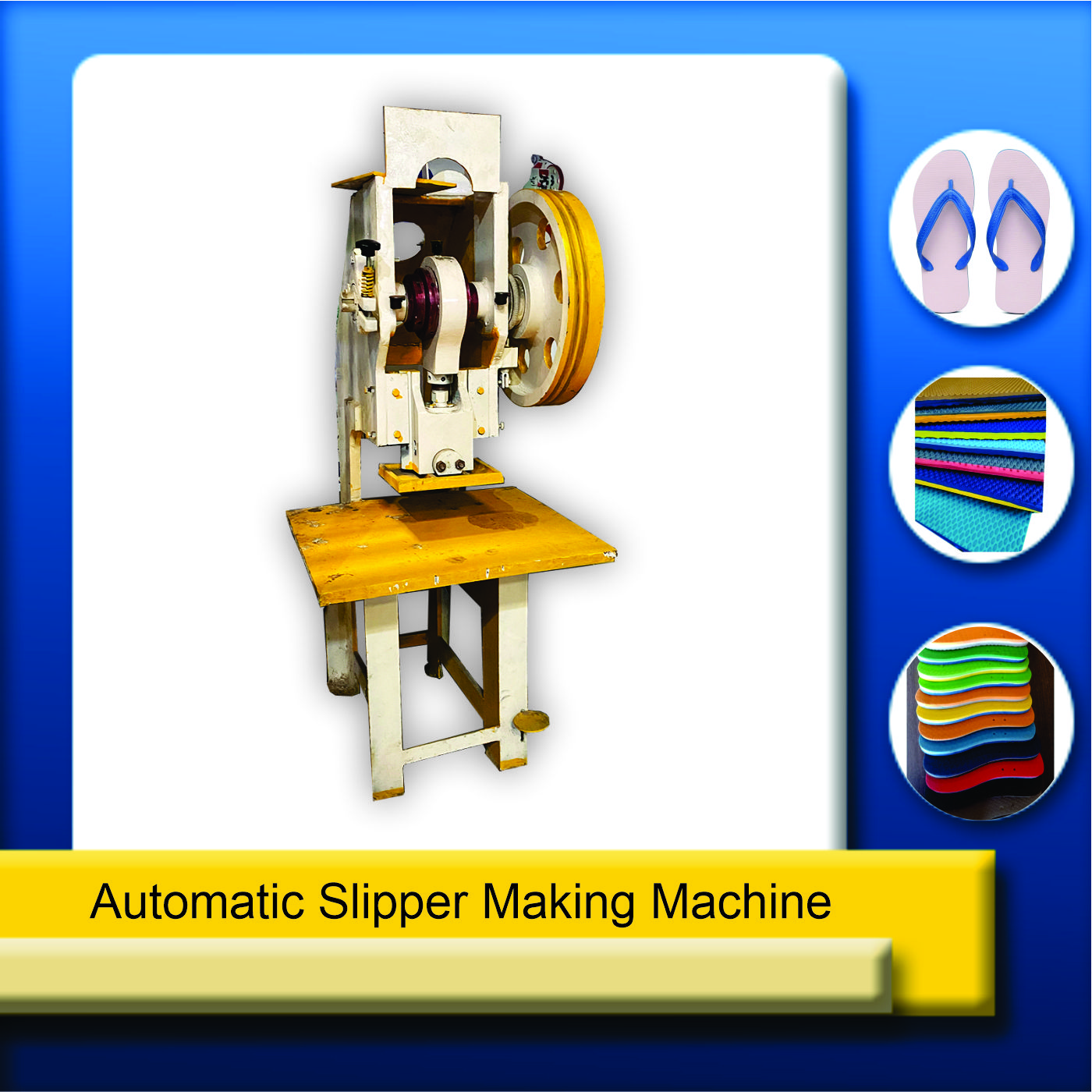

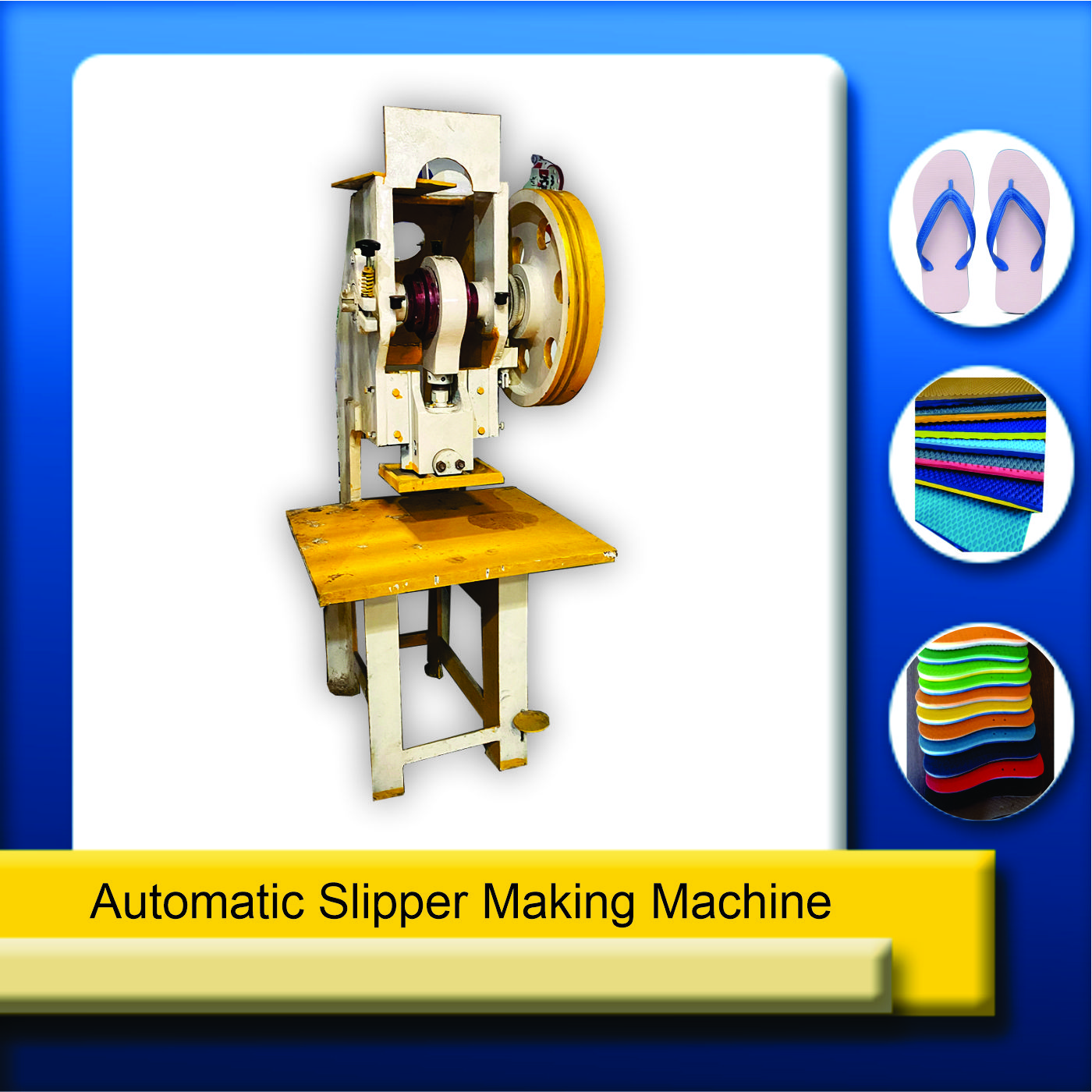

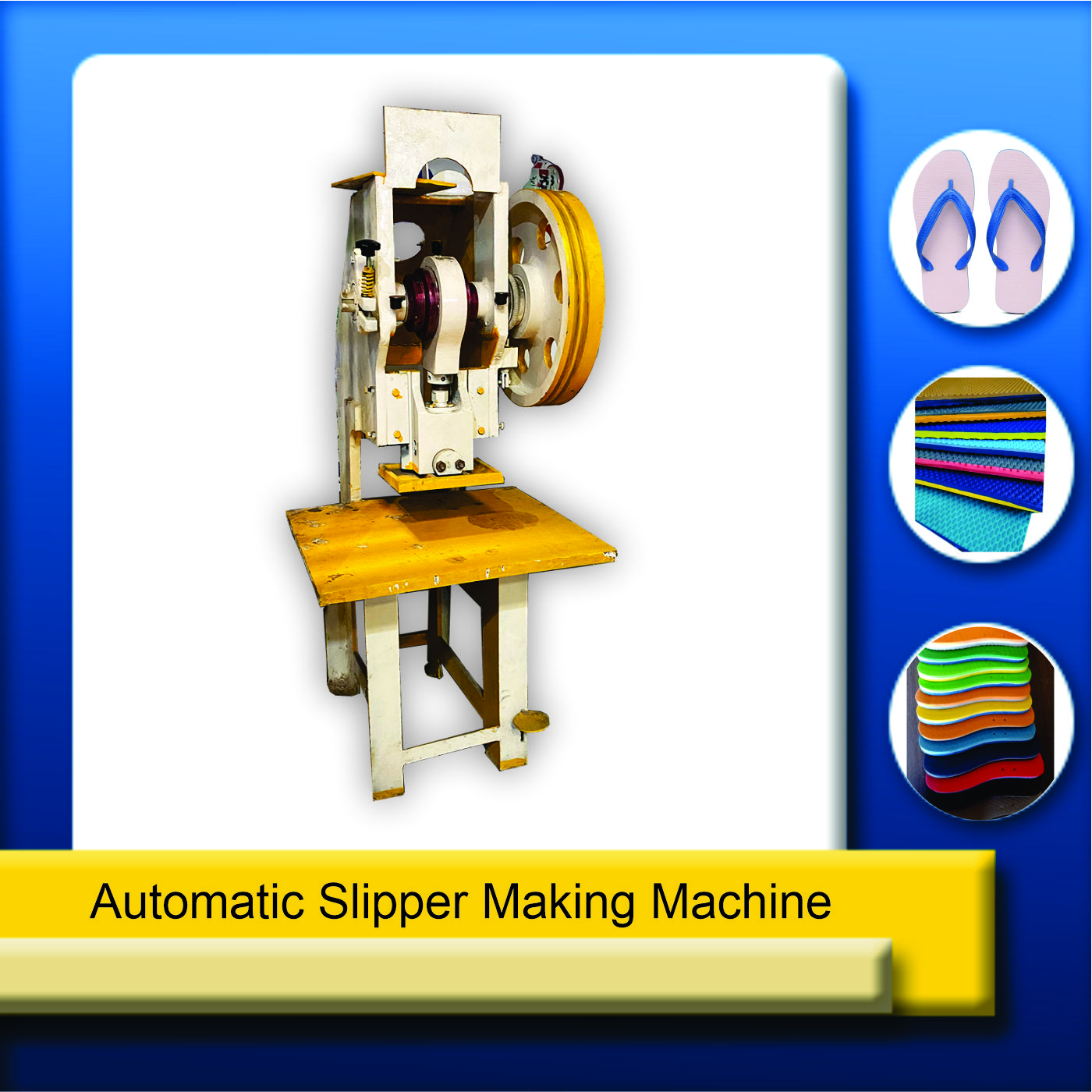

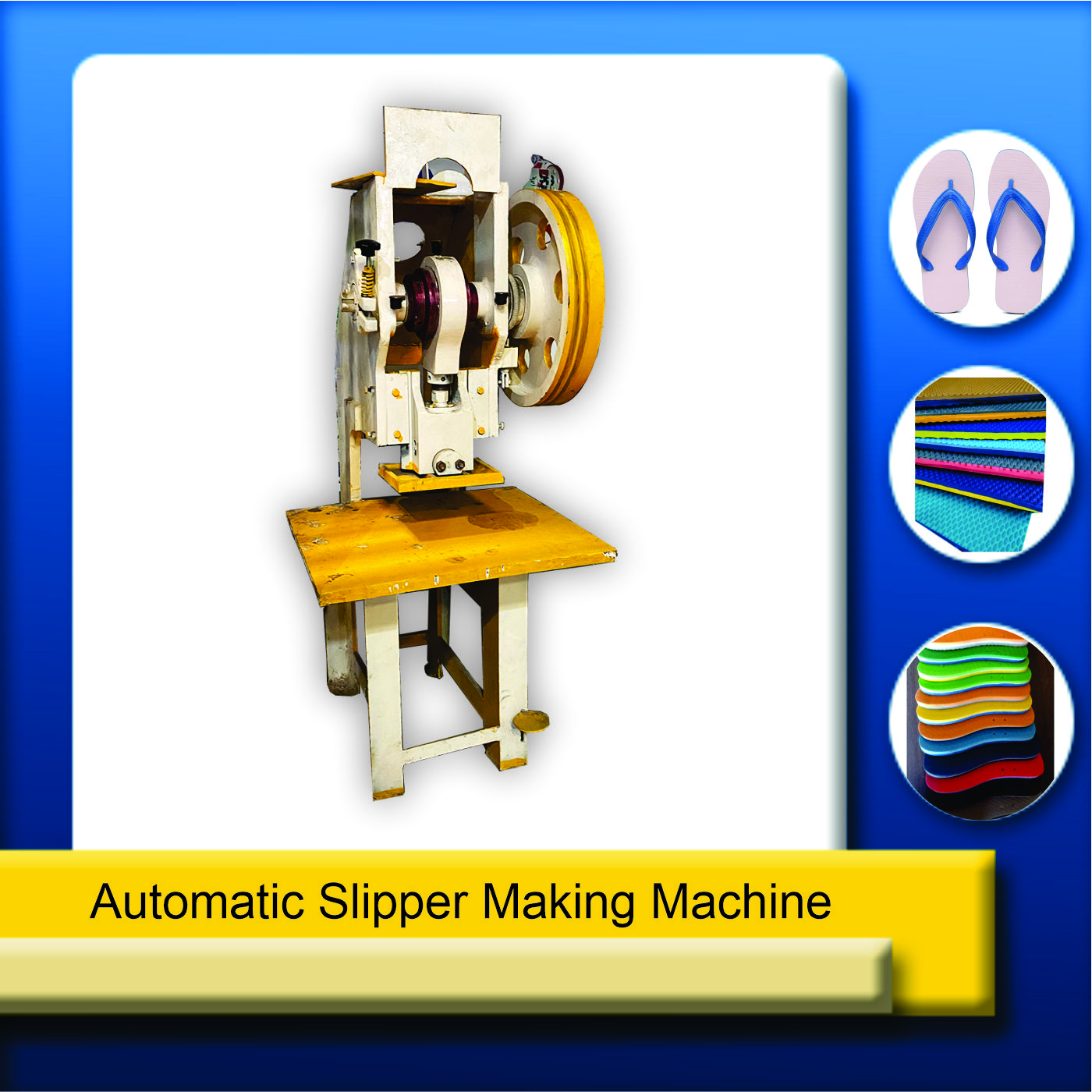

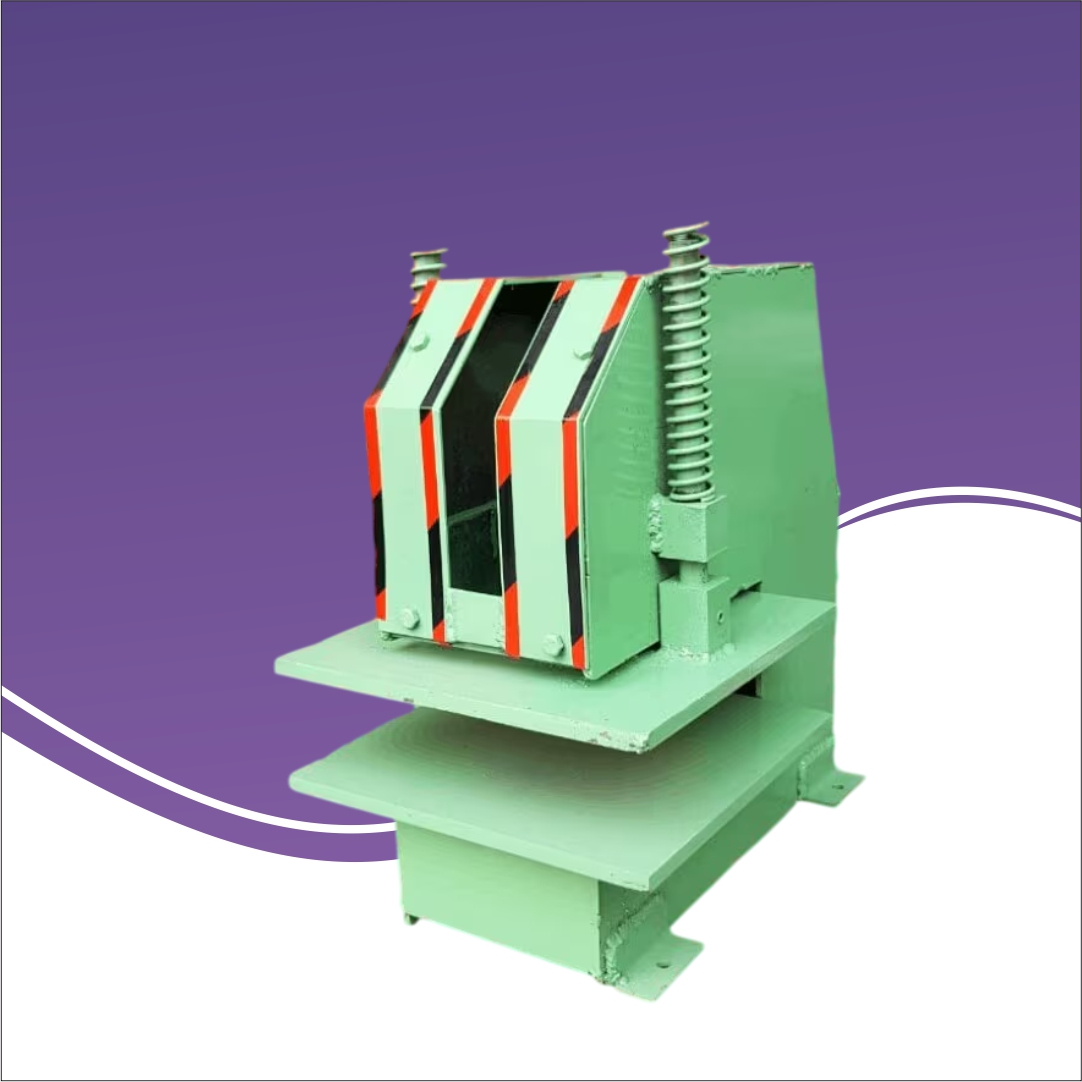

Slipper Making Machine

Price: ₹25000

Slipper Making Machine – Complete Guide by ASVR Engineering

In today’s competitive market, starting a small-scale or large-scale slipper manufacturing business can be a highly profitable