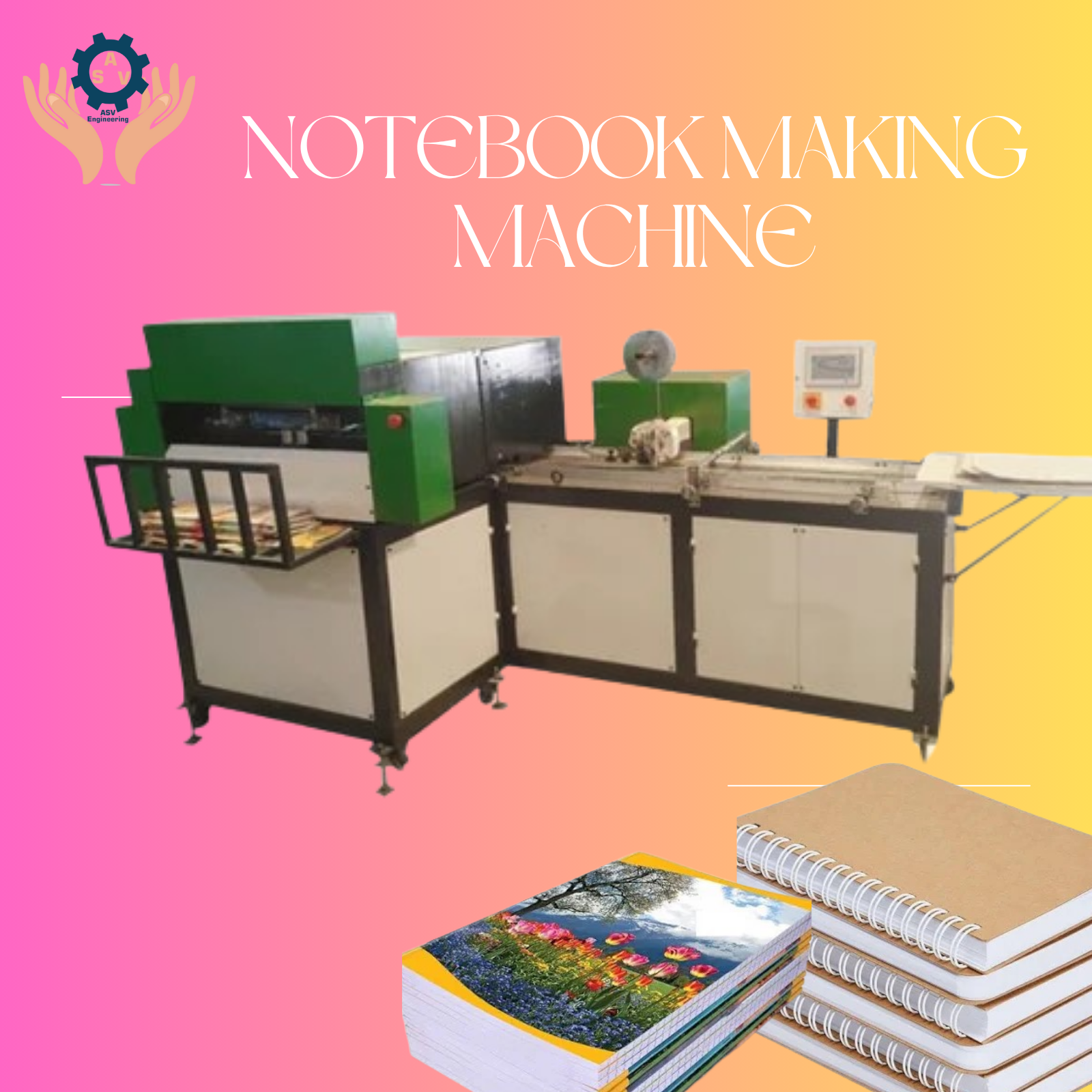

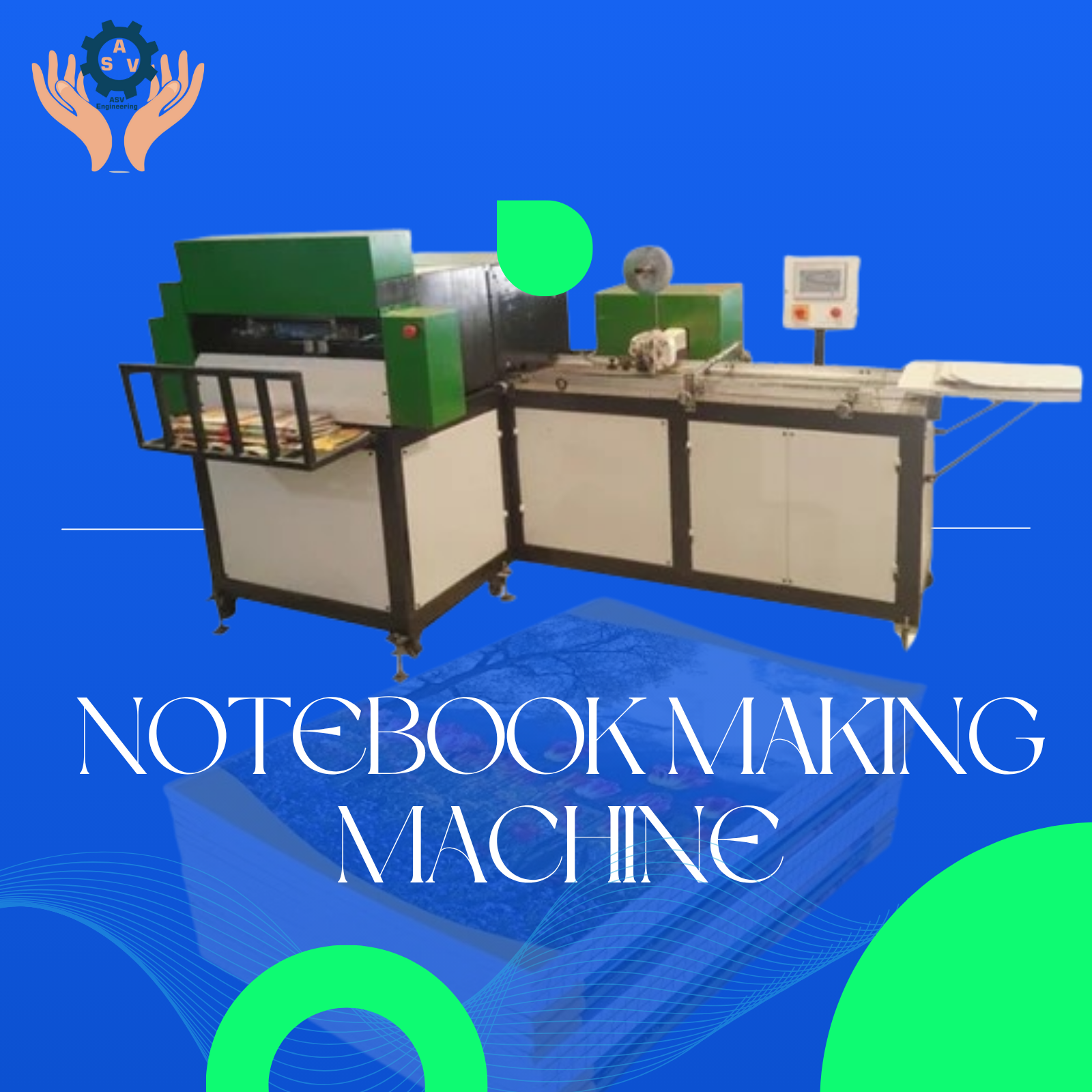

Notebook Cutting and Binding Machines: Complete Guide for Small & Large Scale Production

Price: ₹50000

Notebook Cutting and Binding Machines: Complete Guide for Small & Large Scale Production

