Notebook Making Unit Setup Cost in India 2025 | Complete Guide for Entrepreneurs

Price: ₹50000

Notebook Making Unit Setup Cost in India – 2025 Guide

The stationery market in India is booming, and notebooks remain an evergreen product for students, professionals, and businesses. If you’re planning to start a notebook manufacturing business, knowing the setup cost is crucial for budgeting and planning. This guide provides a detailed breakdown of investment requirements for starting a notebook making unit in 2025.

1. Why Start a Notebook Making Unit?

-

High Demand: Schools, colleges, offices, and coaching centers require notebooks throughout the year.

-

Profit Potential: Low-cost raw materials like paper, glue, and covers lead to high margins.

-

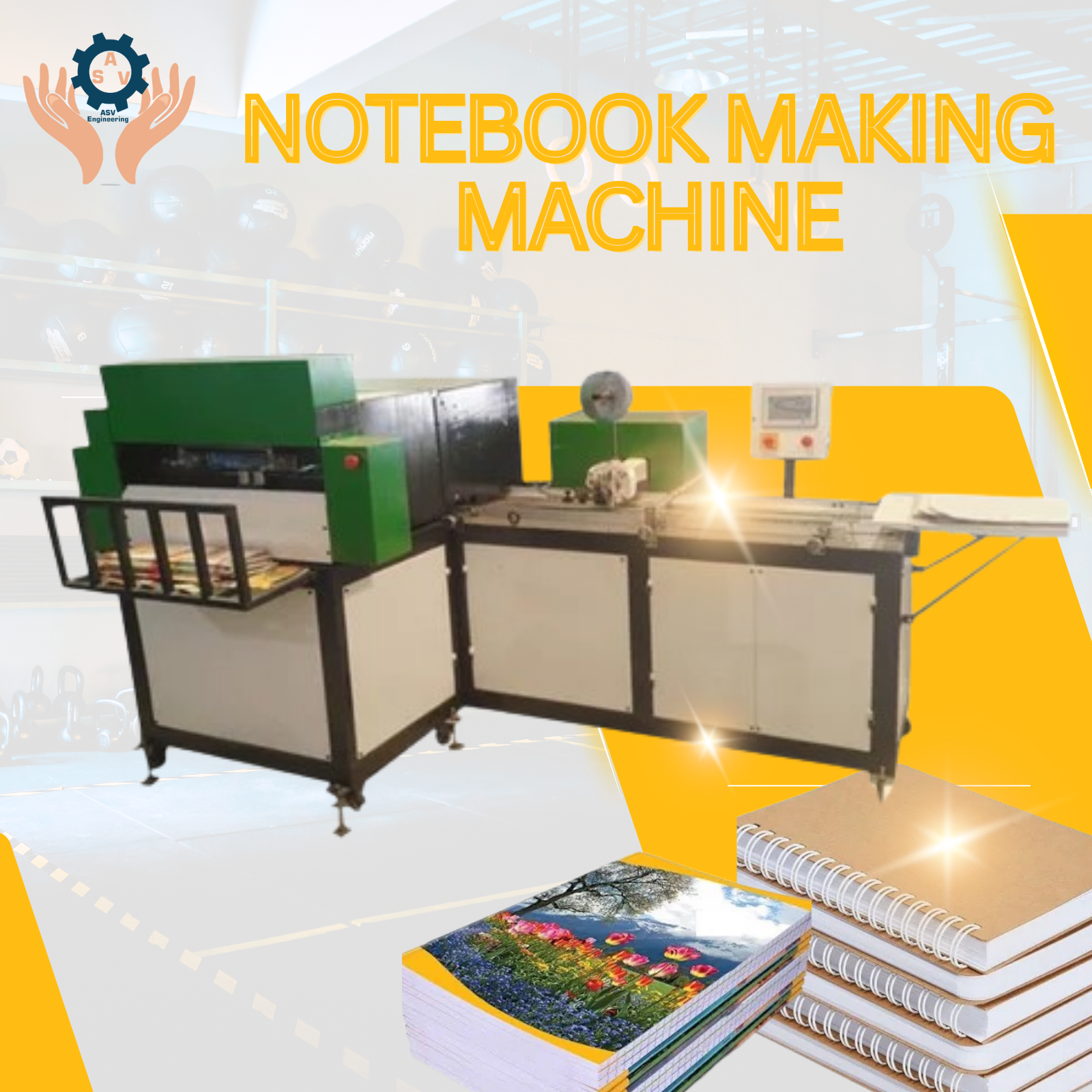

Scalability: Start with a semi-automatic machine and scale up to fully automatic production.

