Manual vs. Automatic Notebook Making Machine – Which One Is Right for Your Business in 2025?

Price: ₹50000

Manual vs. Automatic Notebook Making Machine – Which One to Choose in 2025?

If you’re planning to start a notebook manufacturing business in 2025, one of the first questions you’ll face is whether to choose a manual notebook making machine or an automatic notebook machine. The right decision depends on your production goals, budget, labor availability, and space. This guide compares both types to help you make an informed choice.

📘 Understanding the Two Types

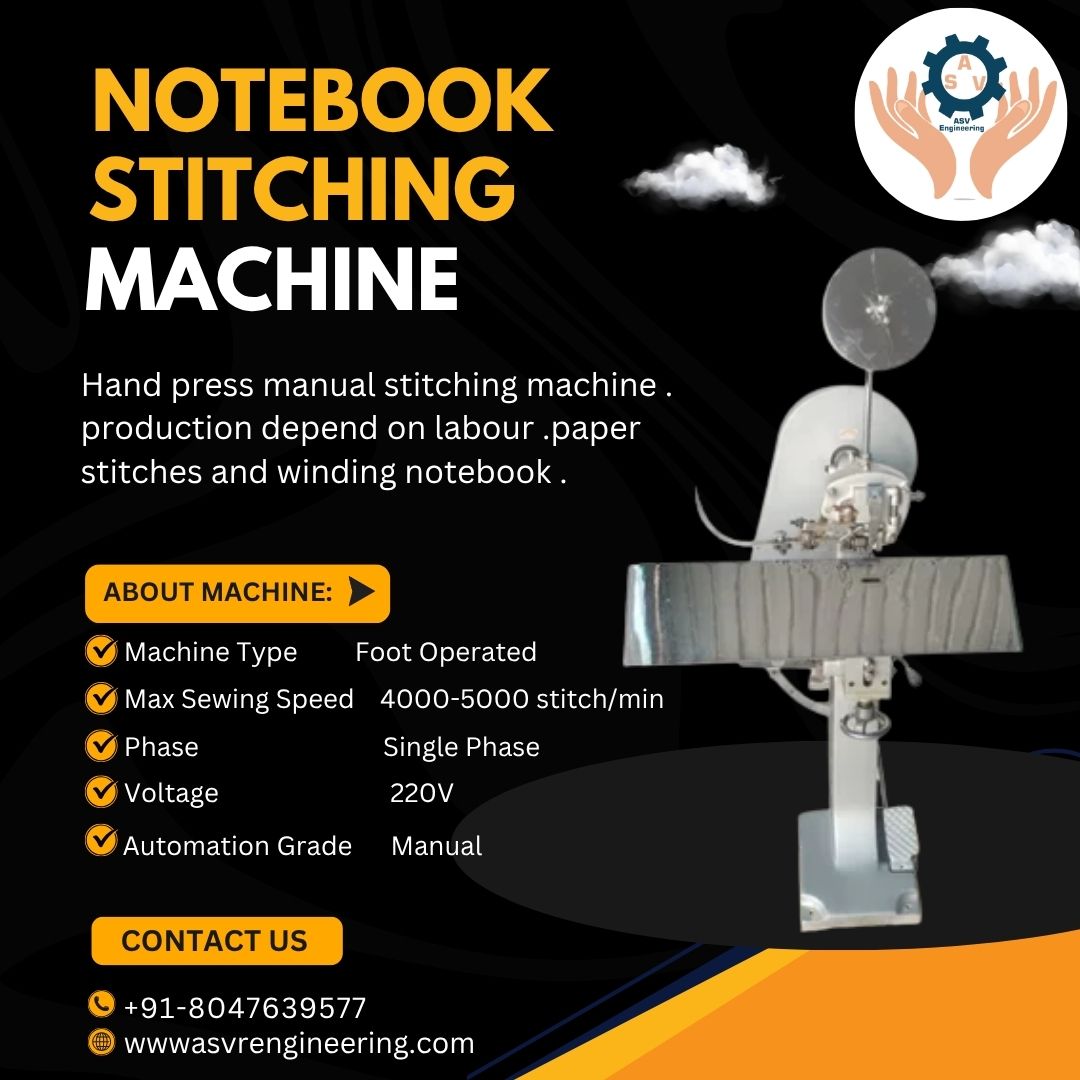

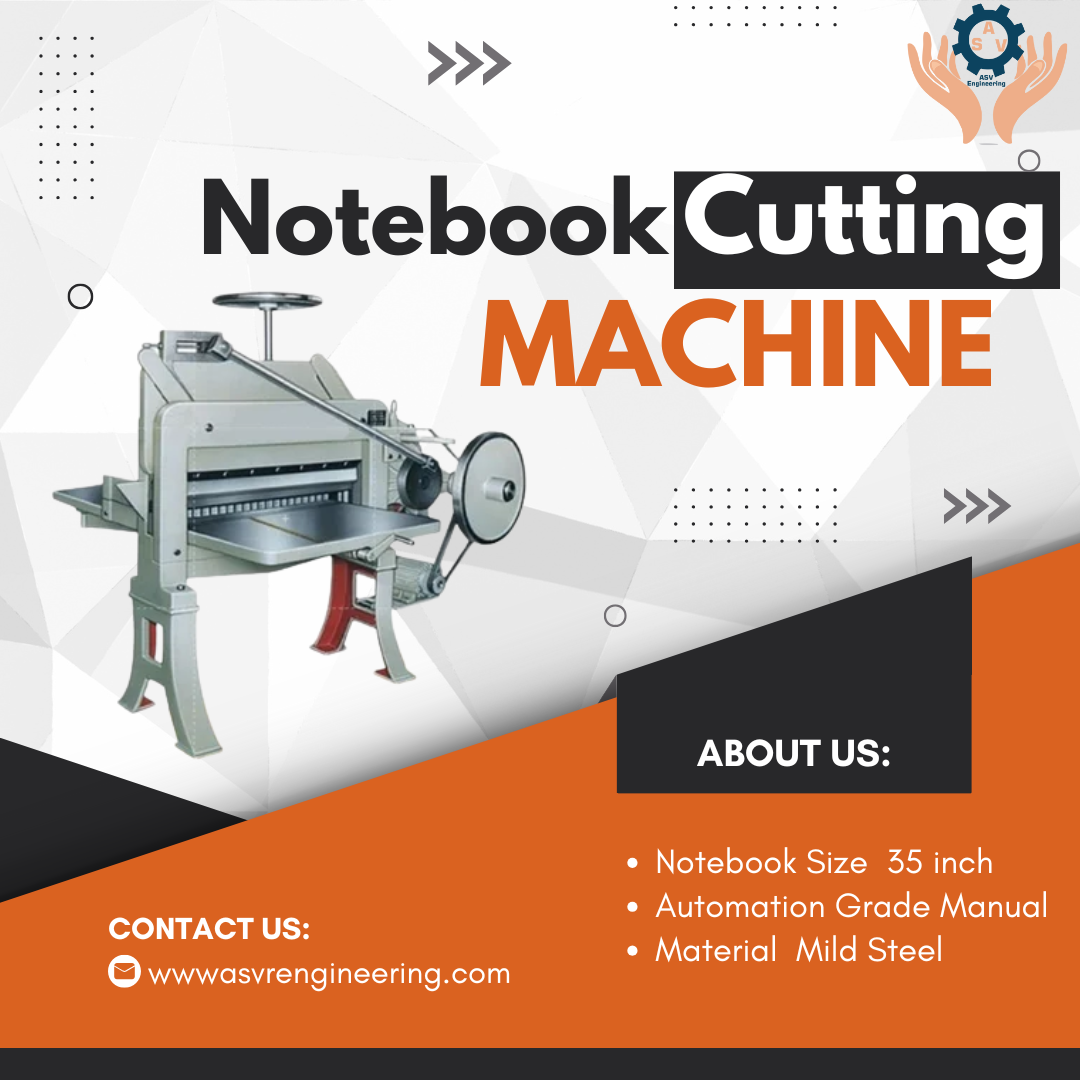

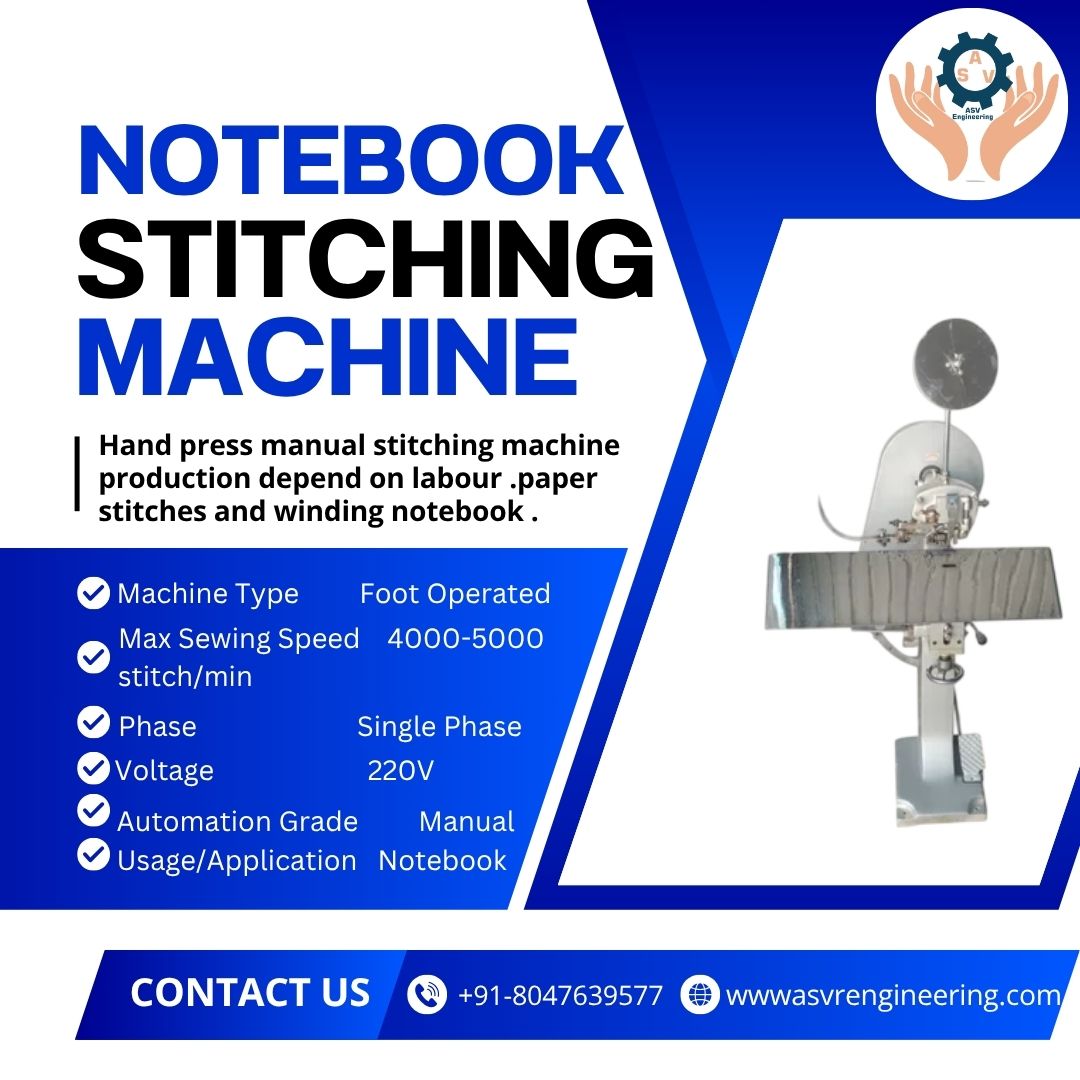

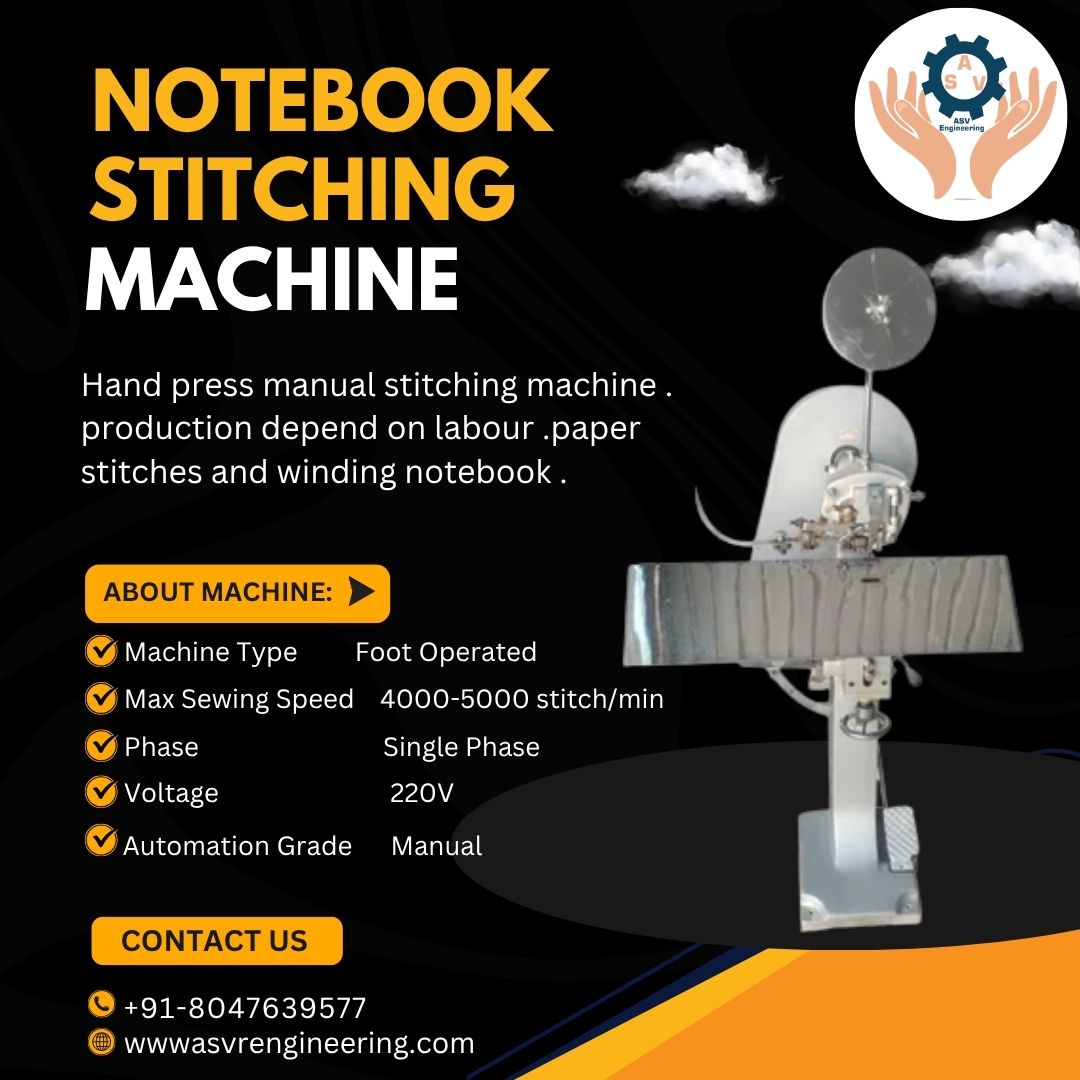

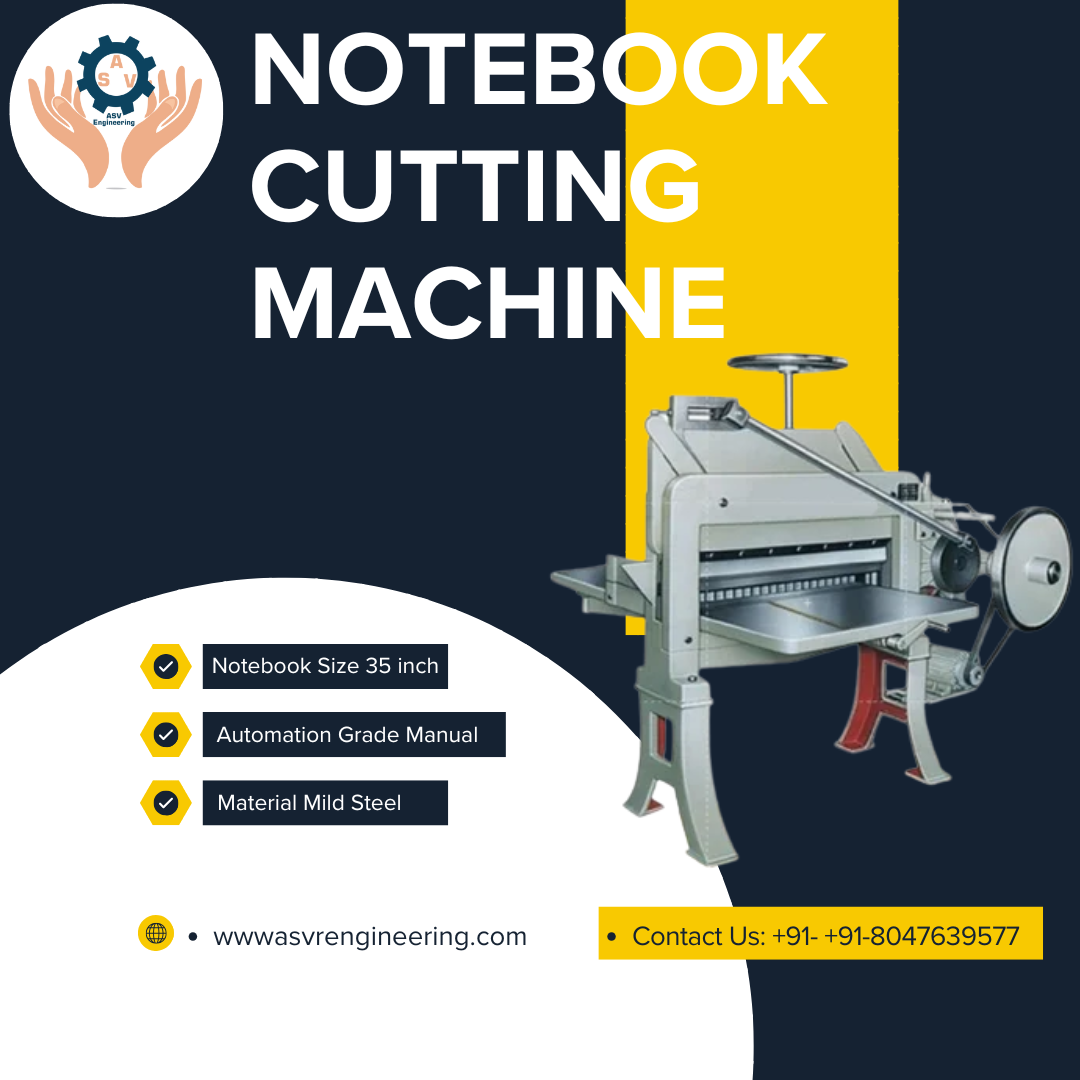

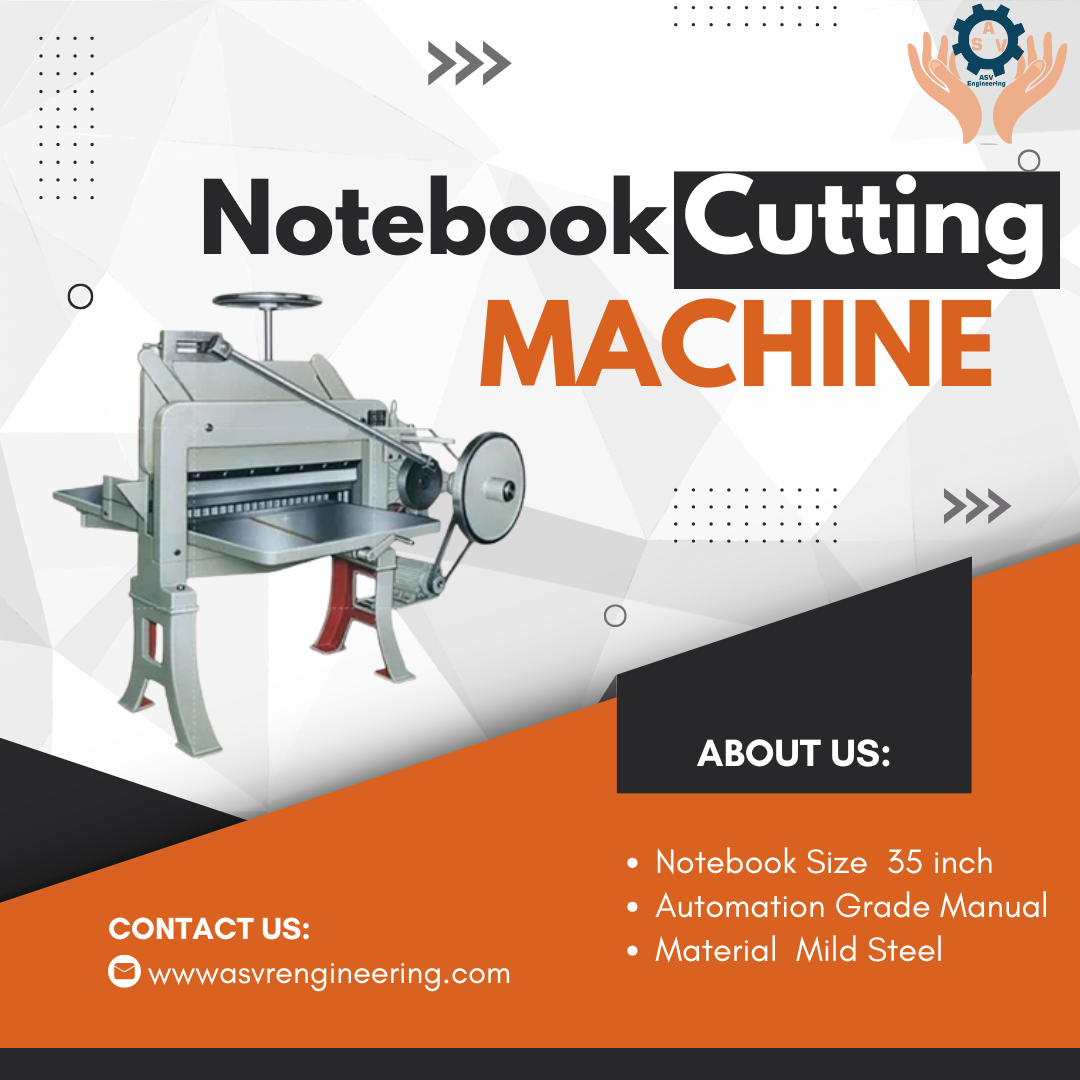

1. Manual Notebook Making Machine

Manual machines require human effort to carry out each step of notebook manufacturing, including cutting, stitching, and binding. They are ideal for low-scale production or businesses just starting with a tight budget.