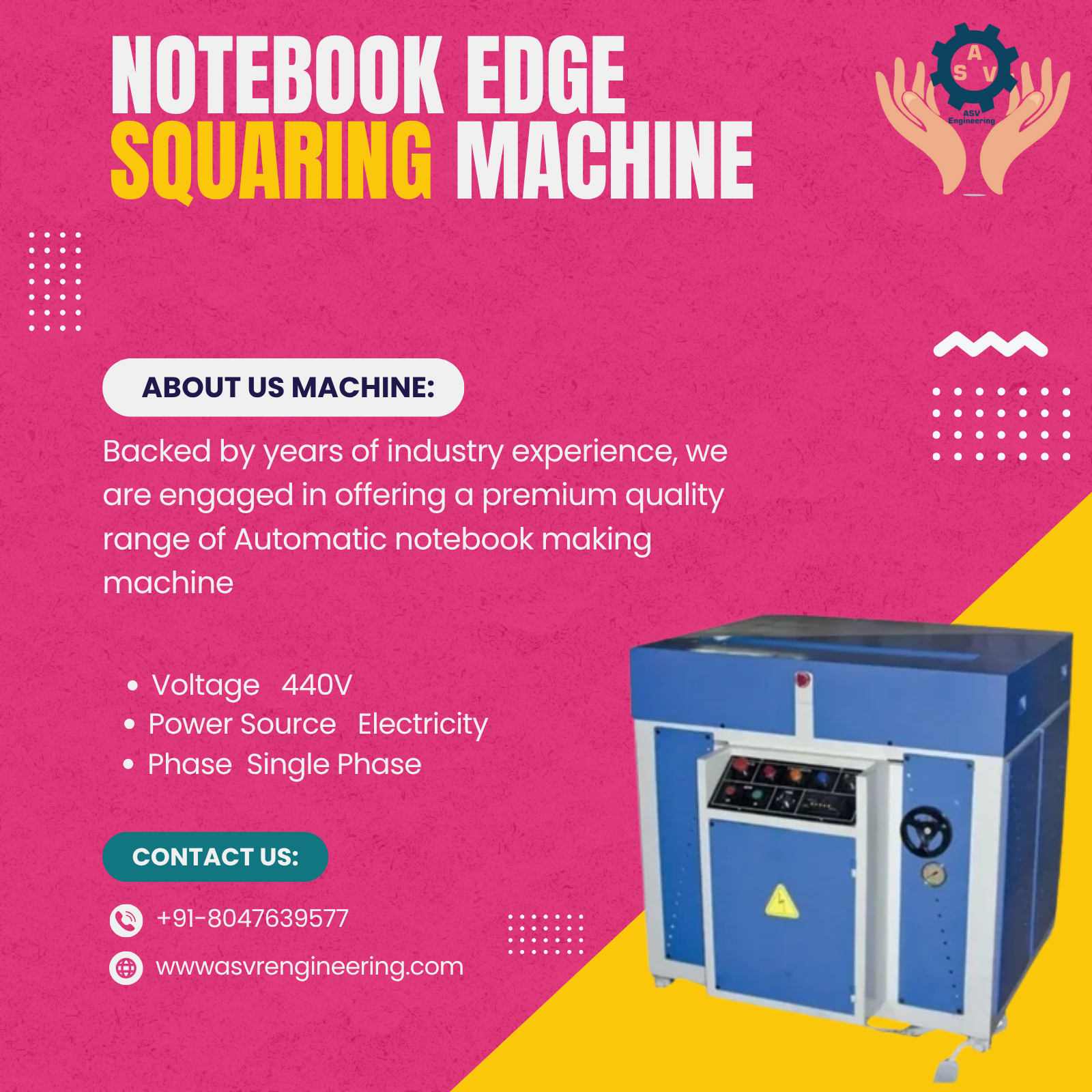

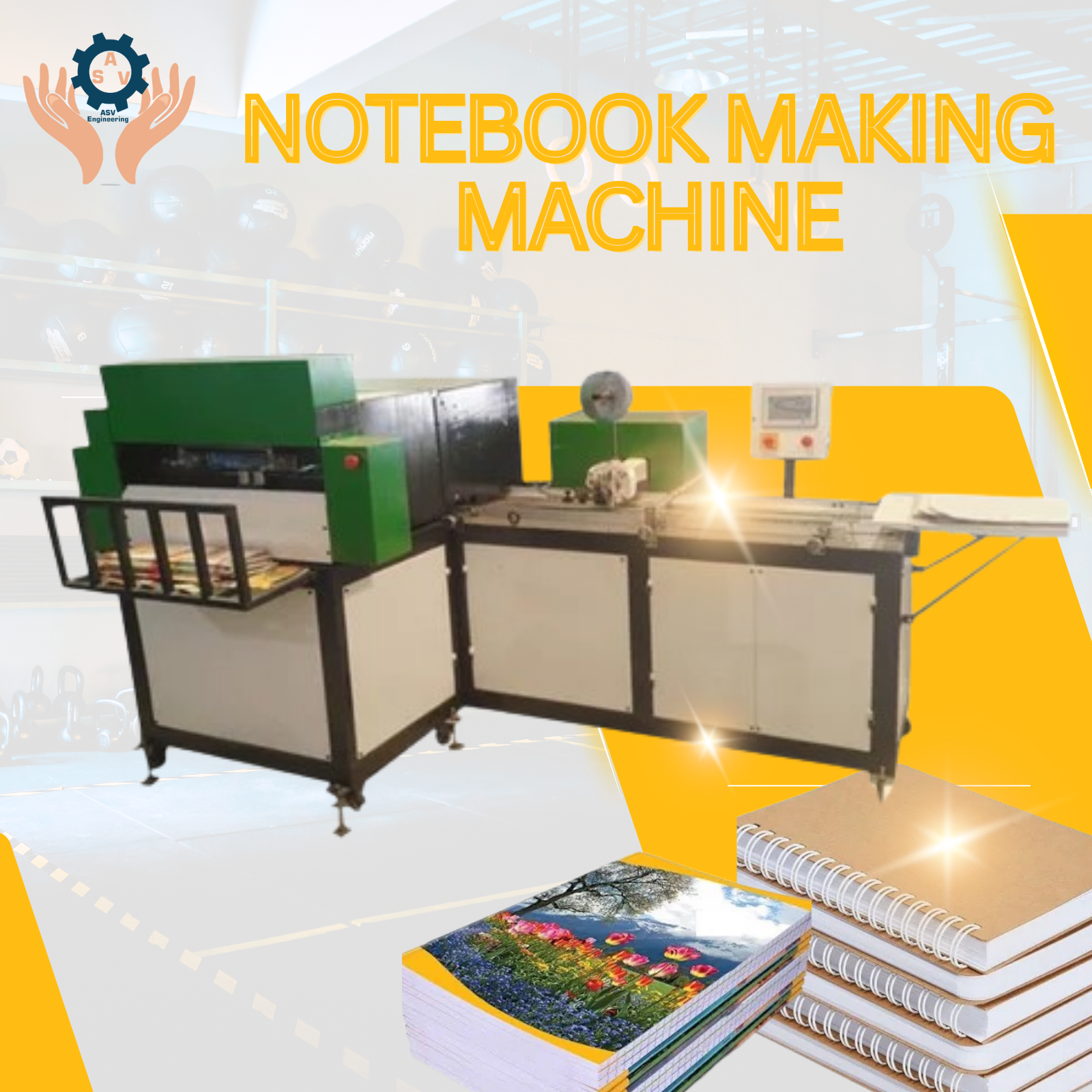

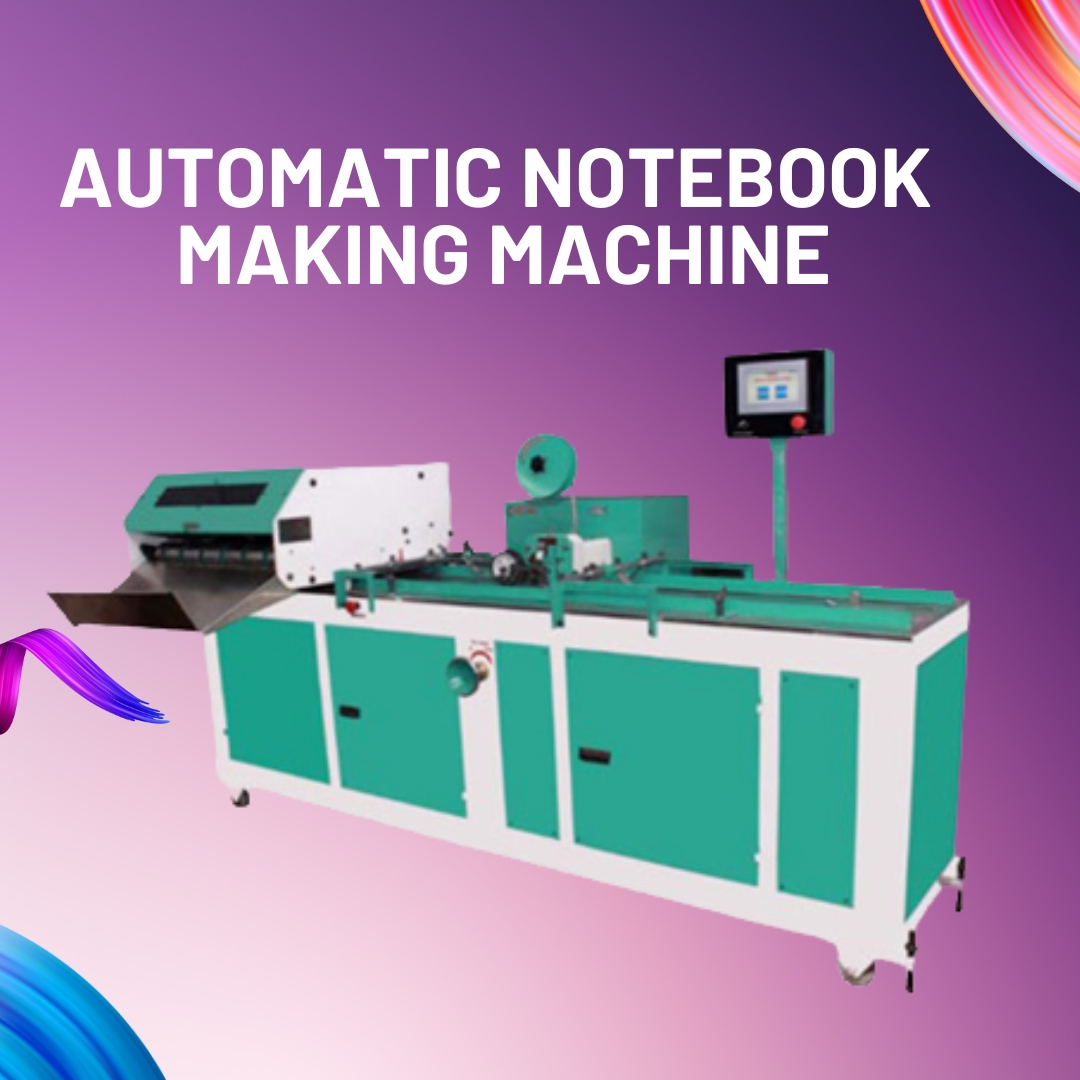

The demand for notebooks never goes out of style. From schools and colleges to offices and personal journaling, notebooks remain an essential part of daily life. For entrepreneurs entering the stationery industry, notebook cutting and binding machines play a crucial role in ensuring high-quality production and efficiency.

Whether you are planning a small-scale notebook making unit or a fully automated notebook production line, investing in the right cutting and binding machinery will determine your speed, cost-efficiency, and product quality.

In this detailed guide, we’ll explore the types, uses, process, advantages, and costs of notebook cutting and binding machines.

🔹 What is a Notebook Cutting and Binding Machine?

A notebook cutting and binding machine is specialized equipment designed to cut large sheets of paper into notebook-sized pages and bind them into finished notebooks using different binding methods.

It combines two essential stages of notebook production:

-

Cutting – Large reams of paper are trimmed into required notebook sizes (A4, A5, etc.) using precision cutting machines.