venture. Slippers are an essential part of daily life, used in households, offices, hotels, and other commercial establishments. With the growing demand for quality, comfortable, and stylish slippers, investing in a Slipper Making Machine from a trusted manufacturer like ASVR Engineering can be the key to your success.

ASVR Engineering, established in 2008, is a leading manufacturer and supplier of industrial machinery in Delhi, India. With years of experience in producing top-quality machines, ASVR Engineering provides the latest automatic and semi-automatic slipper making machines that cater to both small businesses and large-scale industries.

Why Start a Slipper Manufacturing Business?

The footwear industry in India has seen tremendous growth in the past decade, with increasing demand for both traditional and modern designs. Slippers, being one of the most widely used footwear products, have a continuous market. Here are some reasons why investing in a slipper making machine is a smart business idea:

-

High Market Demand: Slippers are used daily across all age groups and genders. Hotels, hospitals, and households constantly require quality slippers.

-

Low Investment, High Returns: Starting a slipper manufacturing unit requires moderate investment with a high-profit margin, especially when using an automatic or semi-automatic machine.

-

Customization Opportunities: You can produce slippers in various materials, colors, and sizes to cater to different markets.

-

Growing Footwear Industry: With India’s footwear industry expanding rapidly, there is a growing demand for modern and quality slippers.

-

Export Potential: Well-manufactured slippers can also be exported, increasing the scope of profit for your business.

