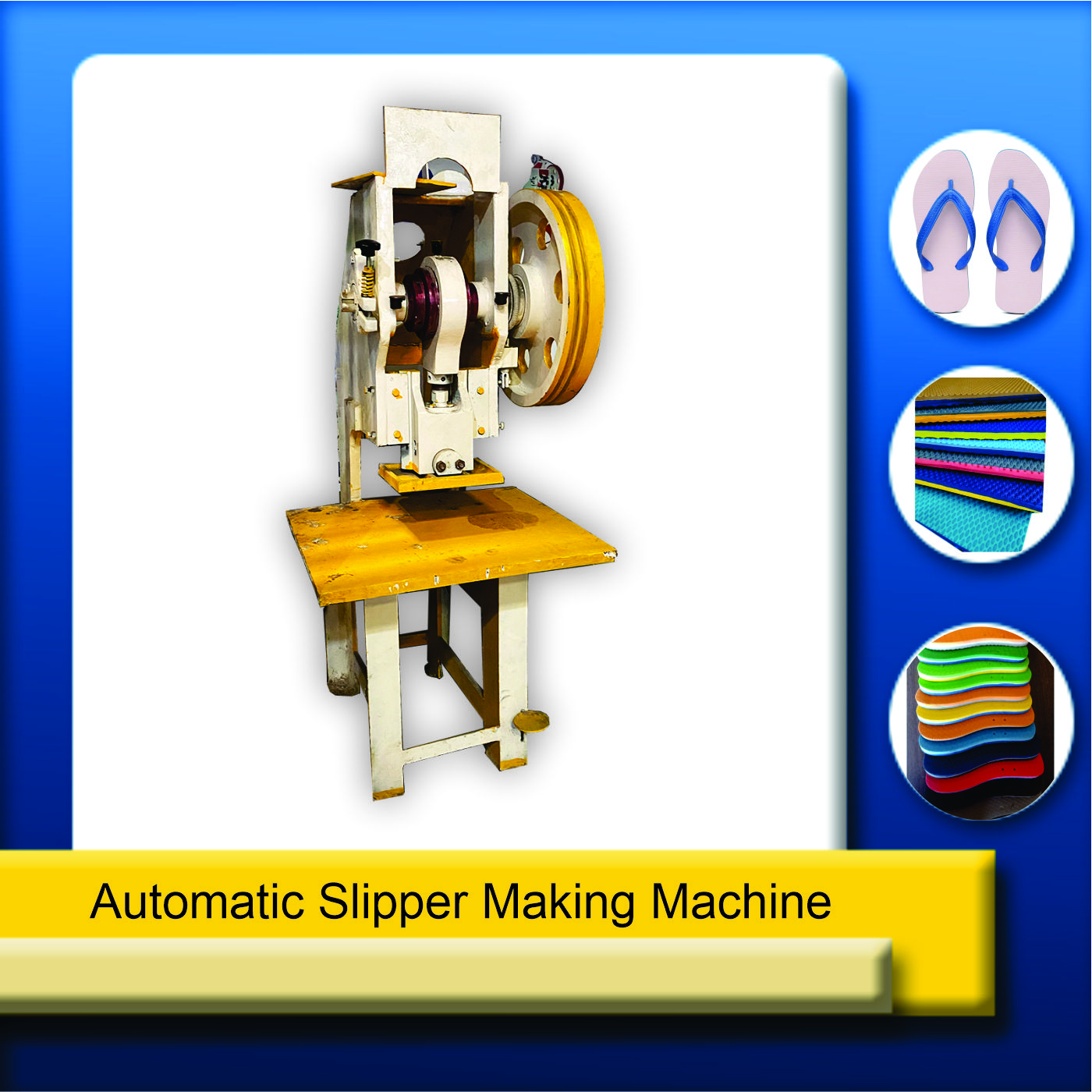

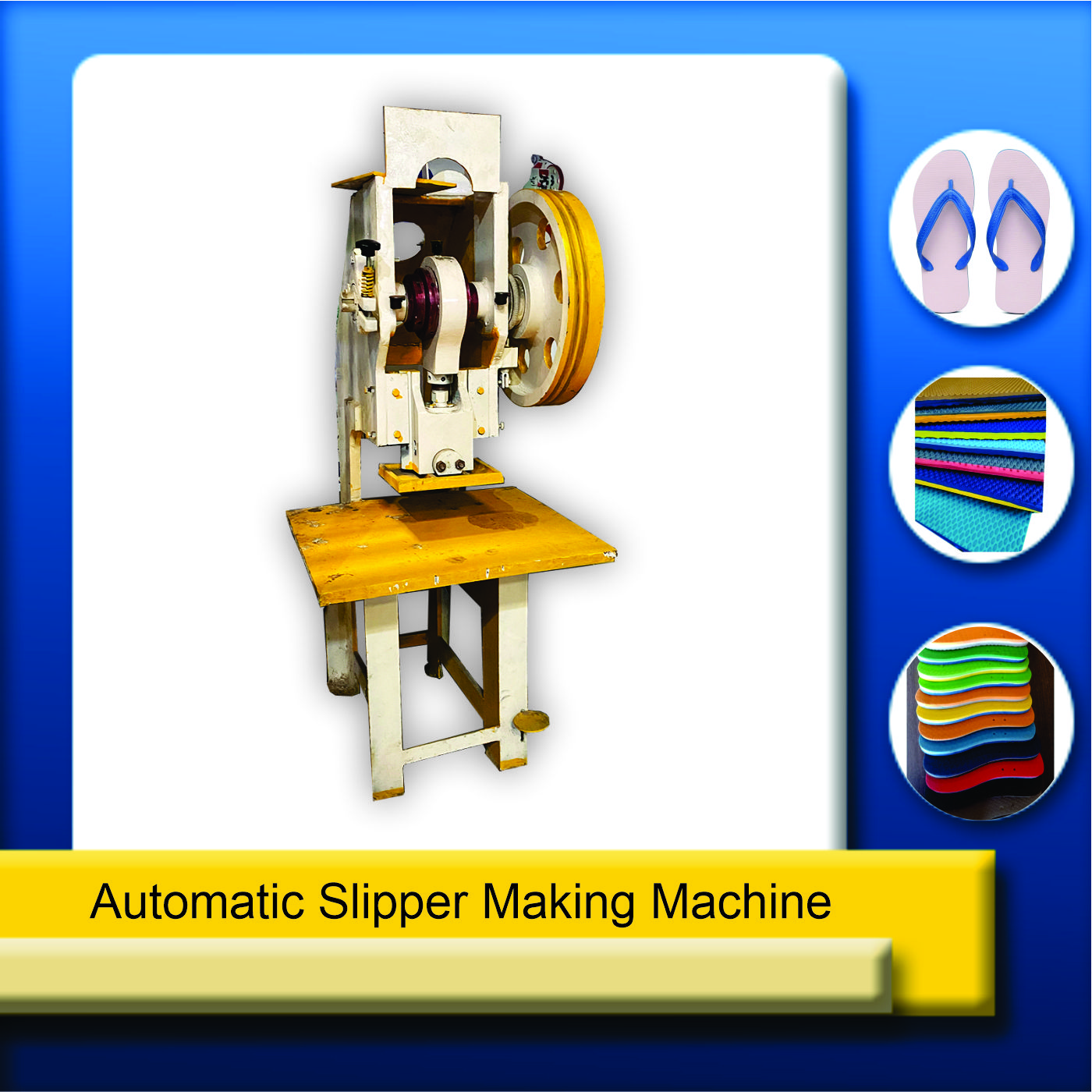

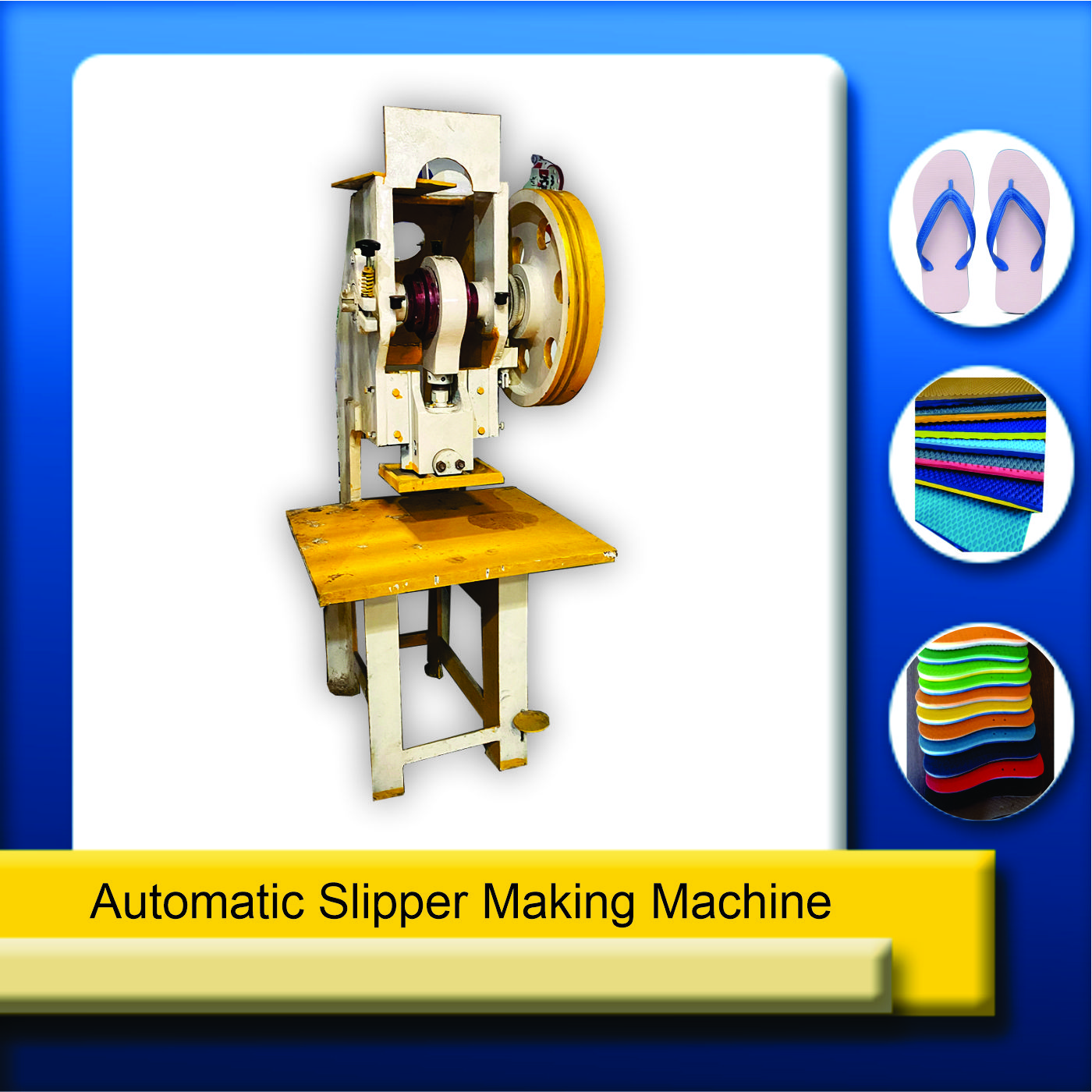

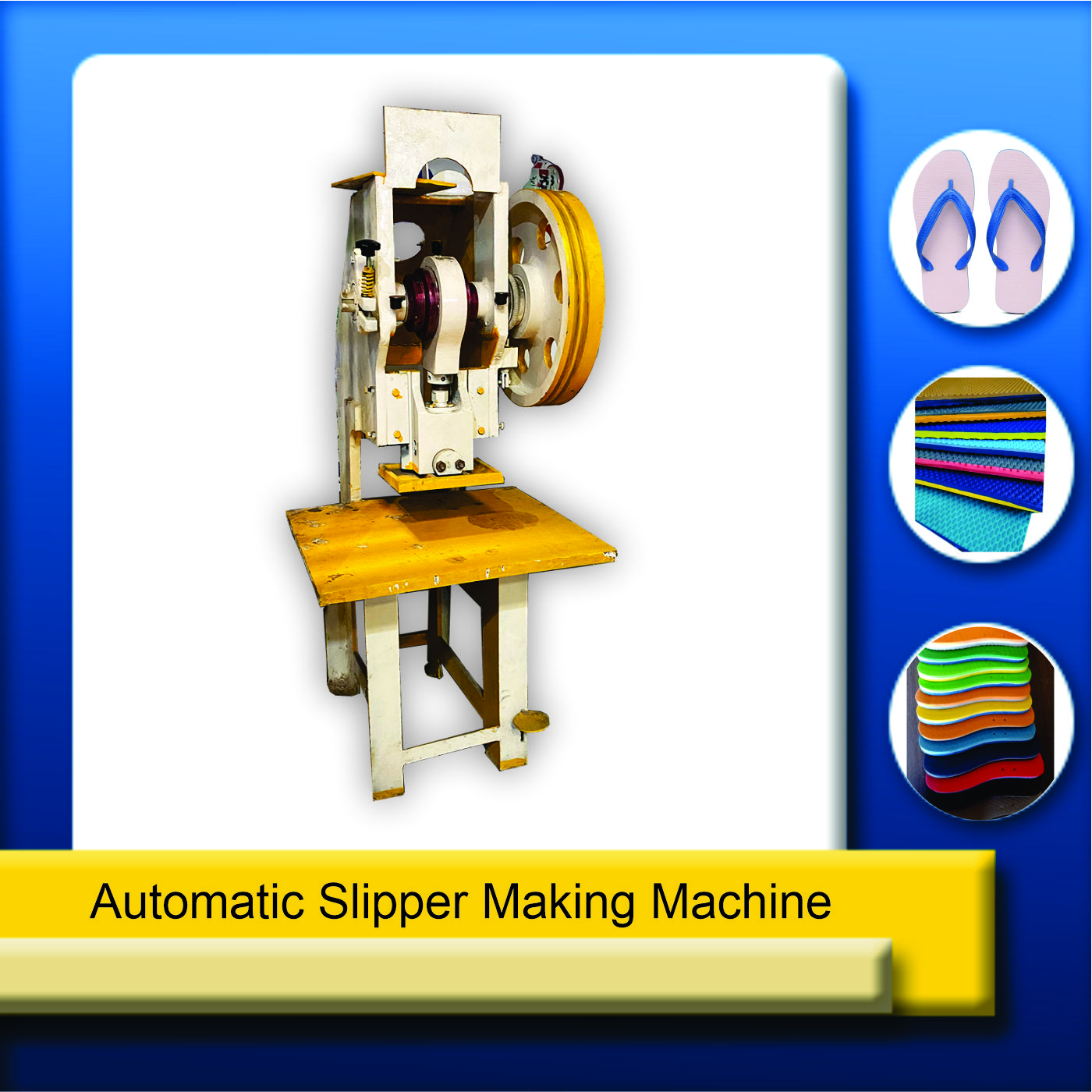

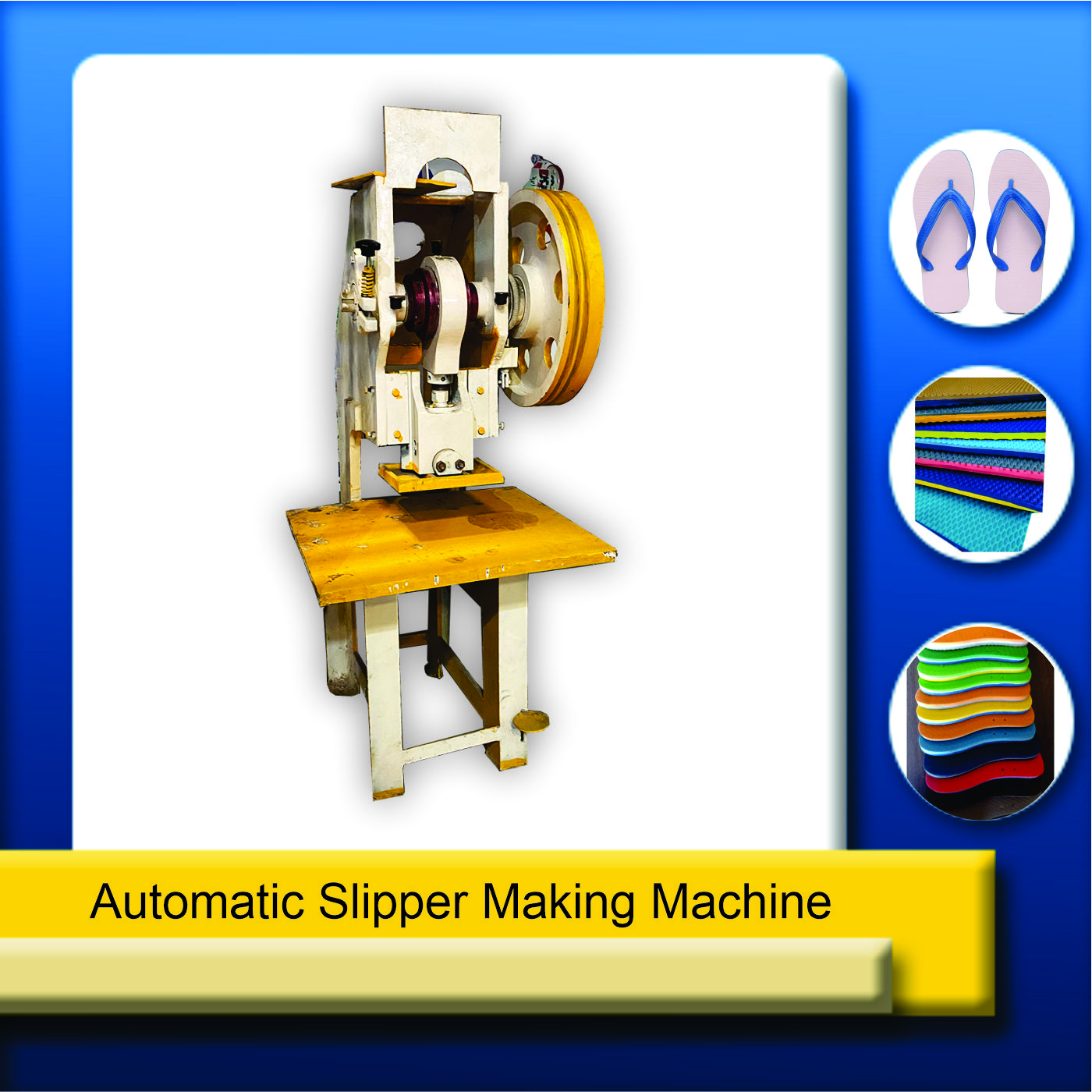

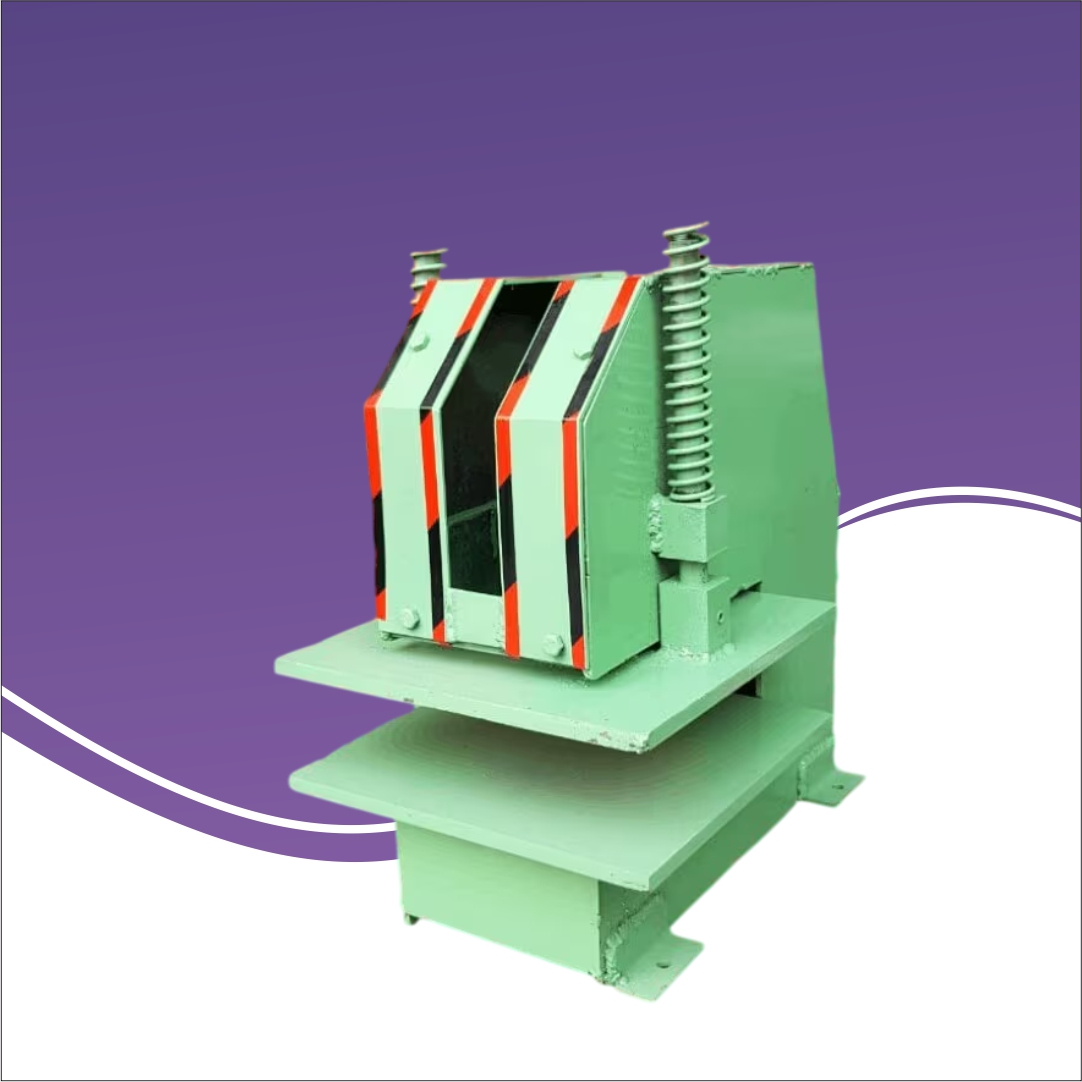

Leading Manual Slipper Making Machine Importers for Small-Scale & Commercial Footwear Manufacturing Units

Price: ₹415000

In India’s rapidly growing footwear industry, the demand for affordable, durable, and easy-to-operate