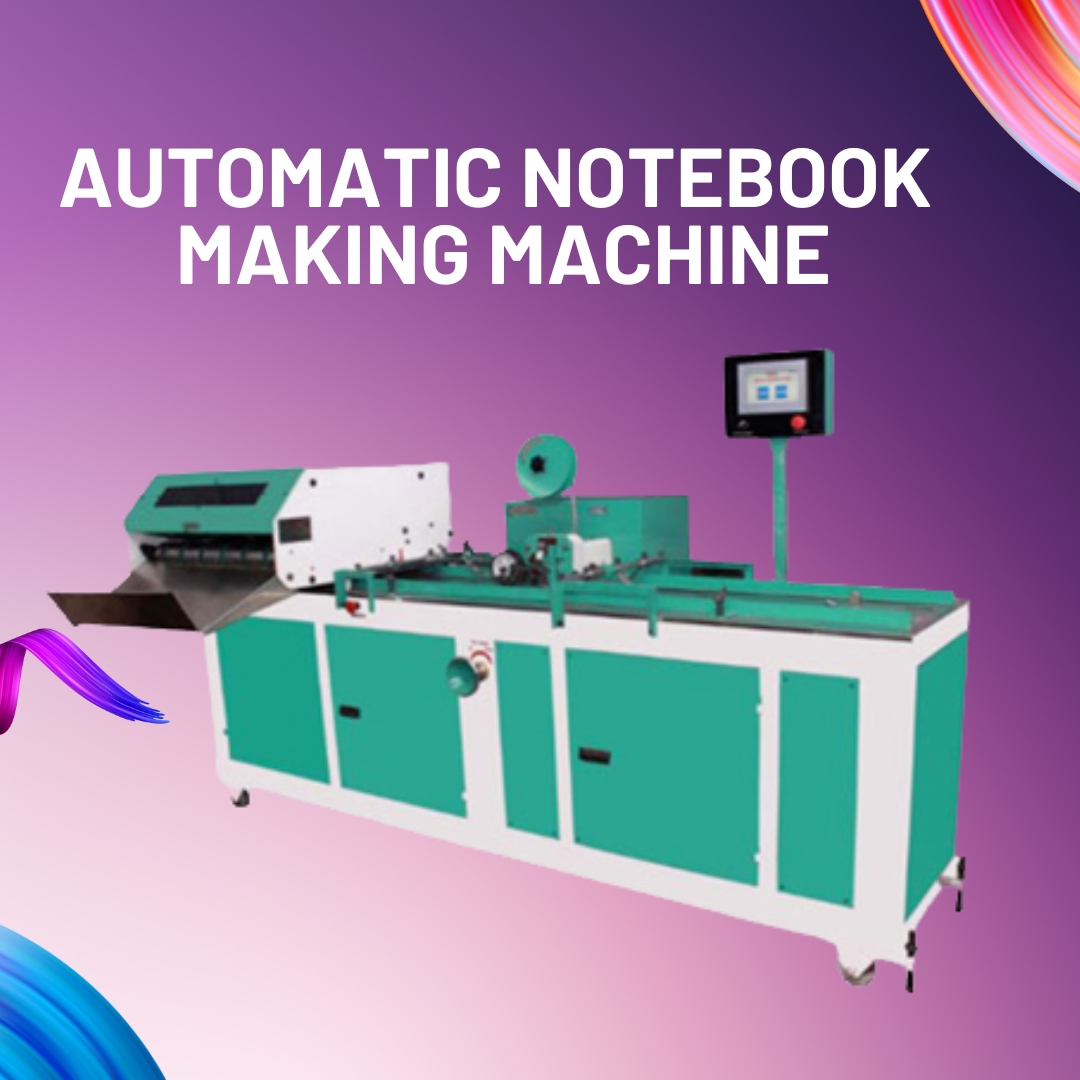

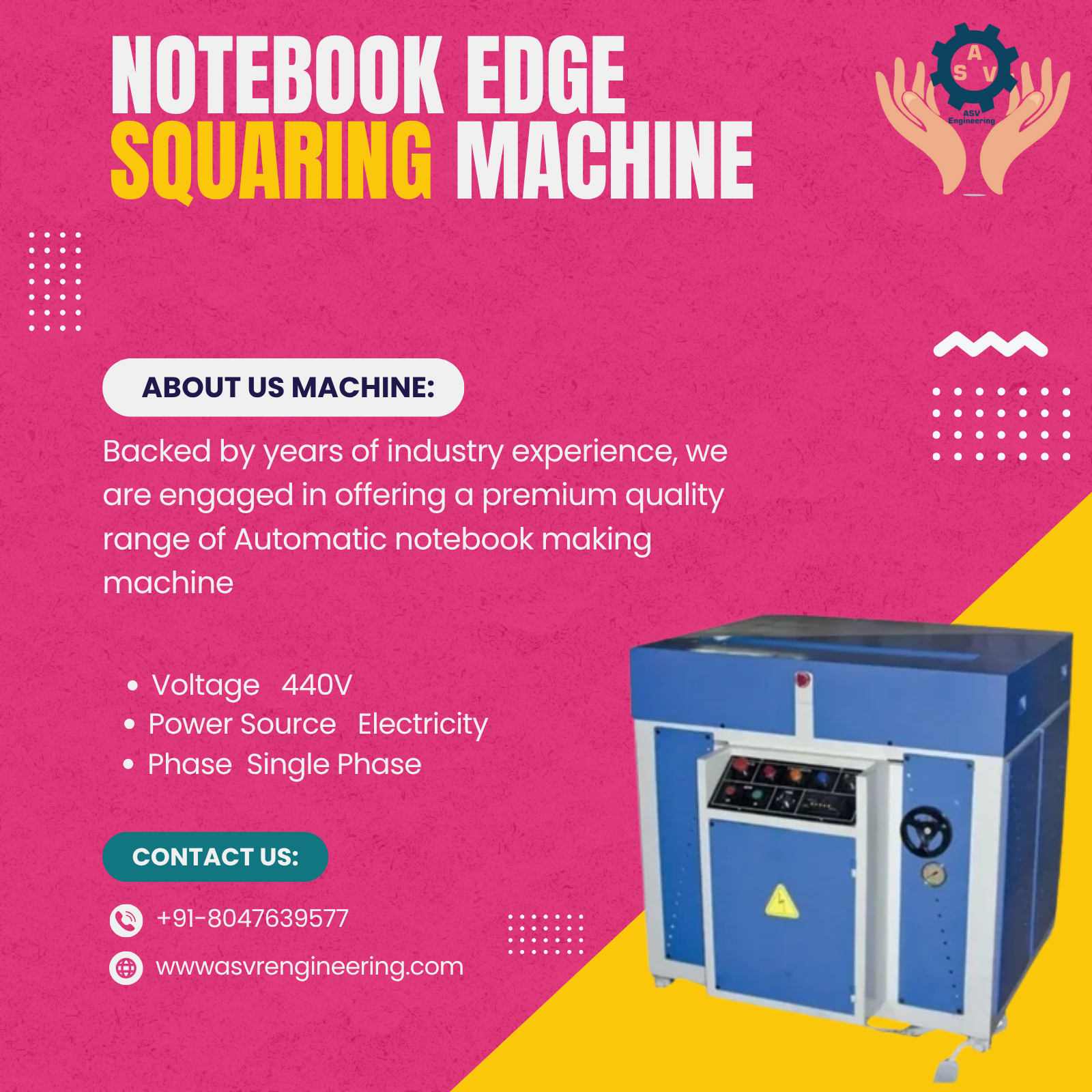

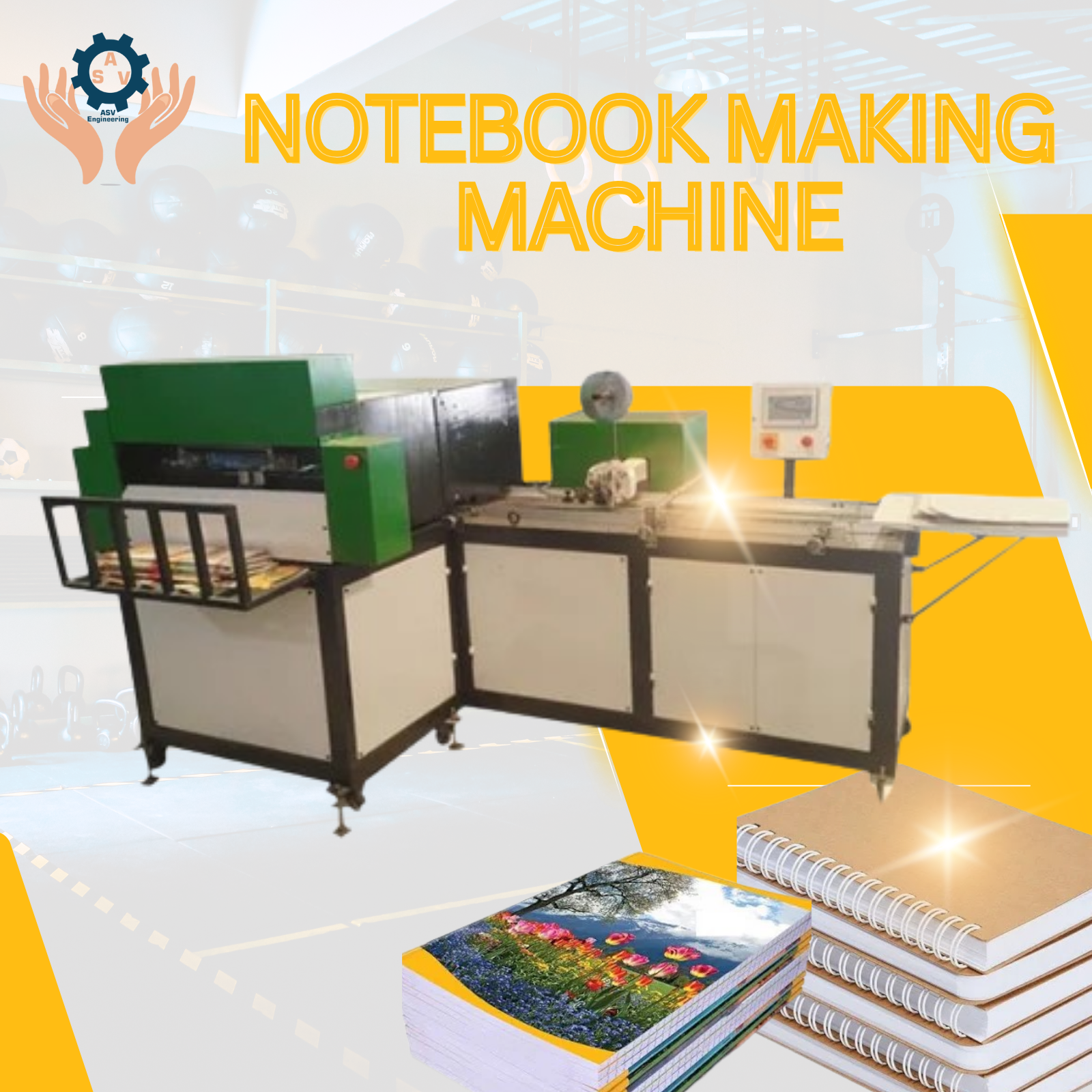

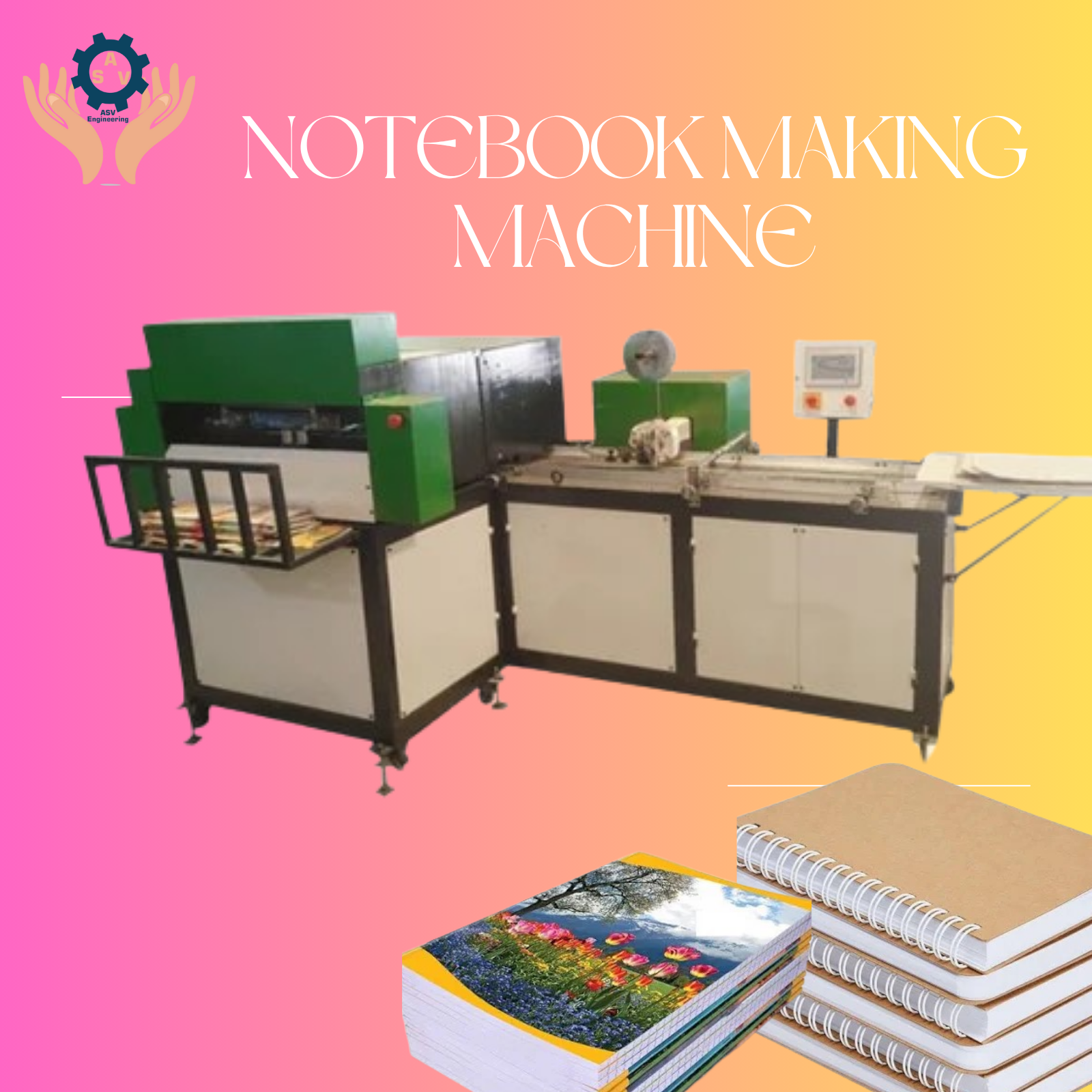

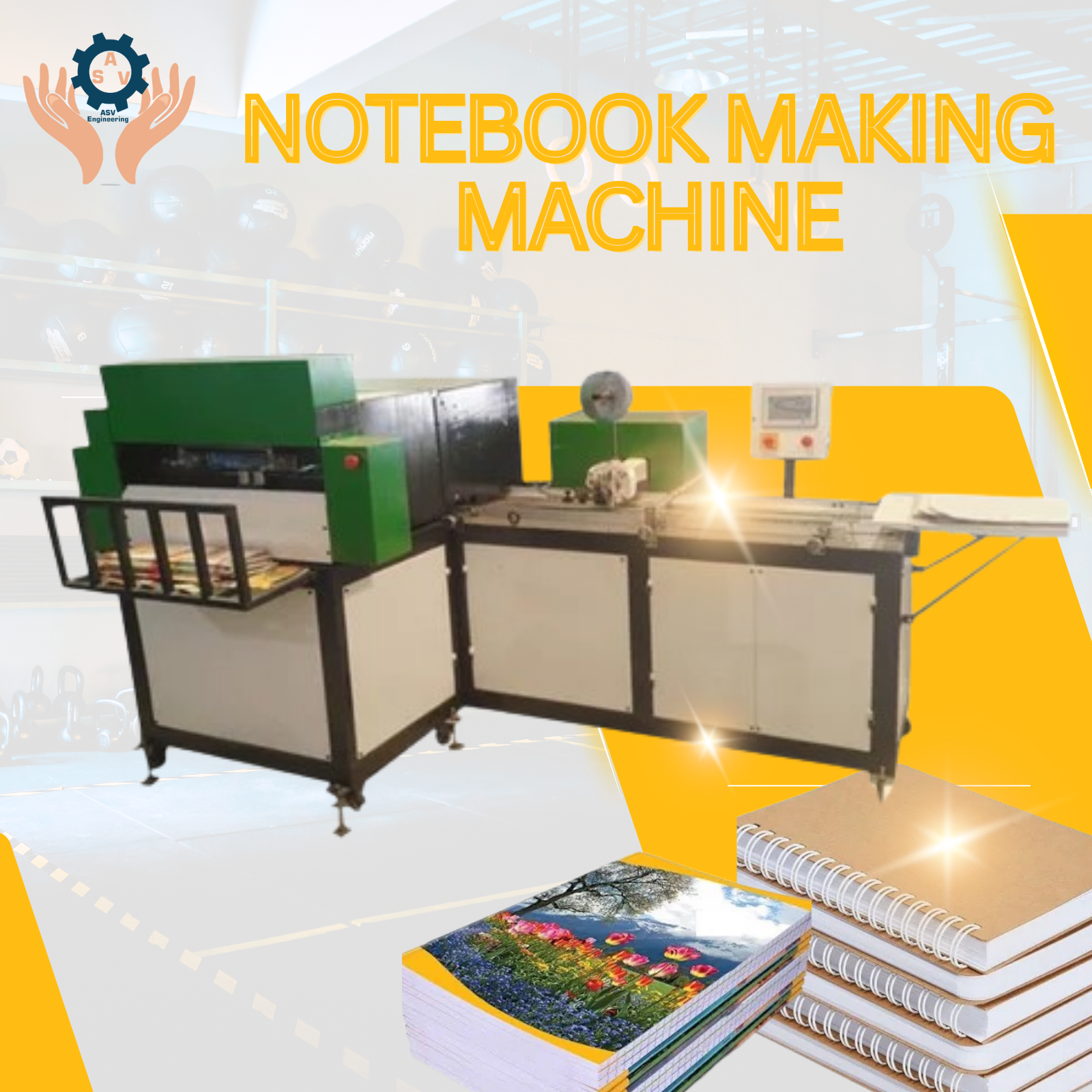

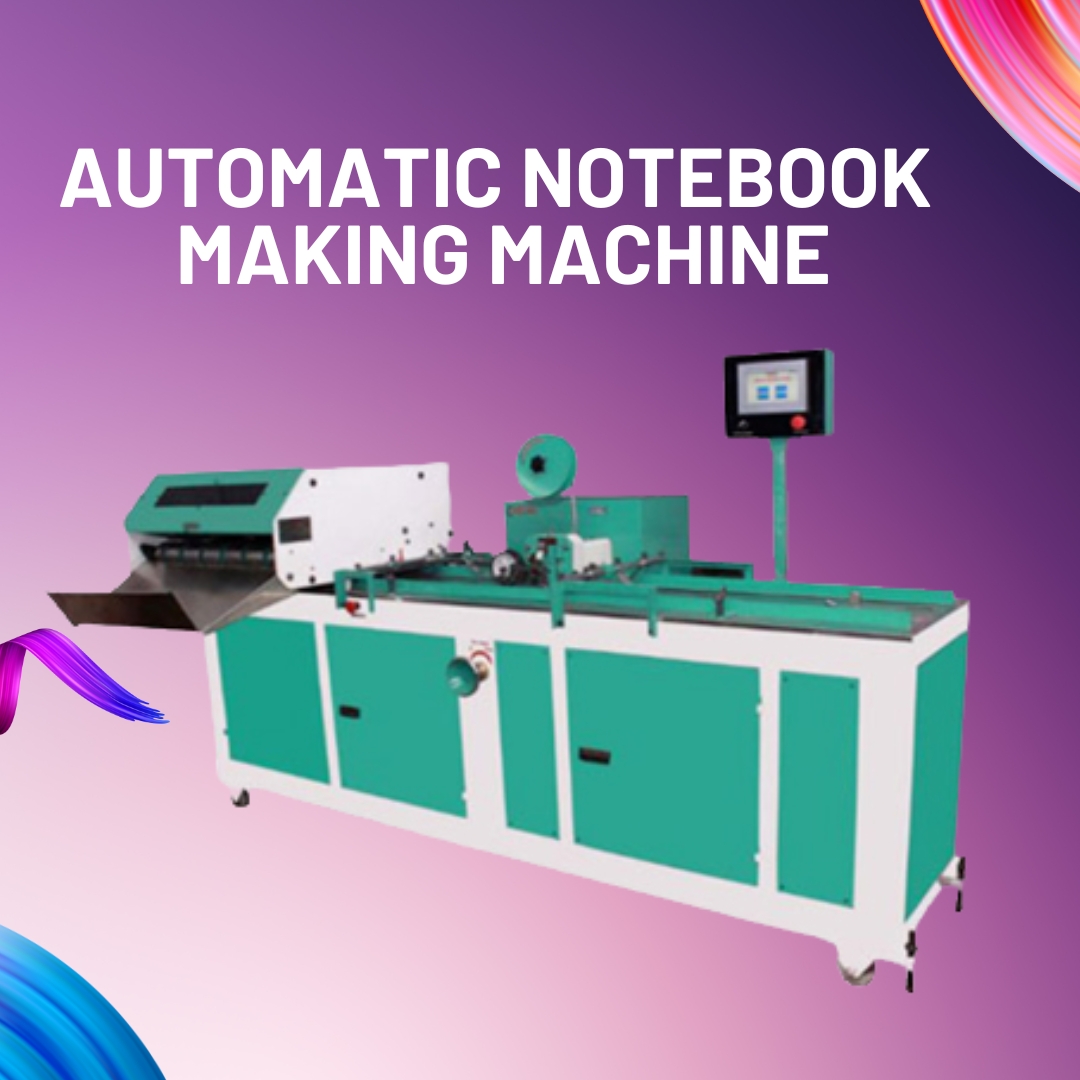

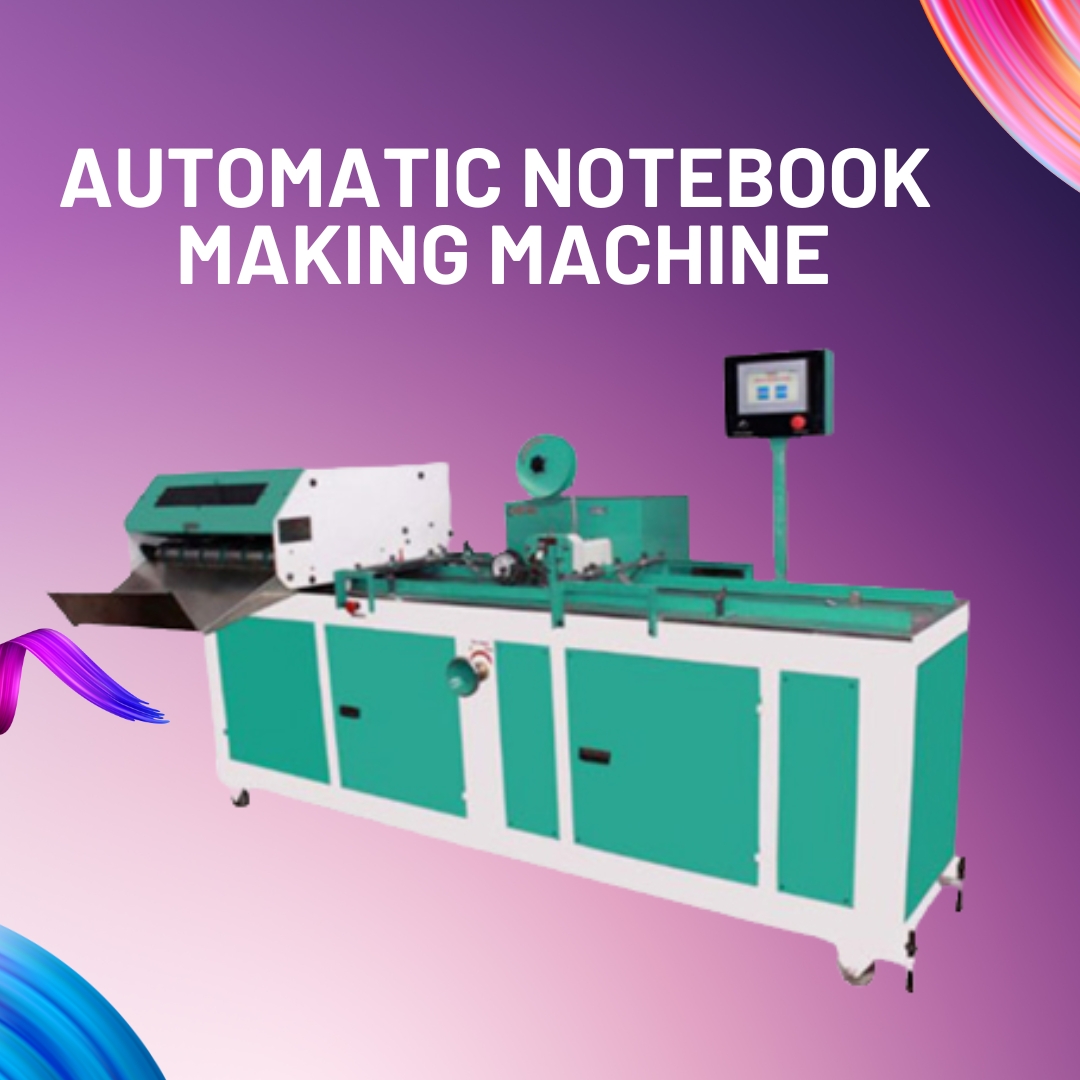

2. Automatic Notebook Making Machine

Automatic machines carry out multiple operations such as cutting, center stitching, folding, and binding with minimal human intervention. These machines are built for higher efficiency and commercial-level output.

🔍 Manual vs. Automatic – Feature Comparison

| Feature | Manual Machine | Automatic Machine |

|---|---|---|

| Initial Investment | ₹25,000 – ₹80,000 | ₹3,00,000 – ₹8,00,000+ |

| Production Capacity | 300 – 800 notebooks/day | 3,000 – 7,000 notebooks/day |

| Labor Requirement | 2–3 people | 1–2 people |

| Power Usage | Very Low / Manual | 2–4 HP motor |