Types of Slipper Making Machines Offered by ASVR Engineering

ASVR Engineering provides a wide range of slipper making machines designed for efficiency, durability, and high production capacity. Depending on your production needs, you can choose from:

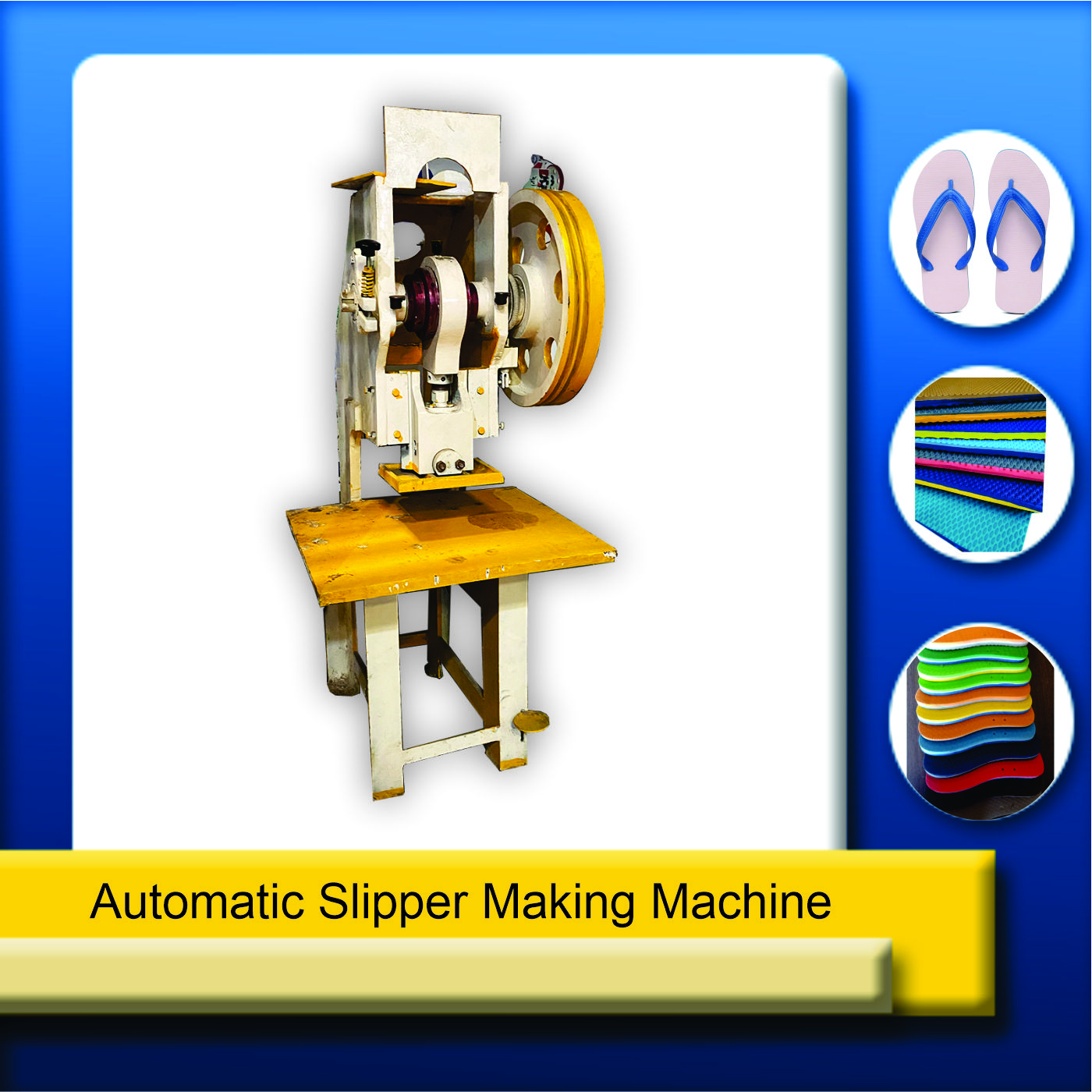

1. Automatic Slipper Making Machines

Automatic machines are perfect for large-scale production. These machines handle most of the slipper manufacturing process, including sole shaping, upper attachment, and finishing. They are designed to reduce manual labor, increase efficiency, and ensure consistent quality.

