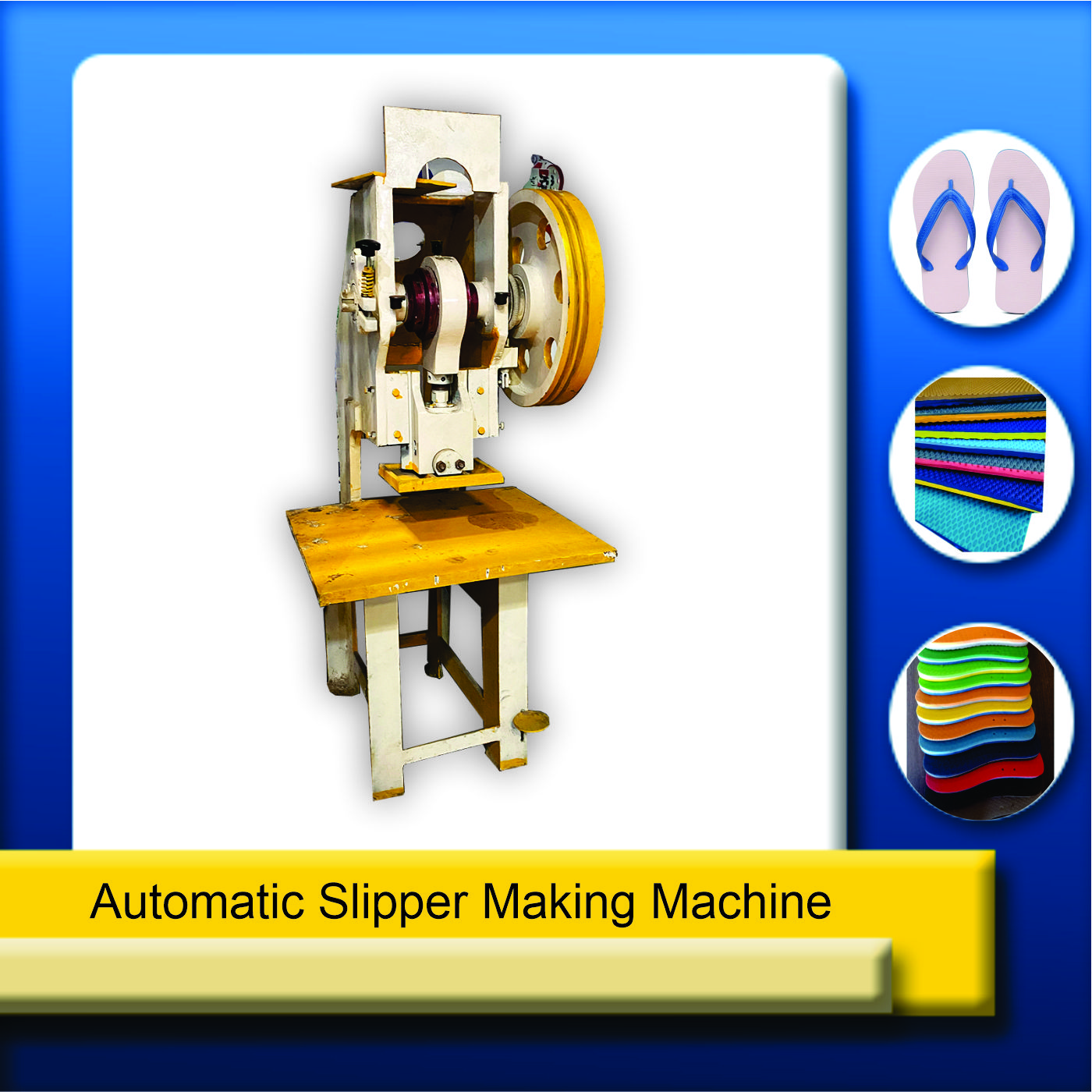

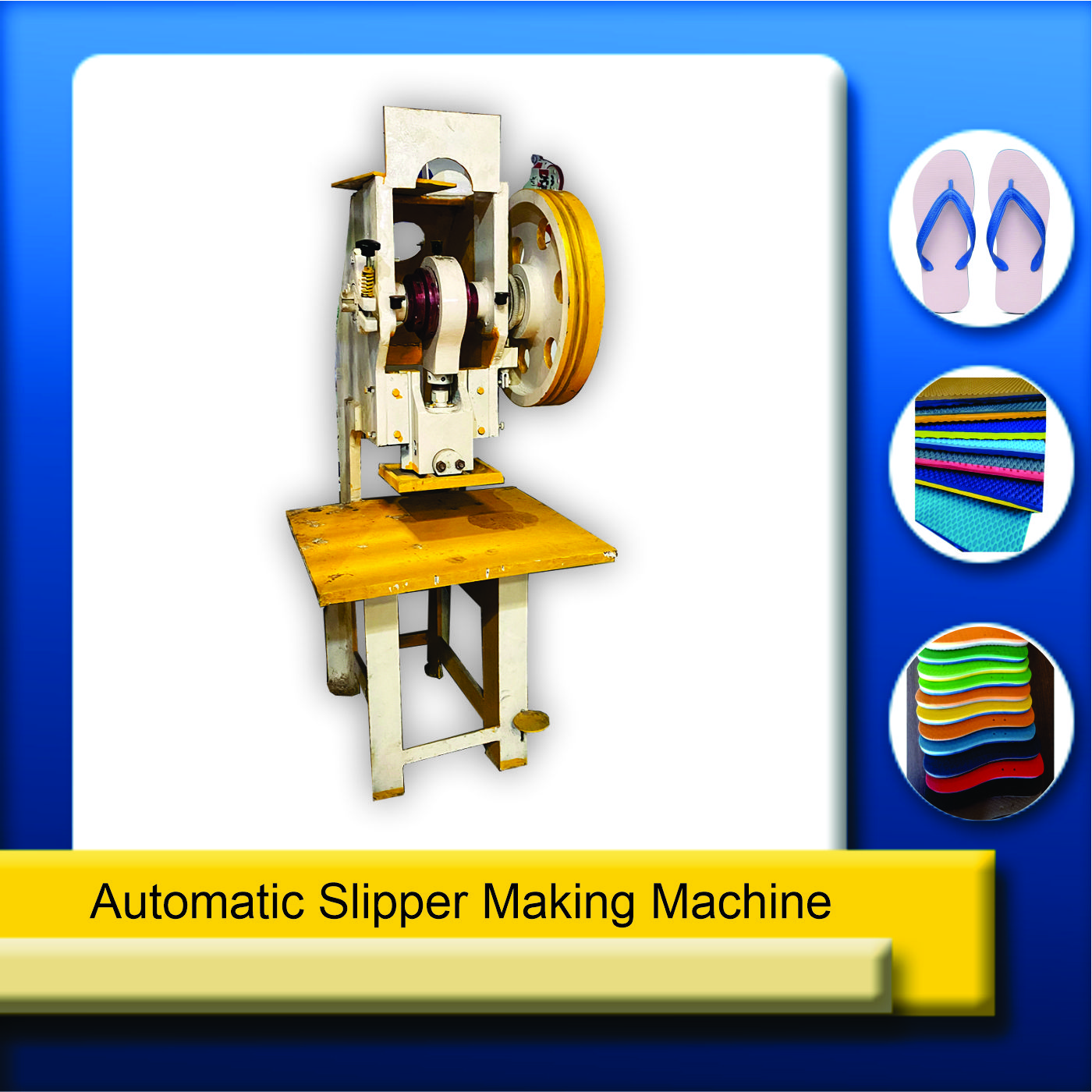

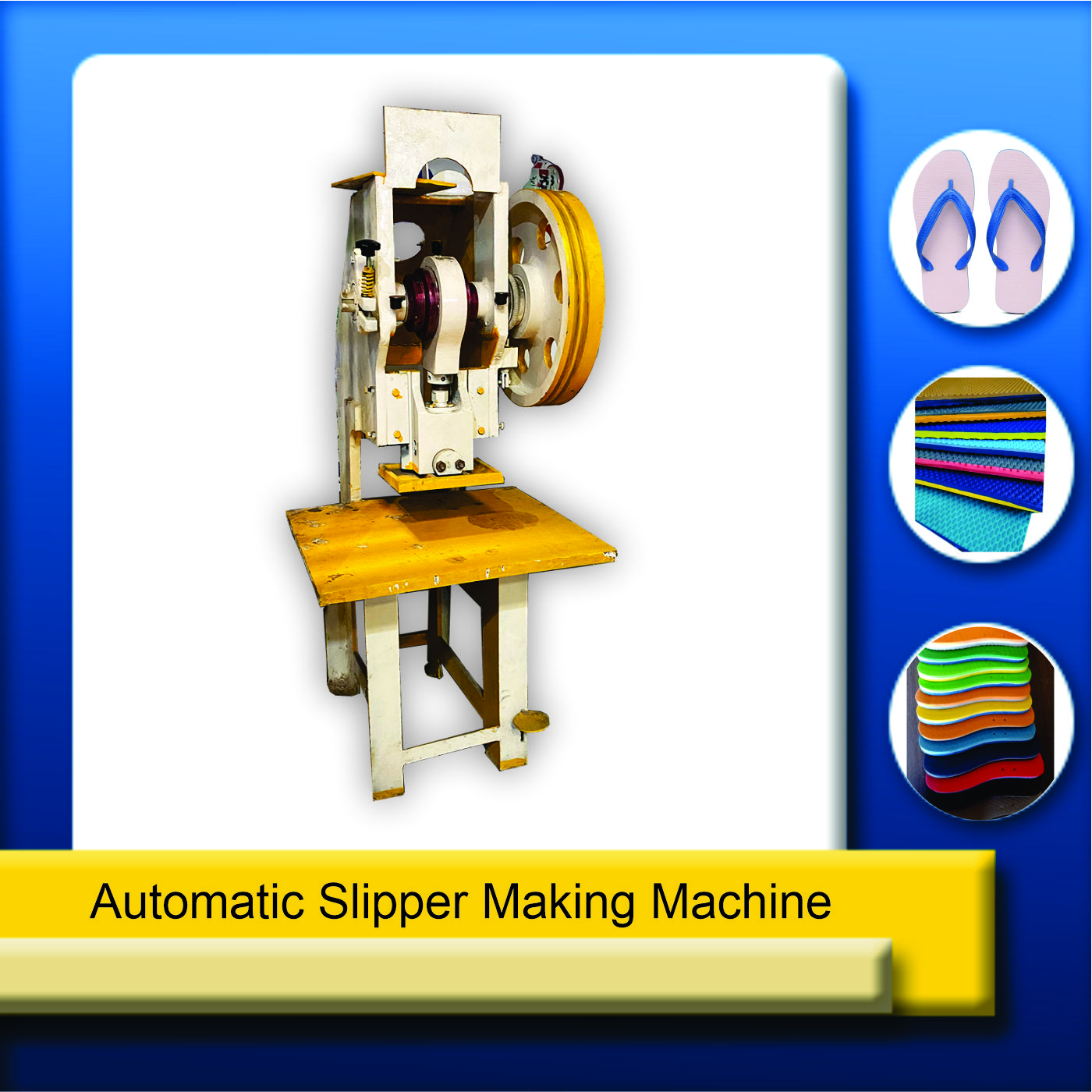

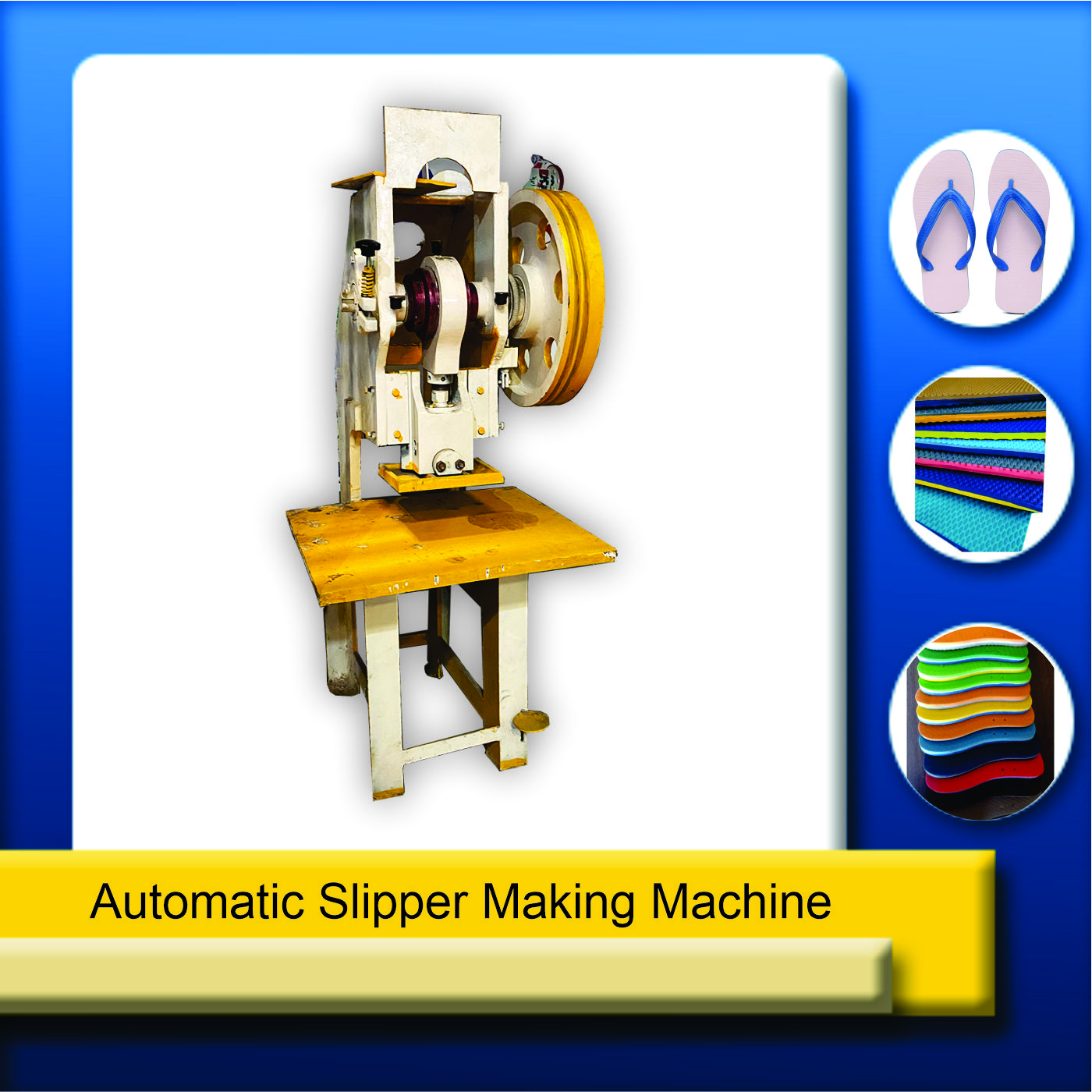

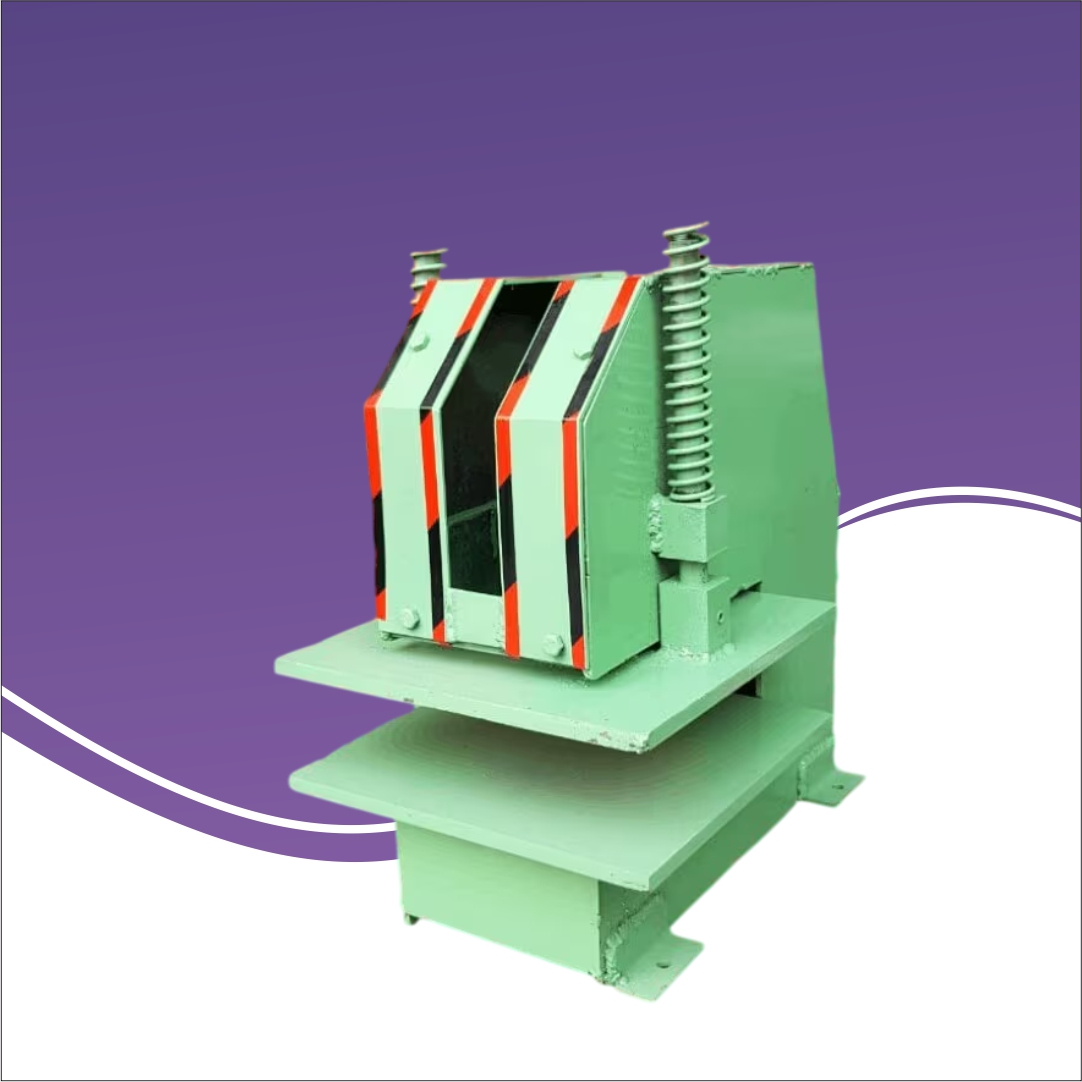

Slipper Making Machine Wholesalers in India | Fully Automatic & Semi-Automatic Machines

Price: ₹24500

India’s footwear market has witnessed consistent growth over the past decade, driven by population expansion, urbanization, rising disposable incomes, and increasing demand for affordable daily-wear footwear. Slippers, flip-flops, and sandals form the backbone of this market because they are essential, economical, and suitable for India’s climate. From rural households to urban consumers, slippers are used daily, making slipper manufacturing a stable and profitable business opportunity.

To meet this ever-growing demand, manufacturers require reliable, high-performance machines that deliver consistent quality, faster production, and lower operational costs. This is where slipper making machine wholesalers in India play a critical role—supplying robust machinery that empowers entrepreneurs, MSMEs, and large factories alike.

Why Choose Professional Slipper Making Machine Wholesalers in India

Buying industrial machinery is a long-term investment. Choosing experienced wholesalers ensures you get machines that are technically sound, durable, and backed by service support. Reputed wholesalers offer:

-

Proven machine designs tested for Indian operating conditions

-

Access to the latest automation technology

-

Guidance on machine selection based on production goals

-

Competitive pricing due to bulk sourcing

-

Reliable after-sales service and spare parts availability

When you work with an established wholesaler like ASVR Engineering, you gain more than just a machine—you gain a manufacturing partner focused on your long-term success.