-

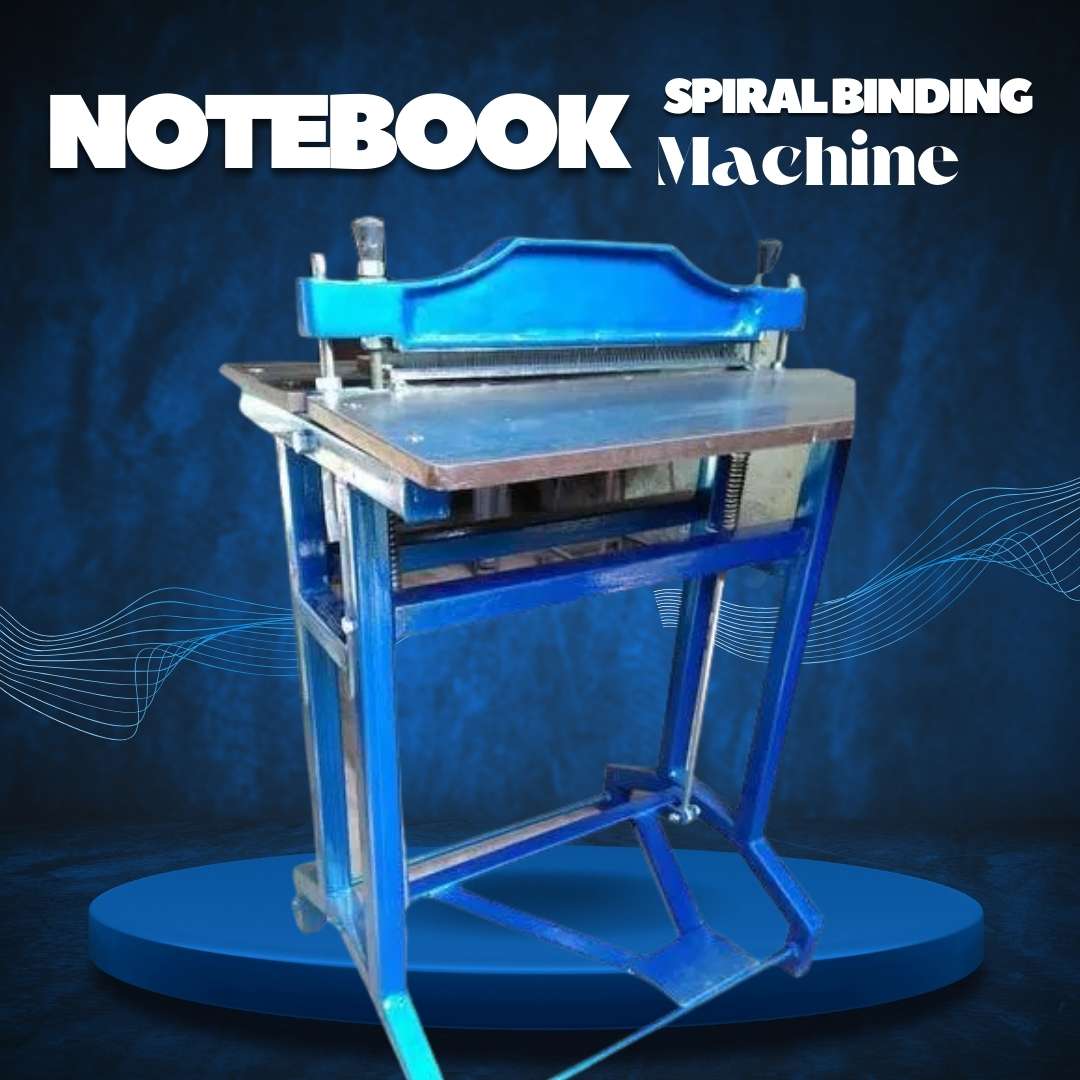

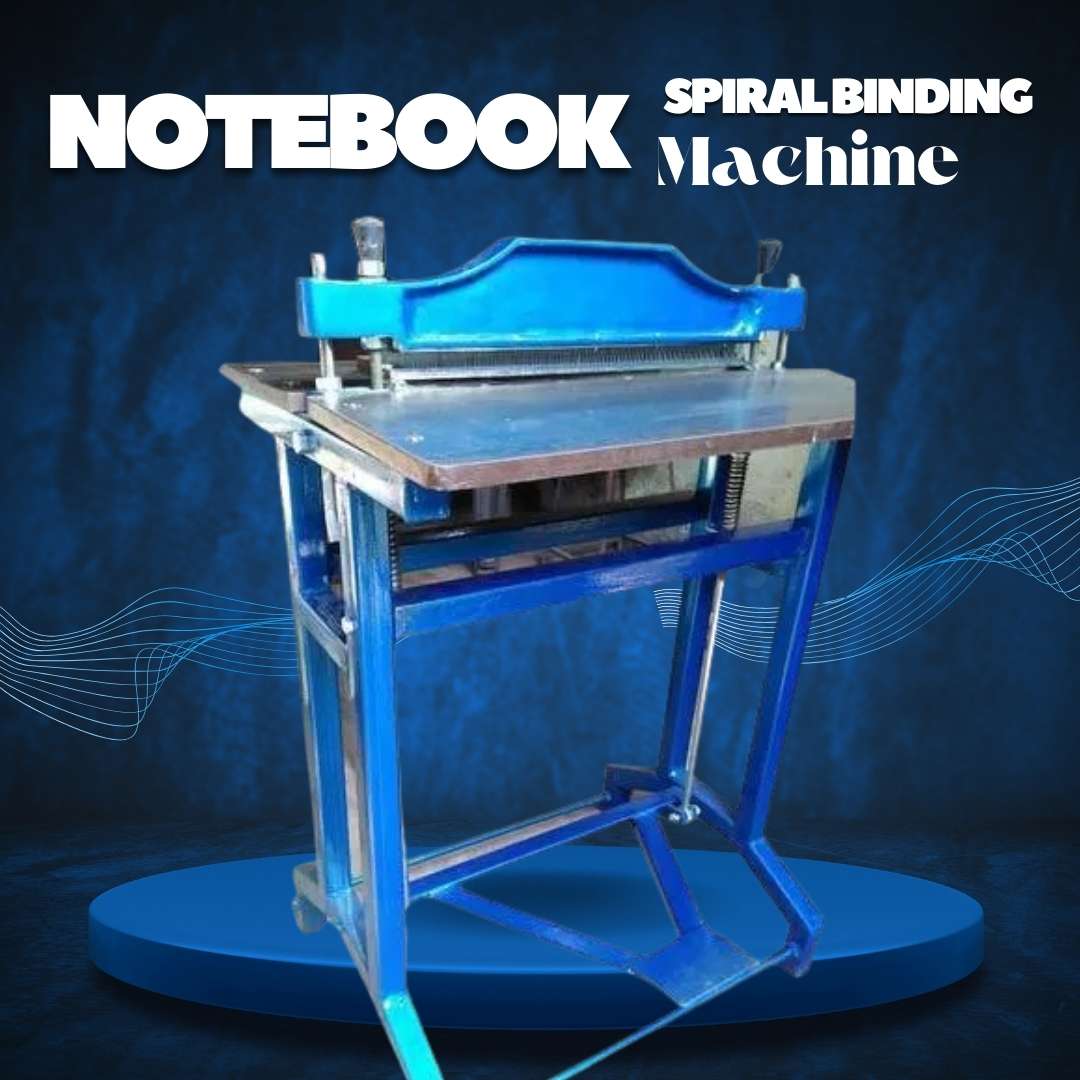

Customization Opportunities: Spiral, wire-o, or perfect binding notebooks can attract premium pricing.

2. Cost Components of a Notebook Making Unit

To set up a small to medium-scale notebook manufacturing unit, the main cost components are:

