Rasgulla Making Machine Manufacturers in India – Automatic & Commercial Sweet Processing Machines

Price: ₹264000

India is a land of sweets, traditions, and celebrations. Among all Indian sweets, rasgulla holds a special place in the hearts of millions. Whether it is a wedding, festival, birthday, or religious function, rasgulla is almost always part of the celebration. With growing demand across sweet shops, dairy units, hotels, and export markets, manual production is no longer sufficient. This is where professional Rasgulla Making Machine Manufacturers in India step in with advanced automatic and commercial sweet processing machines designed for efficiency, hygiene, and large-scale production.

At ASVR Engineering, we specialize in manufacturing high-performance rasgulla making machines that help sweet manufacturers increase output, maintain uniform quality, and reduce labor dependency. Our machines are engineered to meet the modern requirements of commercial kitchens, dairy plants, and large confectionery production units.

Growing Demand for Automatic Rasgulla Making Machines in India

The Indian sweet industry is expanding rapidly. Urbanization, increased consumption, online sweet delivery platforms, and export demand have transformed traditional sweet-making into a structured food processing industry. Rasgulla production, once handled manually by skilled workers, now requires automation for consistency and scalability.

Manual preparation involves multiple stages:

-

Milk curdling

-

Chenna preparation

-

Kneading

-

Ball formation

-

Sugar syrup cooking

-

Controlled boiling

Each step demands precision. Even minor inconsistencies can affect texture, softness, or taste. Automatic rasgulla making machines simplify and standardize this entire process.

What is a Rasgulla Making Machine?

A rasgulla making machine is a specialized commercial food processing system designed to automate the shaping and sometimes processing of chenna balls used to prepare rasgullas. In advanced production setups, it forms part of a complete rasgulla production line that includes:

-

Milk boiling tanks

-

Paneer/chenna making units

-

Kneading machines

-

Ball forming machines

-

Cooking vessels

-

Sugar syrup tanks

Modern machines are built using food-grade stainless steel, ensuring hygiene, durability, and compliance with food safety standards.

Key Features of Automatic Rasgulla Making Machines

When selecting a reliable Rasgulla Making Machine Manufacturer in India, it is important to consider features that ensure productivity and quality.

1. Uniform Ball Formation

The machine ensures consistent size and weight of rasgulla balls, which is essential for commercial sales and packaging.

2. Adjustable Size Settings

Operators can control the size of the rasgulla according to market demand — small, medium, or large.

3. High Production Capacity

Depending on the model, machines can produce hundreds to thousands of pieces per hour.

4. Food-Grade Stainless Steel Body

All contact parts are made from SS 304 or equivalent material for hygiene and long service life.

5. Low Maintenance Design

Simple mechanism and easy cleaning reduce downtime and operational cost.

6. Energy Efficient Operation

Optimized motors and mechanical systems ensure reduced electricity consumption.

Benefits of Installing a Commercial Rasgulla Making Machine

Increased Production Output

Automation allows sweet manufacturers to meet bulk orders from retailers, distributors, and export clients.

Consistent Quality

Every rasgulla produced maintains identical shape, weight, and texture.

Reduced Labor Cost

Manual shaping requires skilled labor. Machines significantly reduce manpower dependency.

Hygienic Processing

Closed system design minimizes human contact, improving food safety.

Faster ROI

With higher productivity and reduced wastage, businesses recover investment quickly.

Applications of Rasgulla Processing Machines

Rasgulla making machines are widely used in:

-

Large sweet shops

-

Dairy processing plants

-

Catering units

-

Hotel kitchens

-

Industrial food production units

-

Sweet export companies

Whether you are running a local sweet shop or a large dairy brand, investing in automatic sweet processing machines enhances your production efficiency.

Types of Rasgulla Making Machines Available in India

Semi-Automatic Rasgulla Machine

Suitable for medium-scale businesses. Requires limited manual support but improves productivity significantly.

Fully Automatic Rasgulla Making Machine

Ideal for large-scale production. Handles shaping and often integrates into complete sweet processing lines.

Complete Rasgulla Production Plant

Includes milk processing, chenna preparation, forming, cooking, and syrup systems for end-to-end automation.

Why Choose ASVR Engineering?

ASVR Engineering is a trusted name in food processing machinery manufacturing in India. With years of experience and technical expertise, we deliver durable and high-performance rasgulla making machines tailored to client requirements.

Our Strengths:

-

Advanced manufacturing infrastructure

-

Skilled engineering team

-

Custom machine design options

-

Strict quality control checks

-

Competitive pricing

-

Timely delivery across India

We understand that every sweet manufacturer has different capacity requirements. Therefore, we provide customized solutions that match production goals and budget.

