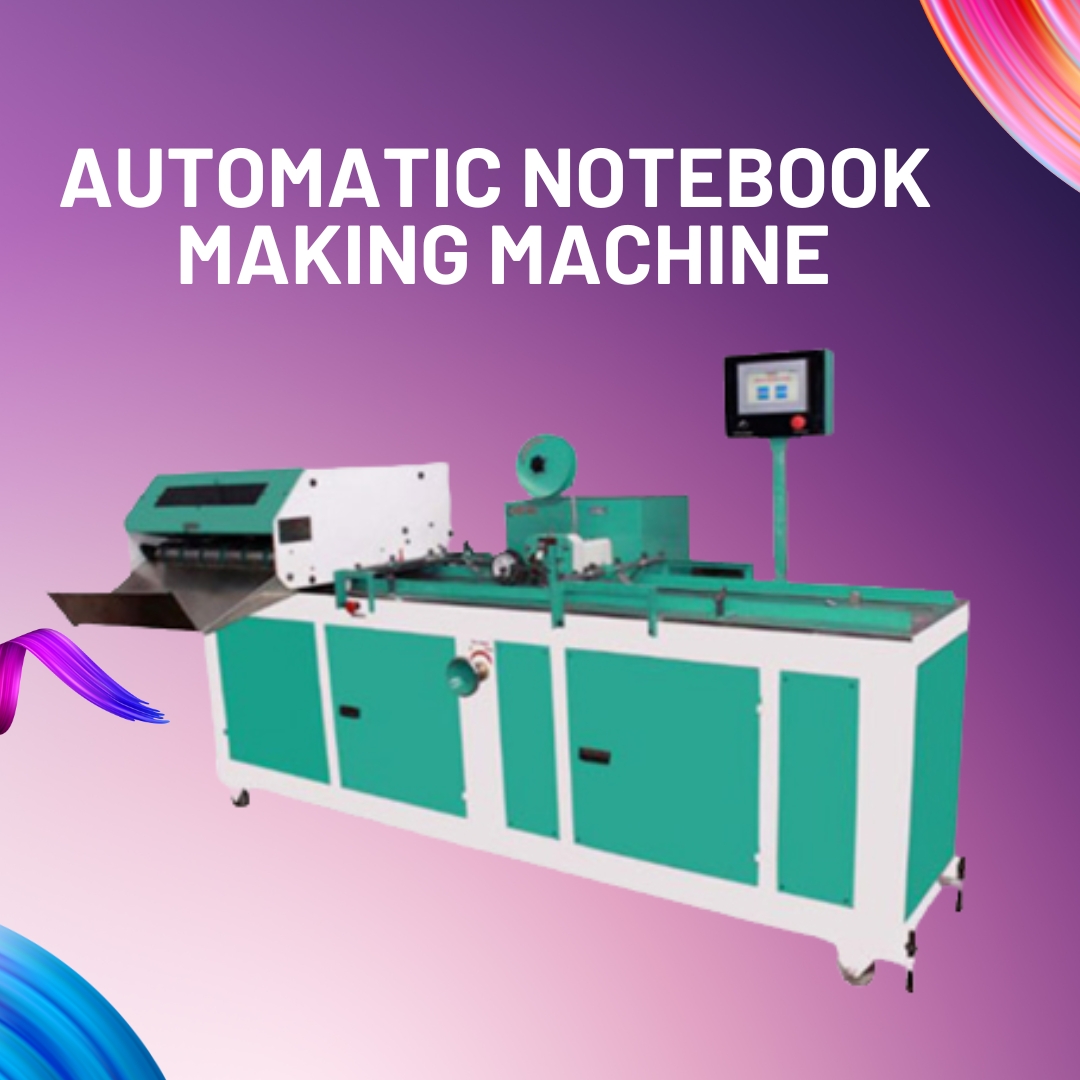

Fully Automatic Notebook Making Unit – Complete Guide to Setup, Machinery, and Profits

Price: ₹50000

Starting a Fully Automatic Notebook Making Unit – Complete Guide for 2025

In today’s digital age, notebooks still remain indispensable tools for students, professionals, businesses, and creative minds. Despite digital gadgets, the stationery market is growing steadily, especially in developing countries like India. This makes notebook manufacturing a profitable business idea for 2025.

If you’re planning to start a fully automatic notebook making unit, this guide will walk you through everything—from machinery and raw materials to investment, profitability, and marketing.

Why Choose a Fully Automatic Notebook Making Unit?

✅ High Production Capacity – Produce thousands of notebooks daily with minimal labor.

✅ Consistency in Quality – Automation ensures error-free cutting, folding, binding, and finishing.

✅ Cost-Effective – Higher upfront investment but reduced long-term labor costs.

✅ Scalability – Suitable for wholesale, retail, and even exports.

✅ Market Demand – Schools, offices, and businesses generate continuous bulk orders.

With automation, you not only save time but also maximize profits, making this setup ideal for entrepreneurs.