Types of Slipper Making Machines Available

Slipper manufacturing involves multiple stages such as material mixing, moulding, sole cutting, shaping, and finishing. Based on scale and automation level, machines are broadly categorized as follows:

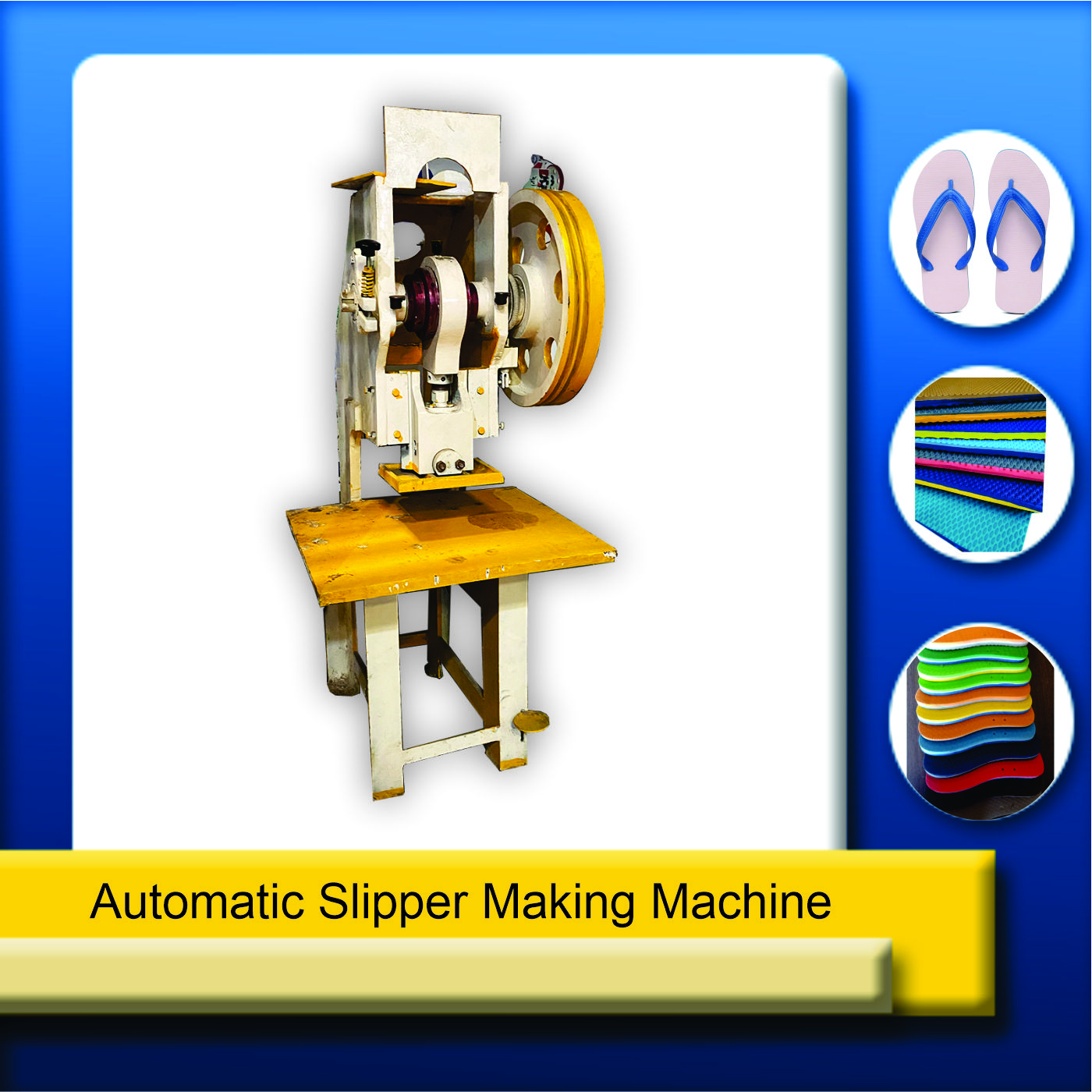

1. Fully Automatic Slipper Making Machines

Fully automatic machines are designed for high-volume production with minimal manual intervention. These machines integrate multiple processes into a single production line, ensuring speed, uniformity, and efficiency.

