Soya Paneer Making Machine

Price: ₹150000

In today’s fast-growing food processing industry, soya paneer (also known as soy paneer or tofu paneer) has emerged as a highly demanded protein-rich food product. With rising health awareness, vegan lifestyles, and increasing demand for plant-based protein, commercial production of soya paneer has become a profitable business opportunity. To meet this demand efficiently, investing in a high-quality Soya Paneer Making Machine is essential.

ASVR Engineering offers advanced, reliable, and cost-effective Soya Paneer Making Machines designed for small, medium, and large-scale production units. Our machines are engineered to deliver consistent quality, higher output, hygiene, and long-term performance.

What is a Soya Paneer Making Machine?

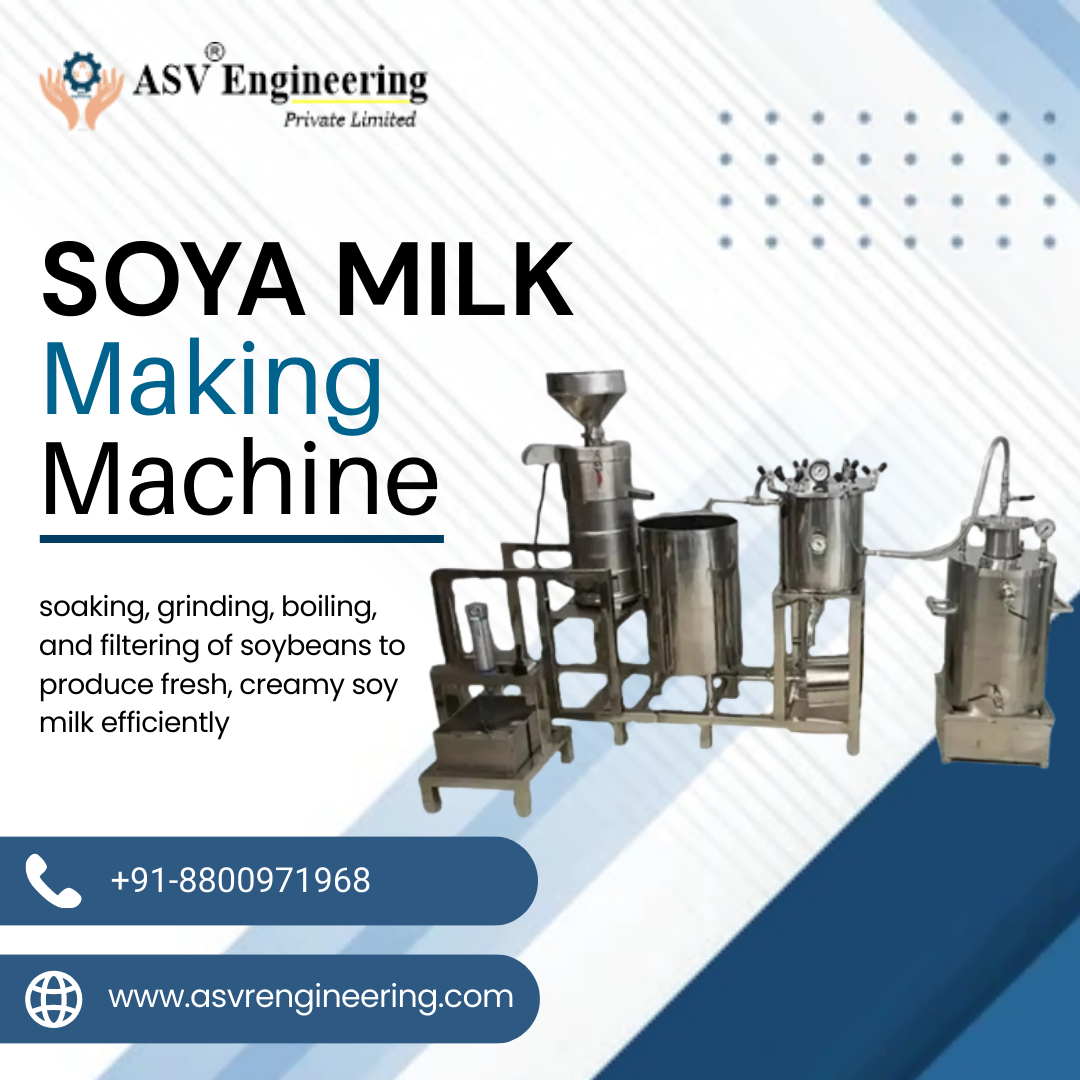

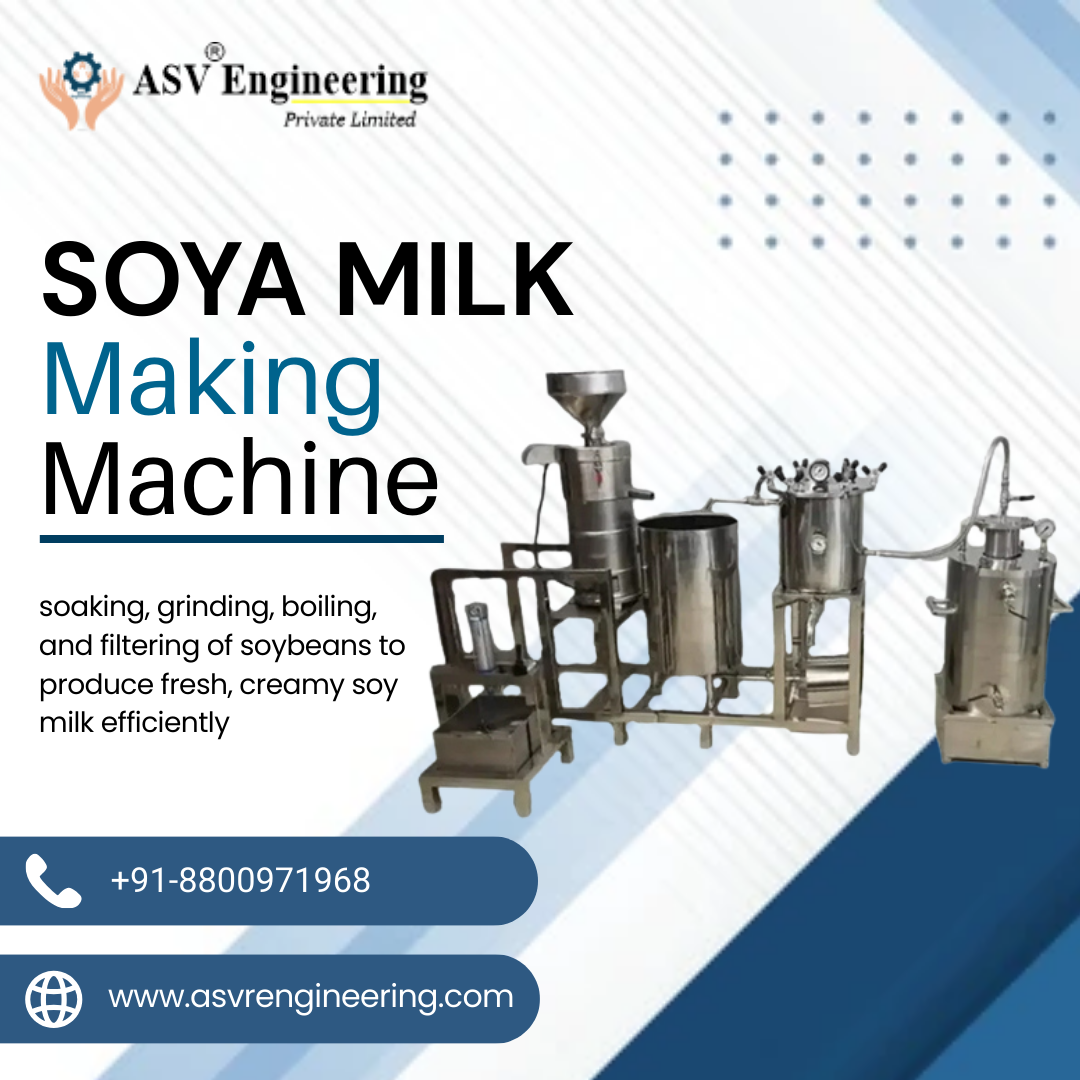

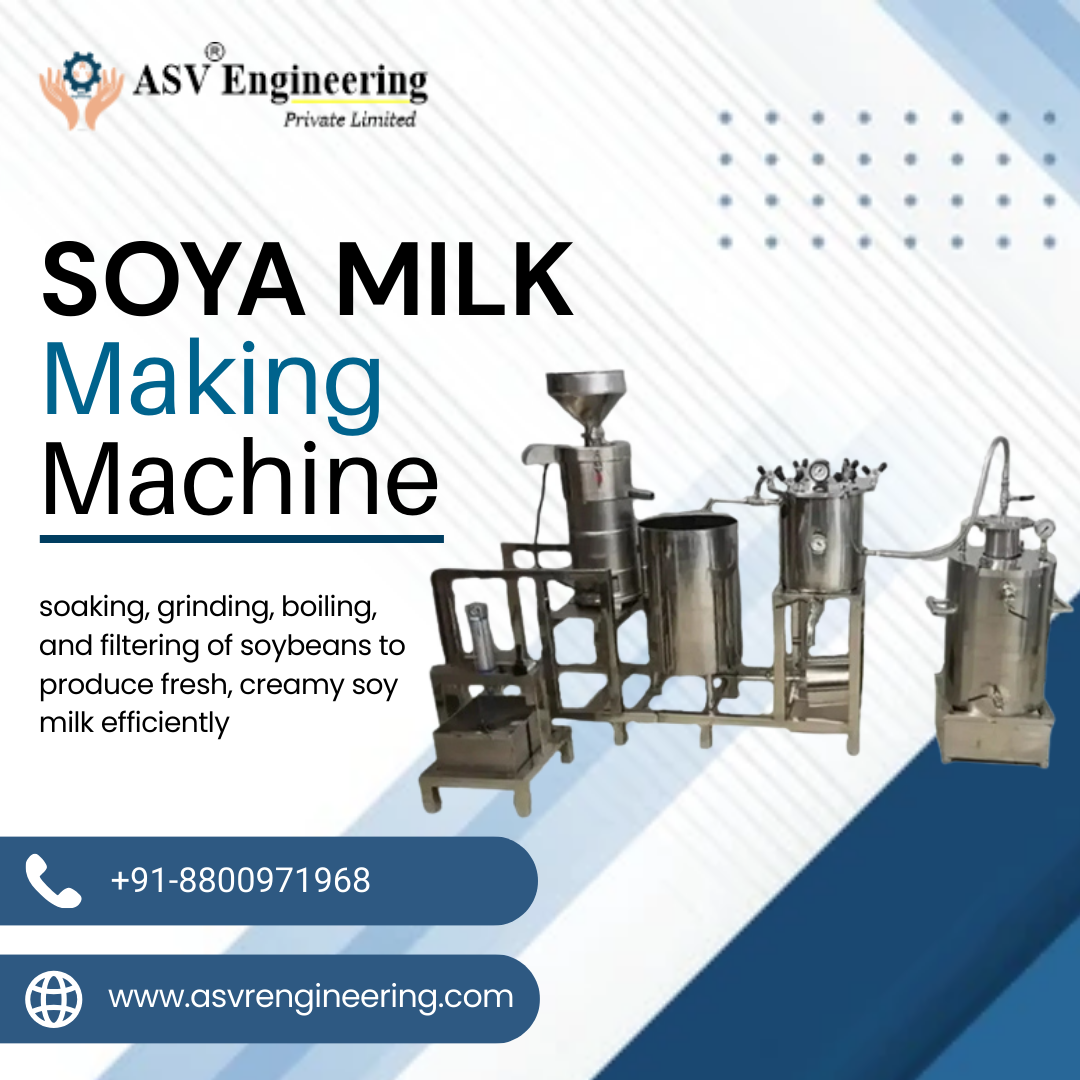

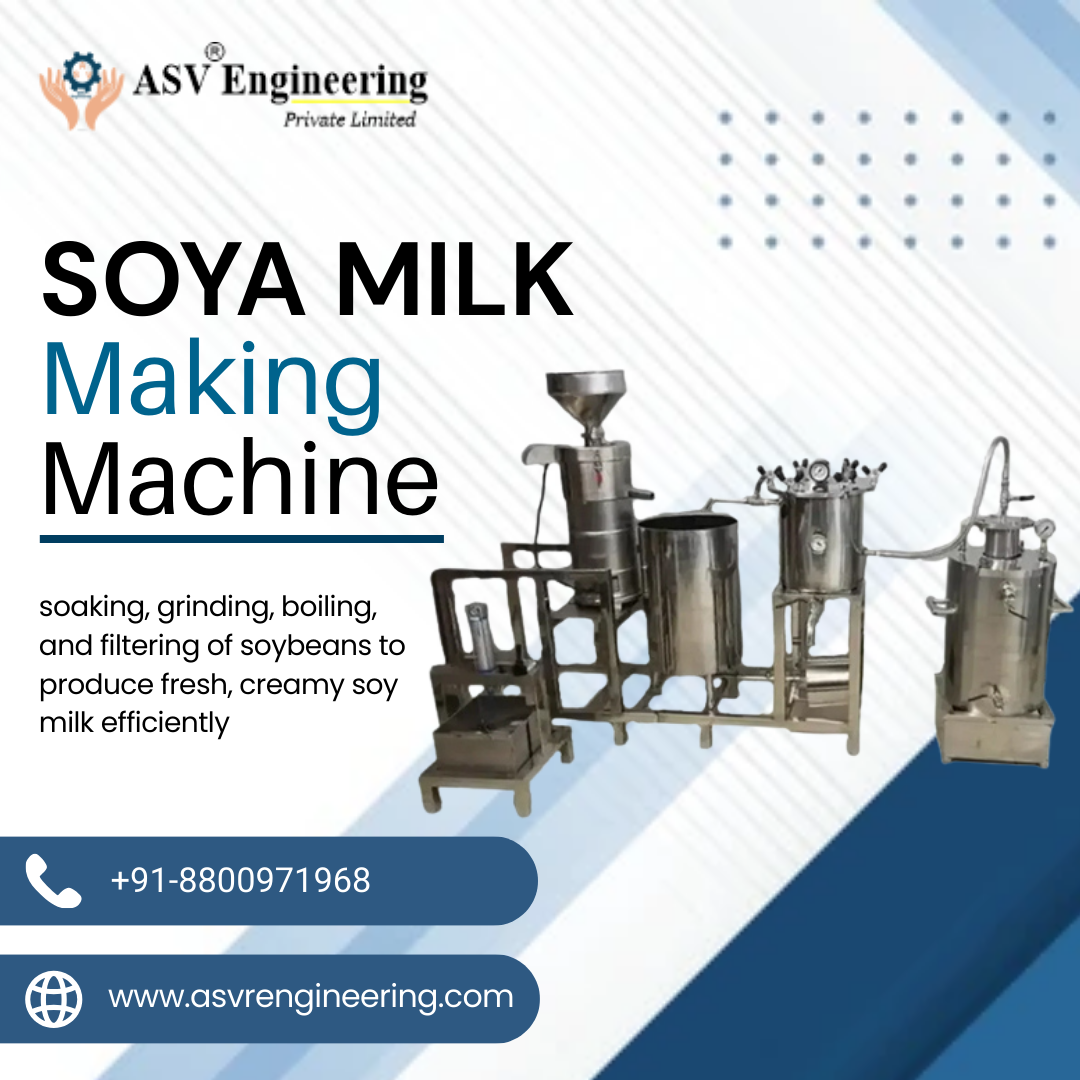

A Soya Paneer Making Machine is a specialized food processing machine used to convert soybeans into high-quality soya paneer through a controlled process of soaking, grinding, heating, coagulation, pressing, and cutting. The machine ensures uniform texture, better taste, and longer shelf life while reducing manual labor and production time.