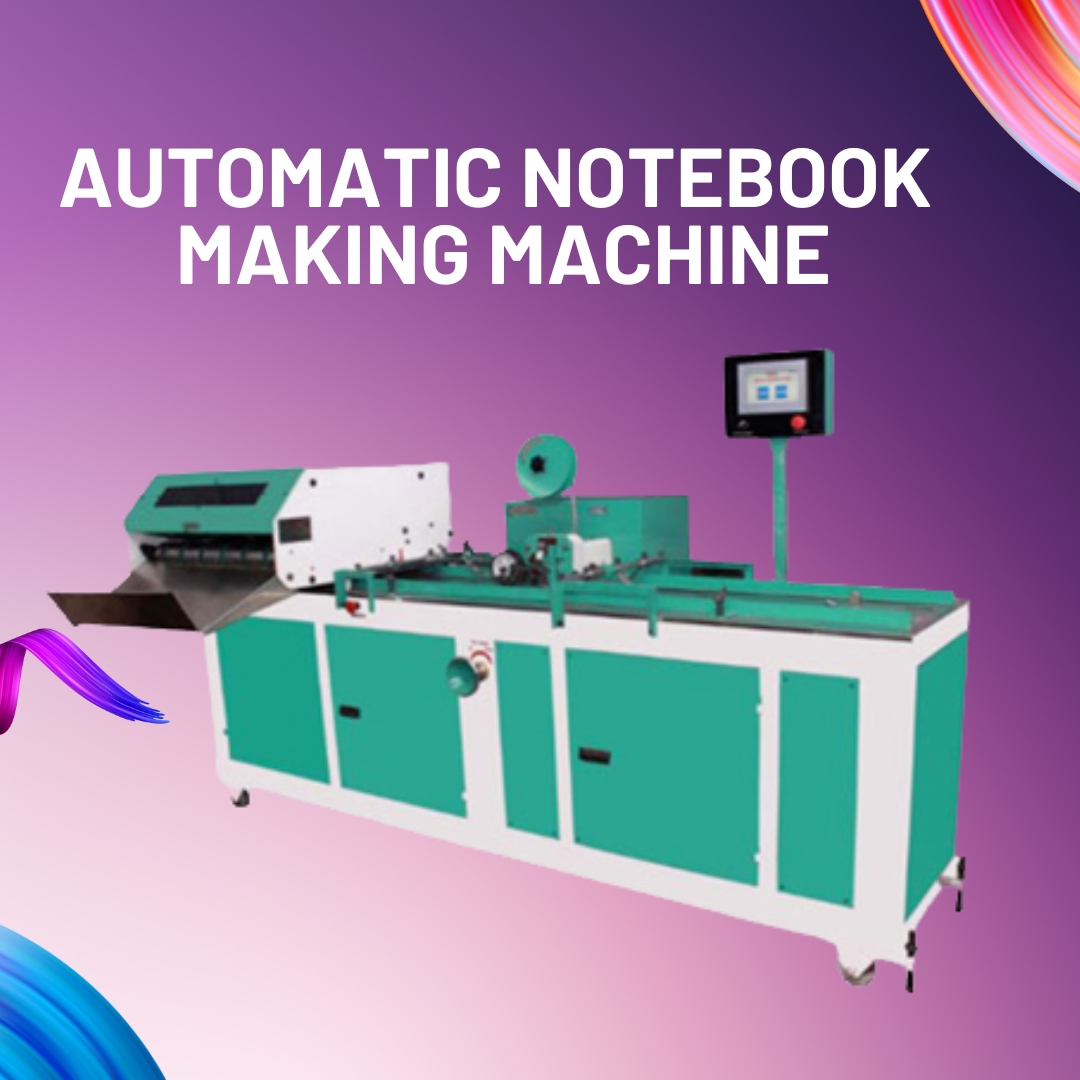

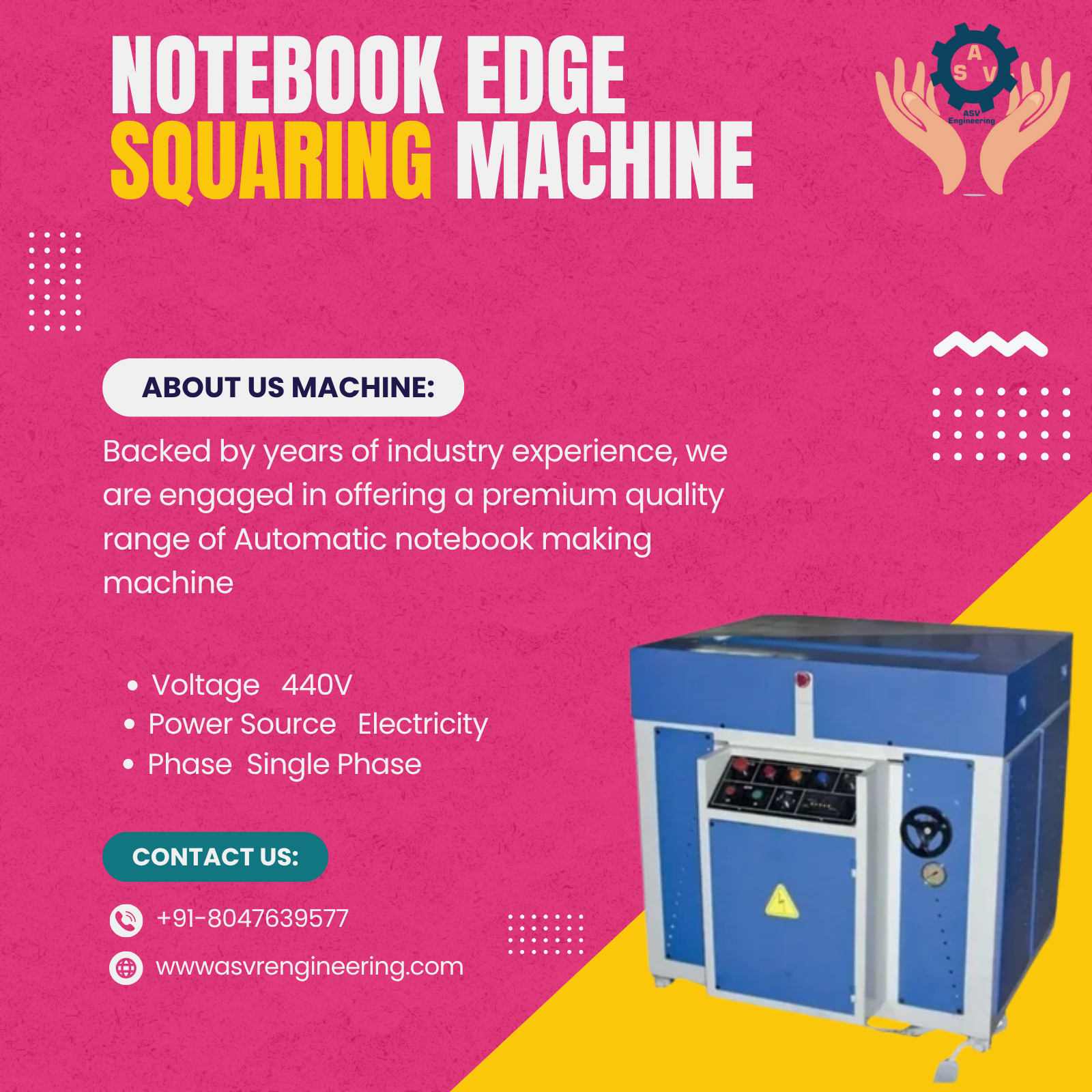

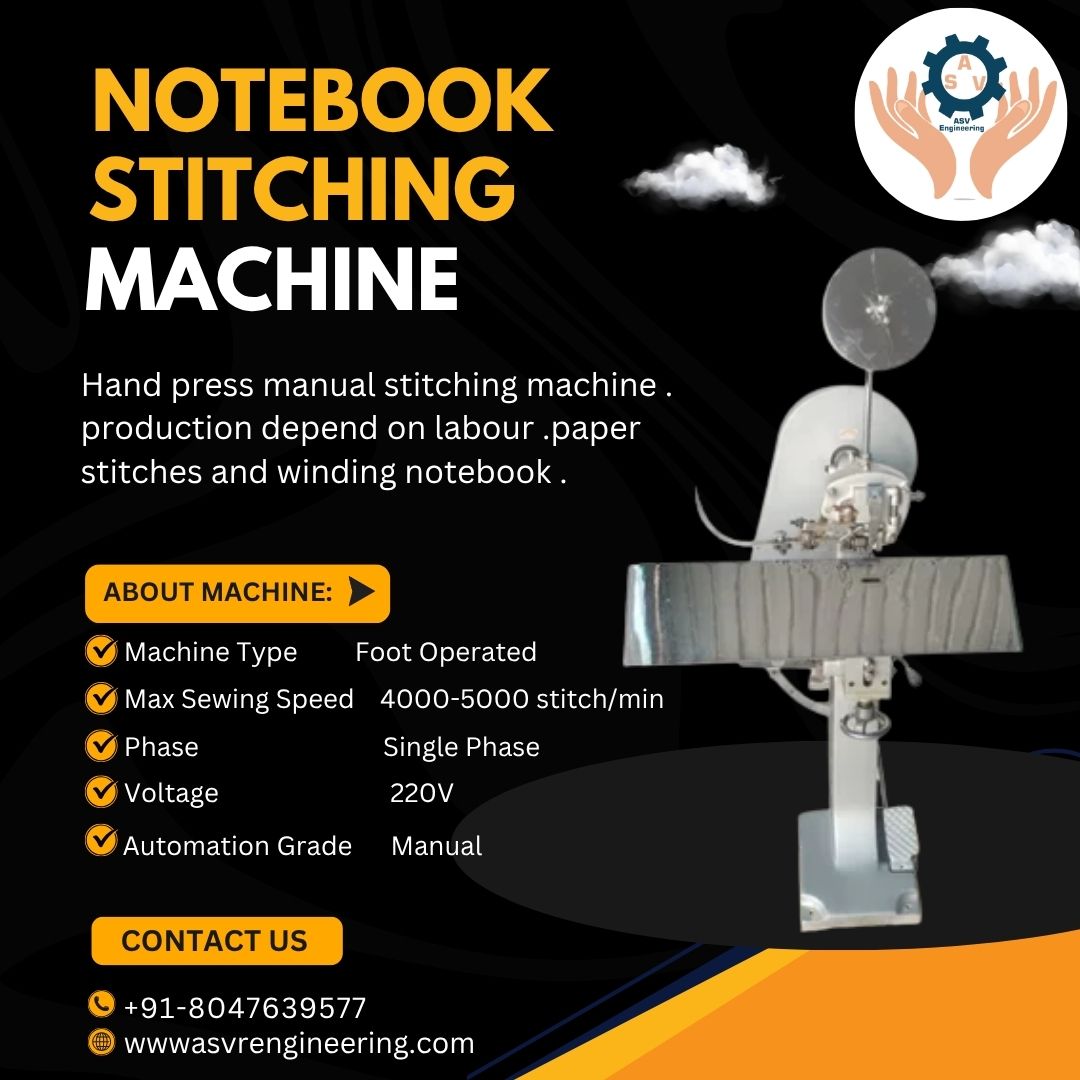

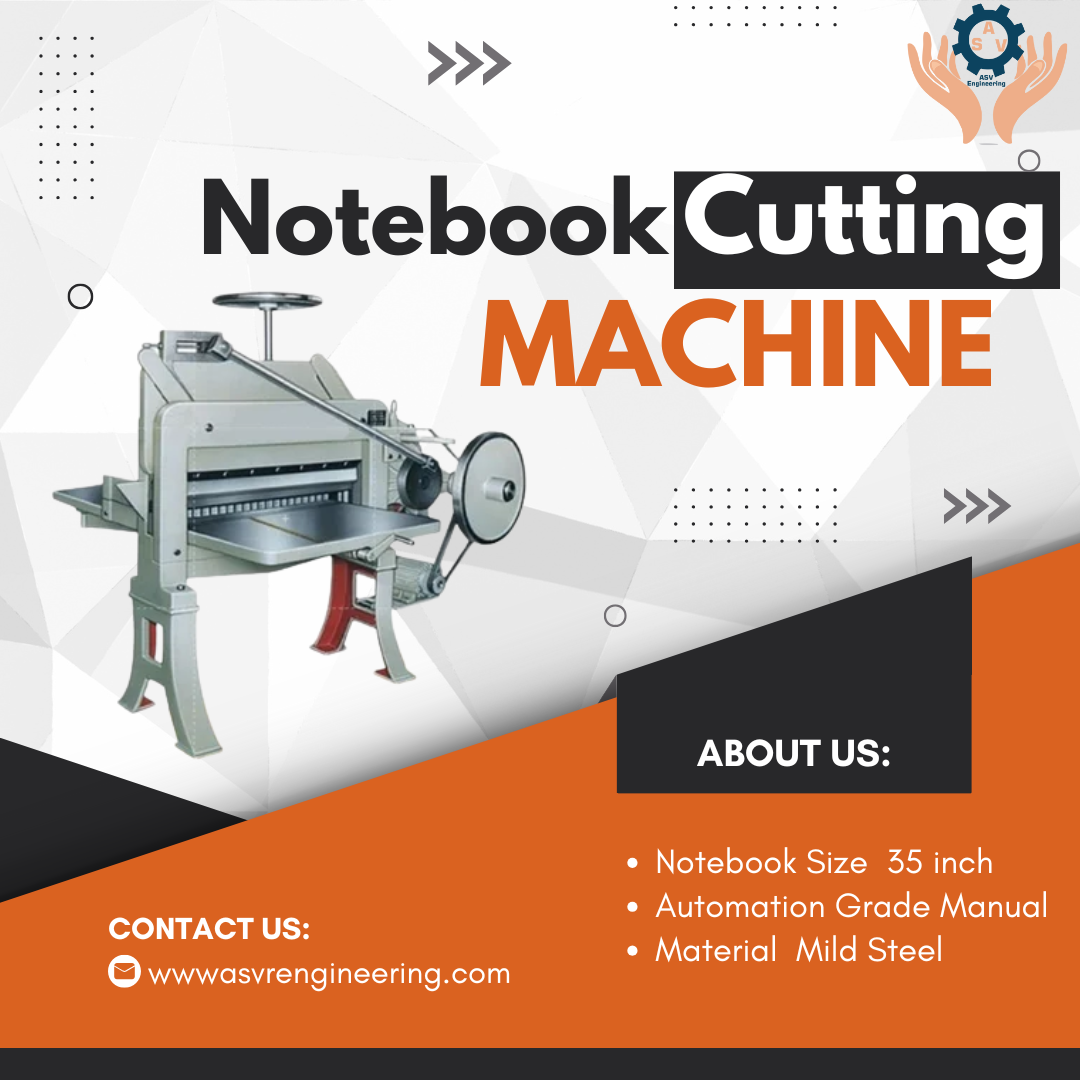