Key Advantages:

-

High production capacity

-

Consistent product quality

-

Reduced labor dependency

-

Lower long-term operating cost

-

Ideal for large-scale factories and export-oriented units

Applications:

-

EVA slippers

-

Rubber slippers

-

PU and foam-based footwear

2. Semi-Automatic Slipper Making Machines

Semi-automatic machines are best suited for small to medium enterprises and startups. These machines require some manual handling but still provide excellent output and flexibility.

Key Advantages:

-

Lower initial investment

-

Easy operation and maintenance

-

Flexible for multiple slipper designs

-

Ideal for regional and local markets

Applications:

-

Local brand slipper production

-

Customized footwear designs

-

Low to medium batch manufacturing

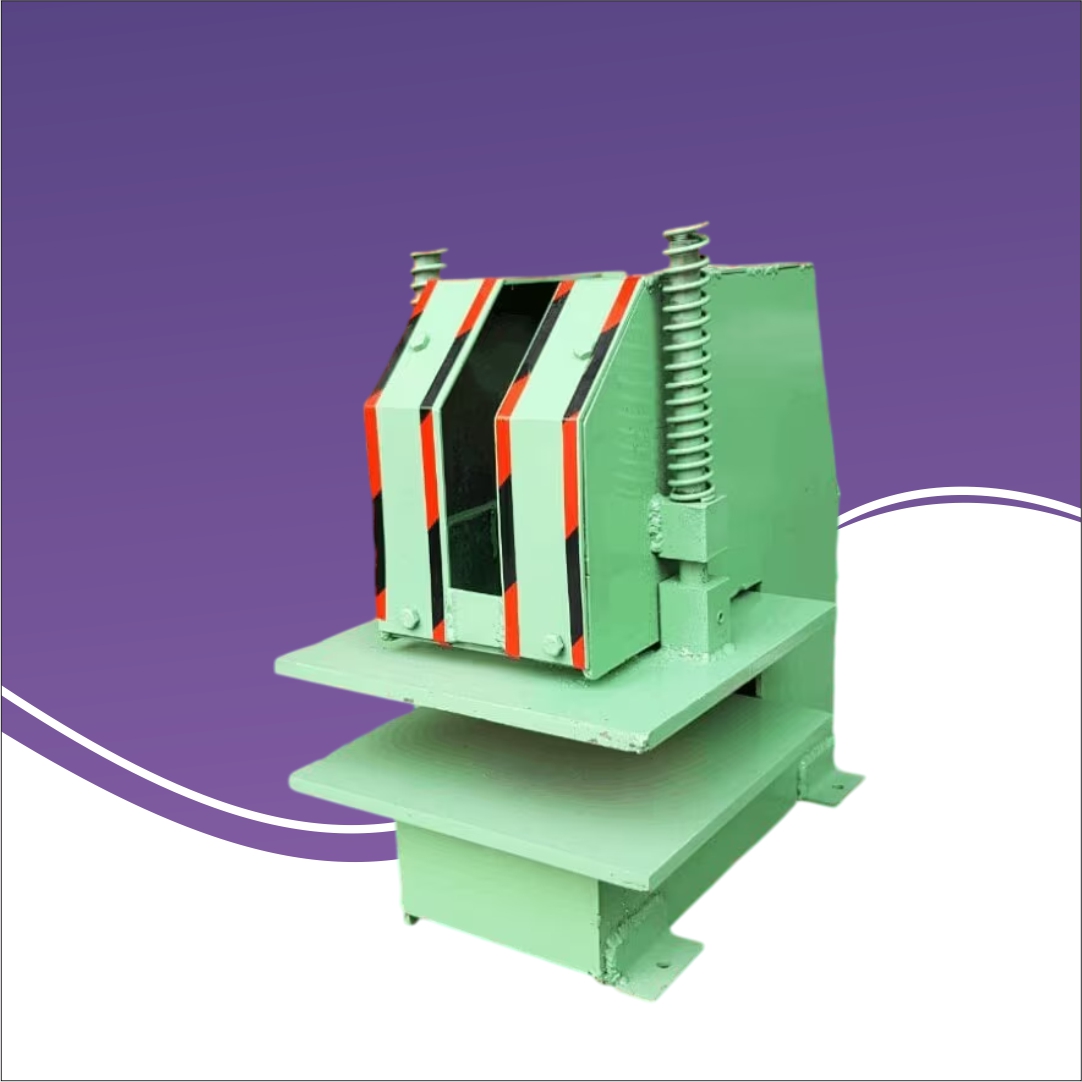

3. Specialized Slipper Manufacturing Machines

In addition to complete lines, wholesalers also provide individual machines used in specific stages of slipper production:

