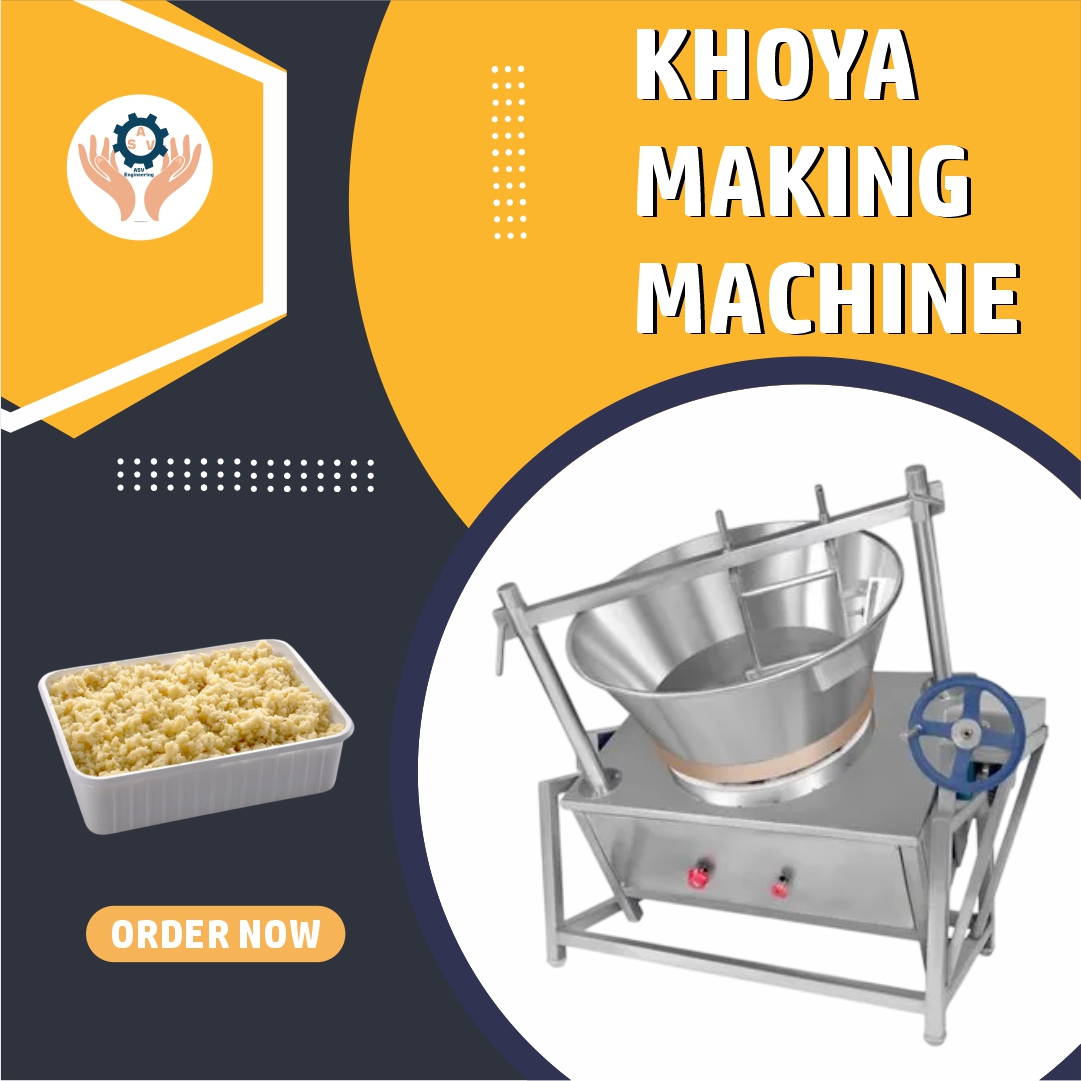

Top Khoya Making Machine Wholesalers for Commercial & Industrial Milk Processing

Price: ₹69000

In India’s vast dairy ecosystem, khoya (mawa) holds a special place. From mithai shops and sweet manufacturers to large dairy plants supplying bulk ingredients, khoya is a daily essential. Producing it consistently, hygienically, and at scale is no longer possible with traditional open-pan methods. This is where modern khoya making machines step in—delivering speed, uniform quality, and food safety while reducing labor and fuel costs.

As one of the top khoya making machine wholesalers for commercial & industrial milk processing, ASVR Engineering supplies robust, performance-driven solutions tailored to Indian dairy conditions. Whether you are a small sweet shop scaling up, a mid-sized dairy expanding production, or a large industrial unit seeking continuous output, the right khoya machine can transform your operation.