| Space Required | 100–150 sq. ft. | 200–400 sq. ft. |

| Maintenance | Minimal | Moderate (depends on automation) |

| Suitability | Home-based or startup units | Commercial, high-output factories |

🎯 Pros and Cons

✅ Manual Machine Pros:

- Low cost and investment risk

- Ideal for learning and small-batch jobs

- Easy to repair and operate

- No need for electricity (in some models)

❌ Manual Machine Cons:

- Slow production rate

- High labor dependency

- Not suitable for large orders

✅ Automatic Machine Pros:

- High-speed production

- Consistent quality and finish

- Less human error and fatigue

- Better ROI in large-scale business

❌ Automatic Machine Cons:

- Higher upfront investment

- Needs stable power supply

- Regular servicing required

💼 Which Machine Should You Choose?

Choosing between manual and automatic notebook machines depends on these factors:

- Budget: If you have a tight budget under ₹1 lakh, manual is your starting point.

- Output Need: For orders above 2,000 notebooks/day, go automatic.

- Labor Availability: If skilled labor is limited, automation is preferable.

- Space: Manual machines require less room, good for home-based units.

💰 Profit Estimation

Manual Machine Example:

- Production: 500 notebooks/day

- Cost per notebook: ₹6

- Selling price: ₹12

- Daily Profit: ₹3,000

Automatic Machine Example:

- Production: 4,000 notebooks/day

- Cost per notebook: ₹5

- Selling price: ₹11

- Daily Profit: ₹24,000

Despite higher investment, automatic machines offer faster ROI within 6–10 months if utilized fully.

🔧 Maintenance & Operation Differences

Manual Machine:

- Simple oiling and blade sharpening

- No electronic components

Automatic Machine:

- Requires monthly maintenance checks

- May need professional technician support

🛠️ Popular Models in India (2025)

- KESYA Compact Manual Notebook Cutter

- Friends Engineering Semi-Automatic Notebook Line

- SK Tech Fully Automatic Notebook Plant

- Ashoka Stitching + Cutting Combo Unit

📦 Essential Add-Ons You Might Need

- Notebook ruling machine (for printing lines)

- Perforation machine (for easy tearing)

- Cover printing machine (optional)

📝 Conclusion – Make the Right Investment in 2025

If you are just starting a notebook making business in India with limited capital, a manual machine is a low-risk way to learn the trade and start earning. However, if you're looking for scalability, consistent quality, and faster production, an automatic notebook making machine is your best investment in 2025.

Need help deciding? Contact us today to get a personalized quote, demo videos, and supplier recommendations based on your business goals and budget.

Buy Now

.jpg)