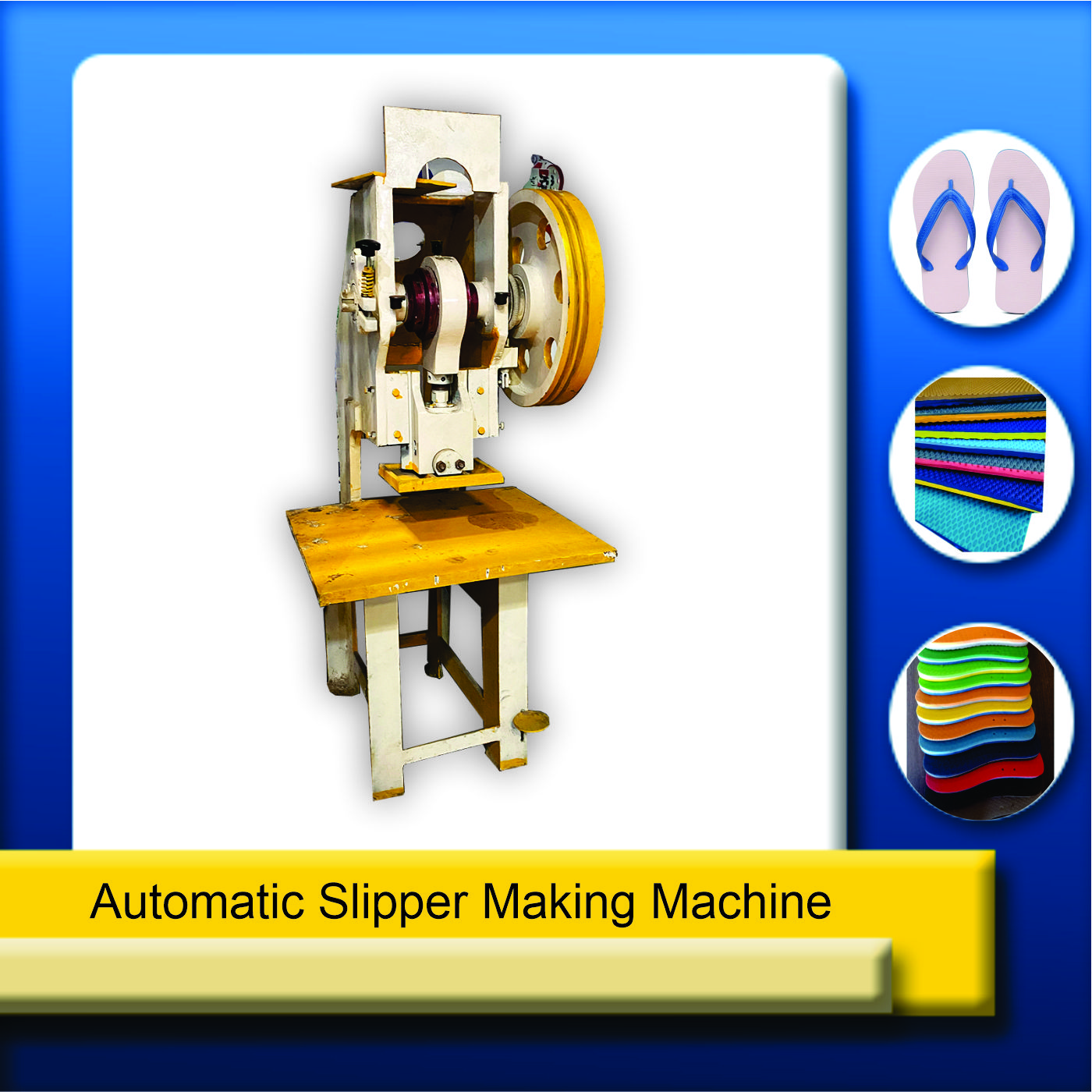

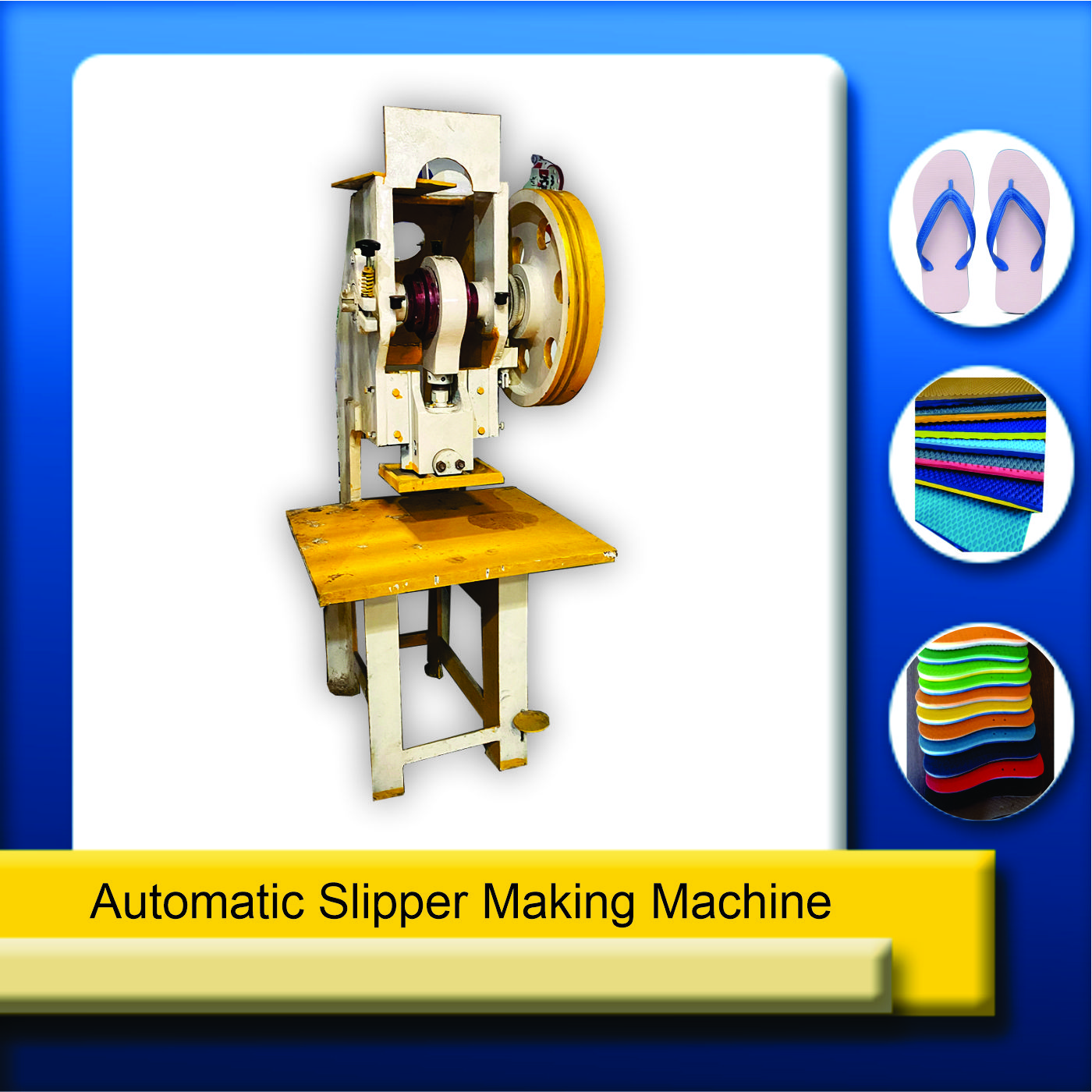

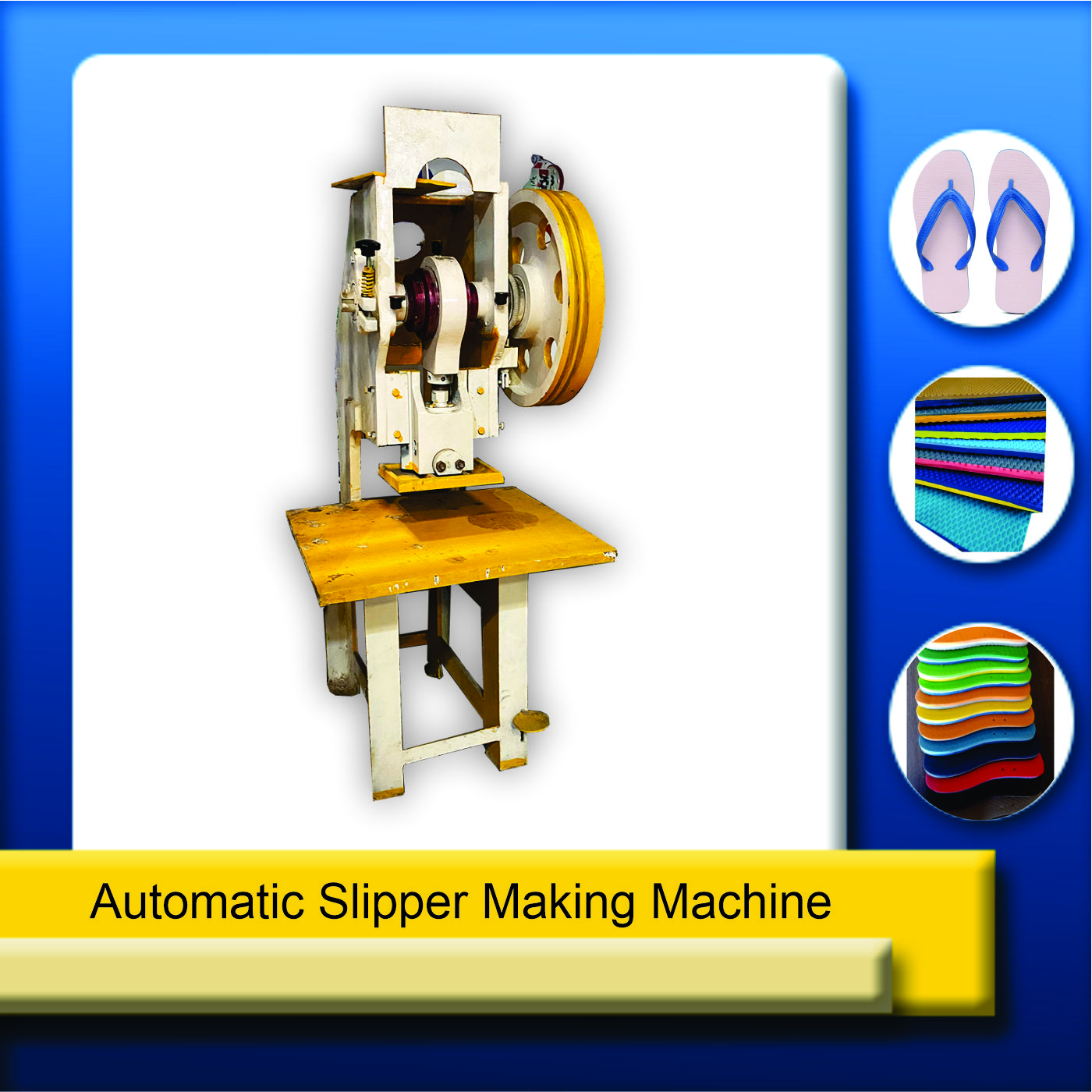

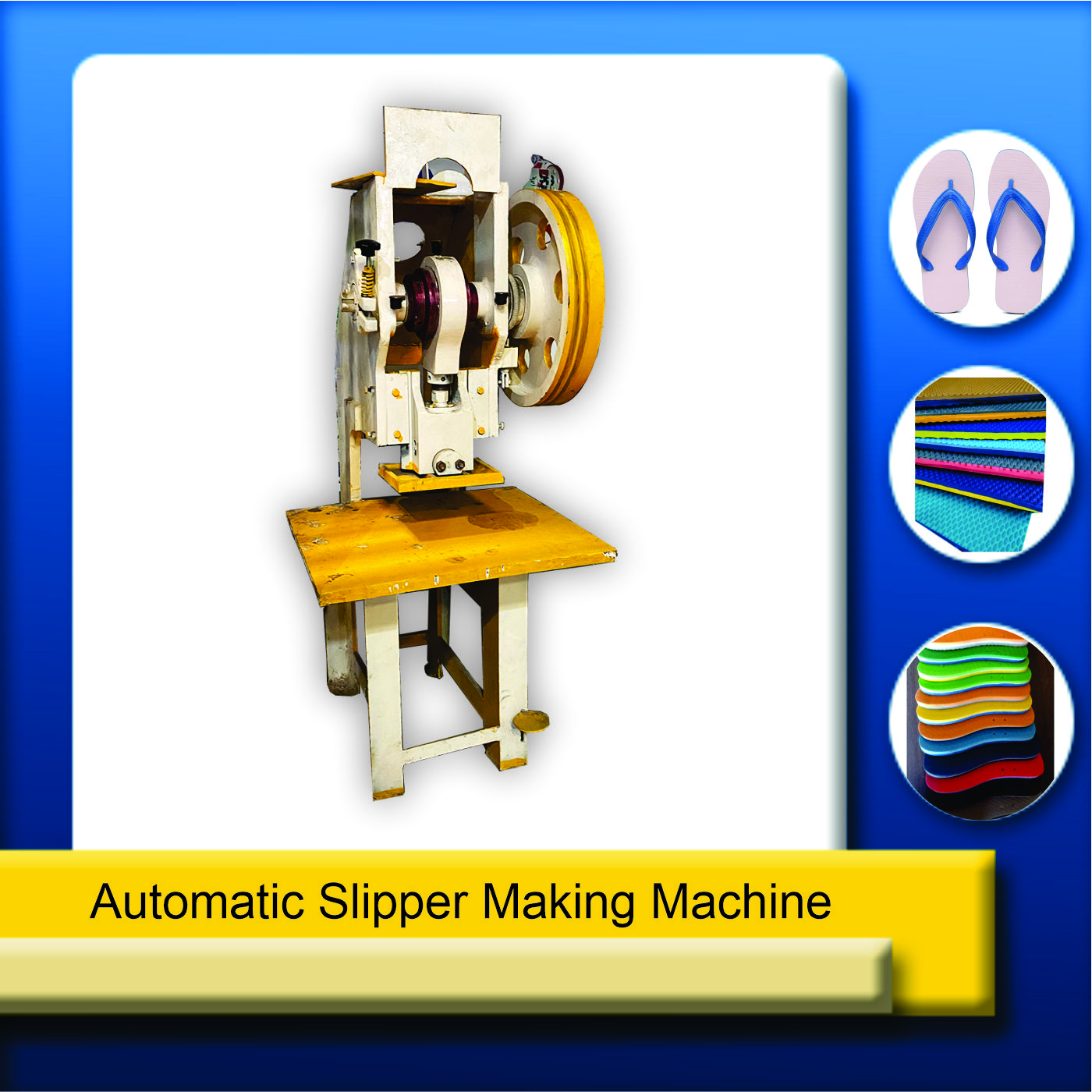

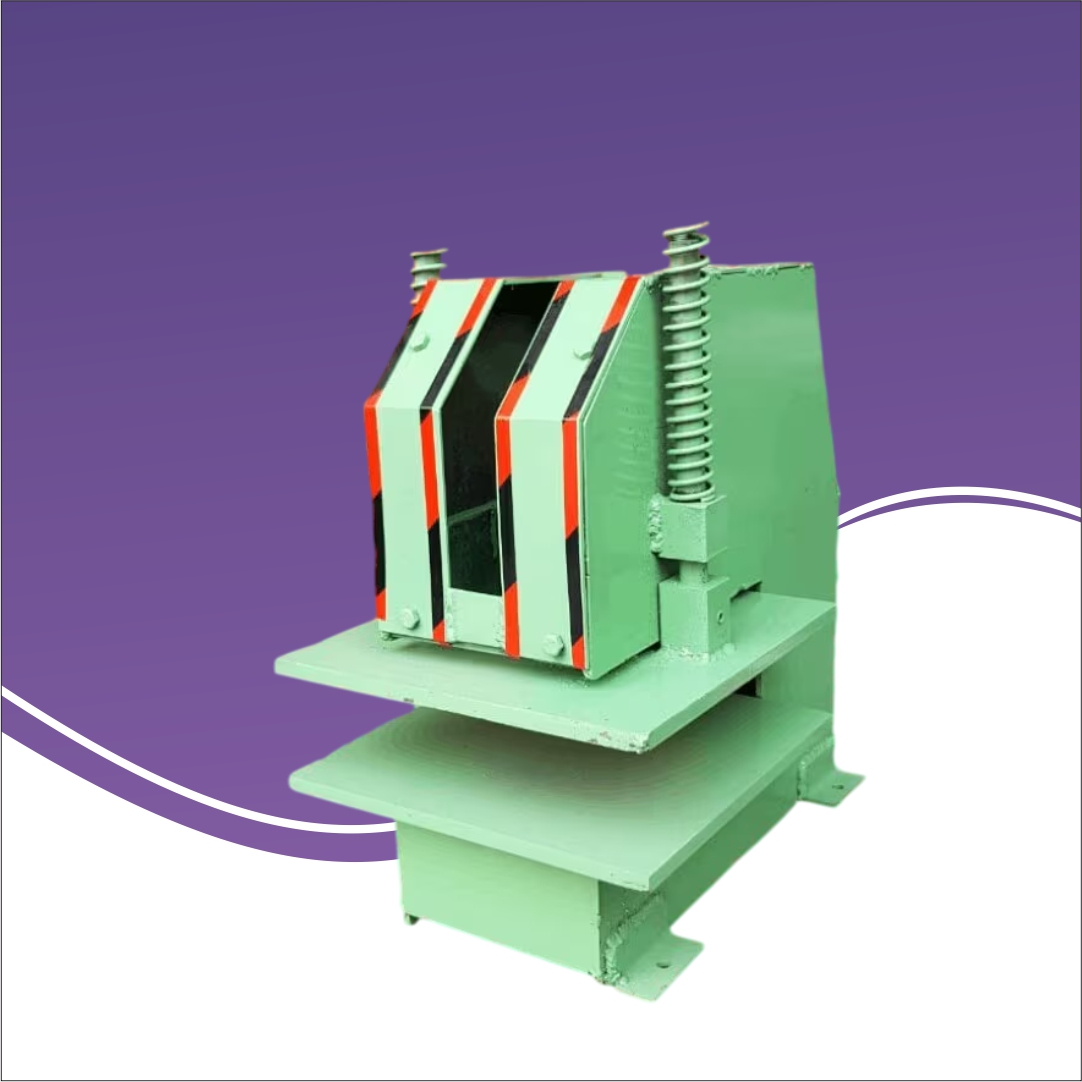

Slipper Making Machine

Price: ₹25500

The footwear industry in India is growing at a remarkable pace, driven by rising demand for affordable, durable, and stylish slippers for daily use. From rural markets to urban retail chains, slippers remain one of the most sold footwear products across all