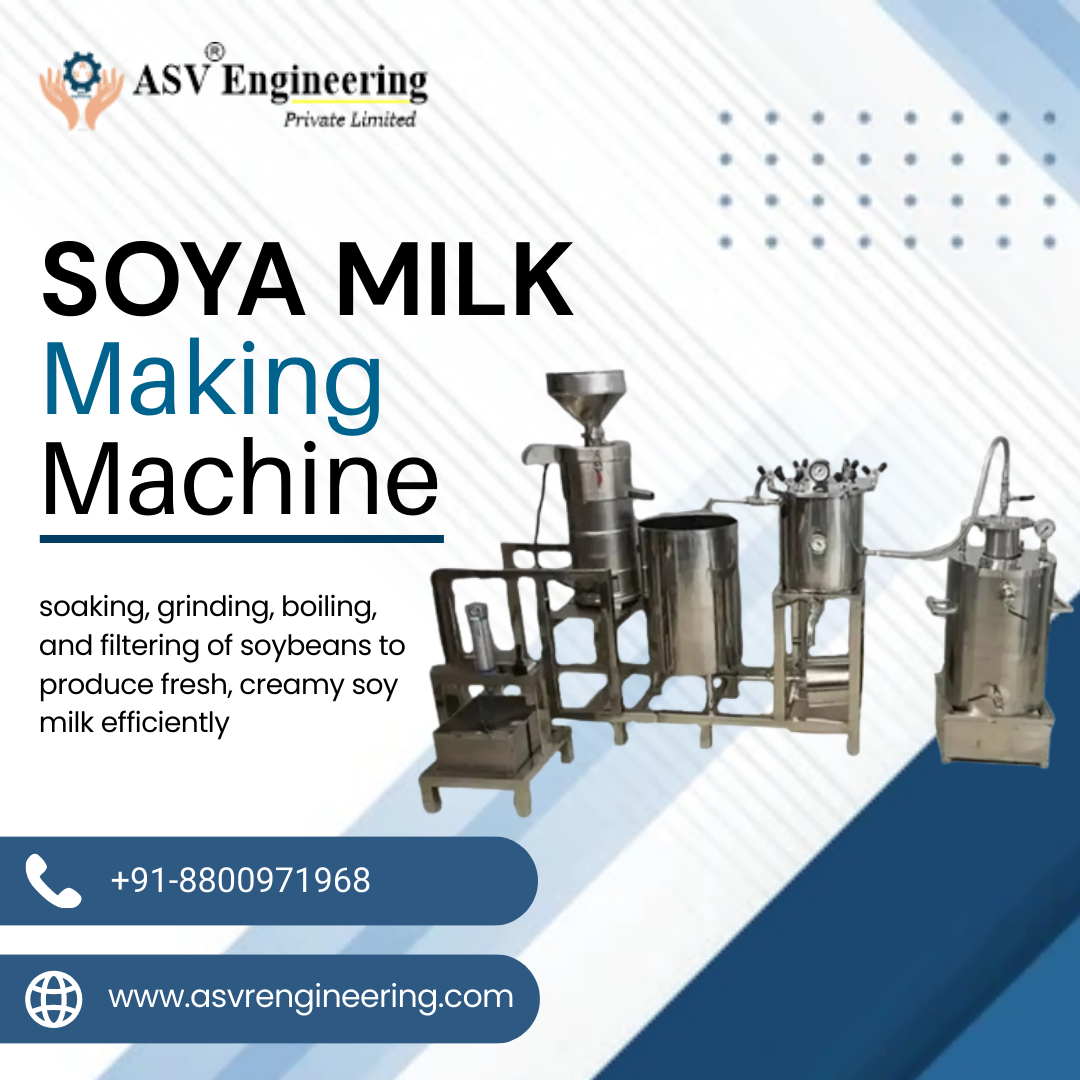

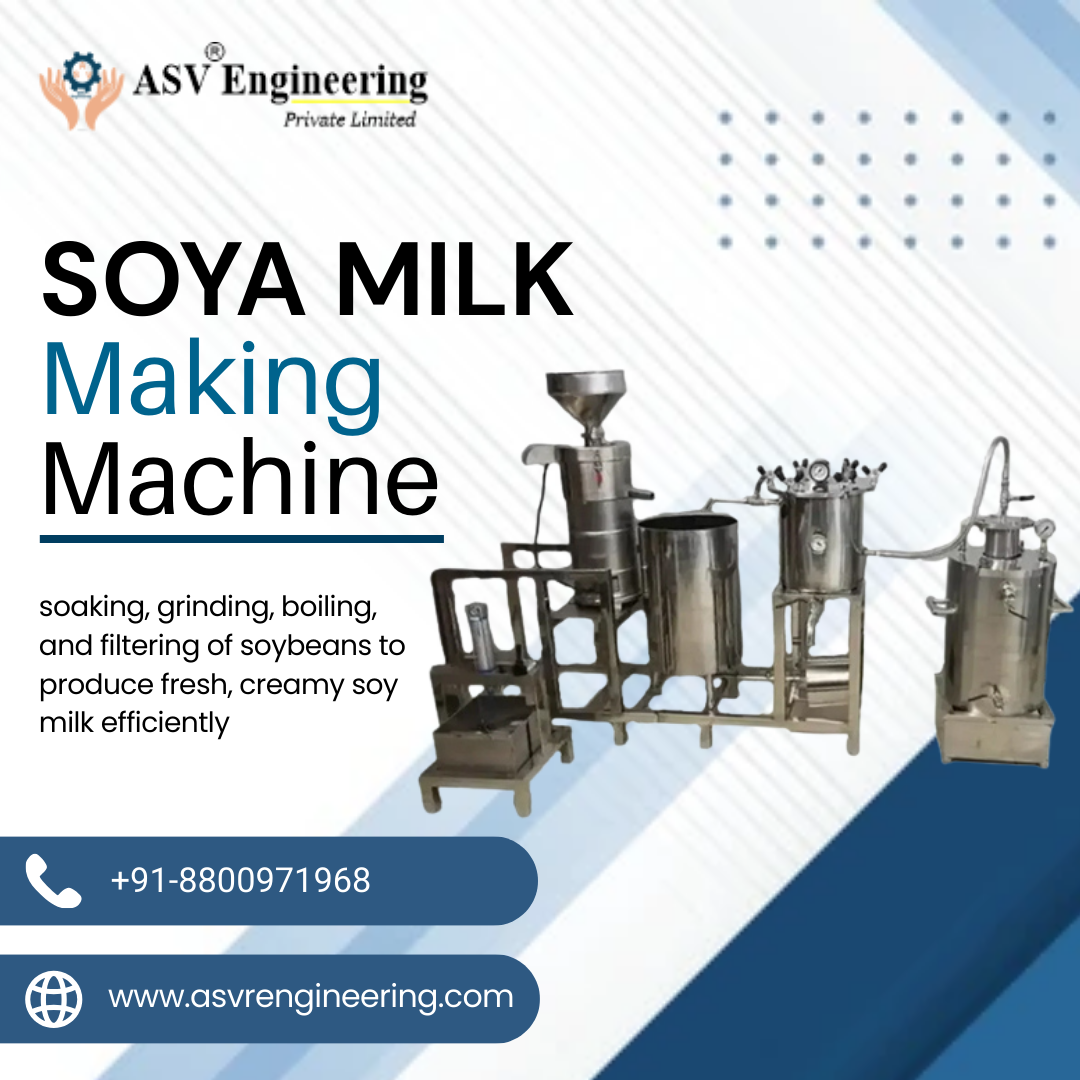

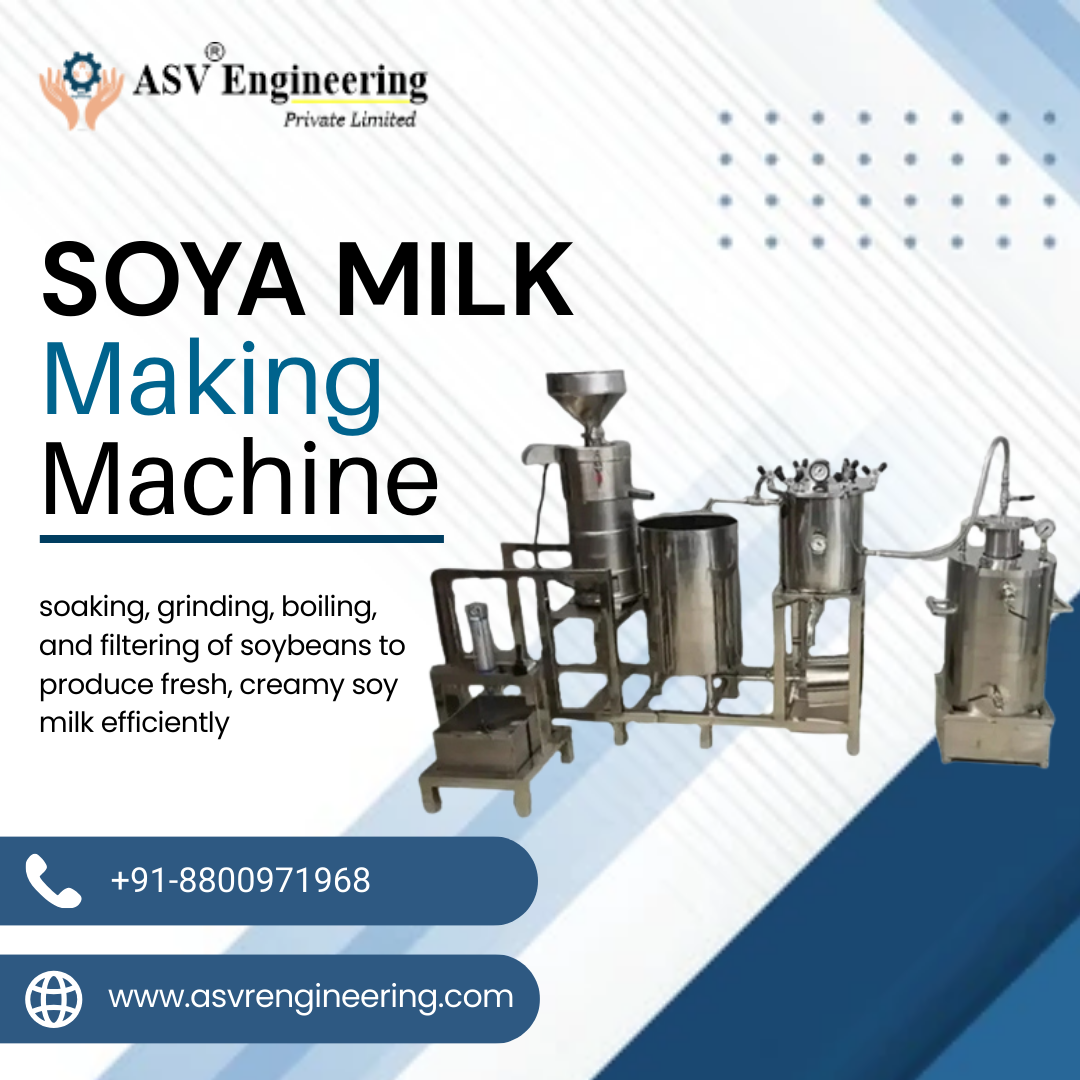

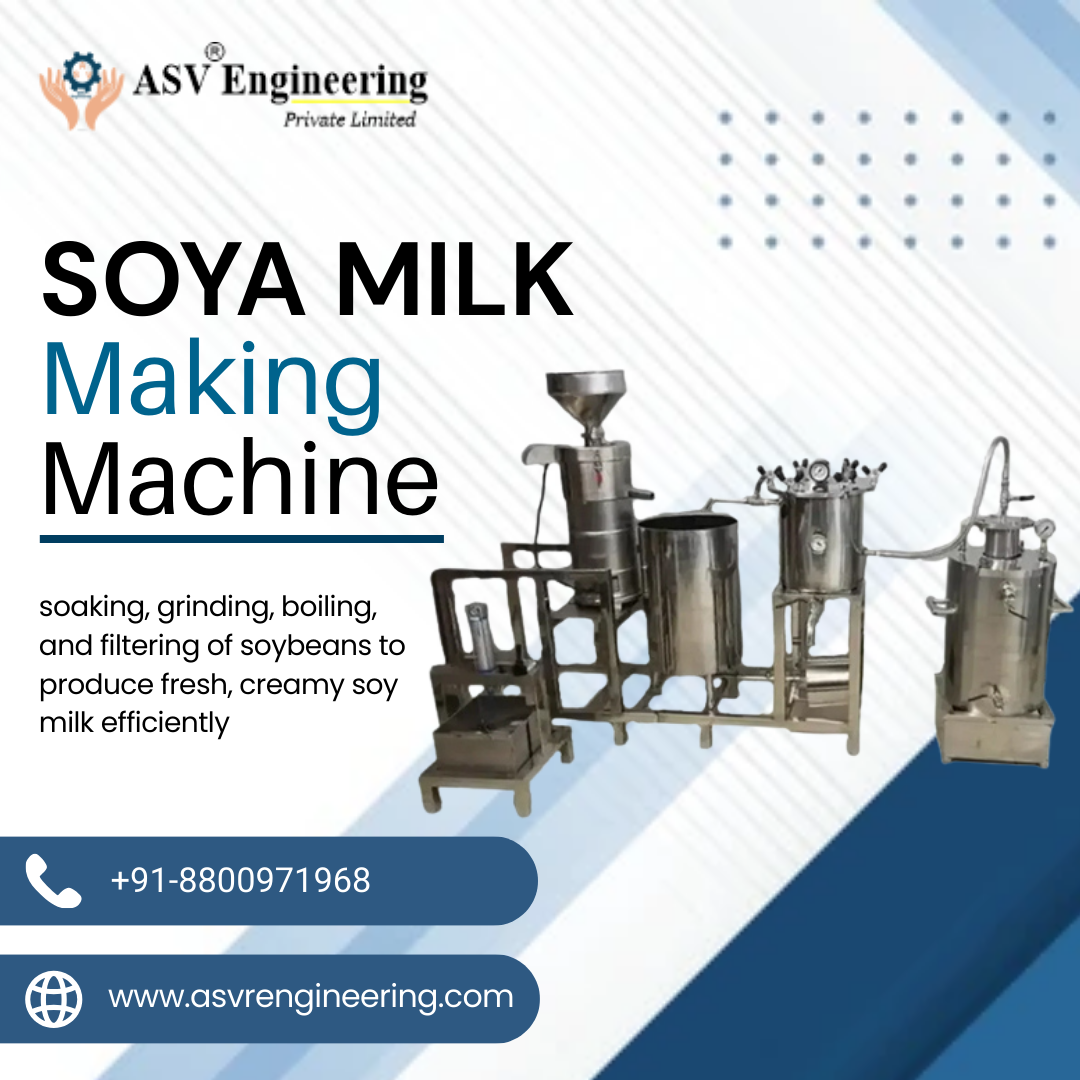

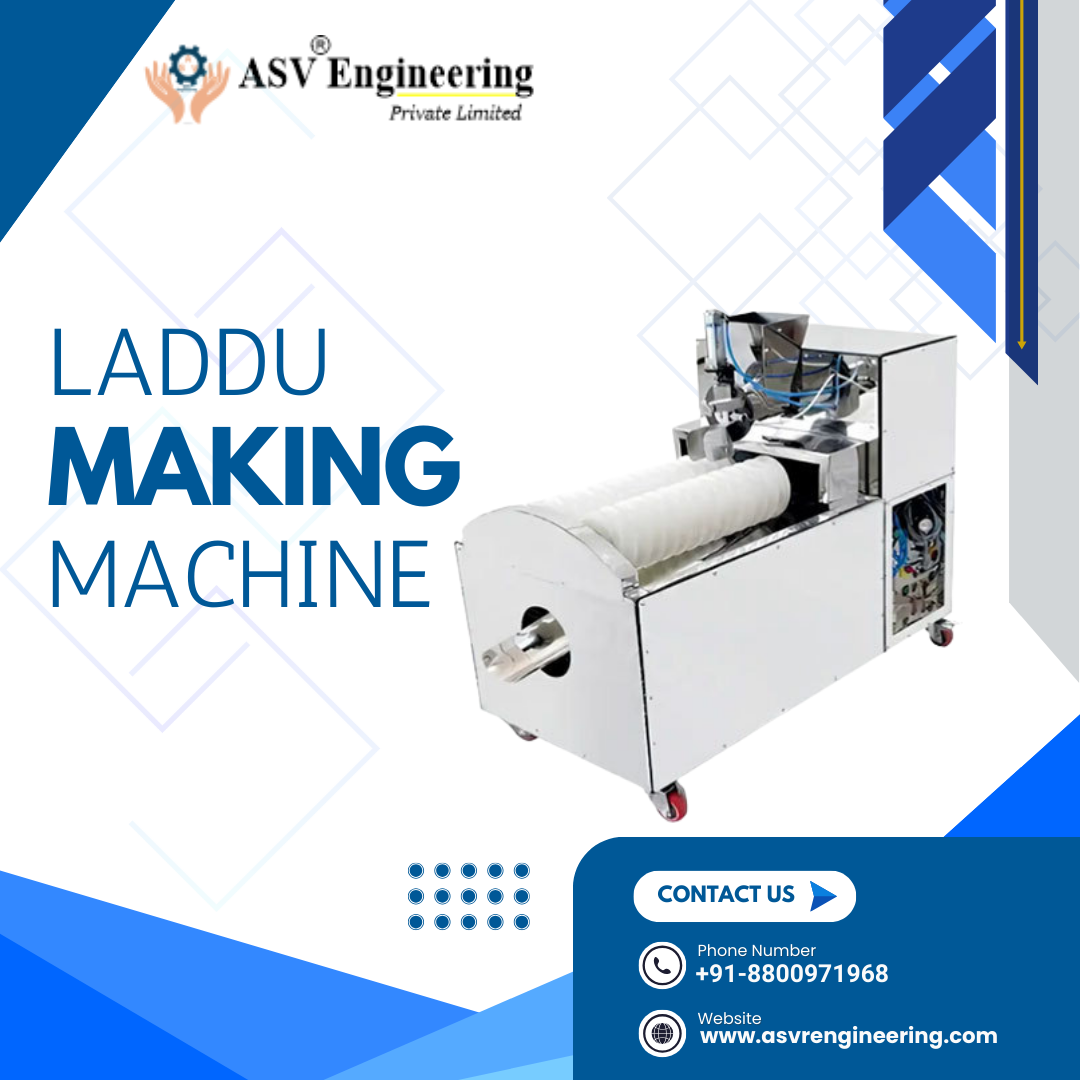

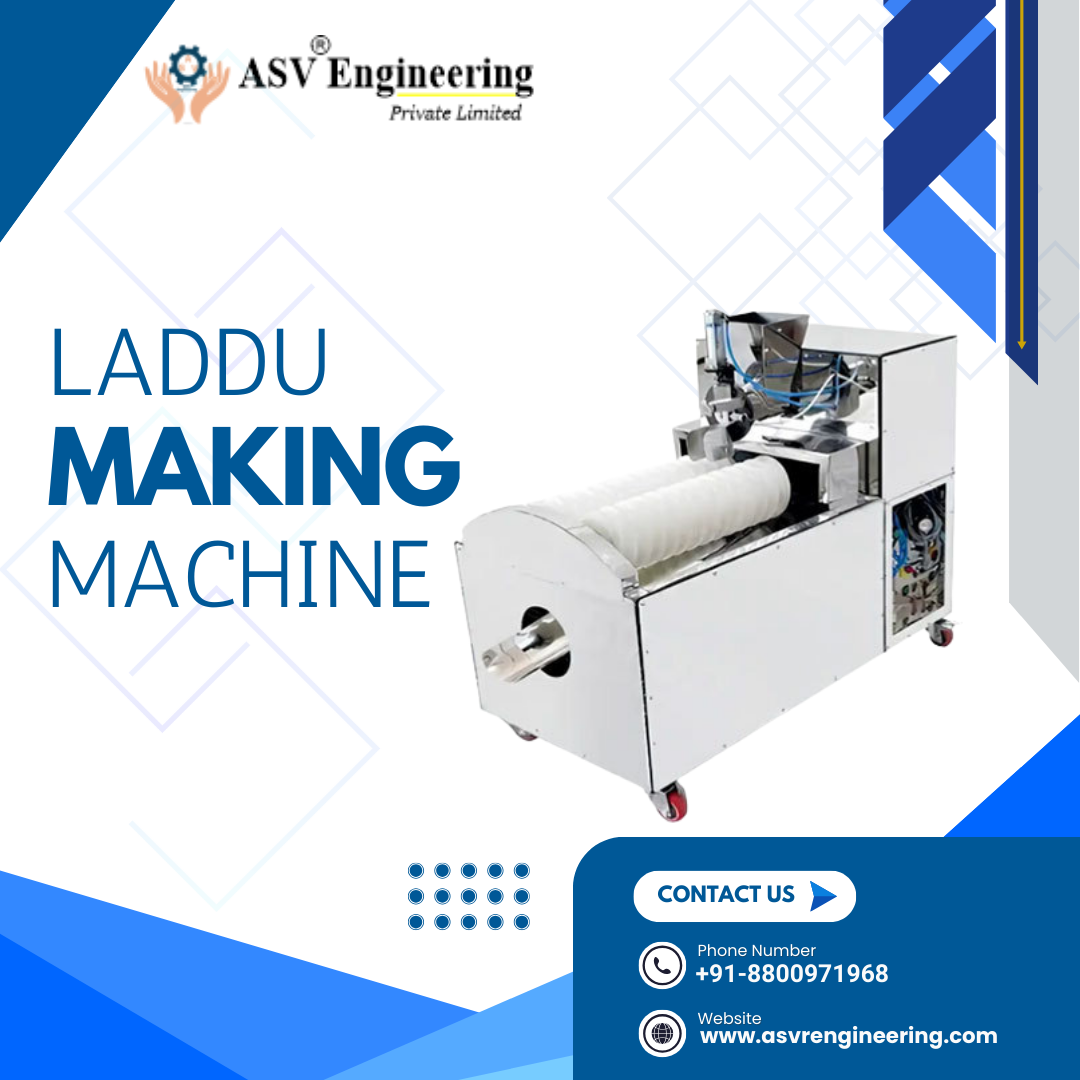

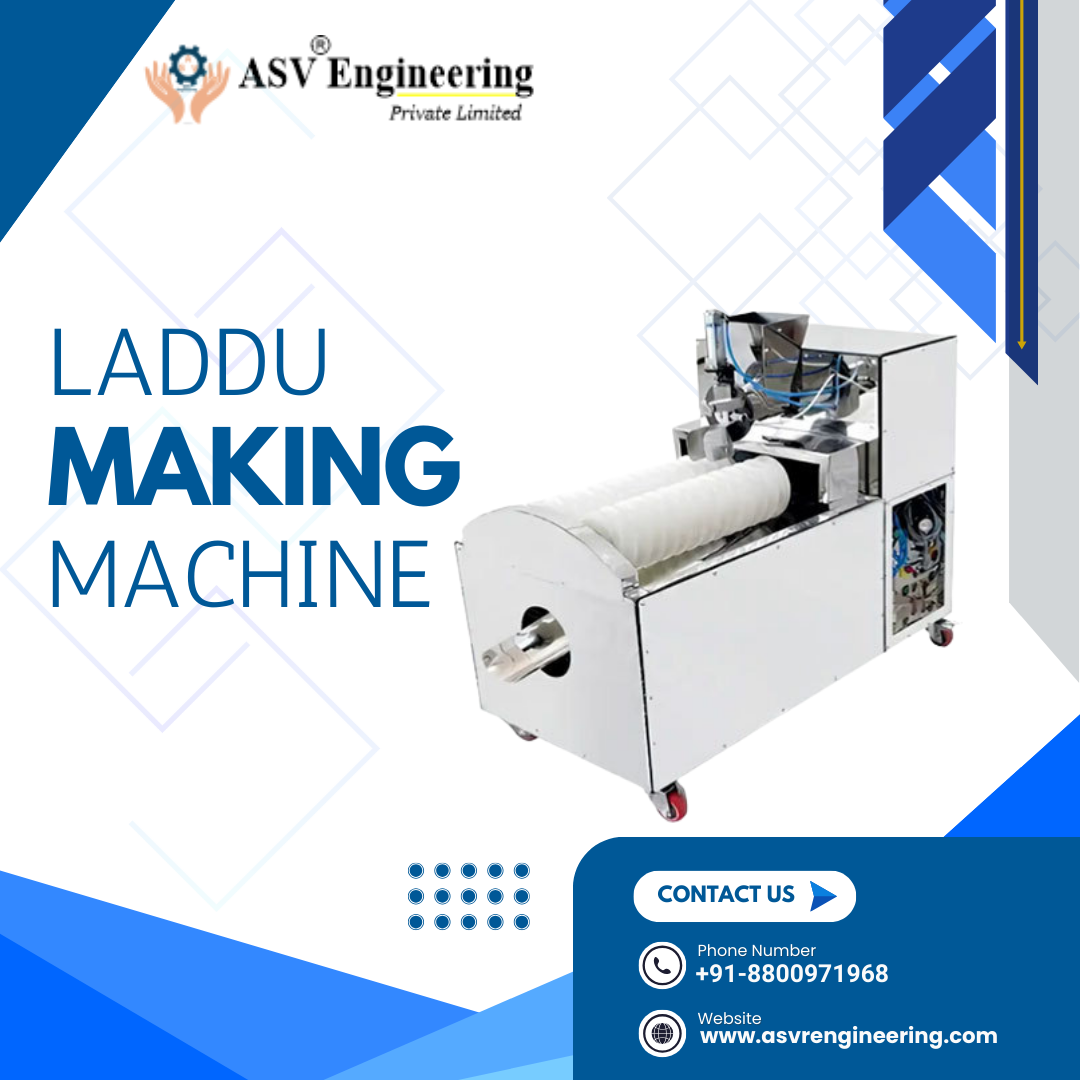

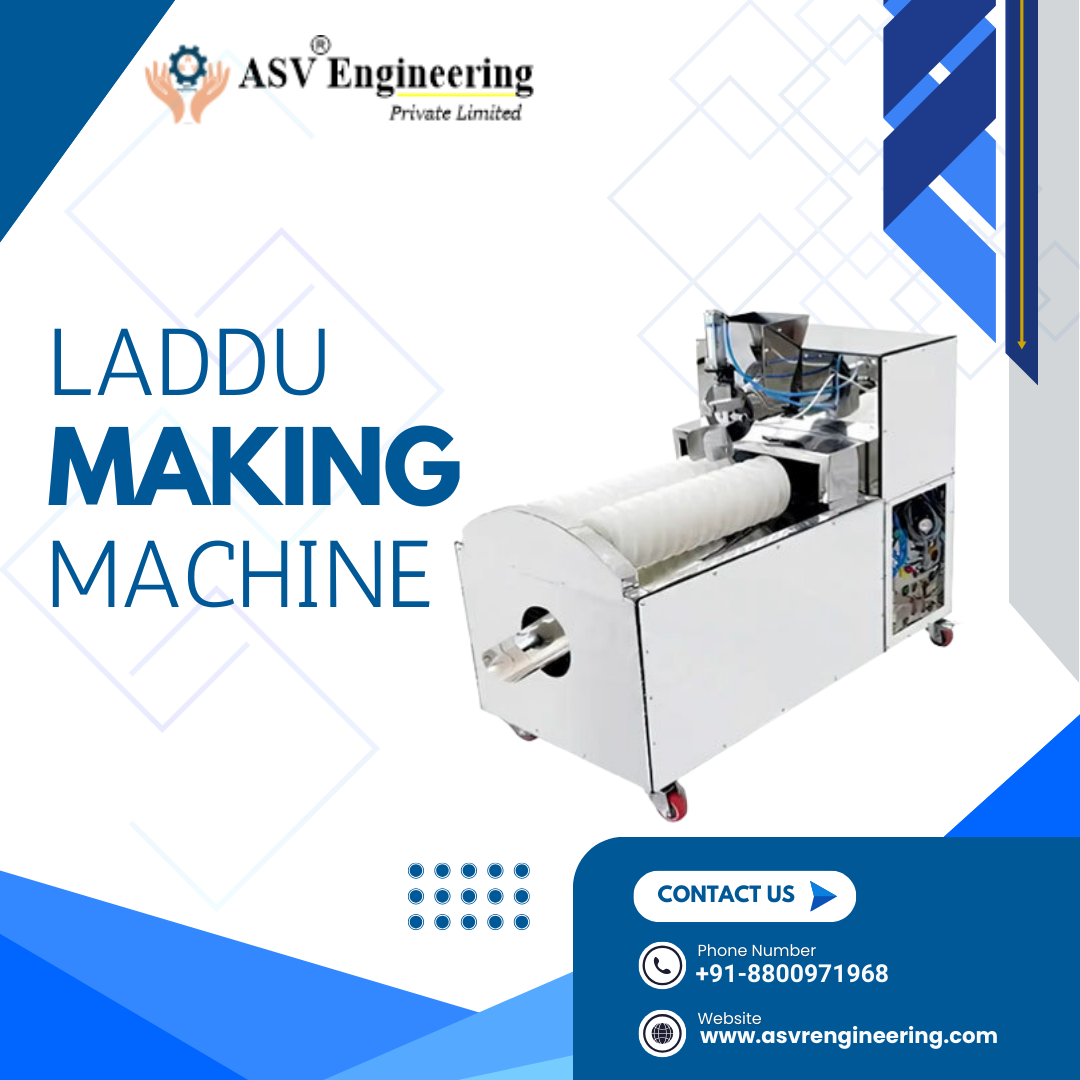

For inquiries and pricing details, contact:

+91-8076004849

+91-8800971968

Website: https://www.asvrengineering.com