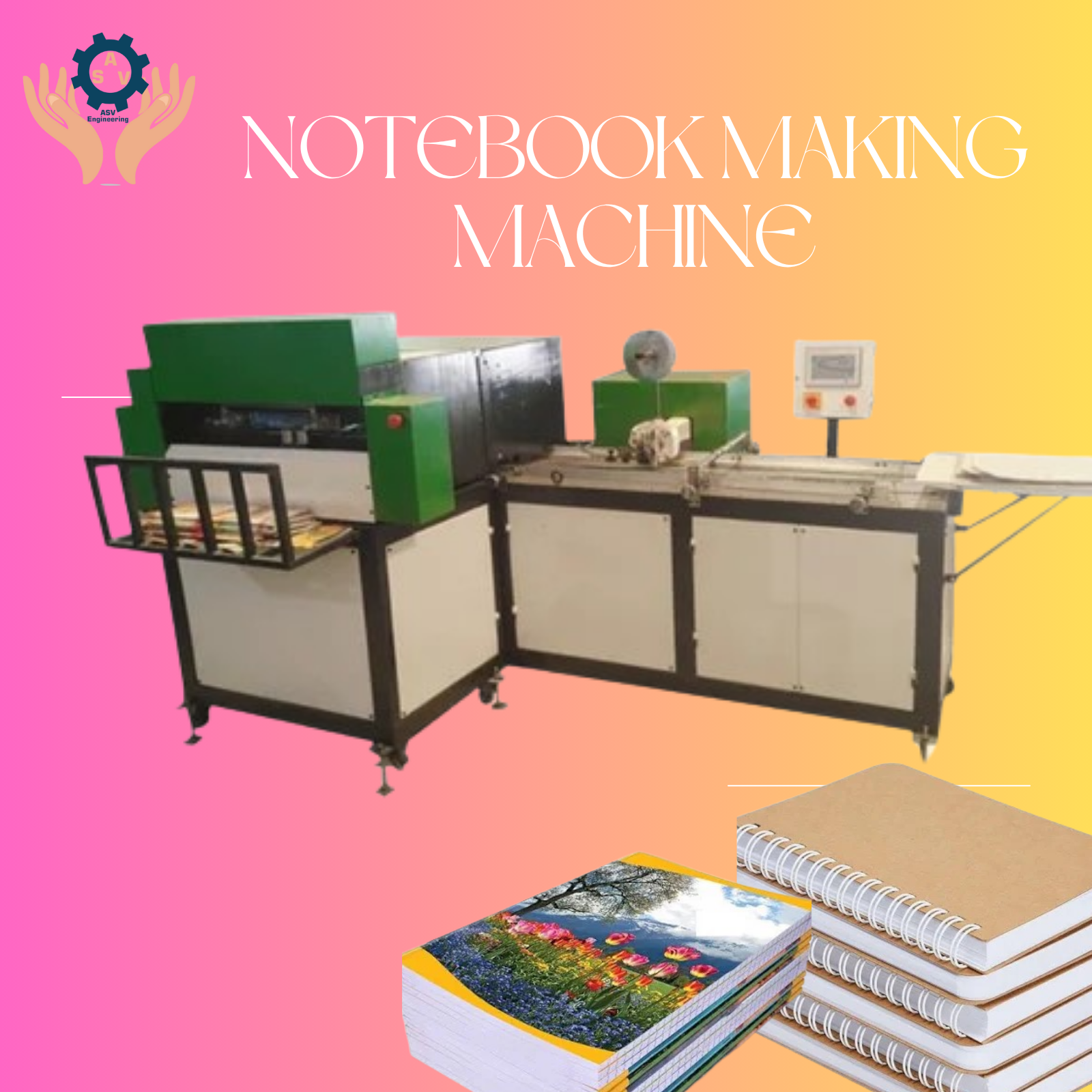

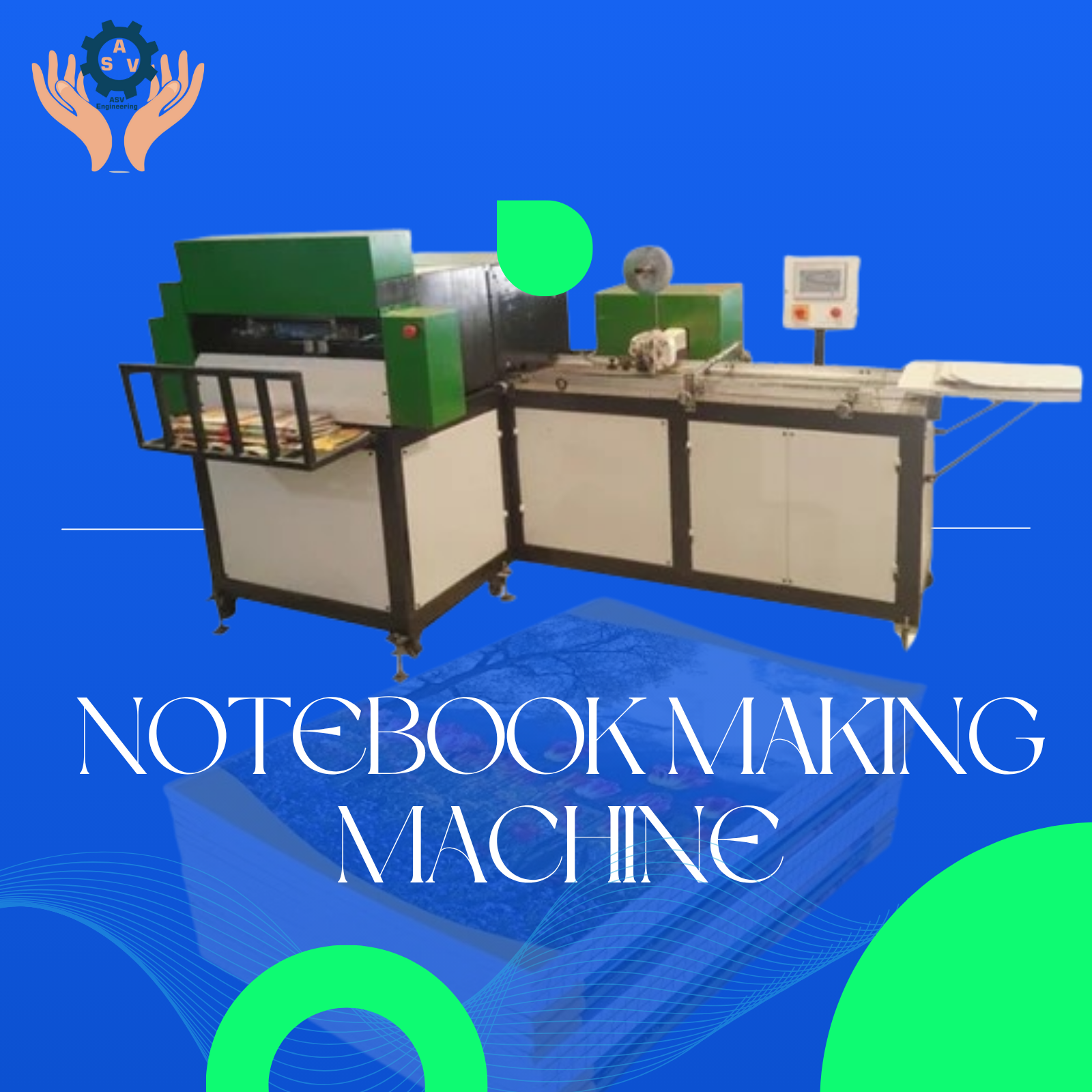

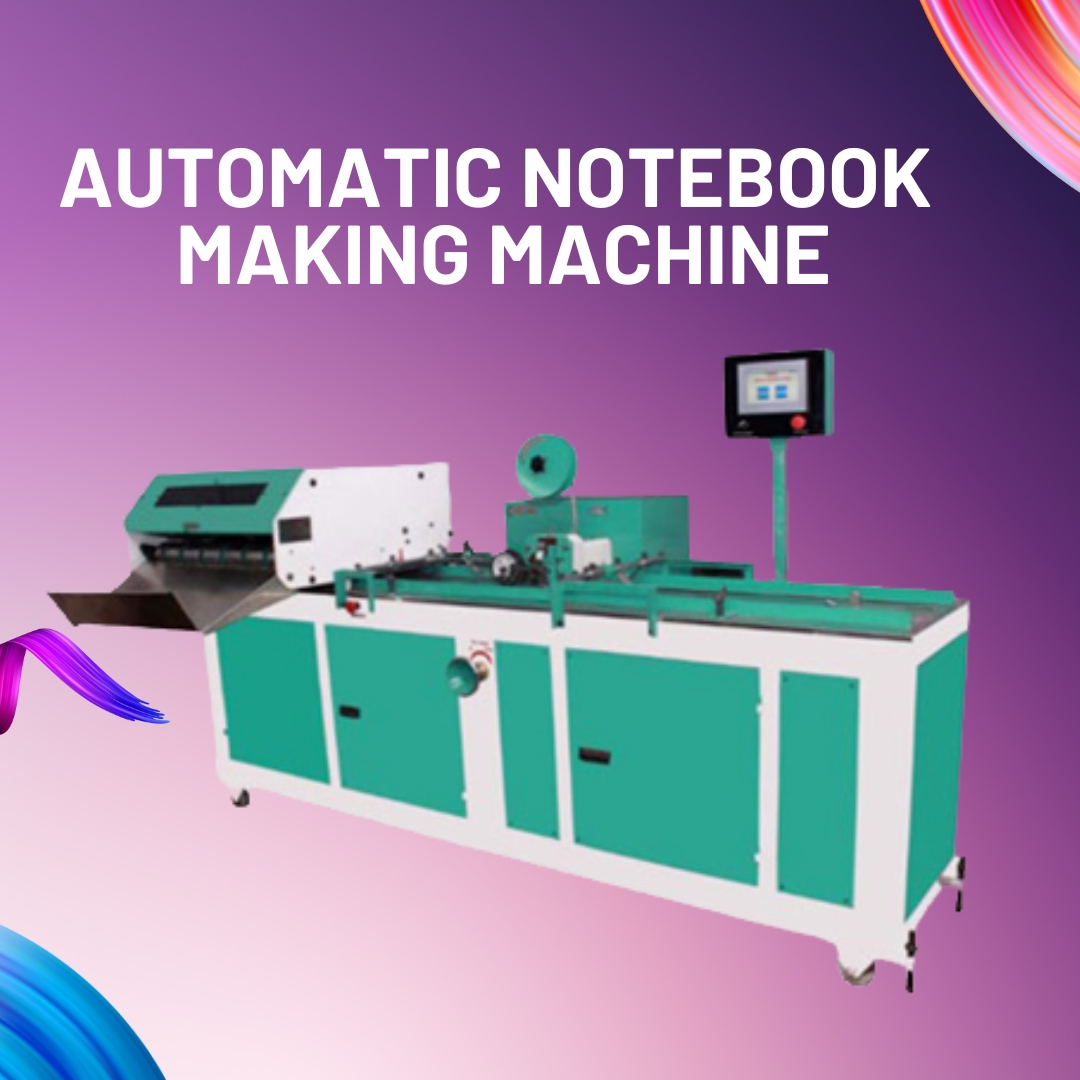

Essential Machinery for a Fully Automatic Notebook Unit

A fully automatic notebook plant requires a combination of machines:

