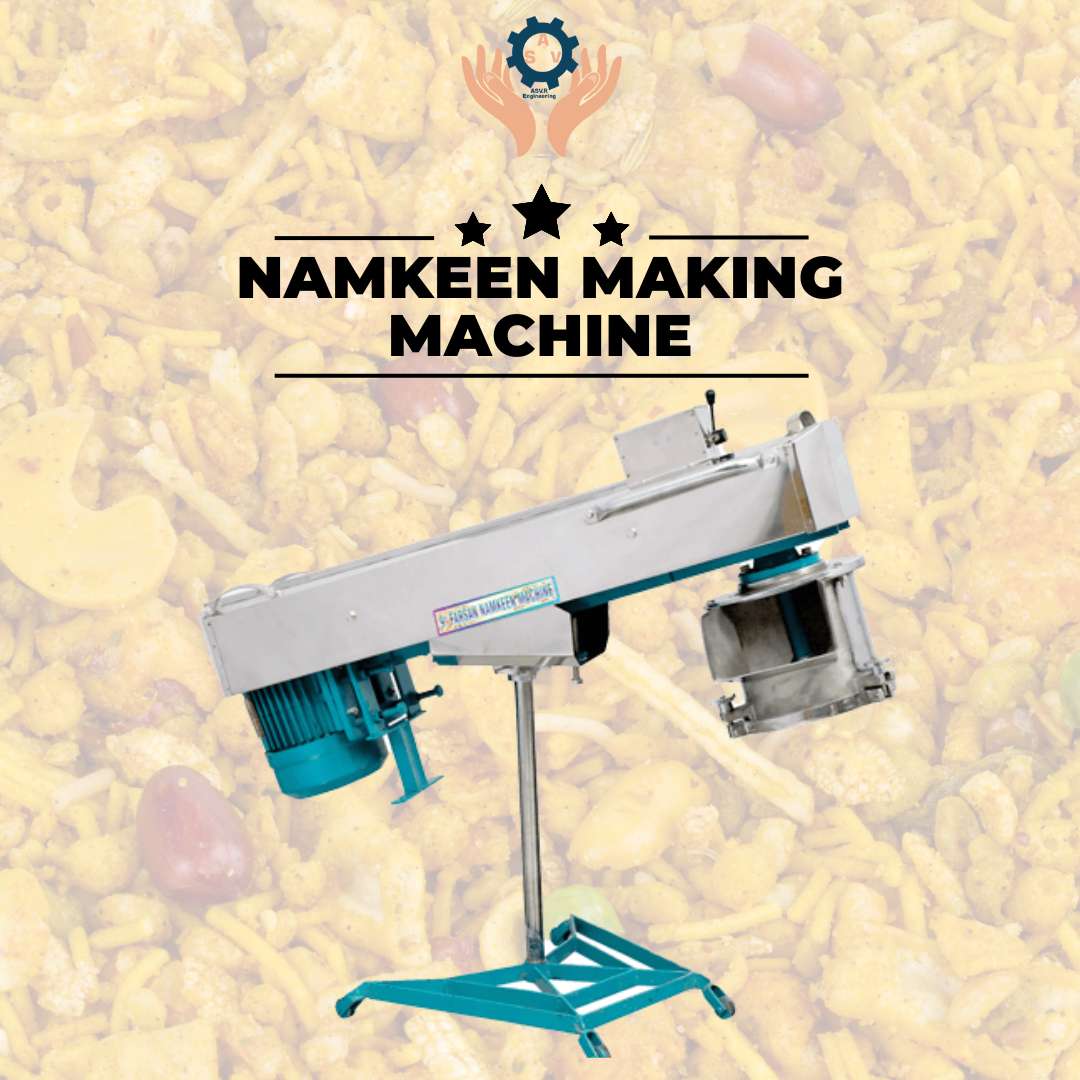

Trusted Namkeen Making Machine Wholesalers in India | High-Capacity, Low-Maintenance Systems

Price: ₹43000

High-Capacity, Low-Maintenance Systems for Growing Snack Businesses

India’s love for namkeen is timeless. From small tea stalls to modern retail shelves, savory snacks are an everyday indulgence across regions. Behind every consistent batch of bhujia, sev, mixture, or chips lies reliable machinery that ensures taste, texture, hygiene, and scale. As one of the trusted namkeen making machine wholesalers in India, ASVR Engineering supports snack manufacturers with robust, production-ready systems designed for performance, durability, and easy upkeep.