Technical Specifications (Typical Range)

While specifications may vary based on model, general features include:

-

Production Capacity: 500 to 5000 pieces per hour

-

Material: SS 304 Food Grade

-

Power Requirement: As per capacity model

-

Motor Type: High-efficiency industrial motor

-

Operation: Semi or Fully Automatic

Customized configurations are available for bulk industrial requirements.

Factors to Consider Before Buying a Rasgulla Making Machine

-

Required production capacity

-

Available workspace

-

Power supply availability

-

Budget planning

-

After-sales support

-

Warranty and spare parts availability

Choosing an experienced manufacturer ensures long-term reliability and service support.

Expanding Business with Sweet Processing Automation

With increasing demand for packaged Indian sweets in supermarkets and international markets, automation is no longer optional—it is essential. Businesses that invest in modern sweet processing machines can:

-

Improve brand reputation

-

Expand distribution networks

-

Supply to large retail chains

-

Enter export markets

-

Maintain standardized quality

Automation helps transform traditional sweet businesses into organized food processing enterprises.

Hygiene and Food Safety Compliance

Modern rasgulla making machines are designed keeping food safety standards in mind. Smooth stainless steel surfaces prevent contamination and allow easy cleaning. Proper drainage systems and minimal manual contact ensure safer food production.

This is especially important for manufacturers supplying to retail chains, hotels, and export markets where strict quality checks are conducted.

Maintenance and Support

ASVR Engineering provides technical guidance and support for installation, training, and maintenance. Regular servicing ensures long machine life and uninterrupted production.

Spare parts are easily available, and our team assists customers in optimizing machine performance.

Conclusion

The demand for rasgulla continues to rise across India and global markets. To meet this demand efficiently, sweet manufacturers must adopt automatic and commercial rasgulla making machines. These machines ensure uniformity, hygiene, higher output, and long-term profitability.

If you are searching for reliable Rasgulla Making Machine Manufacturers in India offering advanced and cost-effective sweet processing machines, ASVR Engineering is your trusted partner.

Upgrade your sweet production with modern automation and take your business to the next level.

For more information, pricing, and technical details:

📞 +91-8076004849

📞 +91-8800971968

🌐 https://www.asvrengineering.com

Buy Now