Features:

-

High-speed production capacity

-

User-friendly operation

-

Minimal maintenance requirements

-

Produces slippers with uniform shape and size

-

Suitable for PU, PVC, rubber, and EVA materials

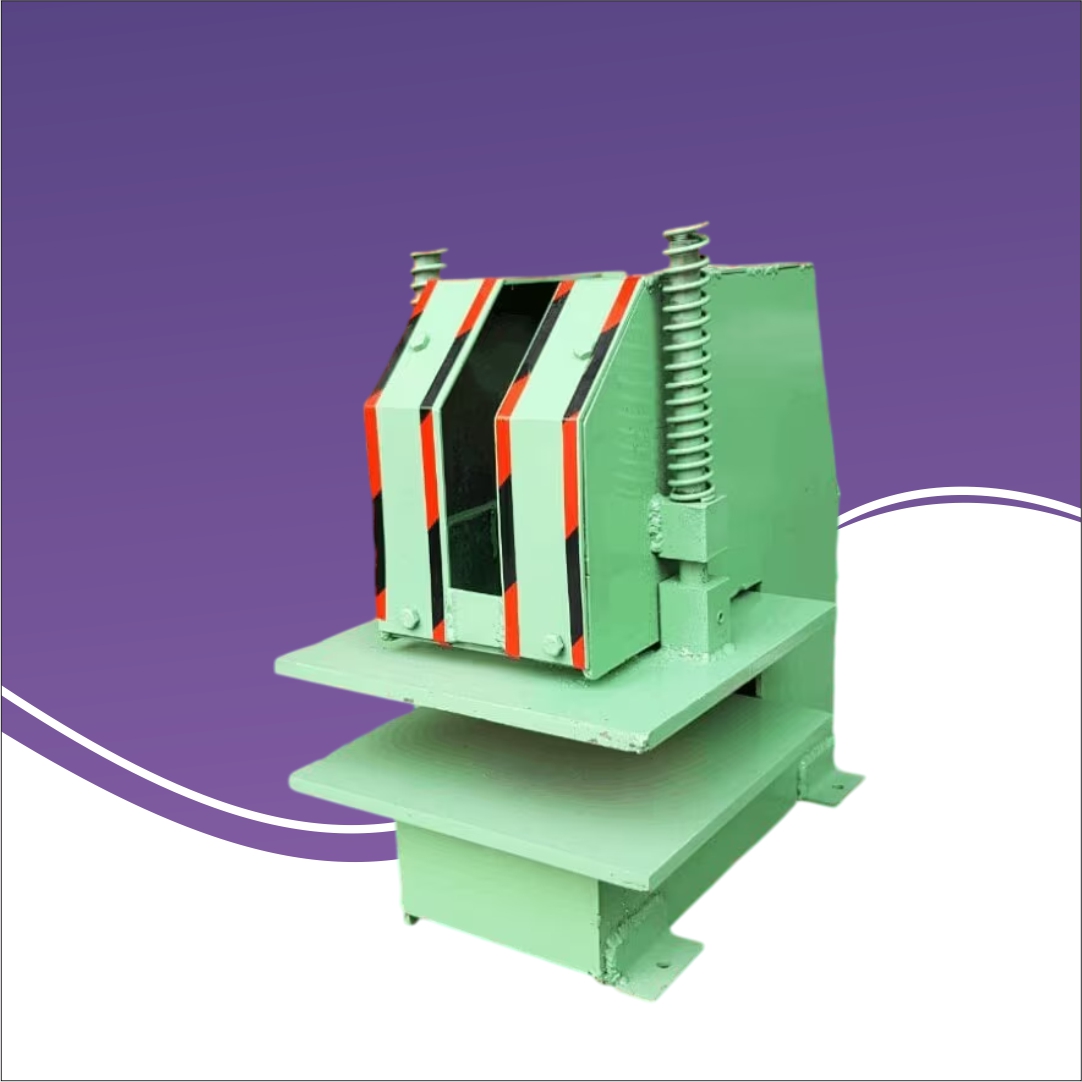

2. Semi-Automatic Slipper Making Machines

Semi-automatic machines are ideal for small and medium-scale businesses. They combine manual intervention with automation to produce high-quality slippers efficiently. These machines are cost-effective and easy to operate.