Why Khoya Making Machines Are Essential Today

Traditional khoya preparation requires constant stirring, high manpower, and precise timing. Even then, consistency can vary batch to batch. In contrast, automatic and semi-automatic khoya making machines are engineered to:

-

Maintain uniform heating for consistent texture and color

-

Reduce milk wastage during evaporation

-

Improve hygiene with closed stainless-steel construction

-

Lower fuel and electricity consumption

-

Increase daily production capacity without compromising quality

For businesses focused on growth and compliance with food safety standards, machine-based khoya production is no longer optional—it’s a competitive necessity.

Understanding Commercial & Industrial Khoya Production

Commercial and industrial milk processing demands reliability. Machines must handle varying milk fat content, long operating hours, and continuous batches. A high-quality khoya making machine is designed with:

-

Food-grade SS 304 / SS 316 steel

-

Steam, gas, or electric heating options

-

Scraper systems to prevent milk burning

-

Uniform evaporation control

-

Easy cleaning and low maintenance

These features ensure smooth operations even under peak production loads.

Types of Khoya Making Machines Available

1. Semi-Automatic Khoya Making Machine

Ideal for sweet shops and medium-scale dairies.

-

Moderate capacity

-

Manual milk feeding with automated heating and stirring

-

Cost-effective and easy to operate

2. Automatic Khoya Making Machine

Best suited for commercial and industrial units.

-

High output with minimal human intervention

-

Continuous stirring and temperature control

-

Consistent khoya quality across batches

3. Steam Operated Khoya Machine

Common in large dairy plants.

-

Uniform indirect heating

-

Energy-efficient for bulk production

-

Excellent product finish

4. Tilting Type Khoya Machine

Designed for ease of discharge and cleaning.

-

Saves time during batch change

-

Reduces product loss

-

Popular in commercial kitchens

Key Features That Matter in a Khoya Making Machine

When sourcing from reliable wholesalers, buyers should look for:

-

Heavy-duty motor and gearbox for long life

-

Efficient scraper blades to avoid milk sticking

-

Uniform thickness and color output

-

Low noise and vibration

-

Compact design for space optimization

-

Easy installation and after-sales support

A well-built machine doesn’t just produce khoya—it ensures peace of mind.

Why Choose ASVR Engineering as Your Khoya Machine Wholesaler

ASVR Engineering has built a strong reputation by supplying durable, high-performance dairy machinery across India. Their khoya making machines are designed after understanding real-world dairy challenges—fluctuating milk quality, long operating hours, and the need for cost efficiency.

What sets ASVR Engineering apart:

-

Machines engineered for Indian dairy conditions

-

Use of premium-grade raw materials

-

Customization options based on capacity and fuel type

-

Competitive pricing for wholesalers and bulk buyers

-

Strong focus on after-sales service and technical support

From consultation to installation, clients receive end-to-end assistance.

Applications of Khoya Making Machines

Khoya machines are widely used in:

-

Sweet manufacturing units (pedha, burfi, gulab jamun)

-

Milk processing plants

-

Dairy cooperatives

-

Mithai shops expanding to bulk production

-

Hotels, caterers, and food factories

Their flexibility makes them suitable for both commercial kitchens and industrial processing lines.

Capacity Range to Suit Every Business

Depending on your production requirement, machines are available in various capacities, such as:

-

50–100 liters per batch (small commercial use)

-

150–300 liters per batch (medium dairy units)

-

500 liters and above (industrial-scale processing)

Choosing the right capacity ensures optimal ROI and smooth workflow.

Energy Efficiency and Cost Savings

Modern khoya making machines are designed to minimize operational costs. Compared to traditional methods, they:

-

Reduce fuel consumption

-

Lower manpower requirements

-

Minimize milk wastage

-

Increase daily output

Over time, these savings significantly improve profitability.

Hygiene and Food Safety Compliance

With increasing focus on food safety, stainless-steel khoya machines help meet hygiene standards. Smooth surfaces, enclosed processing, and easy cleaning reduce contamination risks and support compliance with FSSAI norms.

Maintenance and Long-Term Reliability

A quality machine is an investment. ASVR Engineering machines are known for:

-

Low maintenance requirements

-

Easily available spare parts

-

Long service life even under heavy use

This reliability is why many dairies continue sourcing equipment from trusted wholesalers.

How to Choose the Right Khoya Making Machine

Before purchasing, consider:

-

Daily milk processing volume

-

Available space and power supply

-

Fuel preference (gas, steam, electric)

-

Budget and future expansion plans

Consulting experienced wholesalers ensures you select a machine that fits both current and future needs.

Conclusion

As demand for dairy sweets and milk-based products continues to rise, investing in a high-quality khoya making machine is a smart business move. Working with top khoya making machine wholesalers for commercial & industrial milk processing ensures you get equipment that delivers consistent quality, operational efficiency, and long-term value.

With proven expertise, durable machinery, and customer-focused service, ASVR Engineering stands as a reliable partner for dairies and sweet manufacturers across India.

Contact Details

📞 Phone: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now