age groups. At the heart of this booming sector lies the Slipper Making Machine, a vital investment for entrepreneurs and manufacturers looking to establish or scale a profitable footwear business.

A slipper making machine is designed to automate and simplify the process of manufacturing slippers using materials such as EVA, PU, rubber, PVC, and foam. These machines help manufacturers achieve consistent quality, faster production, and reduced labor dependency, making them an ideal choice for both startups and large-scale factories.

What Is a Slipper Making Machine?

A slipper making machine is specialized industrial equipment used to manufacture different types of slippers, including hawai chappals, EVA slippers, PU slippers, and rubber footwear. Depending on the model, these machines can handle processes such as sole molding, cutting, shaping, embossing, and finishing.

Modern slipper manufacturing machines are engineered to deliver:

-

Uniform sole thickness

-

Smooth finishing

-

High production speed

-

Minimal wastage of raw materials

This combination directly improves profitability and product quality.

Types of Slipper Making Machines Available

1. EVA Slipper Making Machine

EVA (Ethylene Vinyl Acetate) slippers are lightweight, flexible, and extremely popular for daily wear. EVA slipper making machines are designed to mold EVA granules into soft, durable soles with precise shapes and textures. These machines are widely used due to their low raw material cost and high market demand.

2. PU Slipper Making Machine

PU slippers are known for comfort, premium feel, and durability. PU slipper making machines are ideal for manufacturers targeting mid-range and premium footwear markets. These machines ensure accurate molding, excellent cushioning, and long product life.

3. Rubber Slipper Making Machine

Rubber slippers are strong, anti-slip, and suitable for rough usage. Rubber slipper machines are commonly used in mass-production units supplying to wholesalers and institutional buyers.