-

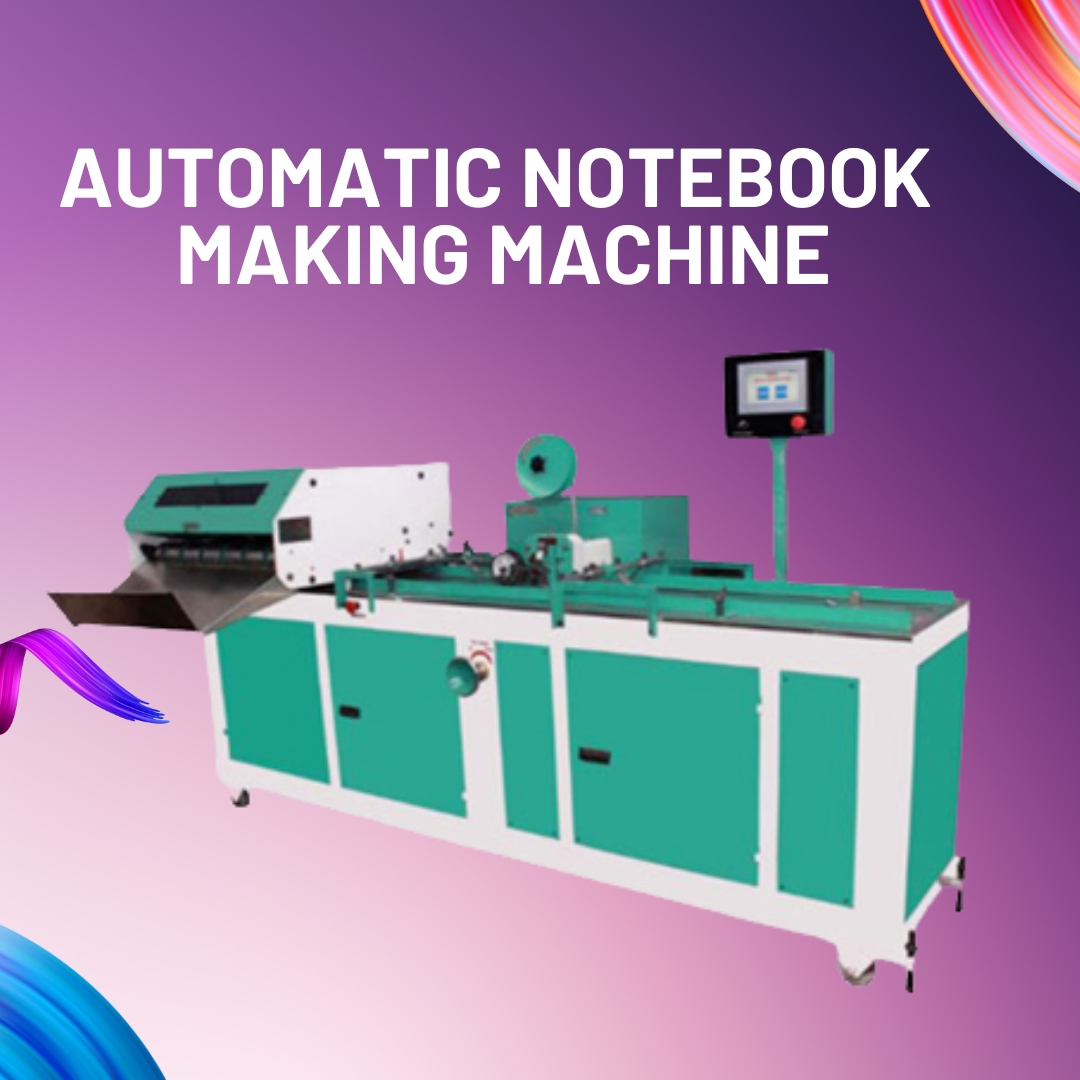

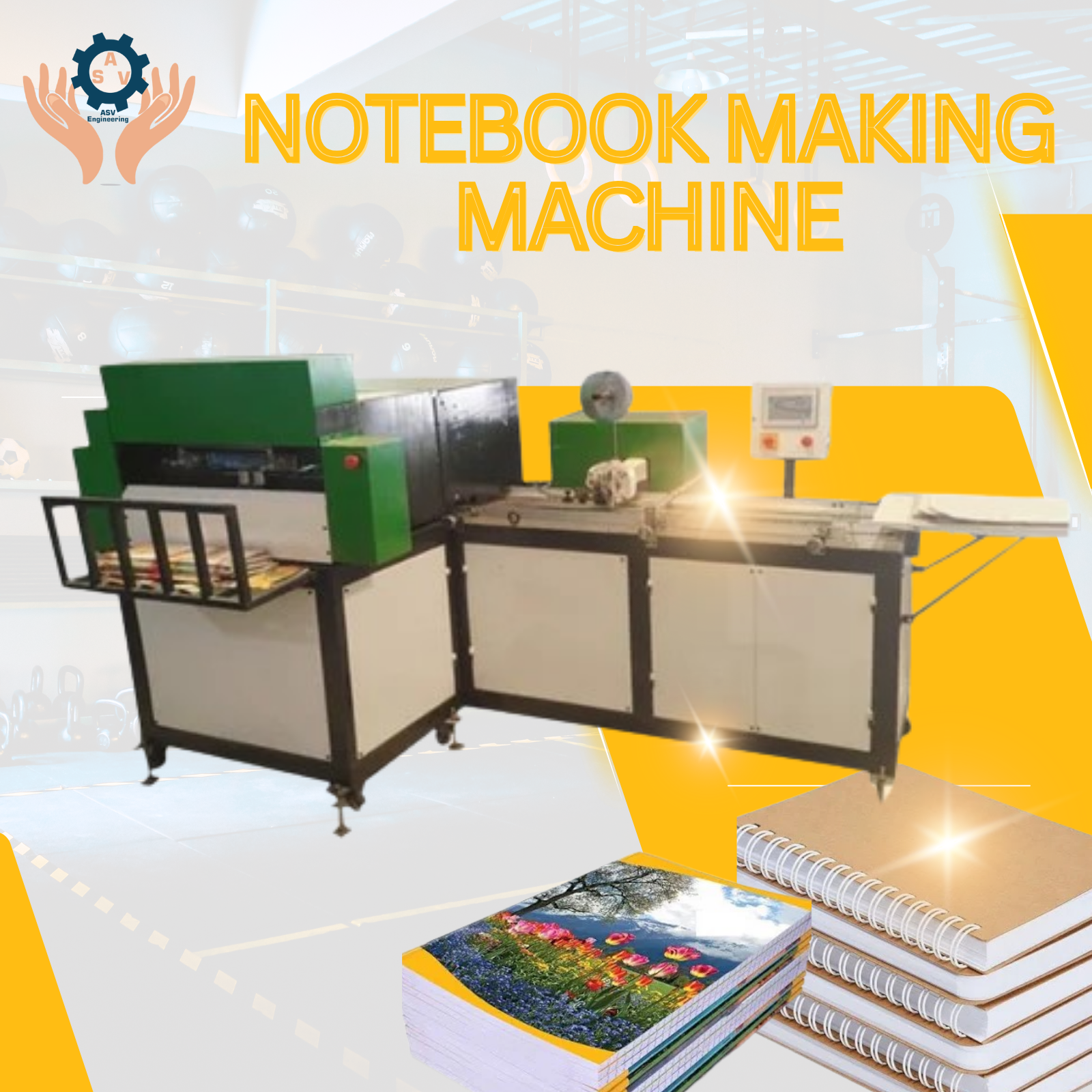

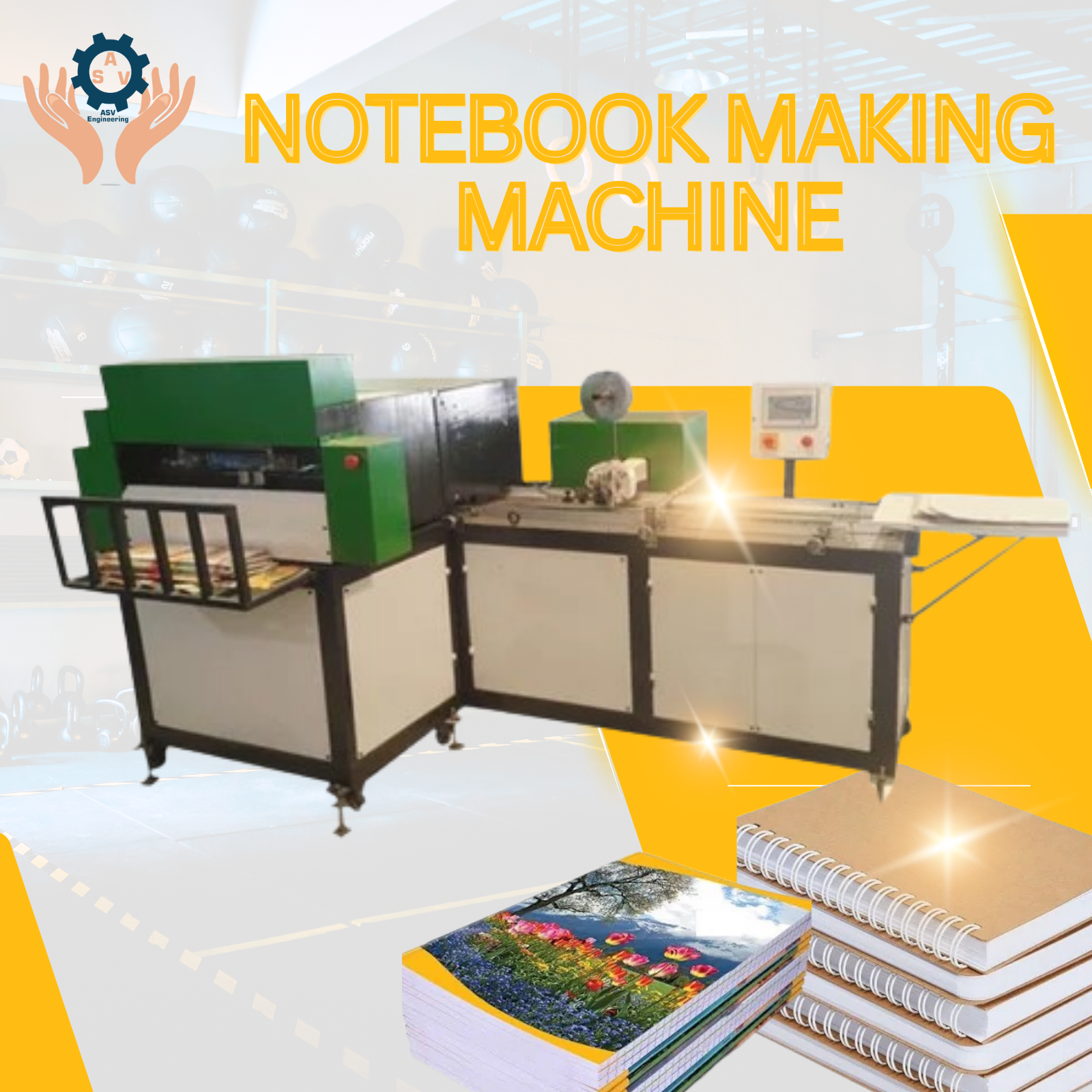

Fully Automatic Notebook Making Machine – Handles folding, ruling, binding, and trimming in one setup.