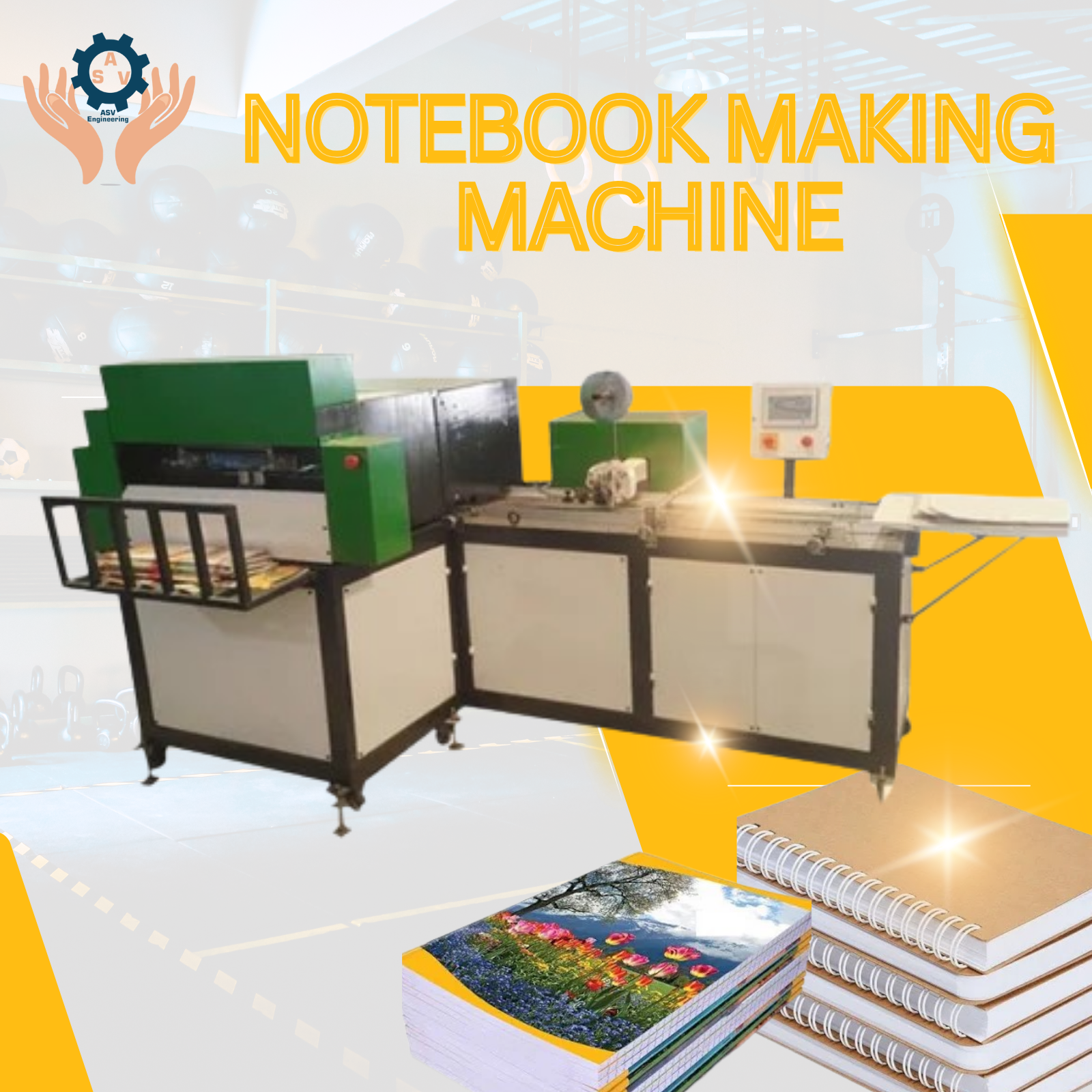

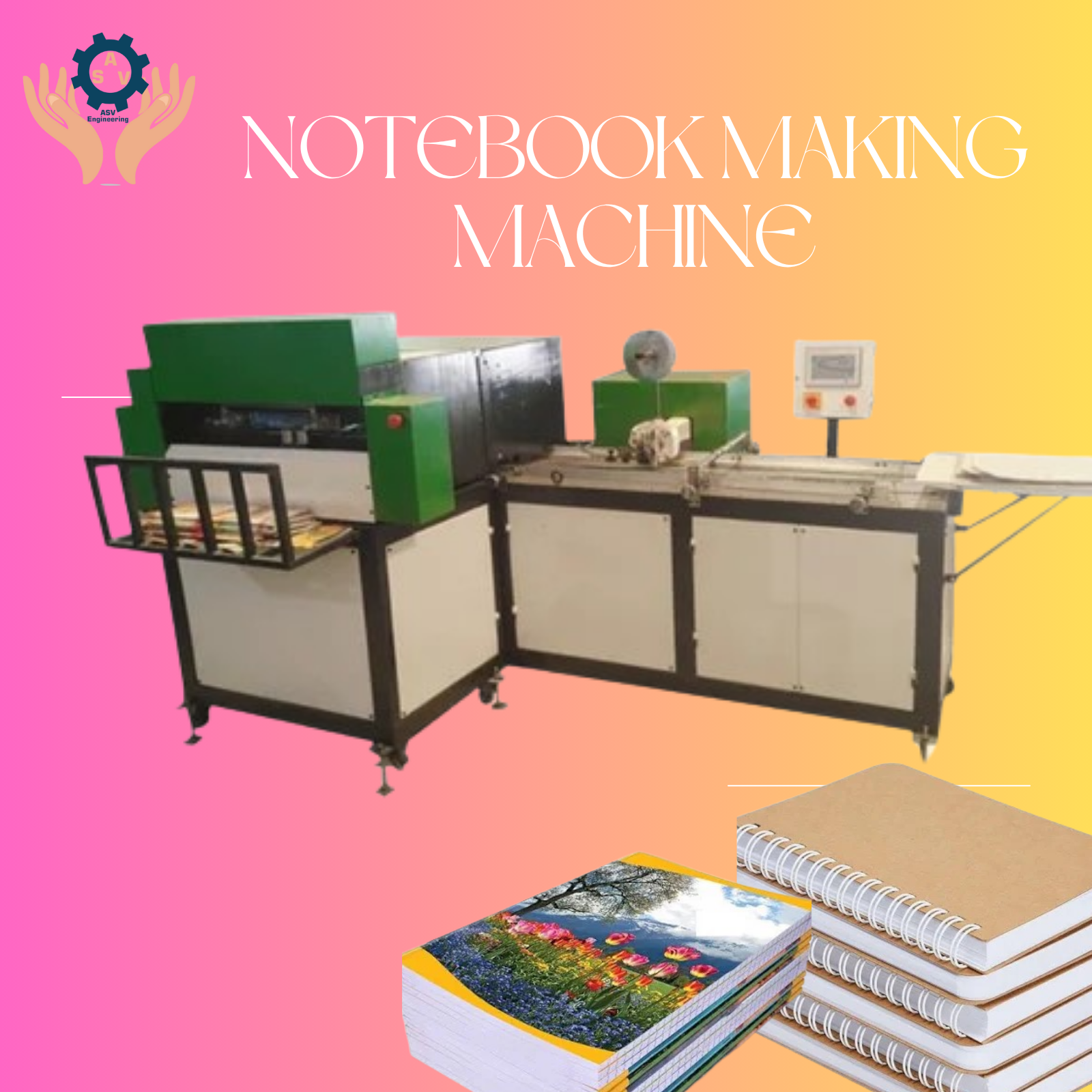

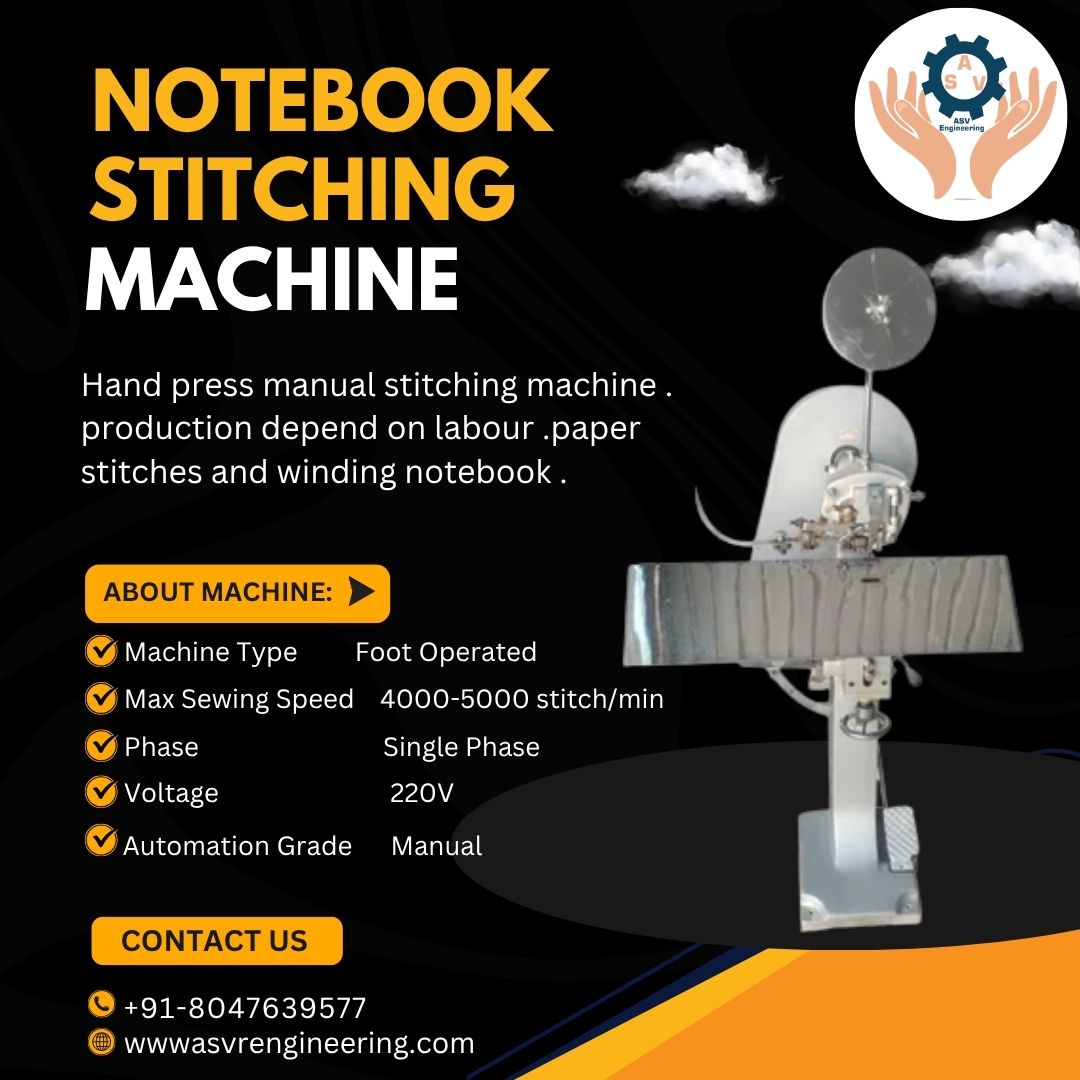

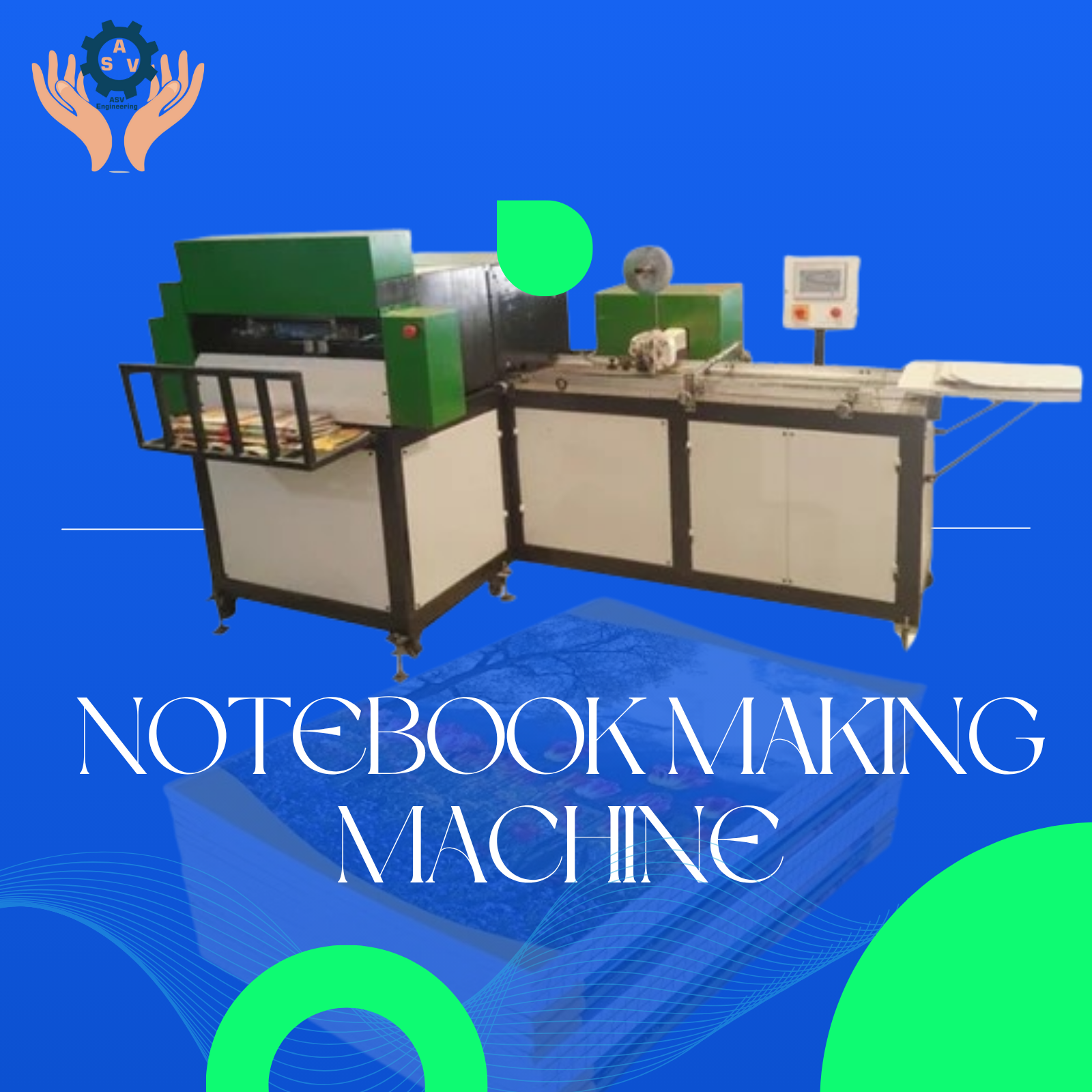

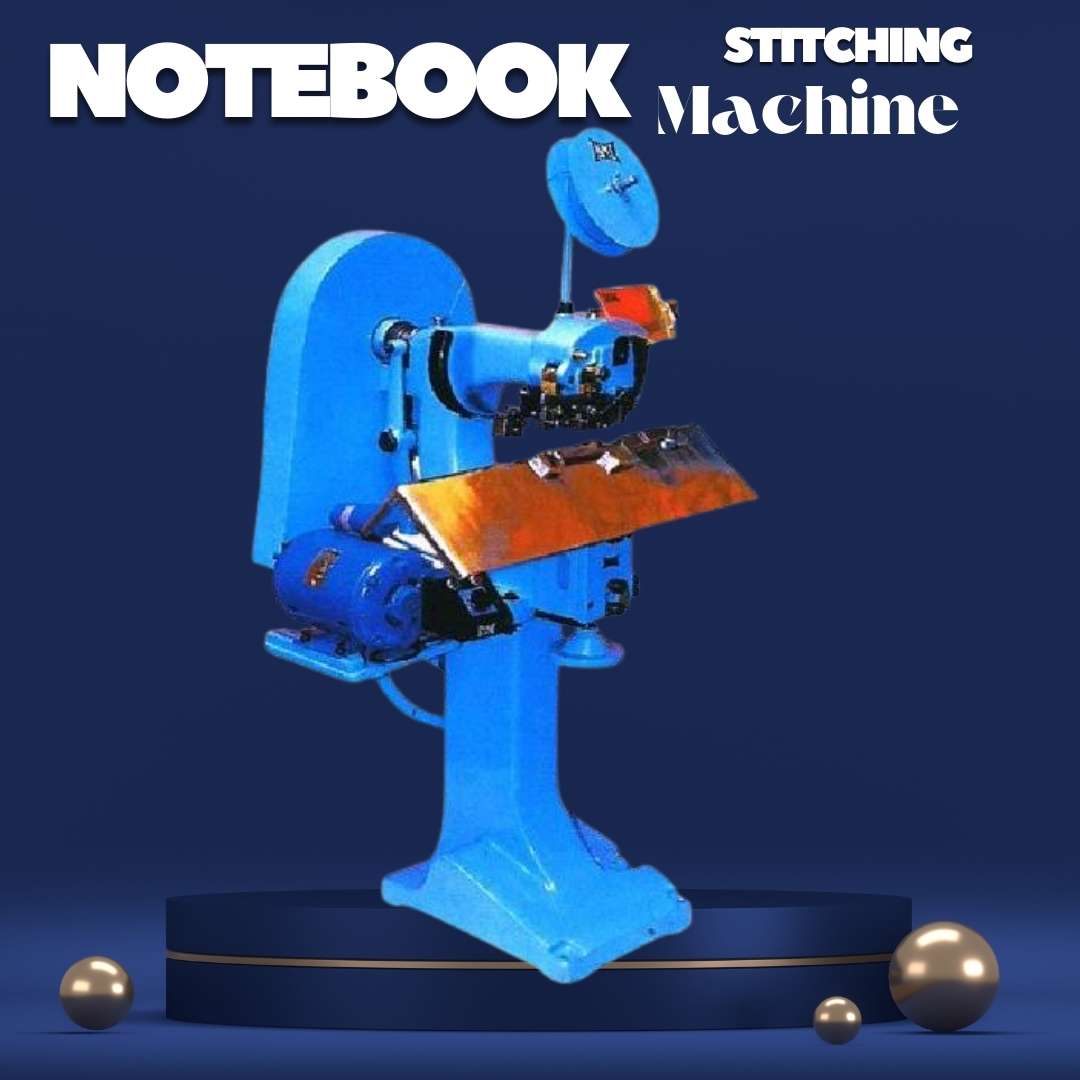