With a deep understanding of food processing requirements and years of hands-on industry exposure, ASVR Engineering supplies high-capacity, low-maintenance namkeen making machines that help businesses meet market demand without compromising quality. Whether you’re setting up a new unit or upgrading an existing line, our solutions are engineered to deliver efficiency, consistency, and long-term value.

Why Namkeen Manufacturing Needs the Right Machinery

Namkeen production is not just about mixing ingredients and frying. It’s a process that demands precision at every stage—dough preparation, shaping, frying, de-oiling, seasoning, cooling, and packaging. Using outdated or mismatched equipment often leads to uneven texture, excess oil absorption, high wastage, and frequent breakdowns.

Modern namkeen making machines are designed to overcome these challenges. They bring automation, control, and hygiene into the process while reducing manpower dependency. As wholesalers, we focus on supplying systems that integrate seamlessly into your workflow and grow with your business.

Comprehensive Range of Namkeen Making Machines

1. Dough Mixing & Preparation Units

Uniform dough consistency is the foundation of quality namkeen. Our mixers ensure even blending of flour, spices, and oil, minimizing batch variations and improving downstream processing.

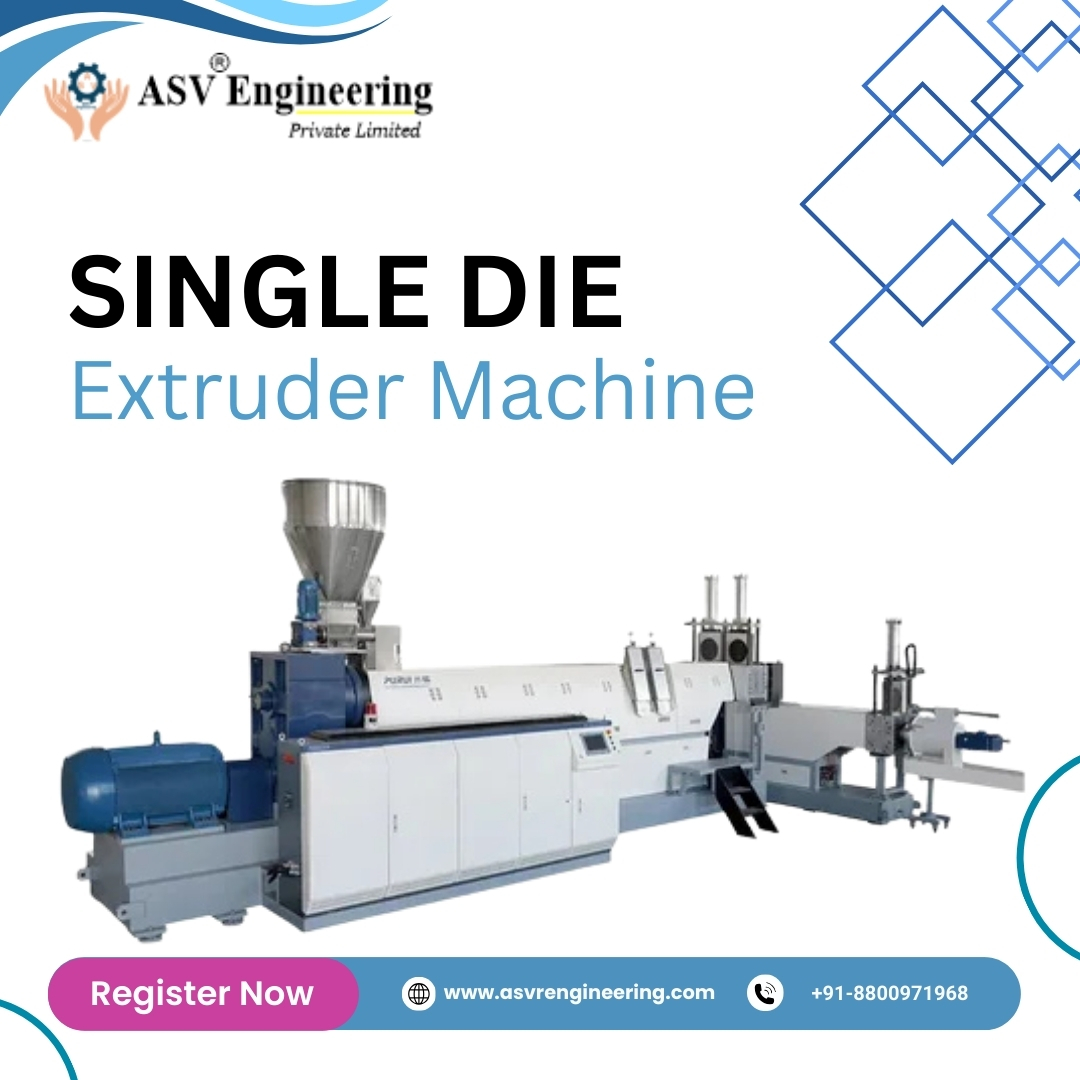

2. Extrusion & Forming Machines

From sev and bhujia to gathiya and noodles, extrusion machines shape products with accuracy. Adjustable dies and controlled pressure allow you to switch product variants without lengthy downtime.

3. Continuous & Batch Fryers

Engineered for temperature stability and oil efficiency, our fryers deliver consistent color and crunch. Options include gas or electric heating, automatic oil circulation, and filtration for longer oil life.

4. De-Oiling & Seasoning Systems

Centrifugal de-oiling units reduce excess oil, improving taste and shelf life. Seasoning drums ensure uniform flavor coating with minimal waste.

5. Cooling Conveyors & Packaging

Cooling conveyors prepare products for packaging, while compatible packing machines help maintain freshness and brand presentation.

What Makes ASVR Engineering a Trusted Wholesaler?

Proven Quality & Durability