manufacturing equipment has increased significantly. From small home-based units to expanding commercial footwear factories, entrepreneurs are constantly looking for reliable machinery that ensures consistent output without heavy investment. Manual slipper making machines have emerged as one of the most practical solutions for startups, MSMEs, and even established manufacturers who want cost efficiency with dependable performance.

As leading manual slipper making machine importers, ASVR Engineering plays a vital role in bridging the gap between global manufacturing technology and Indian footwear businesses. With a strong focus on quality, affordability, and after-sales support, ASVR Engineering has become a trusted name for businesses aiming to manufacture slippers, chappals, and footwear soles efficiently.

Understanding Manual Slipper Making Machines

Manual slipper making machines are designed to support footwear production where automation is not essential or where controlled manual operation offers better flexibility. These machines are particularly suitable for:

-

Small-scale slipper manufacturing units

-

Cottage industries and self-employment ventures

-

Rural and semi-urban footwear businesses

-

Startups with limited capital investment

-

Backup or auxiliary production lines in large factories

Unlike fully automatic systems, manual machines offer ease of use, low maintenance, and high durability. They allow manufacturers to maintain better control over production while keeping operational costs low.

Why Manual Slipper Making Machines Are Still in High Demand

Despite the availability of automated footwear machinery, manual slipper making machines continue to enjoy strong demand in India and other developing markets. The reasons are clear:

-

Low Investment, High Return

Manual machines require significantly less capital compared to automated systems, making them ideal for new entrepreneurs. -

Ease of Operation

These machines do not require skilled technicians. Basic training is enough to start production. -

Low Power Consumption

Many manual slipper making machines operate without electricity or with minimal power, reducing operational expenses. -

Simple Maintenance

With fewer mechanical and electronic components, maintenance costs remain minimal. -

Production Flexibility

Manual operation allows easy customization in design, size, and material handling.