-

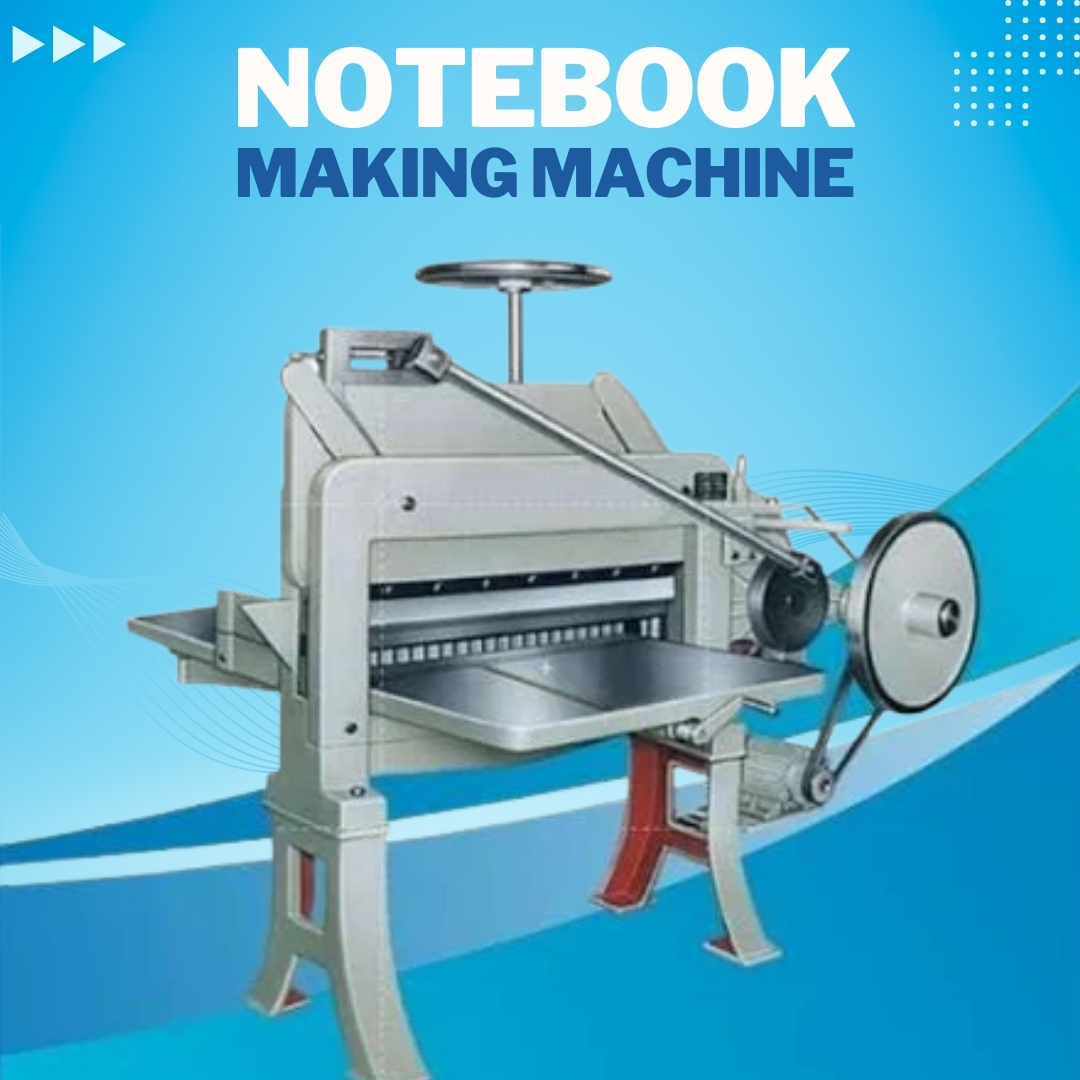

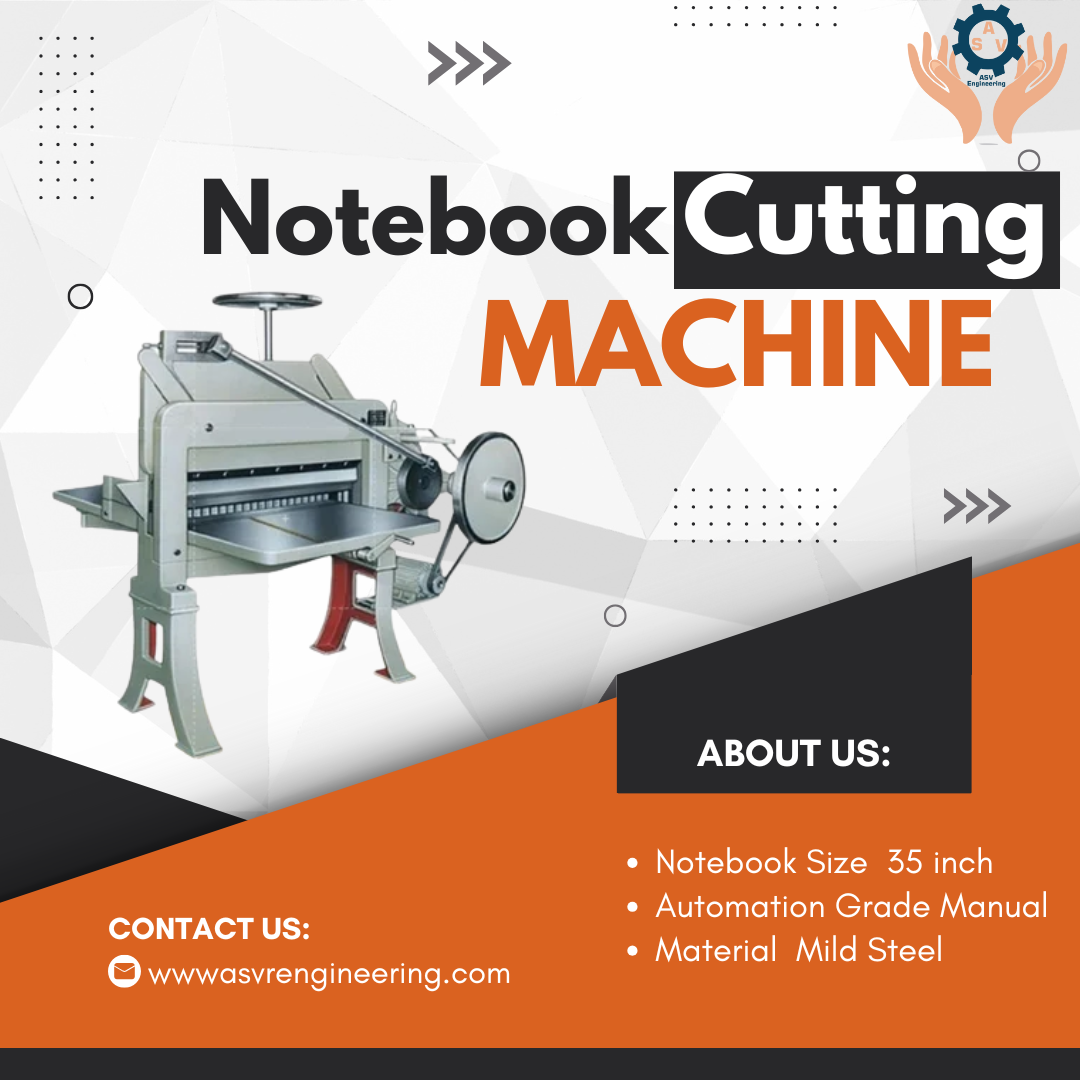

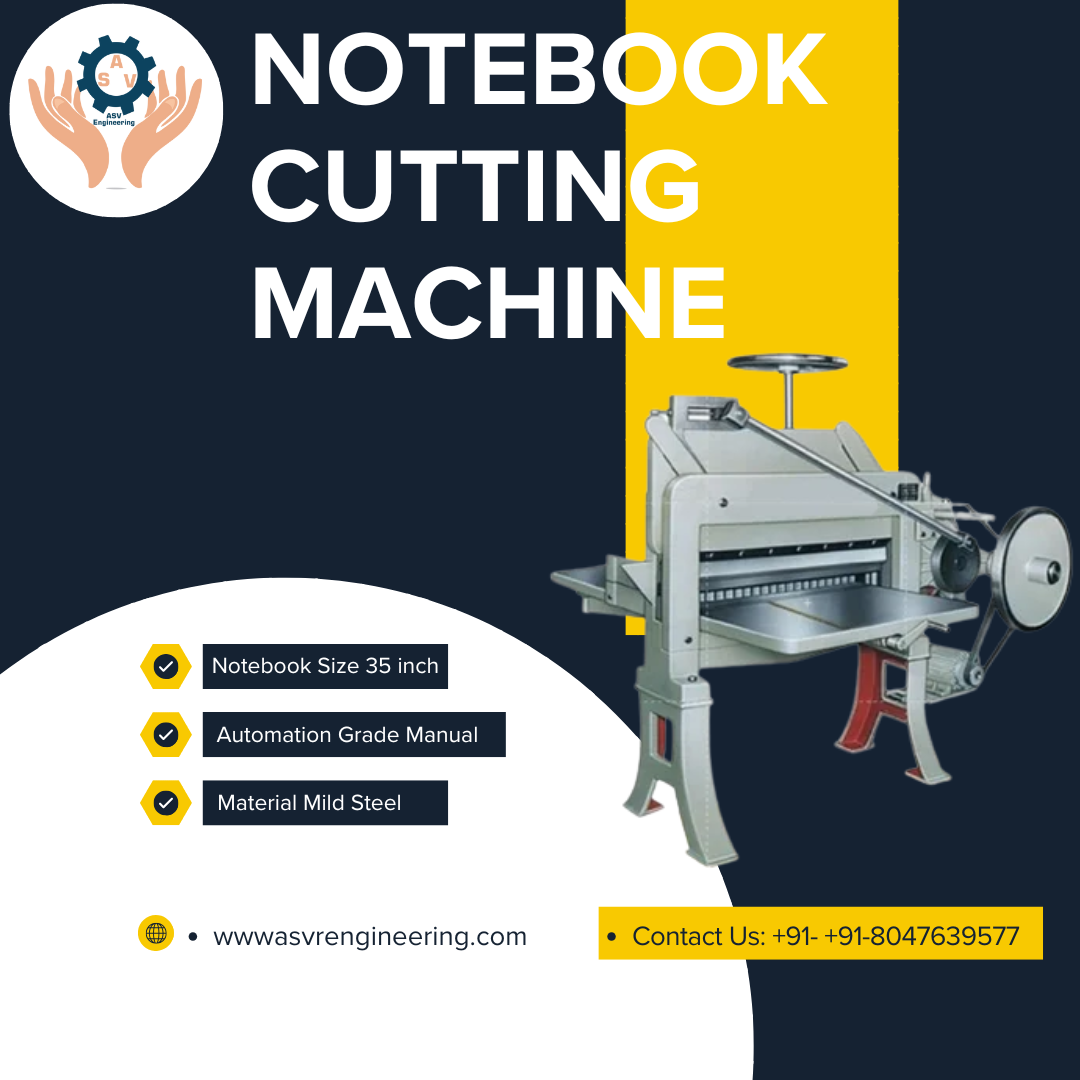

Notebook Cutting Machine (Guillotine Cutter) – Ensures precise paper and cover cutting.