Unlike traditional manual methods, modern machines provide:

-

Better hygiene

-

Higher production capacity

-

Consistent quality

-

Lower operational cost

Growing Demand for Soya Paneer in India

The Indian food market is witnessing a steady rise in demand for soy-based products due to:

-

Increasing vegan and vegetarian population

-

High protein requirement among fitness-conscious consumers

-

Use of soya paneer in hotels, restaurants, hostels, hospitals, and cloud kitchens

-

Rising awareness of cholesterol-free and lactose-free foods

Because of this trend, food entrepreneurs are actively investing in automatic soya paneer making machines for commercial production.

How the Soya Paneer Making Machine Works

The working process of the machine is carefully designed to ensure maximum yield and quality:

1. Soybean Soaking & Cleaning

Cleaned soybeans are soaked in water to soften them for further processing.

2. Grinding & Slurry Preparation

The soaked beans are ground into a fine slurry using high-efficiency grinders.

3. Cooking & Heating

The slurry is heated at controlled temperatures to eliminate raw flavor and improve protein extraction.

4. Coagulation Process

Food-grade coagulants are added to separate soy milk solids, forming paneer curds.

5. Pressing & Molding

The curds are pressed using molds to remove excess water and give paneer its shape.

6. Cutting & Packaging

The final product is cut into uniform blocks, ready for packaging and sale.

Key Features of ASVR Engineering Soya Paneer Making Machine

Our machines are built to meet industrial standards and food safety norms.

-

Fully Automatic / Semi-Automatic Options

-

Food-Grade Stainless Steel Construction

-

High Production Efficiency

-

Low Power Consumption

-

Easy Operation & Maintenance

-

Uniform Texture & Taste Output

-

Hygienic and Safe Processing

-

Long Machine Life

Each machine is designed keeping Indian working conditions in mind, ensuring durability and consistent performance.

Production Capacity Options

ASVR Engineering offers machines suitable for different production requirements:

-

Small-scale units

-

Medium commercial plants

-

Large industrial soya paneer manufacturing units

Capacity options can be customized based on:

-

Daily production target

-

Available space

-

Budget requirements

Benefits of Using a Commercial Soya Paneer Making Machine

Investing in a professional machine brings multiple advantages:

Higher Profitability

Reduced wastage and higher yield increase overall profit margins.

Consistent Quality

Uniform paneer blocks improve customer satisfaction and brand trust.

Time & Labor Saving

Automation reduces dependency on skilled labor.

Hygienic Production

Meets food safety standards required for commercial sales.

Scalability

Easy to expand production as demand grows.

Applications of Soya Paneer

Soya paneer produced using our machines is widely used in:

-

Hotels and restaurants

-

Catering services

-

Hostels and mess kitchens

-

Hospitals and diet centers

-

Packaged food manufacturing units

-

Supermarkets and retail brands

Why Choose ASVR Engineering?

ASVR Engineering is known for delivering reliable food processing machinery across India. Our focus is not just selling machines, but providing complete support for your business growth.

Our Strengths

-

Proven industry experience

-

Precision-engineered machines

-

Competitive pricing

-

On-time delivery

-

After-sales support

-

Custom machine solutions

We believe in building long-term relationships with our clients by delivering quality and performance they can trust.

Quality & Hygiene Standards

All machines are manufactured using:

-

Food-grade SS material

-

Robust welding and finishing

-

Easy-to-clean design

-

Safe electrical components

This ensures compliance with food safety and hygiene norms required for commercial food production.

Installation & Support

ASVR Engineering provides:

-

Machine installation guidance

-

Operator training

-

Technical support

-

Maintenance assistance

Our support team ensures smooth operation and minimal downtime.

Soya Paneer Making Machine Price

The price of a Soya Paneer Making Machine depends on:

-

Capacity requirement

-

Automation level

-

Custom features

For accurate pricing and specifications, customers are encouraged to contact us directly.

Contact Details

📞 Phone:

+91-8076004849

+91-8800971968

🌐 Website:

https://www.asvrengineering.com

Conclusion

The Soya Paneer Making Machine from ASVR Engineering is an ideal solution for entrepreneurs and food manufacturers looking to enter or expand in the soy-based food market. With reliable performance, hygienic design, and efficient output, our machines help you produce premium-quality soya paneer that meets market demand and food safety standards.

If you are planning to start or upgrade your soya paneer production unit, ASVR Engineering is your trusted partner for long-term success.

Buy Now