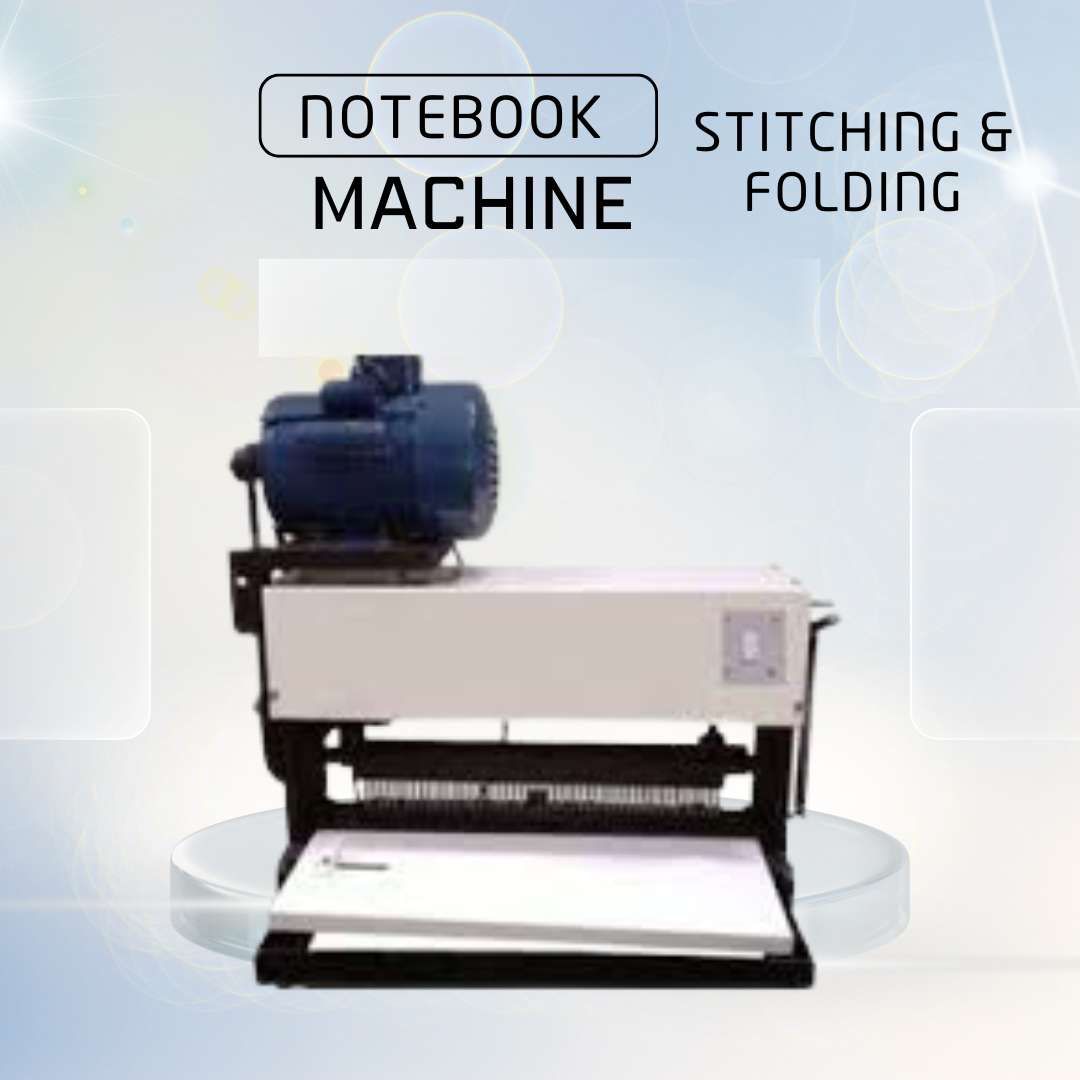

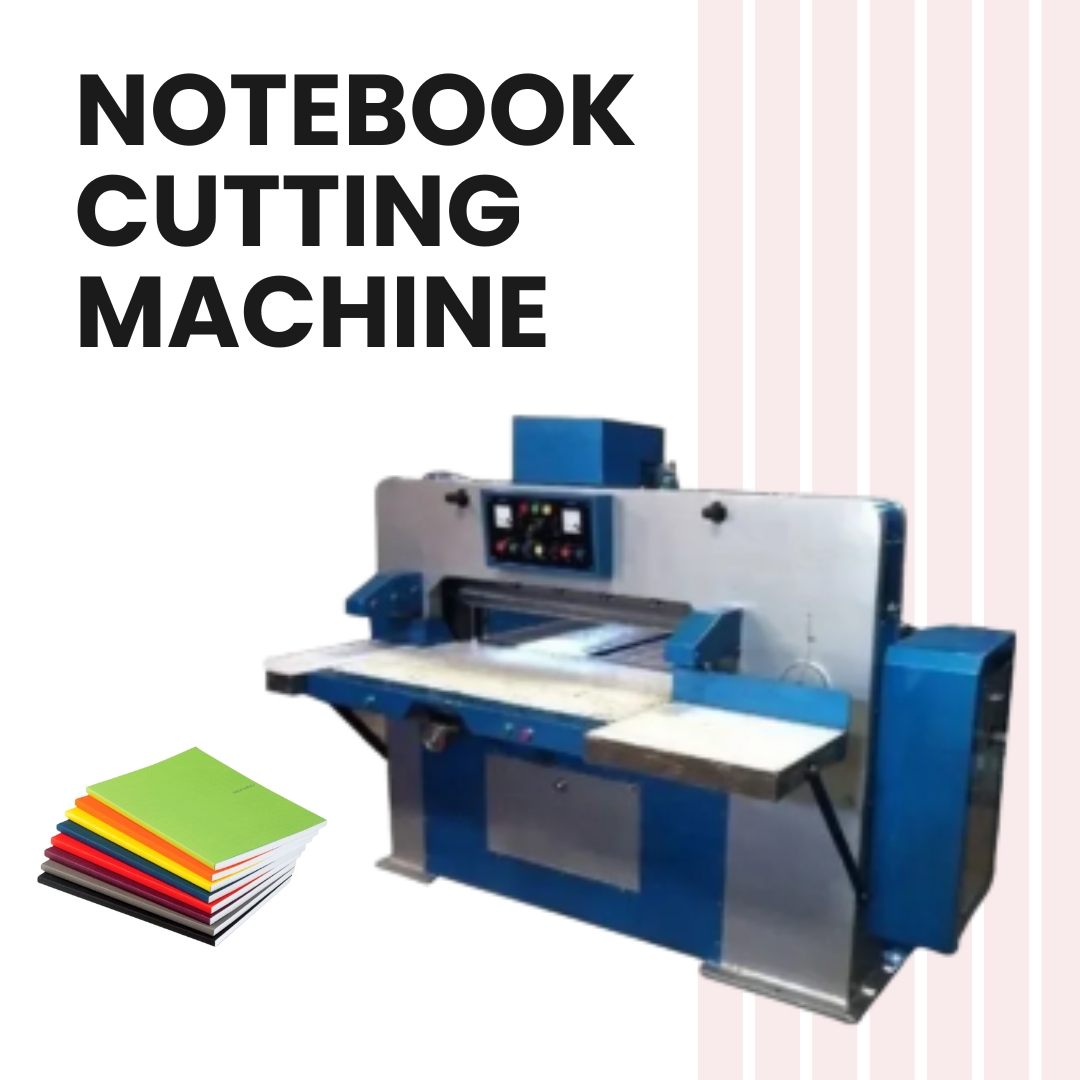

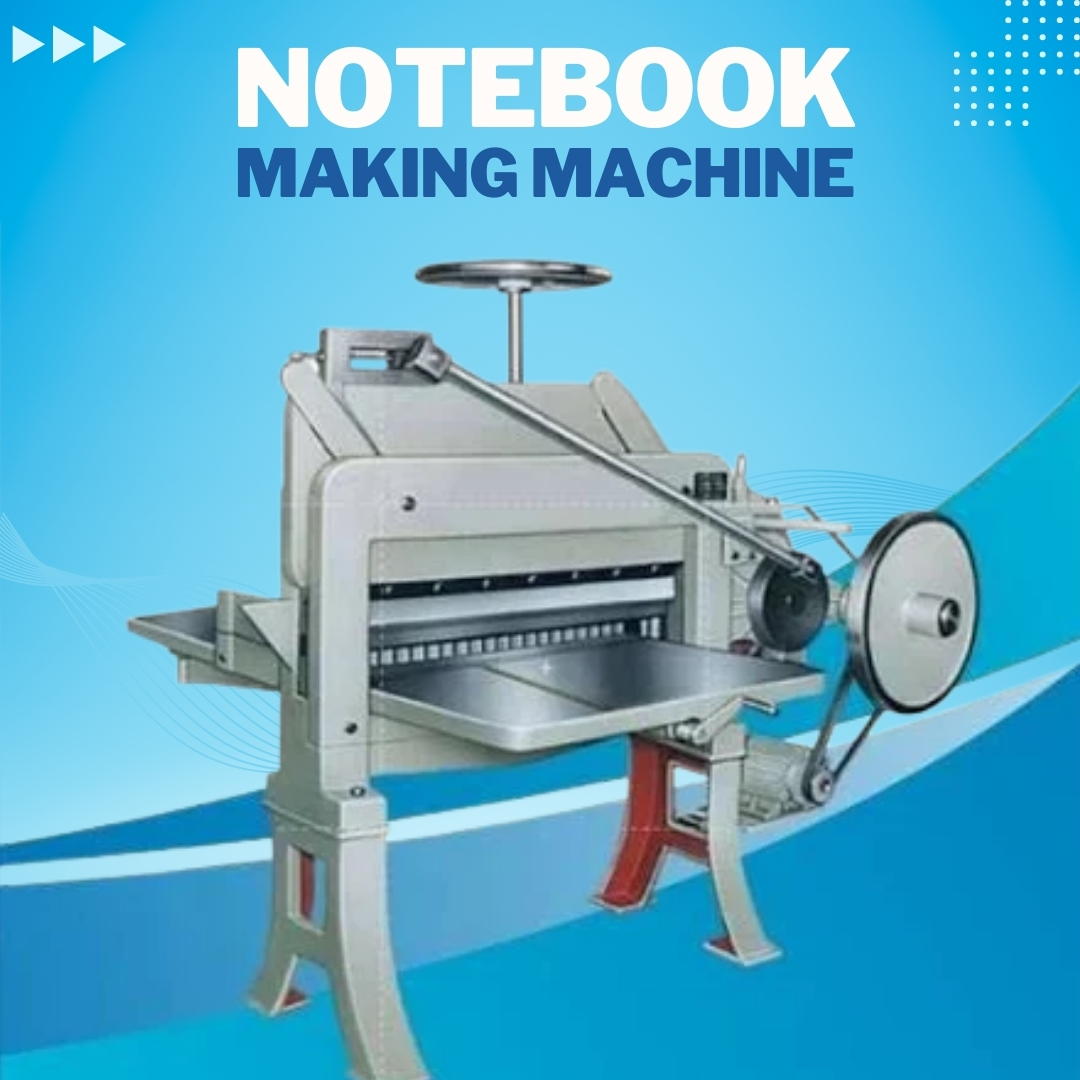

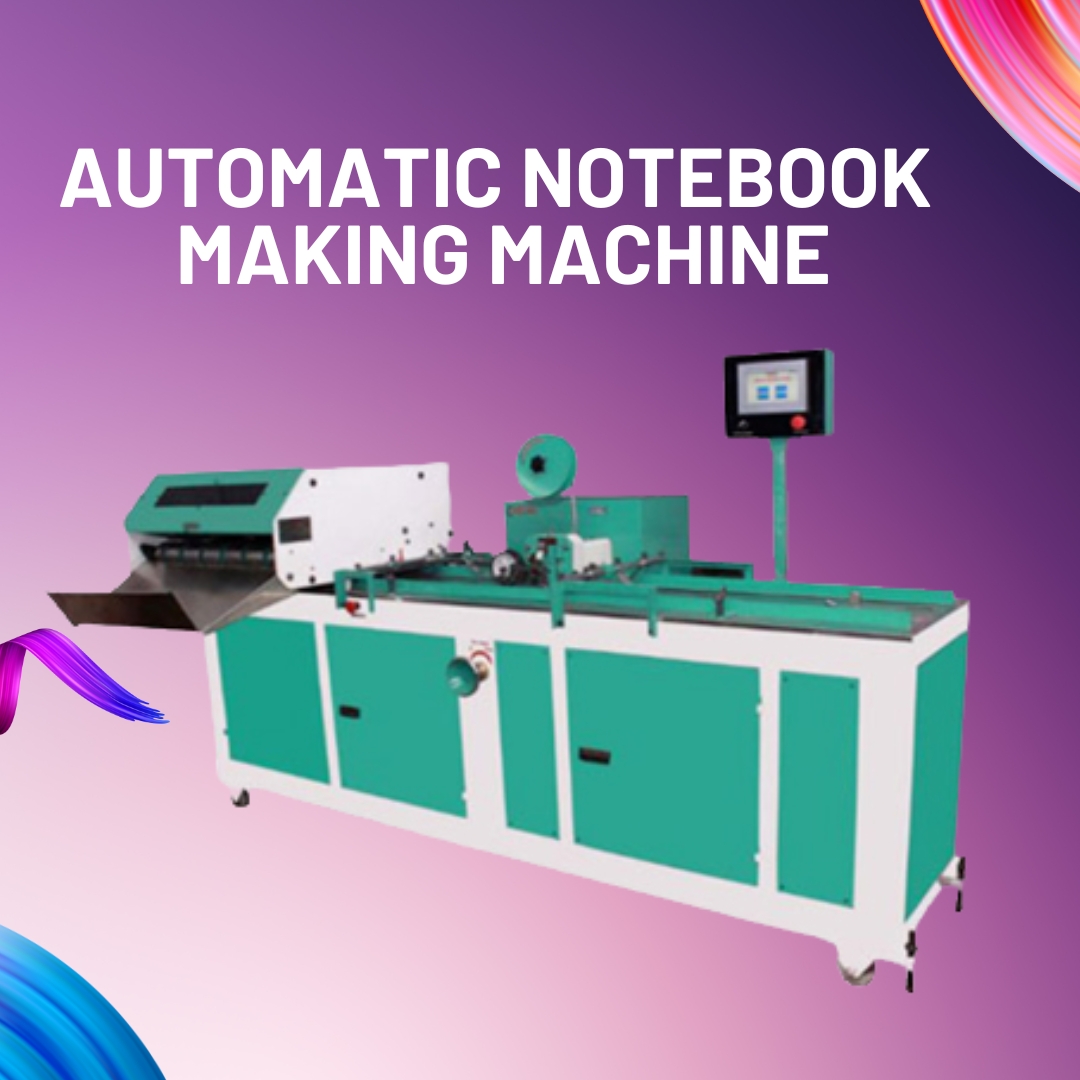