-

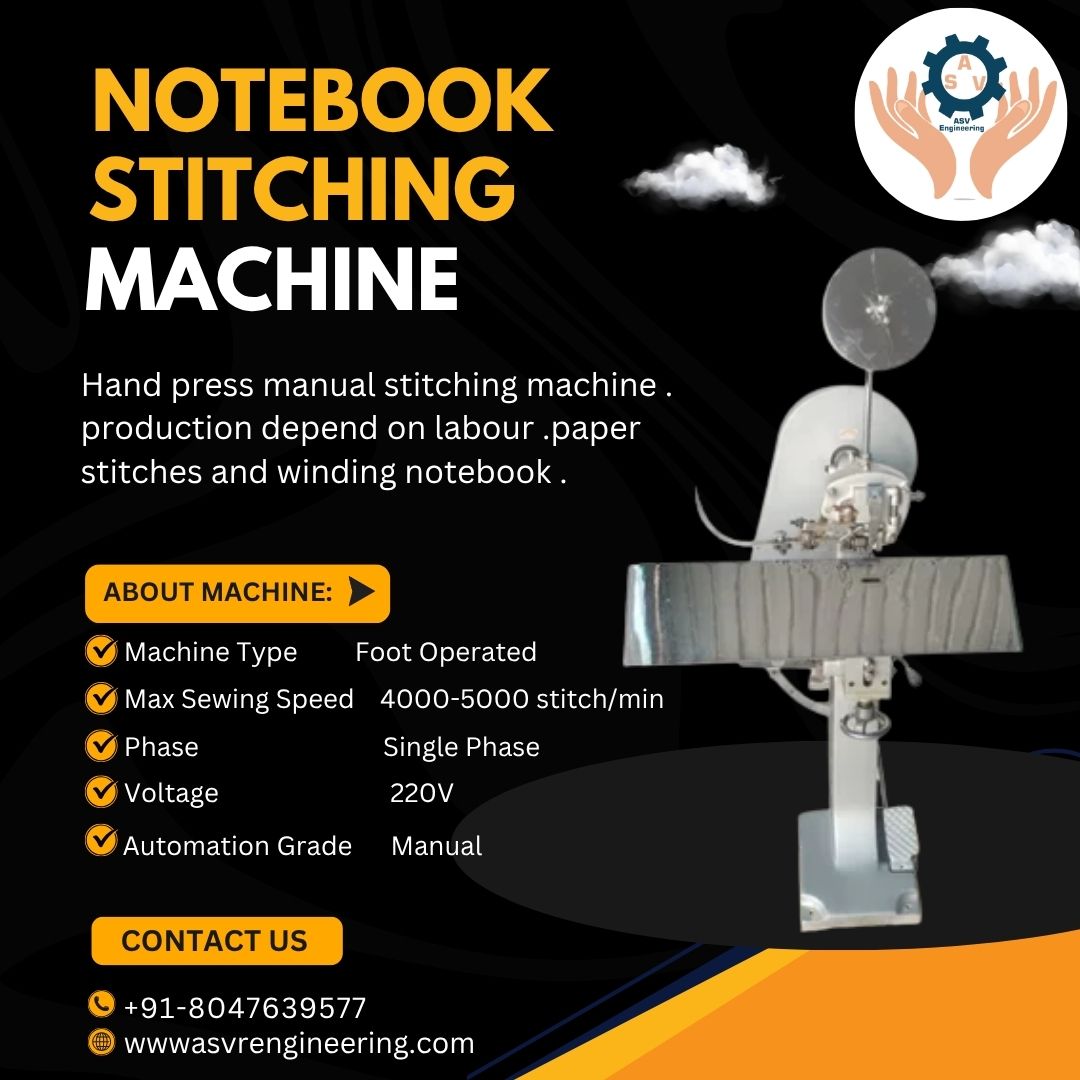

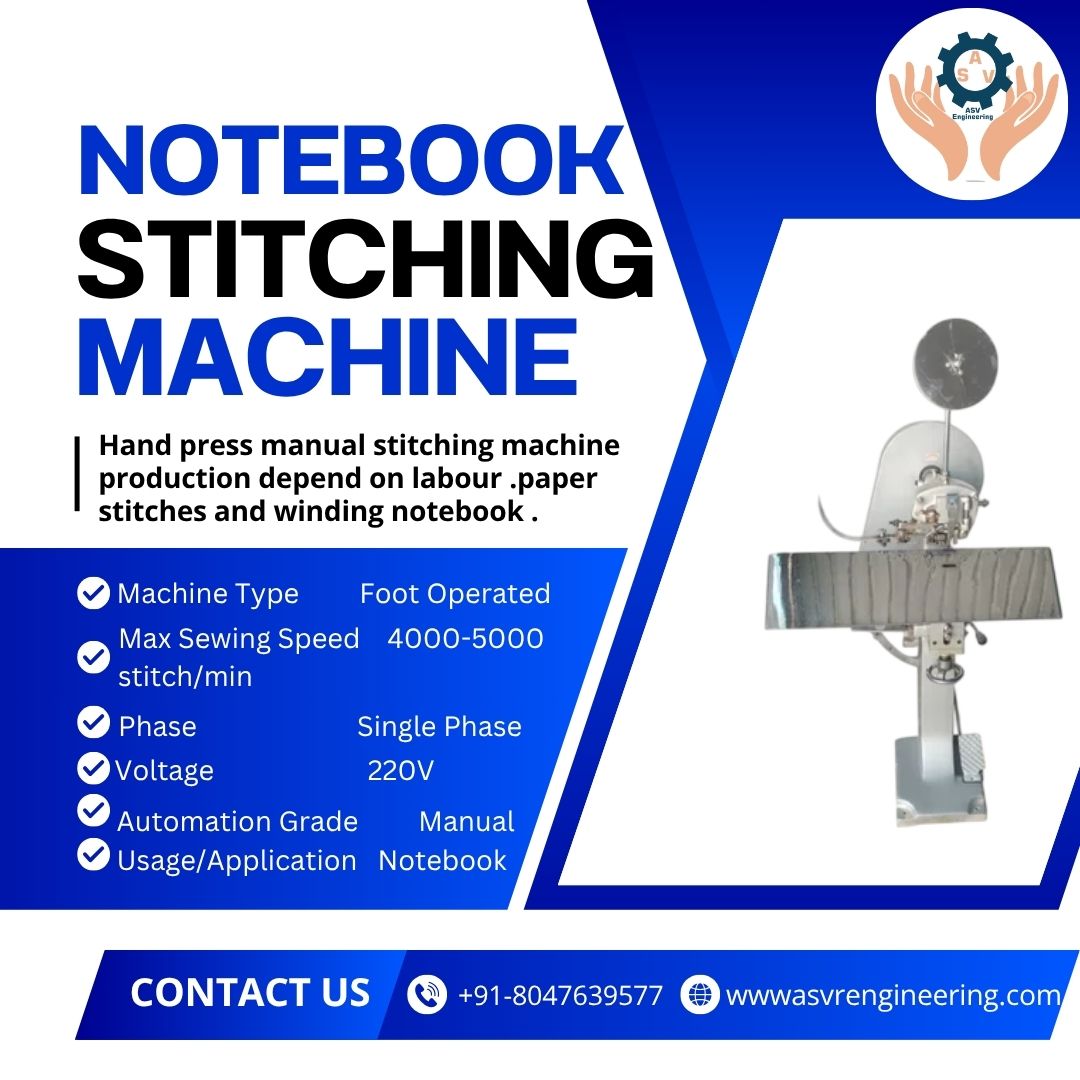

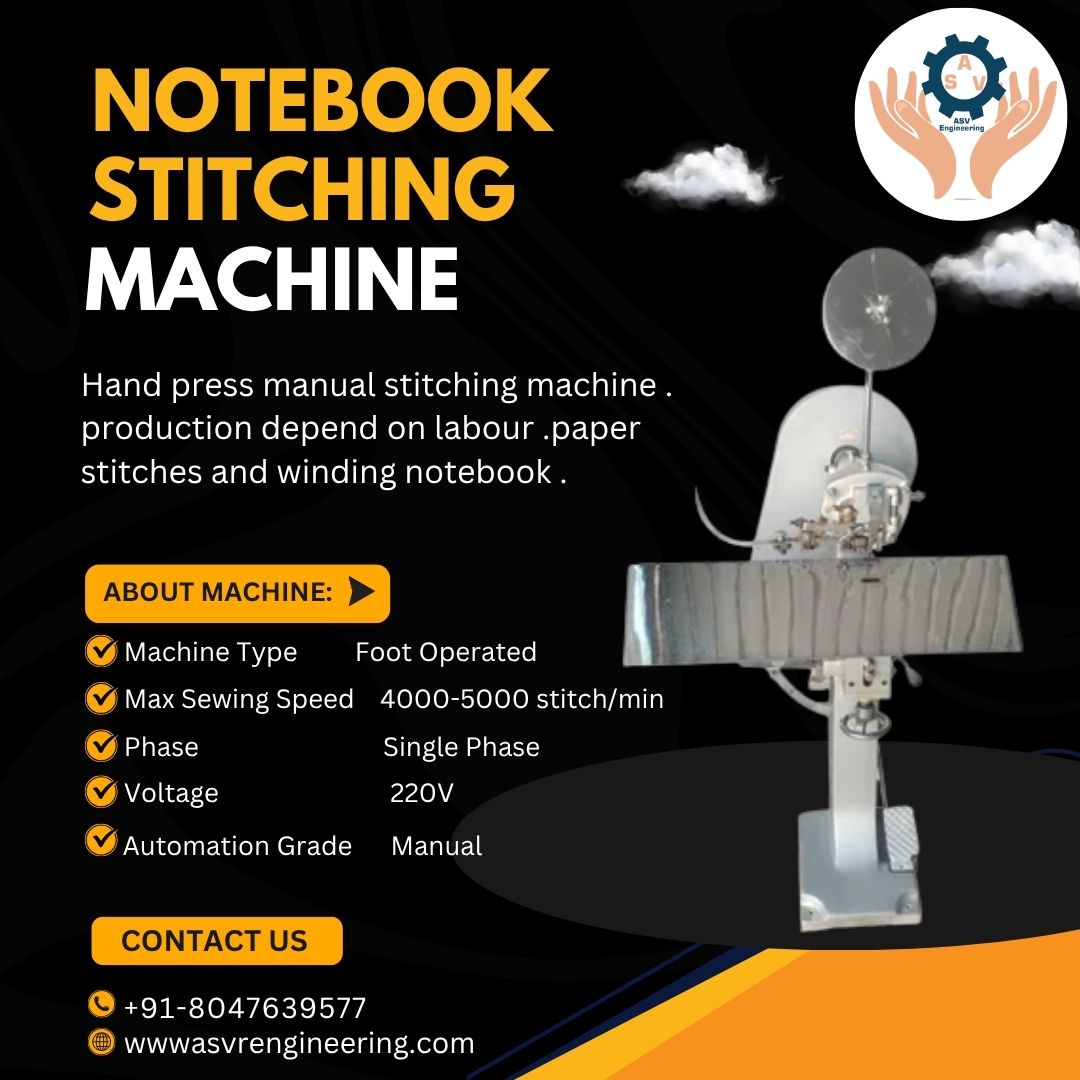

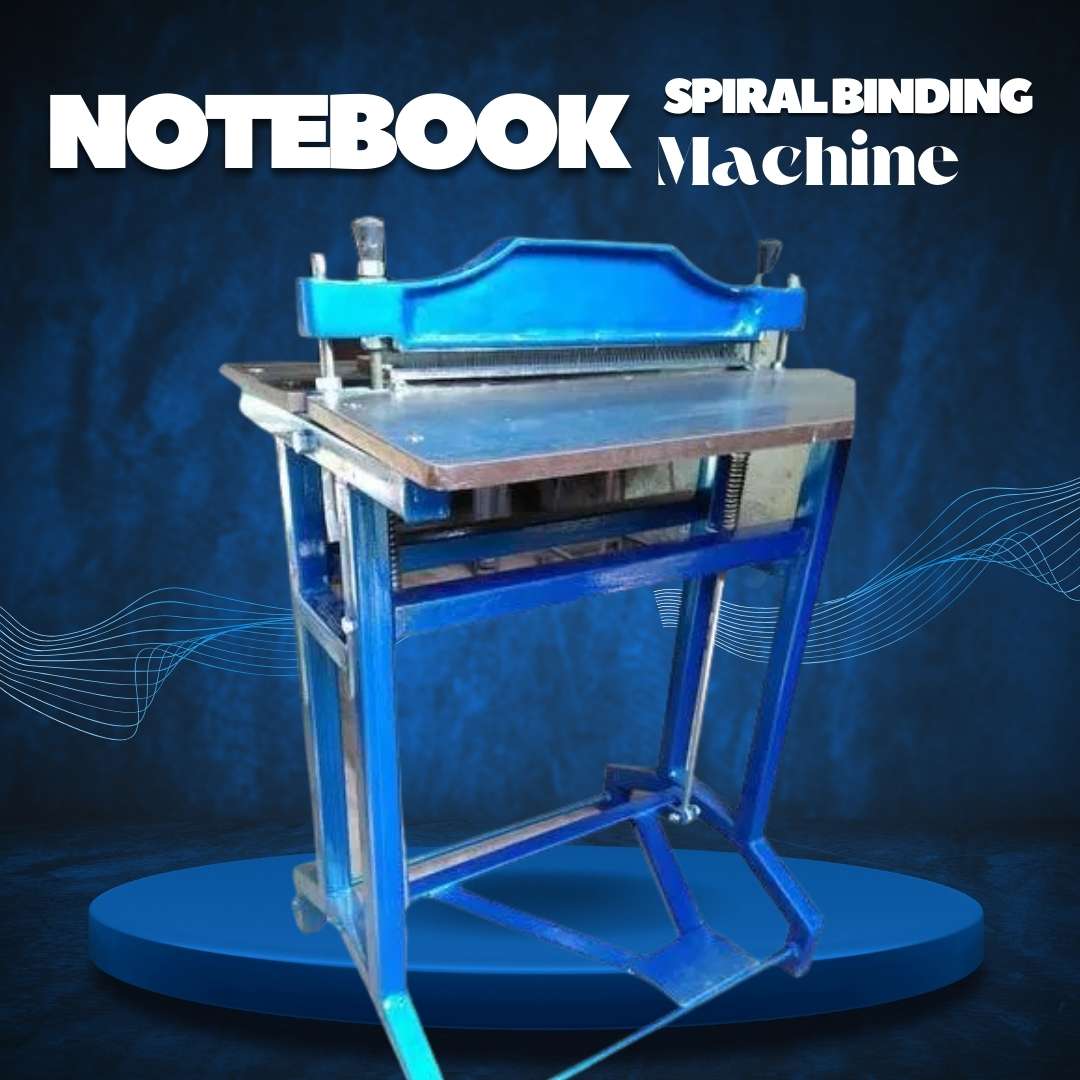

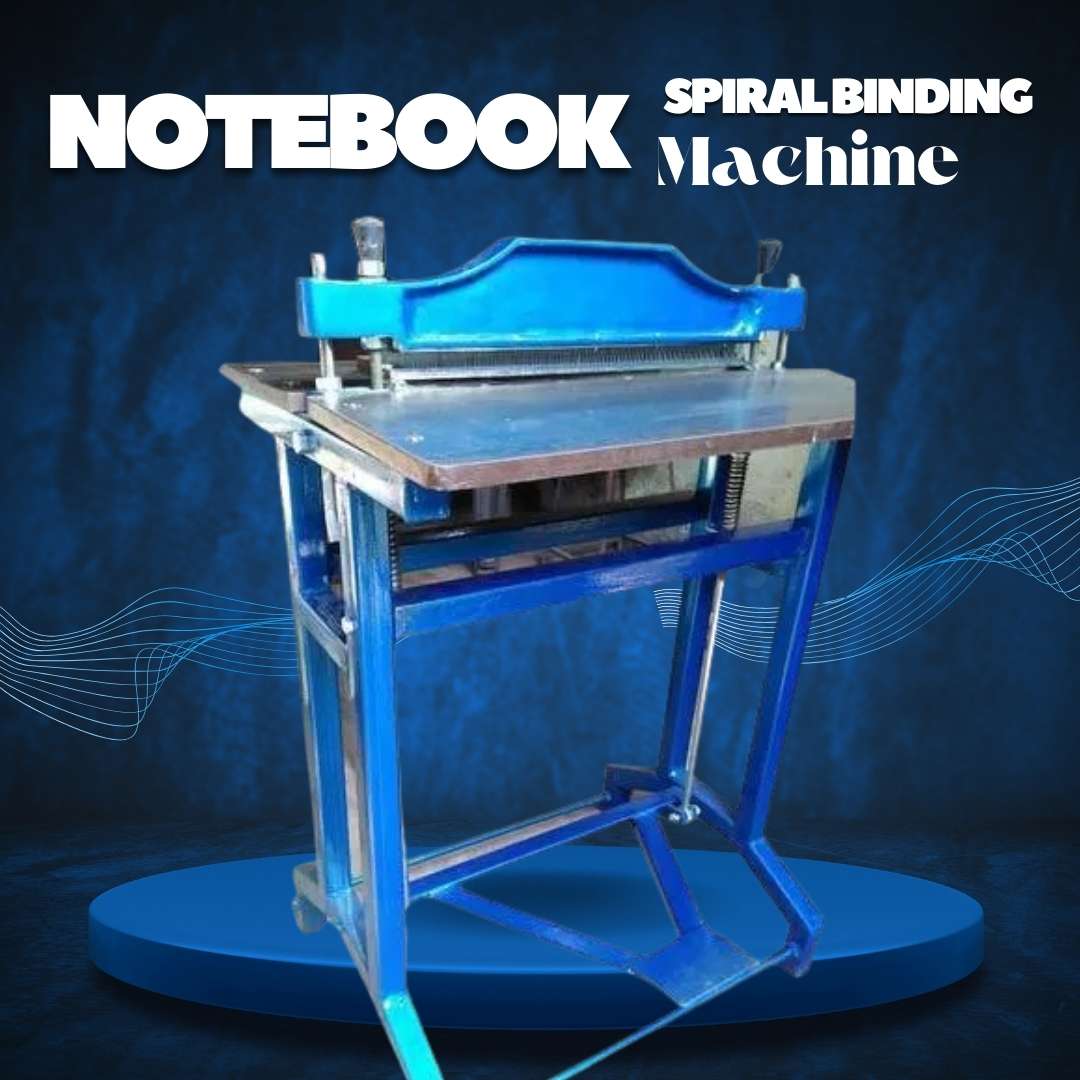

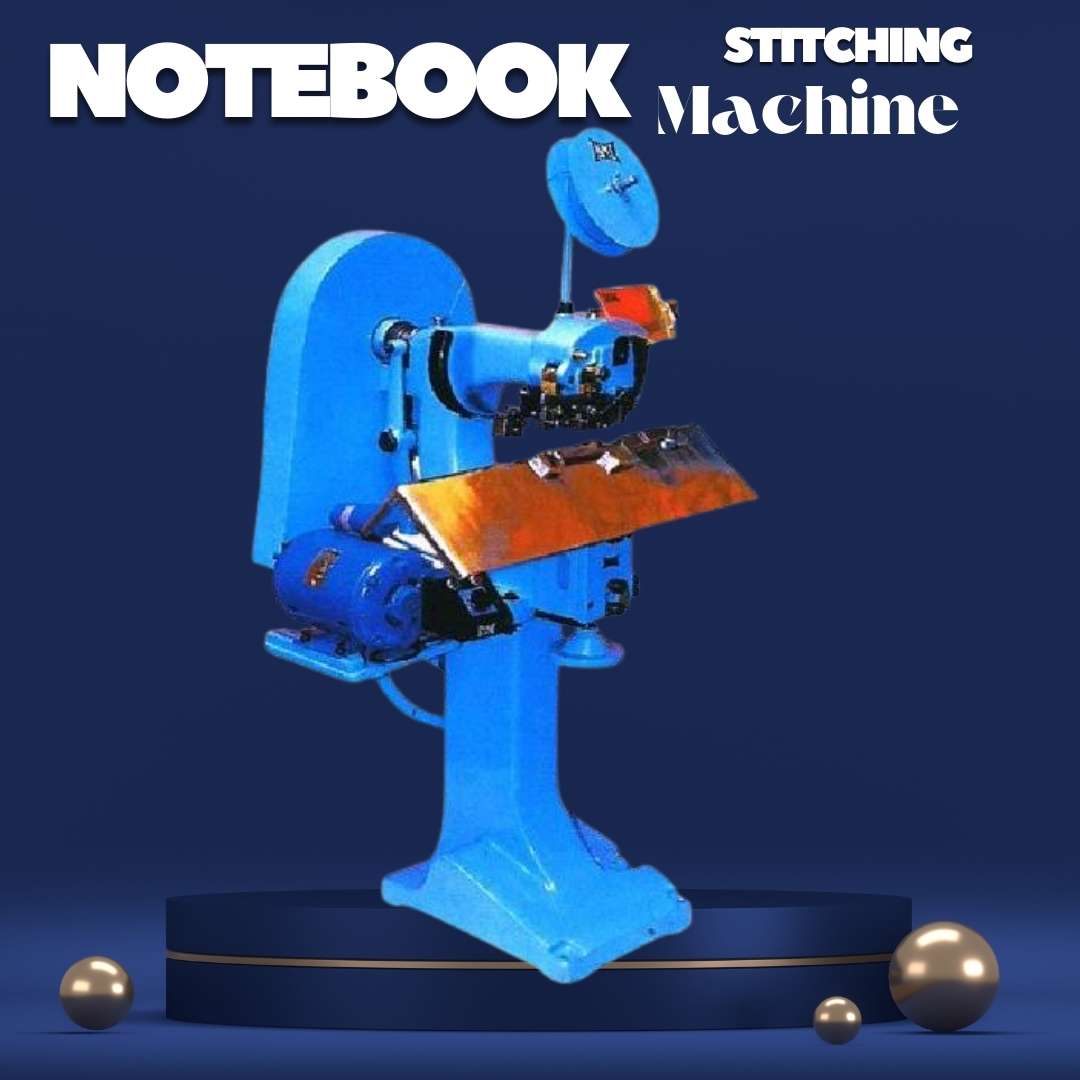

Notebook Binding Machine – For spiral, wire-O, stitching, or perfect binding.

-

Folding & Creasing Machine – Aligns paper sheets neatly.

-

Printing & Ruling Machine – For ruled, grid, or customized page layouts.