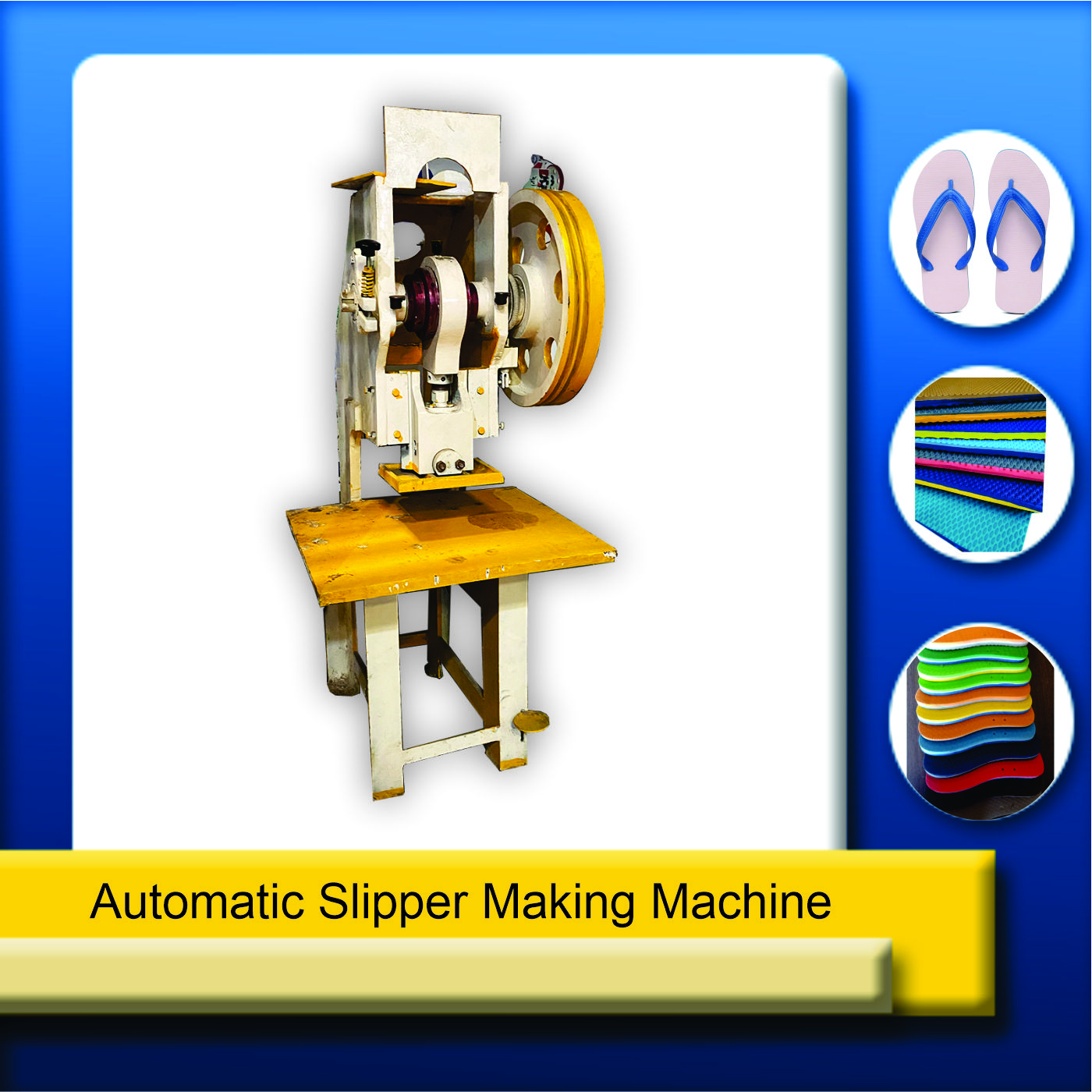

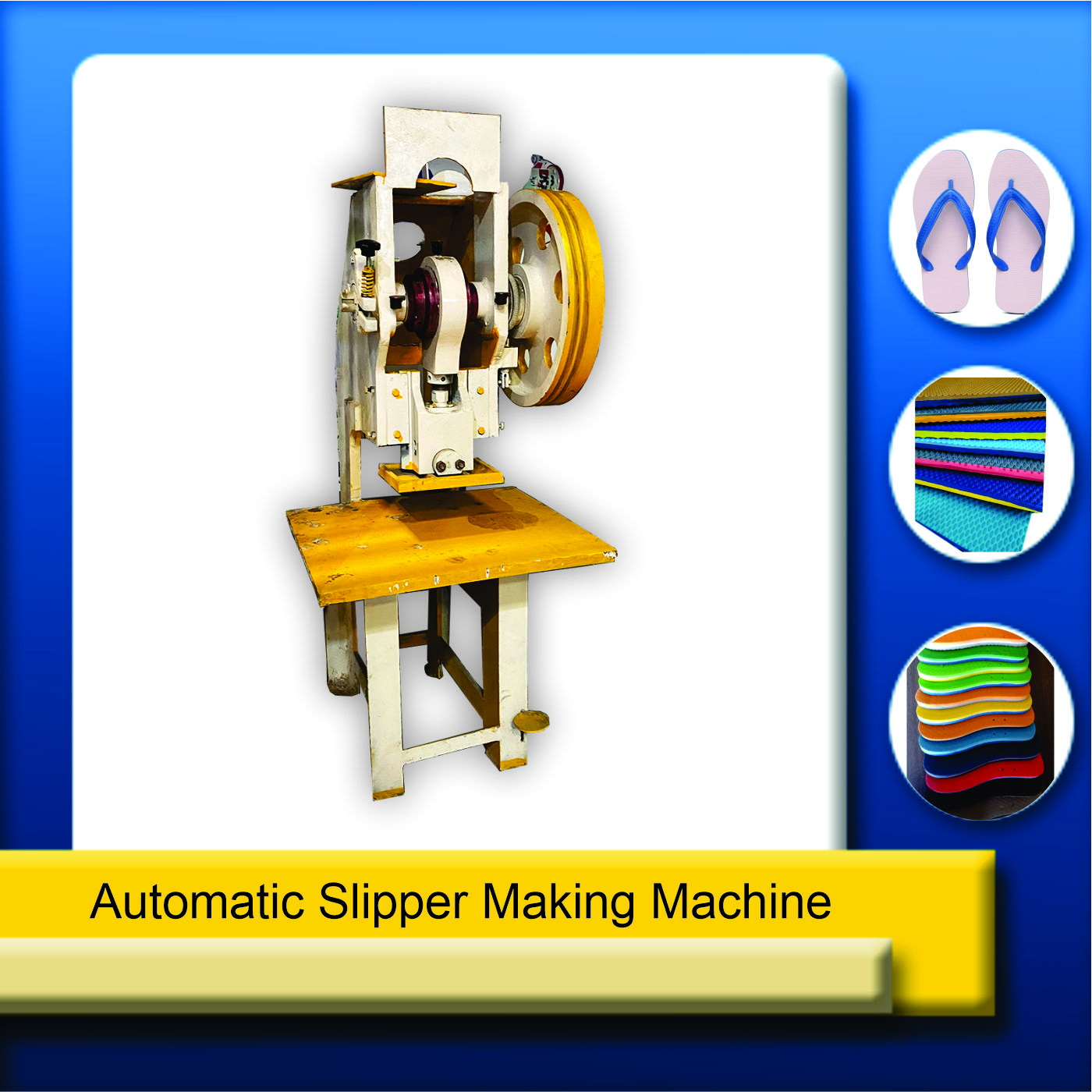

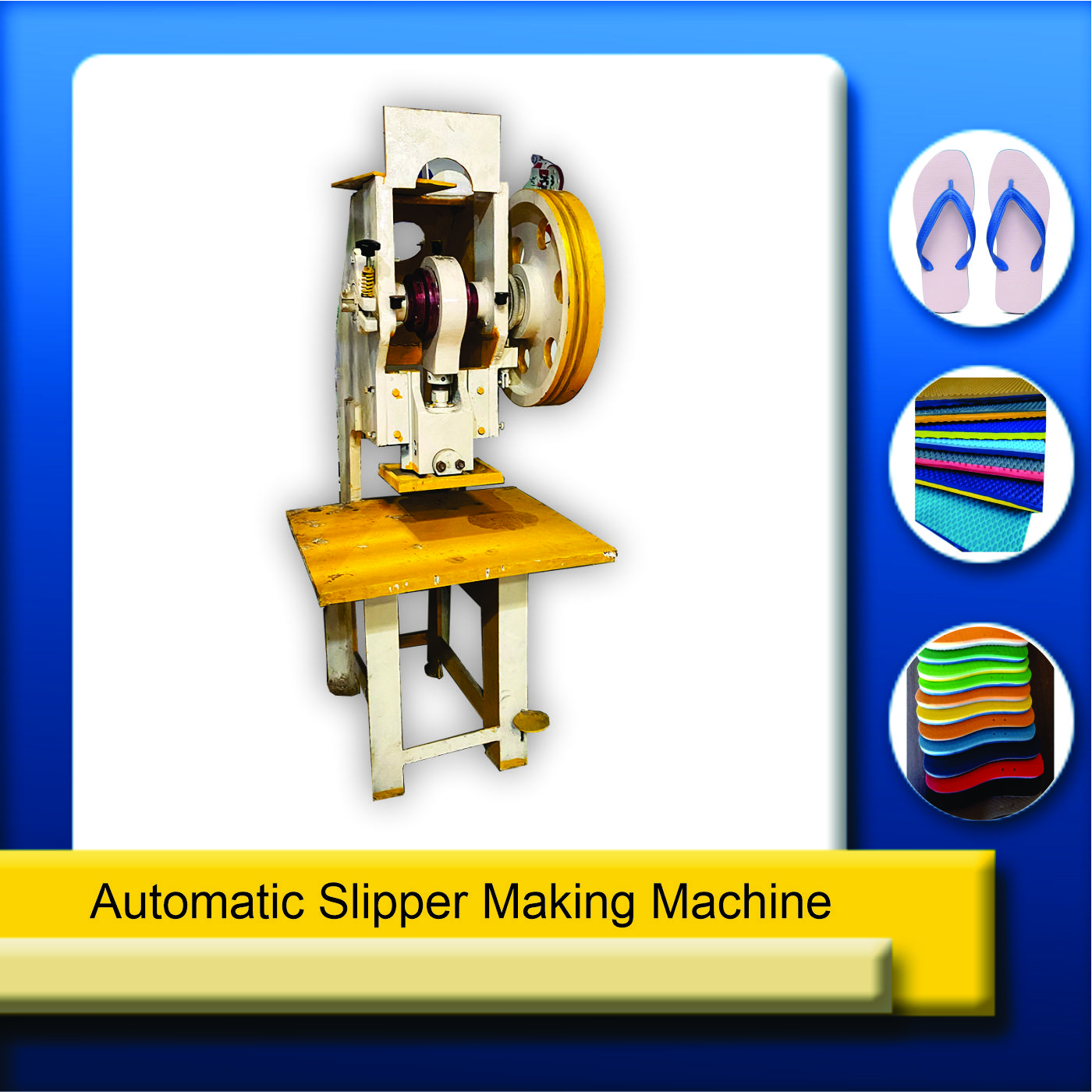

4. Automatic Slipper Making Machine

Automatic machines are designed for high-volume production with minimal human intervention. They offer faster cycle times, consistent output, and reduced labor costs, making them suitable for large factories.