Features:

-

Affordable initial investment

-

Easy to operate and maintain

-

Produces slippers in various sizes and designs

-

Reduces labor cost while maintaining productivity

-

Flexible for different materials

Components of a Slipper Making Machine

Understanding the basic components of a slipper making machine helps in ensuring proper usage and maintenance. ASVR Engineering’s machines include:

-

Hydraulic Press: For sole shaping and compression

-

Heating System: To mold soles and upper materials efficiently

-

Automatic Cutting Tools: Ensures precise cutting of soles and straps

-

Conveyor System: Smooth movement of materials for assembly

-

Control Panel: Easy operation with digital controls

-

Attachment Mechanism: For combining soles with upper materials

-

Durable Frame: Provides stability and long life for the machine

Materials Used in Slipper Making

ASVR Engineering machines are compatible with a variety of materials, allowing you to produce diverse types of slippers:

-

PVC (Polyvinyl Chloride): Lightweight and durable, suitable for casual and home slippers

-

PU (Polyurethane): Flexible, high-quality material for stylish and comfortable slippers

-

EVA (Ethylene Vinyl Acetate): Soft, lightweight, and shock-absorbing for indoor and outdoor use

-

Rubber: Long-lasting and slip-resistant, ideal for commercial and outdoor slippers

Why Choose ASVR Engineering for Slipper Making Machines?

There are several reasons why ASVR Engineering is the preferred choice for entrepreneurs and manufacturers:

-

High-Quality Machines: All machines are designed with precision engineering to deliver long-lasting performance.

-

Affordable Prices: ASVR Engineering provides competitive pricing without compromising on quality.

-

Customization Options: Machines can be tailored to meet specific production needs.

-

Experienced Team: Professional support from experienced engineers ensures smooth operation and guidance.

-

After-Sales Support: Quick response for installation, maintenance, and spare parts.

-

Trusted Manufacturer: Established in 2008, ASVR Engineering has built a strong reputation in Delhi and across India.

How to Operate a Slipper Making Machine

Operating a slipper making machine is straightforward, especially with ASVR Engineering’s user-friendly designs:

-

Material Preparation: Prepare the sole and upper materials according to the size and design required.

-

Machine Setup: Turn on the machine and adjust the temperature, pressure, and speed as per the material type.

-

Molding Process: Place the sole material in the hydraulic press to shape the base of the slipper.

-

Upper Attachment: Attach the straps or upper portion of the slipper using the automatic mechanism.

-

Finishing: Trim excess material and ensure proper finishing for smooth edges and neat design.

-

Quality Check: Inspect each slipper for uniformity, strength, and design accuracy.

With practice, production can reach high efficiency, and the machines can produce hundreds of slippers daily.

Maintenance Tips for Slipper Making Machines

Proper maintenance ensures your machine runs efficiently and lasts longer:

-

Clean the machine after each use to remove dust and leftover materials

-

Lubricate moving parts regularly

-

Check hydraulic oil levels and replace as needed

-

Inspect electrical components and wires periodically

-

Schedule routine professional maintenance from ASVR Engineering’s service team

Business Growth Opportunities with Slipper Making Machines

Investing in a slipper making machine opens multiple business avenues:

-

Wholesale Slipper Manufacturing: Supply to retailers, hotels, and hospitals.

-

Customized Designs: Offer personalized slippers for events, branding, or corporate gifts.

-

Export Market: Export slippers to international markets for higher revenue.

-

Online Retailing: Sell directly to customers through e-commerce platforms.

-

Diversification: Expand your product line to include flip-flops, sandals, and other footwear products.

Slipper Making Machine Price in India

The price of a slipper making machine varies depending on the type (automatic or semi-automatic), production capacity, and material compatibility. ASVR Engineering offers machines at affordable prices without compromising quality. Businesses can choose the machine that fits their budget and production needs, ensuring high returns on investment.

For a personalized quote, contact ASVR Engineering at:

📞 +91-8076004849, +91-8800971968

🌐 https://www.asvrengineering.com

Buy Now

.jpg)