Role of Importers in Quality Footwear Machinery

Importers play a crucial role in ensuring Indian manufacturers receive machinery that meets global standards. As an experienced importer, ASVR Engineering sources machines from trusted international manufacturers known for precision engineering and long operational life.

Each machine is carefully selected based on:

-

Build quality and material strength

-

Output consistency

-

Suitability for Indian working conditions

-

Ease of spare part availability

-

Compliance with safety standards

This ensures that businesses investing in manual slipper making machines receive reliable equipment that delivers long-term value.

Manual Slipper Making Machines for Small-Scale Units

Small-scale footwear manufacturers form the backbone of India’s slipper industry. Manual machines are particularly beneficial for such units because they:

-

Require minimal floor space

-

Allow gradual scaling of production

-

Reduce dependency on skilled labor

-

Enable affordable entry into the footwear business

ASVR Engineering supports small entrepreneurs by offering machines that are robust, easy to install, and capable of consistent daily output. These machines are ideal for producing EVA slippers, rubber chappals, and basic footwear soles.

Solutions for Commercial Footwear Manufacturing Units

For medium and commercial-scale footwear manufacturers, manual slipper making machines are often used as:

-

Secondary production units

-

Sample and prototype development machines

-

Specialized design or seasonal product lines

Importing high-quality manual machines ensures smooth integration with existing production setups. ASVR Engineering provides consultation to help commercial units select machines that align with their production goals and material requirements.

Quality Assurance and Performance Reliability

One of the key factors that differentiate a professional importer from a reseller is quality assurance. Every manual slipper making machine supplied by ASVR Engineering undergoes strict inspection before delivery. This includes:

-

Structural strength testing

-

Alignment and pressure checks

-

Smooth operation verification

-

Safety component inspection

Such checks ensure that customers receive machines that are ready for immediate use and capable of delivering consistent results over long operational hours.

After-Sales Support and Technical Guidance

Purchasing machinery is only the first step; long-term performance depends on service and support. ASVR Engineering emphasizes strong after-sales assistance, including:

-

Installation guidance

-

Basic operational training

-

Spare parts support

-

Maintenance advice

-

Technical troubleshooting

This customer-centric approach ensures minimal downtime and maximum productivity for footwear manufacturers.

Why Choose ASVR Engineering as Your Import Partner

When selecting a manual slipper making machine importer, businesses look for reliability, transparency, and technical expertise. ASVR Engineering stands out because of:

-

Years of experience in industrial machinery imports

-

Strong supplier network across international markets

-

Honest pricing without hidden costs

-

Proven track record with footwear manufacturers

-

Dedicated customer support team

Their commitment to quality and customer satisfaction makes them a preferred choice for slipper making machine imports in India.

Supporting Entrepreneurship and Employment

Manual slipper making machines play a significant role in promoting self-employment and local manufacturing. By providing affordable and durable machines, ASVR Engineering indirectly supports:

-

Rural entrepreneurship

-

Women-led manufacturing units

-

Skill development initiatives

-

Local employment generation

This aligns well with India’s “Make in India” and MSME development goals.

Applications of Manual Slipper Making Machines

These machines are widely used for manufacturing:

-

EVA slippers

-

Rubber chappals

-

PU-based footwear soles

-

Low-cost daily-use slippers

-

Customized local market footwear

Their versatility makes them suitable for diverse production needs.

Long-Term Value for Growing Businesses

Investing in a high-quality manual slipper making machine is not just about current production—it’s about long-term growth. With proper maintenance, these machines can operate efficiently for years, helping businesses scale gradually without financial strain.

ASVR Engineering ensures that every machine delivered offers durability, performance stability, and ease of future upgrades if required.

Contact ASVR Engineering

If you are planning to start or expand your slipper manufacturing unit, choosing the right importer is critical. ASVR Engineering offers expert guidance, reliable machinery, and complete support for your footwear manufacturing journey.

📞 Contact Numbers:

+91-8076004849

+91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now

.jpg)