5. Semi-Automatic Slipper Making Machine

Semi-automatic machines are ideal for small and medium enterprises. They offer a balance between affordability and efficiency, allowing manufacturers to gradually scale operations.

Key Features of Advanced Slipper Making Machines

A high-quality slipper making machine comes with several advanced features that ensure smooth operation and long-term reliability:

-

Robust Construction: Heavy-duty body designed for continuous industrial use

-

Energy Efficiency: Optimized power consumption for lower operating costs

-

Precision Molding: Accurate sole shapes and uniform thickness

-

User-Friendly Controls: Easy operation and minimal training required

-

Low Maintenance: Designed with easily replaceable parts

-

High Output Capacity: Suitable for bulk production requirements

These features help manufacturers maintain consistent quality while meeting market demand efficiently.

Benefits of Investing in a Slipper Making Machine

1. High Profit Potential

Slipper manufacturing is a high-volume, fast-moving business. With the right machine, manufacturers can achieve quick returns on investment due to low production costs and steady demand.

2. Scalable Business Model

Whether you start small or plan a large factory, slipper making machines allow easy scalability. You can increase production by adding more machines as demand grows.

3. Consistent Quality

Machine-based production ensures uniform quality, which is essential for building brand trust and securing repeat orders.

4. Reduced Labor Dependency

Automation significantly reduces the need for skilled labor, lowering operational challenges and expenses.

5. Wide Market Demand

From local retailers to export markets, slippers have year-round demand, making this business relatively stable compared to seasonal industries.

Applications of Slipper Making Machines

Slipper making machines are used in various segments of the footwear industry, including:

-

Daily-wear slippers for men, women, and children

-

School and institutional footwear

-

Hotel and hospitality slippers

-

Promotional and customized slippers

-

Export-quality footwear products

This versatility makes the machine suitable for manufacturers catering to diverse customer segments.

Why Choose ASVR Engineering for Slipper Making Machines?

ASVR Engineering is a trusted name in industrial machinery manufacturing, known for delivering reliable, efficient, and durable solutions for the footwear industry. The company focuses on providing machines that are engineered to meet real production challenges faced by Indian manufacturers.

What Sets ASVR Engineering Apart?

-

Proven Engineering Expertise: Machines designed for Indian working conditions

-

Quality Components: Use of high-grade materials and precision parts

-

Technical Support: Guidance for installation, operation, and maintenance

-

Customized Solutions: Machines tailored to specific production needs

-

After-Sales Service: Reliable support to ensure long machine life

With a strong focus on customer satisfaction, ASVR Engineering ensures that every slipper making machine delivers consistent performance and long-term value.

How to Start a Slipper Making Business with the Right Machine

Starting a slipper manufacturing unit involves careful planning and the right equipment selection. Here’s a simple roadmap:

-

Market Research: Identify demand, price range, and target customers

-

Machine Selection: Choose between EVA, PU, rubber, automatic, or semi-automatic machines

-

Raw Material Sourcing: Secure quality EVA, PU, or rubber materials

-

Production Setup: Install machines and set up basic finishing processes

-

Quality Control: Ensure consistent product standards

-

Distribution: Build connections with wholesalers, retailers, or online platforms

With a reliable slipper making machine, even first-time entrepreneurs can enter this industry with confidence.

Maintenance and Longevity of Slipper Making Machines

Proper maintenance ensures long machine life and uninterrupted production. Regular lubrication, timely inspection of molds, and basic cleaning routines help keep the machine running efficiently. ASVR Engineering provides clear maintenance guidelines and support, making it easy for operators to manage daily operations without technical complications.

Future Scope of Slipper Manufacturing Industry

The slipper manufacturing industry continues to grow with changing fashion trends, rising population, and increasing focus on comfort footwear. Demand for lightweight, eco-friendly, and customized slippers is opening new opportunities for manufacturers who invest in modern slipper making machines.

Automation, improved materials, and better designs will further enhance profitability in the coming years, making this the right time to invest in advanced footwear machinery.

Contact Details

If you are planning to start or expand your slipper manufacturing business, get in touch with ASVR Engineering for reliable and efficient slipper making machines.

Contact Numbers:

+91-8076004849

+91-8800971968

Website:

https://www.asvrengineering.com

Buy Now

.jpg)