All machines are fabricated using food-grade stainless steel and industrial-grade components. This ensures corrosion resistance, easy cleaning, and compliance with food safety standards.

High-Capacity Performance

Designed for commercial and industrial use, our systems handle large volumes without strain, making them ideal for expanding manufacturers and contract packers.

Low Maintenance, High Uptime

Thoughtful engineering reduces wear and tear. Simple mechanisms, accessible parts, and clear operating manuals keep maintenance costs low and production uninterrupted.

Energy-Efficient Design

Optimized motors, heat retention systems, and smart controls help cut energy consumption—an important factor in managing operational costs.

Customization & Scalability

No two snack businesses are the same. We offer customized configurations based on product range, capacity requirements, and available space, ensuring future scalability.

Supporting Small, Medium & Large Snack Manufacturers

ASVR Engineering works with a wide spectrum of clients—from entrepreneurs launching their first namkeen brand to established companies scaling nationwide distribution. Our role as wholesalers allows us to provide cost-effective pricing without compromising on quality, along with dependable after-sales support.

We understand the practical challenges of Indian manufacturing environments—power fluctuations, raw material variations, and continuous operation. That’s why our machines are built to perform reliably under real-world conditions.

Applications Across the Snack Industry

-

Sev, bhujia, gathiya, aloo bhujia

-

Mixtures and fried snack blends

-

Chips, pellets, and specialty namkeen

-

Regional and traditional snack varieties

With flexible tooling and process control, manufacturers can diversify product lines and respond quickly to market trends.

Nationwide Supply & Technical Support

As a reputed wholesaler, ASVR Engineering serves clients across India with timely delivery and installation assistance. Our technical team provides guidance on setup, operation, and routine maintenance, ensuring you get the best return on investment from day one.

Contact Numbers:

📞 +91-8076004849

📞 +91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now

Related Posts

Trusted Automatic Namkeen Making Machine Importers Supplying Cost-Effective & Fully Automated Plants

(9).jpg)

(9).jpg)

(9).jpg)

(9).jpg)

(1).png)

(1).png)

(1).png)

(12).jpg)

(12).jpg)

(12).jpg)