-

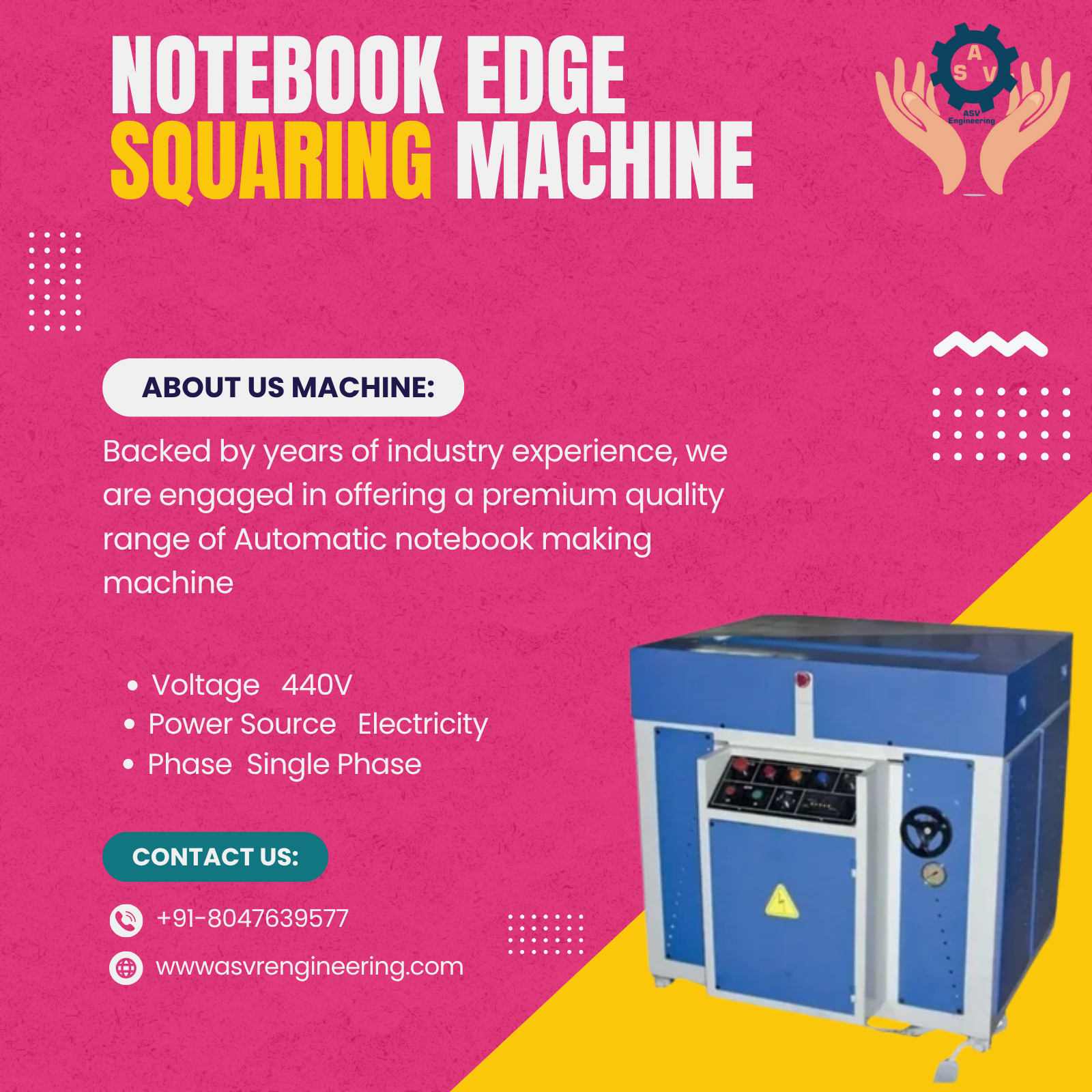

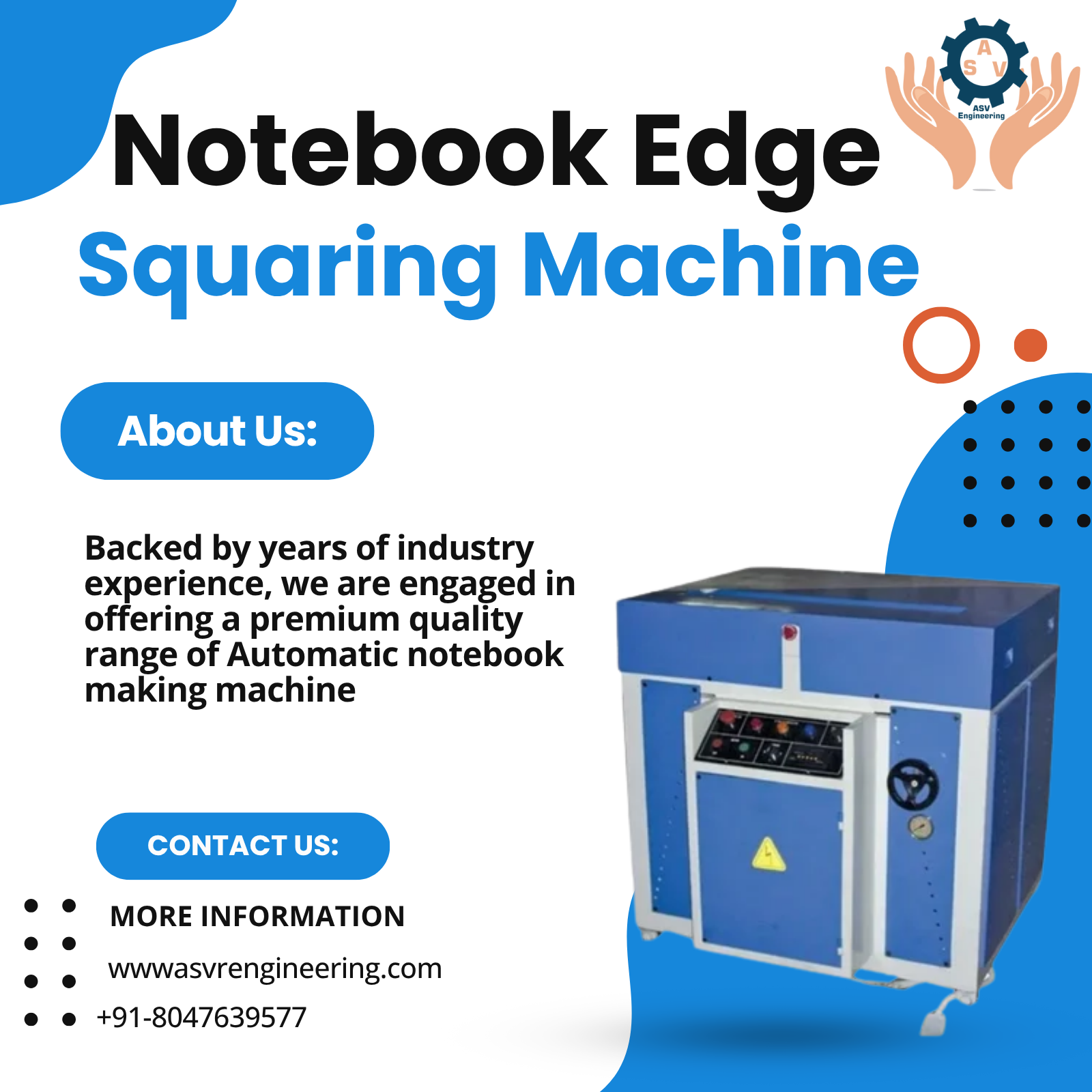

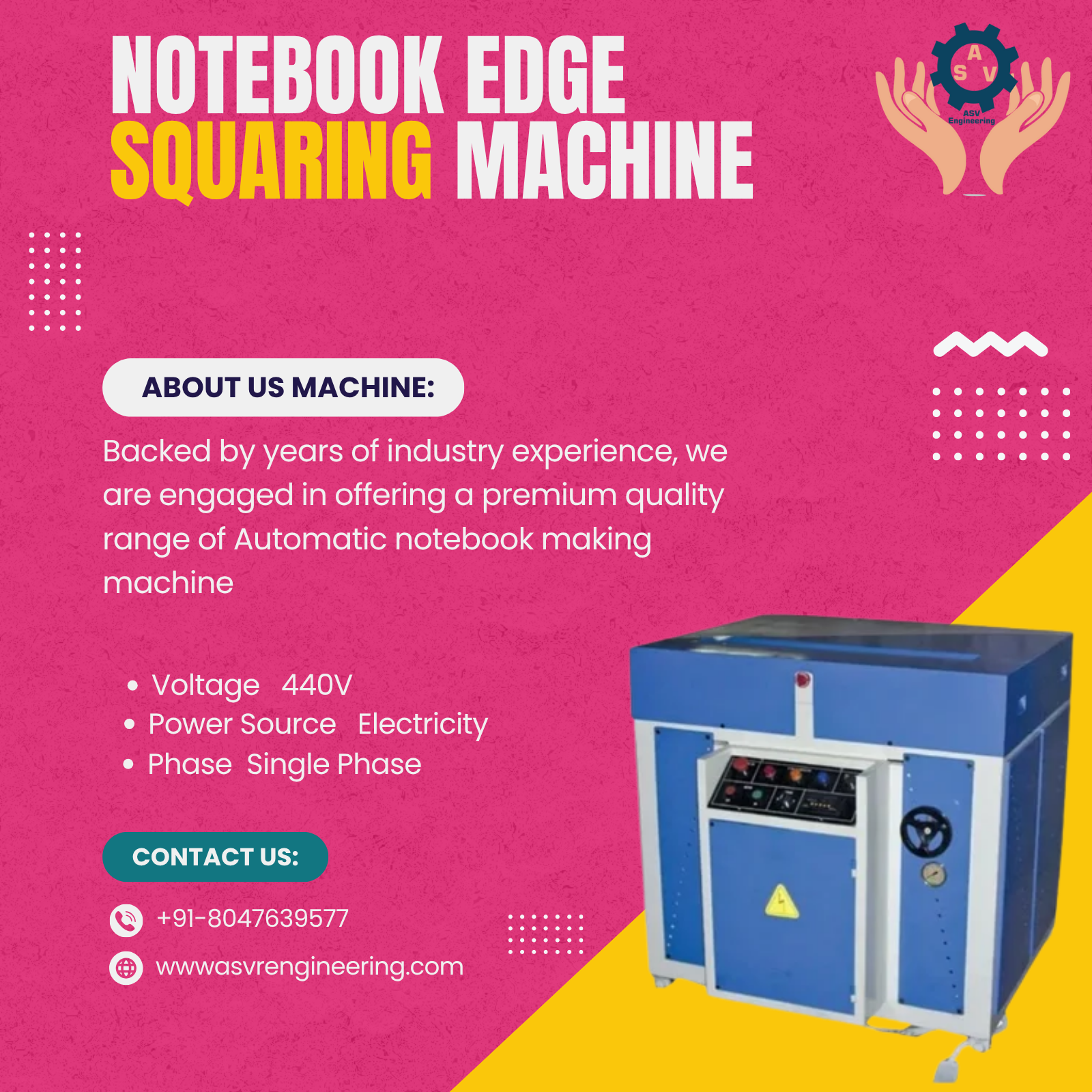

Edge Squaring Machine – Provides sharp notebook edges.

-

Cover Laminating Machine (Optional) – For premium and durable covers.

-

Packaging Machine – For bulk and safe packaging.

👉 A complete plant setup ensures speed, quality, and higher productivity.

Raw Materials Required

To run your unit smoothly, you will need:

-

Paper – Ruled, plain, or grid sheets.

-

Covers – Laminated, printed, or plain cardstock.

-

Binding Material – Spiral wires, stitching thread, or glue.

-

Printing Ink & Consumables – For ruling, logos, and branding.

-

Packaging Materials – Cartons, boxes, shrink wrap.

Notebook Manufacturing Process in a Fully Automatic Unit

-

Paper Cutting & Printing – Sheets cut to size and ruled/printed.

-

Folding & Collating – Pages folded and arranged.

-

Cover Preparation – Printed & laminated covers prepared.

-

Binding – Spiral, stitching, or perfect binding applied.

-

Trimming & Squaring – Edges cut neatly.

-

Branding & Packaging – Logo added and notebooks packed for supply.

Investment & Cost Estimation

-

Fully Automatic Notebook Machine – ₹15,00,000 – ₹30,00,000

-

Additional Machinery – ₹5,00,000 – ₹10,00,000

-

Raw Materials (Initial Stock) – ₹2,00,000 – ₹5,00,000

👉 Total Investment: ₹20,00,000 – ₹40,00,000 approx.

Profit Margin in Notebook Manufacturing

-

Cost per Notebook: ₹8 – ₹12

-

Selling Price: ₹15 – ₹40