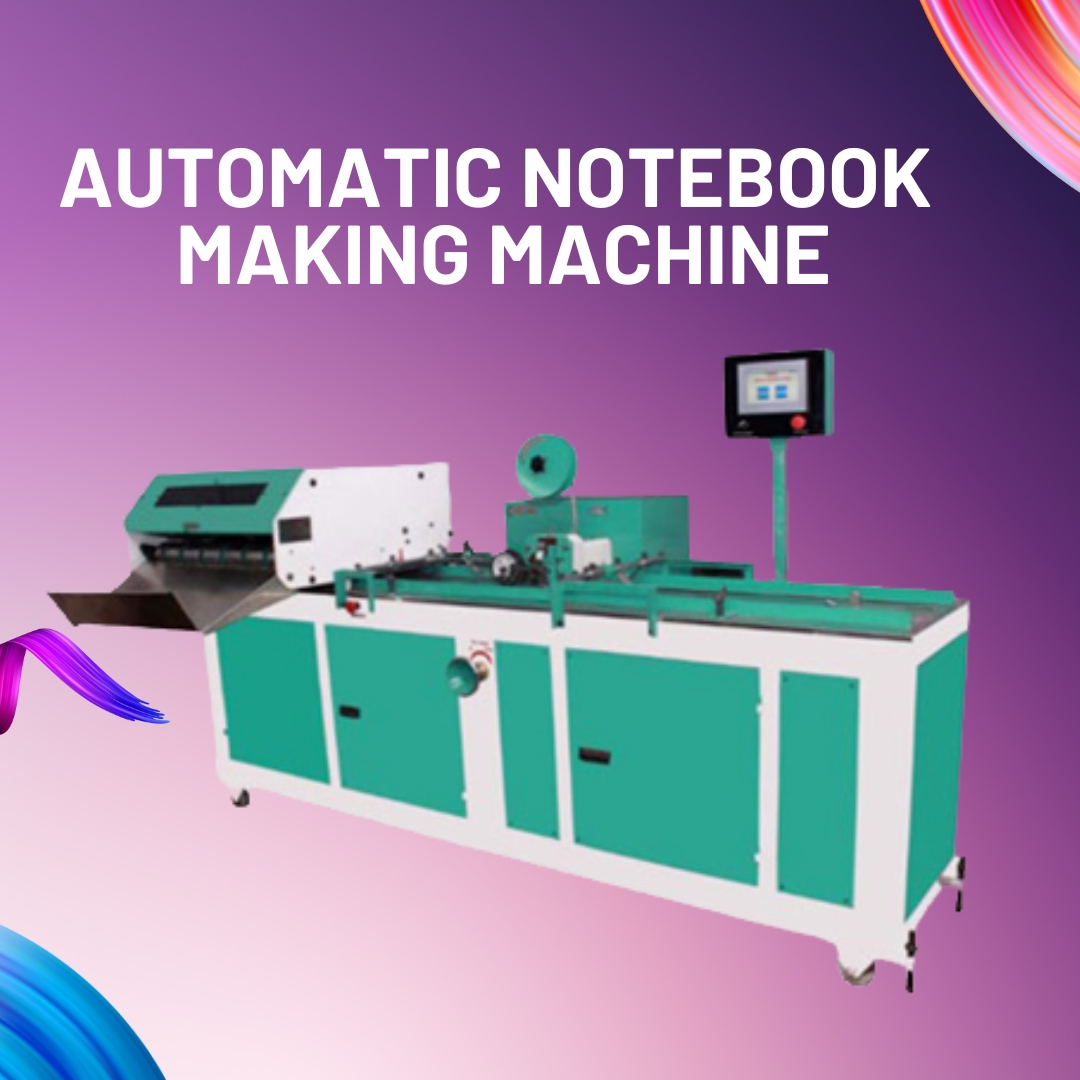

A. Machinery Cost

| Machine Type | Cost (INR) | Purpose |

|---|---|---|

| Manual Notebook Making Machine | 50,000 – 1,50,000 | Small-scale, low production |

| Semi-Automatic Notebook Machine | 2,50,000 – 5,00,000 | Medium-scale production |

| Fully Automatic Notebook Machine | 15,00,000 – 30,00,000 | High-volume production |