-

Slipper sole cutting machines

-

Hydraulic press machines

-

EVA moulding machines

-

Slipper trimming and finishing machines

-

Material mixing and foaming machines

These machines can be purchased individually or combined to form a customized slipper production setup.

Materials Supported by Modern Slipper Making Machines

Today’s slipper making machines are engineered to handle a wide range of raw materials, ensuring versatility and product diversity:

-

EVA (Ethylene Vinyl Acetate): Lightweight, flexible, and durable

-

Rubber: High grip, strength, and long-lasting performance

-

PU (Polyurethane): Premium finish and comfort

-

Foam and PVC: Cost-effective and easy to mould

Advanced machines allow manufacturers to switch materials with minimal downtime, helping businesses adapt to market trends.

Slipper Making Machine Applications Across India

Slipper making machines supplied by Indian wholesalers are used across multiple business segments:

-

MSME footwear manufacturing units

-

Export-oriented footwear factories

-

Private label and OEM production

-

Government-supported self-employment projects

-

Rural and semi-urban manufacturing clusters

With proper machinery, entrepreneurs can serve local markets as well as scale up for national and international distribution.

Key Features to Look for in a Slipper Making Machine

When investing in slipper manufacturing equipment, the following features are crucial:

-

Heavy-duty steel body for long operational life

-

Precision moulding for uniform sole thickness

-

Energy-efficient motors and hydraulics

-

User-friendly control panels

-

Safety mechanisms for operators

-

Easy maintenance and spare part availability

Reliable wholesalers ensure that all machines meet industrial standards and are tested before dispatch.

Slipper Making Machine Price in India

The price of slipper making machines in India depends on several factors:

-

Level of automation (manual, semi-automatic, fully automatic)

-

Production capacity per day

-

Material compatibility

-

Machine size and configuration

-

Customization requirements

Semi-automatic machines are ideal for entrepreneurs with limited budgets, while fully automatic machines offer higher ROI for large-scale manufacturers. A trusted wholesaler helps you choose the right balance between cost and performance.

Why ASVR Engineering is a Trusted Name Among Wholesalers

ASVR Engineering has built a strong reputation as a reliable supplier of slipper making machines across India. Their focus on engineering quality, customer satisfaction, and after-sales support makes them a preferred choice among footwear manufacturers.

What Sets Them Apart:

-

Wide range of fully automatic and semi-automatic machines

-

Strong technical expertise and industry experience

-

Transparent pricing and honest consultation

-

Pan-India delivery and service support

-

Machines designed for Indian production environments

Whether you are starting a new slipper manufacturing unit or upgrading an existing plant, ASVR Engineering provides solutions that grow with your business.

After-Sales Support and Service

One of the biggest advantages of working with established wholesalers is dependable after-sales service. Timely installation, operator training, and technical assistance ensure uninterrupted production. Availability of genuine spare parts further extends machine life and minimizes downtime.

Slipper Making Business: A Profitable Opportunity

With low raw material costs, high market demand, and scalable production options, slipper manufacturing is considered one of the most profitable small-to-medium industrial ventures in India. By investing in the right machines and partnering with experienced wholesalers, entrepreneurs can achieve faster break-even and sustainable growth.

Contact ASVR Engineering

If you are looking for slipper making machine wholesalers in India offering reliable, efficient, and cost-effective solutions, get in touch with ASVR Engineering today.

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website: https://www.asvrengineering.com

Their team will guide you in selecting the right slipper making machine based on your production needs, budget, and long-term business goals.

Buy Now

.jpg)