-

Profit Margin: 30% – 50%

-

Monthly Earnings (Medium Unit): ₹2,00,000 – ₹5,00,000

With bulk school orders, corporate branding, and exports, profits can be even higher.

Popular Binding Styles in Fully Automatic Units

📌 Spiral Binding – Affordable, flexible, and widely used.

📌 Wire-O Binding – Premium, professional look.

📌 Perfect Binding – Clean finish, used in diaries & corporate notebooks.

📌 Center Stitching – Common for school exercise books.

Marketing & Sales Channels

-

Wholesale & Retail Supply – Target stationery shops, schools, and book distributors.

-

Corporate Branding – Offer customized notebooks for businesses.

-

E-commerce Sales – Sell via Amazon, Flipkart, or your own website.

-

Export Market – Rising global demand for eco-friendly notebooks.

Pro Tips for Success

✅ Use eco-friendly paper to attract eco-conscious buyers.

✅ Create a unique brand identity with attractive covers.

✅ Start with a niche – school notebooks, designer journals, or office supplies.

✅ Upgrade machinery regularly for better productivity.

Final Words

A fully automatic notebook making unit is one of the most profitable and future-ready businesses in the stationery industry. With automation, you can achieve higher production, better quality, and consistent profits.

If you are serious about starting, connect with trusted notebook making machine suppliers, calculate your investment smartly, and enter this evergreen market with confidence.

Buy Now

.jpg)