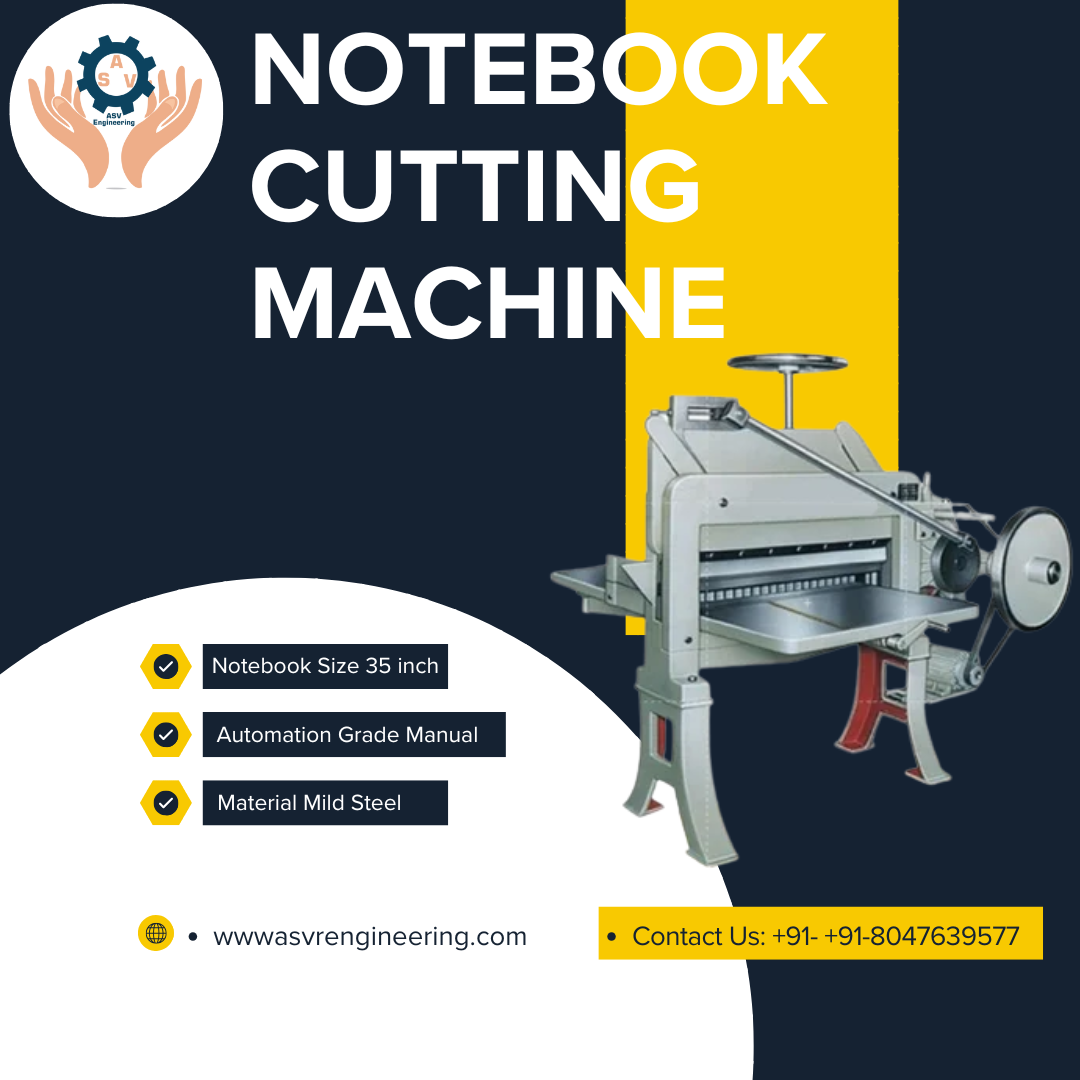

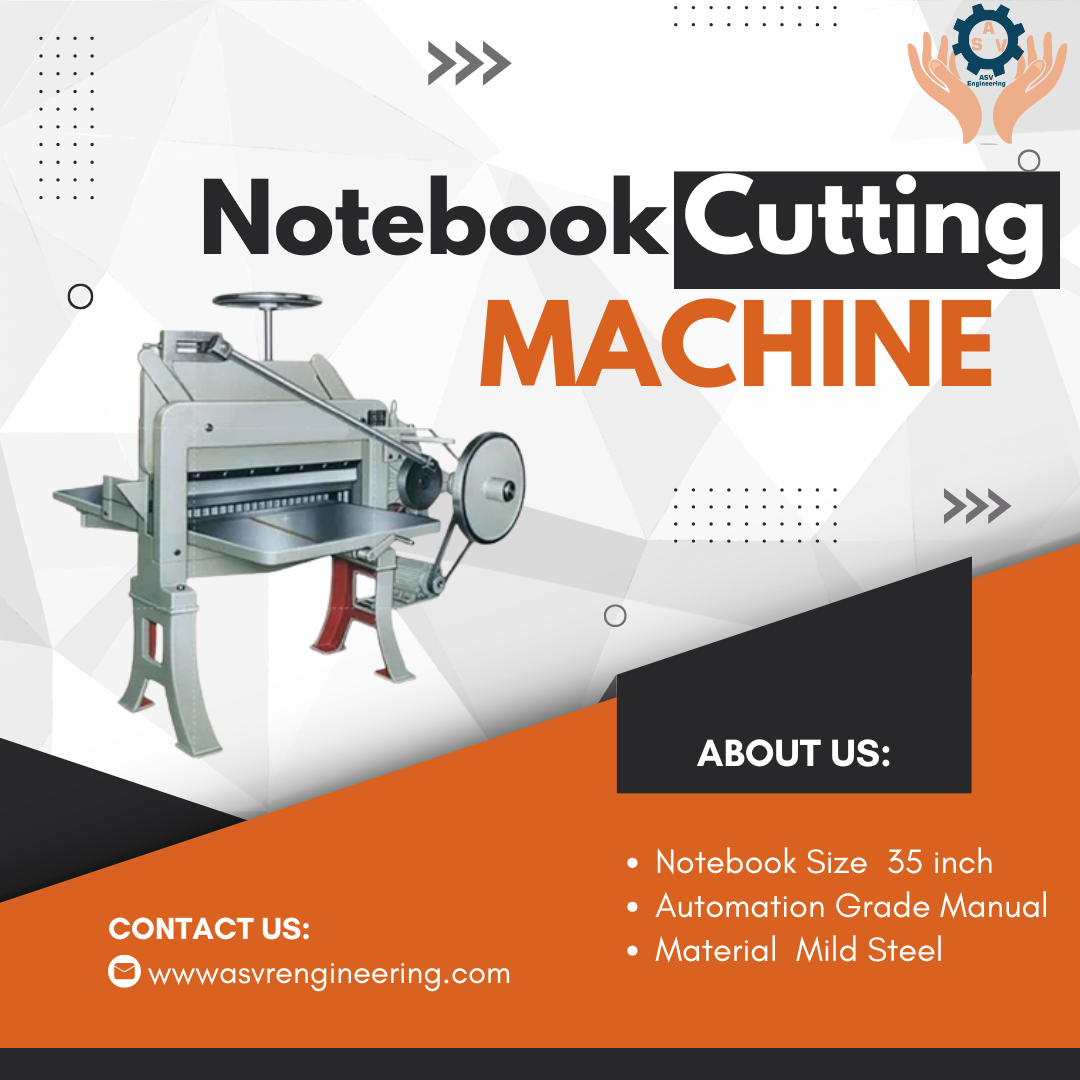

| Paper Cutting Machine (Guillotine) | 50,000 – 2,00,000 | Cutting sheets precisely |

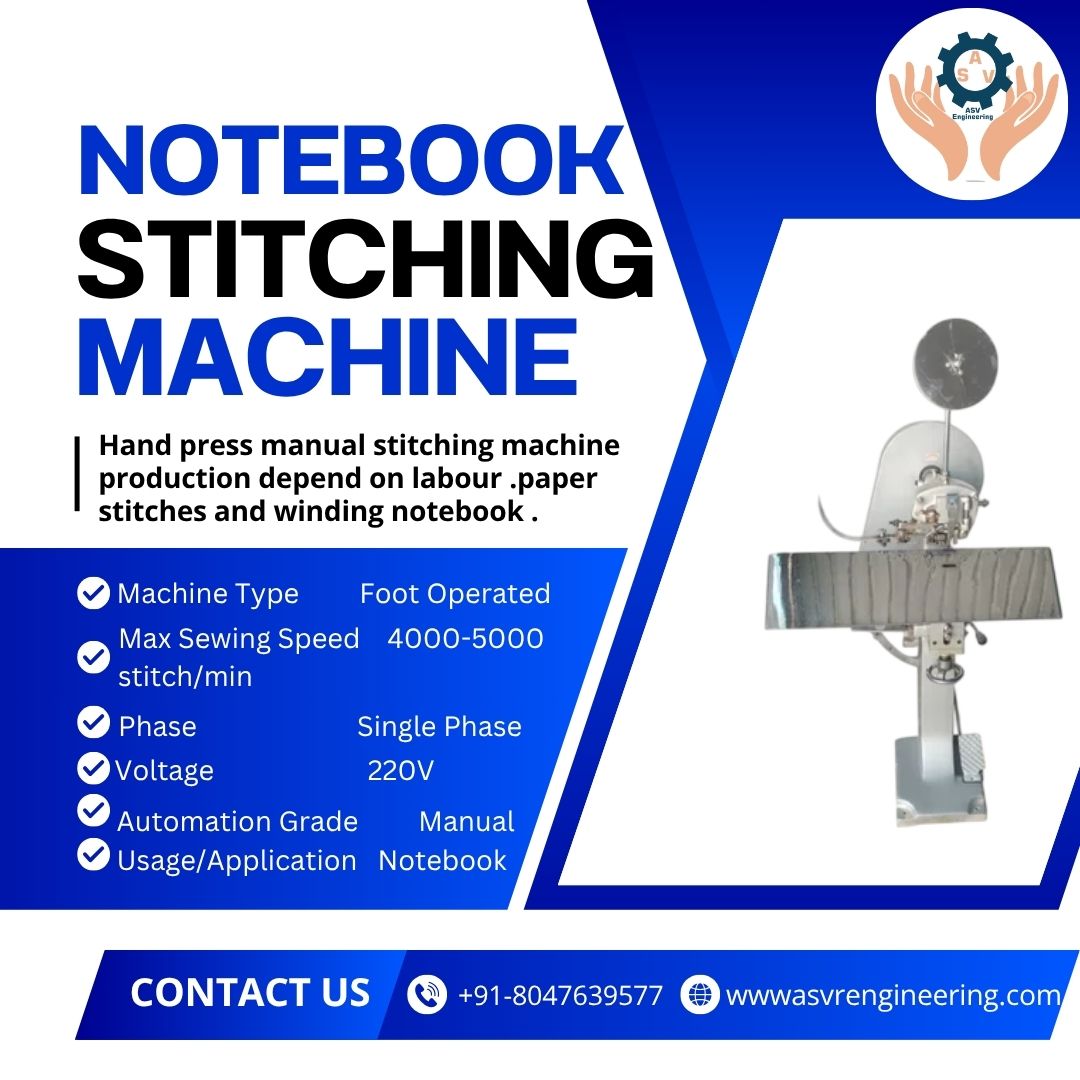

| Notebook Binding Machine | 1,00,000 – 3,00,000 | Spiral, wire-o, or perfect binding |

| Folding & Pressing Machine | 50,000 – 2,00,000 | Smooth page alignment |

| Printing & Ruling Machine | 1,00,000 – 3,00,000 | Inner page printing & ruling |

Tip: Semi-automatic machines are ideal for beginners and small entrepreneurs, while fully automatic machines are suited for large-scale commercial units.

B. Raw Material Cost

-

Paper (inner sheets): ₹30–50/kg

-

Covers (cardstock or laminated): ₹50–80/kg

-

Binding material (spiral wires, glue, stitching): ₹20–30/kg

-

Packaging material (cartons, polythene sheets): ₹5–10 per notebook

Pro Tip: Using recycled or eco-friendly paper can reduce costs and attract environmentally conscious customers.

C. Labor Cost

-

Small unit (manual/semi-automatic): 2–5 workers, ₹8,000–15,000 per month per worker

-

Large unit (fully automatic): 3–6 operators, ₹12,000–20,000 per month per worker

D. Utilities & Miscellaneous

-

Electricity: ₹5,000–10,000 per month

-

Rent (small workshop): ₹5,000–20,000 per month depending on city

-

Miscellaneous maintenance: ₹3,000–5,000

3. Total Investment Estimate

| Unit Type | Total Investment Range |

|---|---|

| Small-Scale (Manual/Semi-Automatic) | ₹3,00,000 – ₹7,00,000 |

| Medium-Scale (Semi-Automatic) | ₹8,00,000 – ₹15,00,000 |

| Large-Scale (Fully Automatic) | ₹20,00,000 – ₹40,00,000+ |

This includes machinery, raw materials for initial production, labor, and other setup costs.

4. Profit Potential

-

Cost per notebook: ₹8–12

-

Selling price: ₹15–40

-

Profit margin: 30–50% depending on scale and customization

-

Monthly Earnings:

-

Small-scale unit: ₹50,000 – ₹1,50,000

-

Medium-scale unit: ₹2,00,000 – ₹5,00,000

-

Large-scale unit: ₹5,00,000 – ₹10,00,000+

-

Profit increases with higher production capacity and better distribution channels.

5. Steps to Start a Notebook Making Unit

-

Market Research – Identify demand in your area and target customers (schools, offices, corporate).

-

Choose Machinery – Decide between manual, semi-automatic, or fully automatic machines based on budget and scale.

-

Setup Workshop – Ensure sufficient space, power supply, and storage for raw materials.

-

Procure Raw Materials – Secure a reliable supplier for paper, covers, and binding materials.

-

Hire Skilled Operators – Especially for semi-automatic or fully automatic machines.

-

Branding & Marketing – Promote notebooks through local distributors, retailers, and online platforms.

6. Tips for Reducing Setup Cost

-

Start with semi-automatic machines and gradually upgrade.

-

Purchase used or refurbished machinery from trusted suppliers.

-

Optimize raw material usage to reduce wastage.

-

Target bulk orders for schools and offices to ensure continuous revenue.

Conclusion

Setting up a notebook making unit in India is a lucrative business opportunity in 2025. The total setup cost depends on the scale, machinery type, and raw materials you choose. A small or medium-scale unit can be started with ₹3–15 lakh, while fully automatic units may require ₹20 lakh or more.

With consistent demand, high-profit margins, and opportunities for bulk orders, notebook manufacturing remains one of the most promising small-scale industrial businesses for entrepreneurs.

Start your notebook making business today by planning your setup cost, choosing the right machine, and targeting the right market.

Buy Now

.jpg)