-

Binding – Pages are assembled and secured with spiral binding, wire-o binding, perfect binding, or stitching.

This integration helps notebook manufacturers save time, reduce manual labor, and maintain product consistency.

🔹 Types of Notebook Cutting Machines

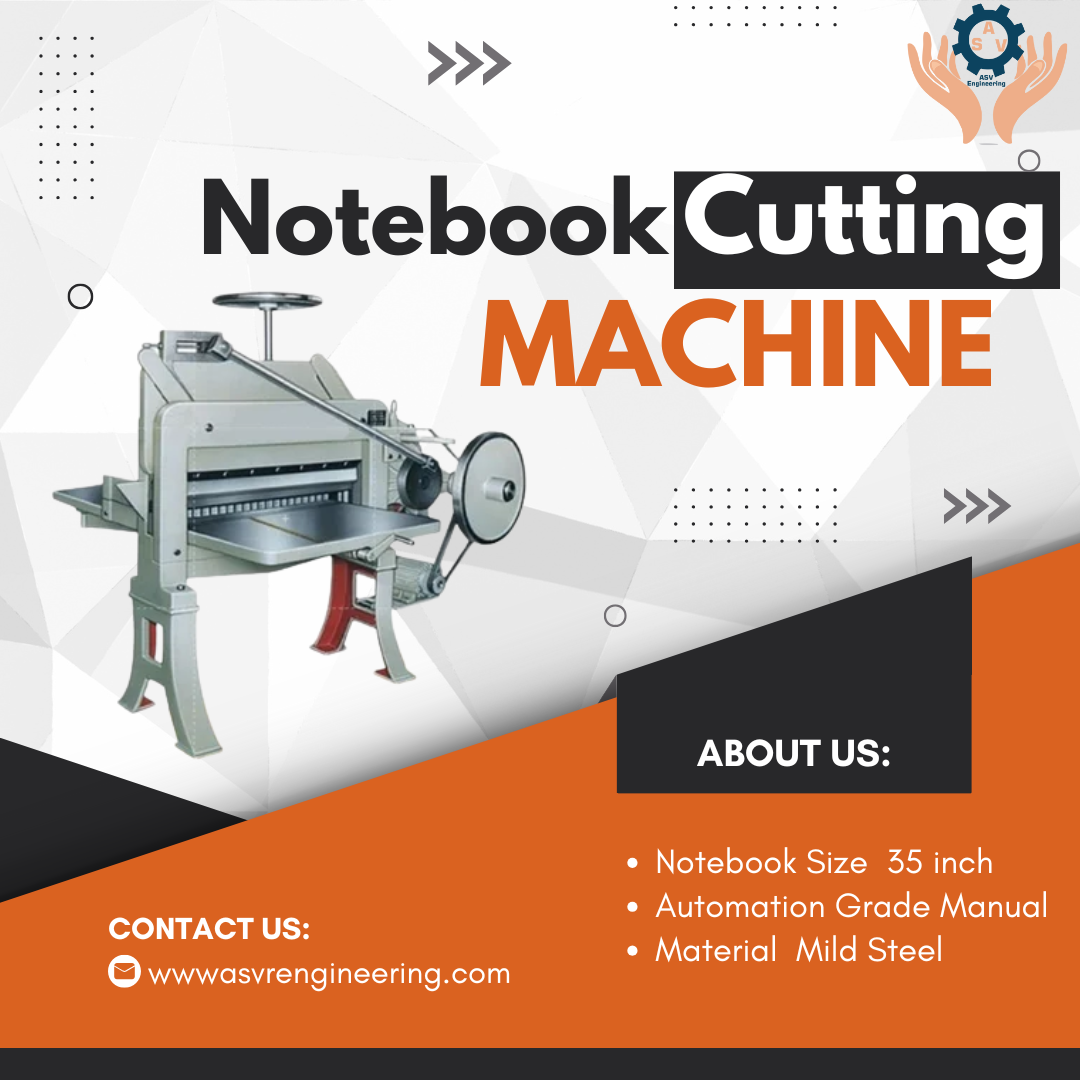

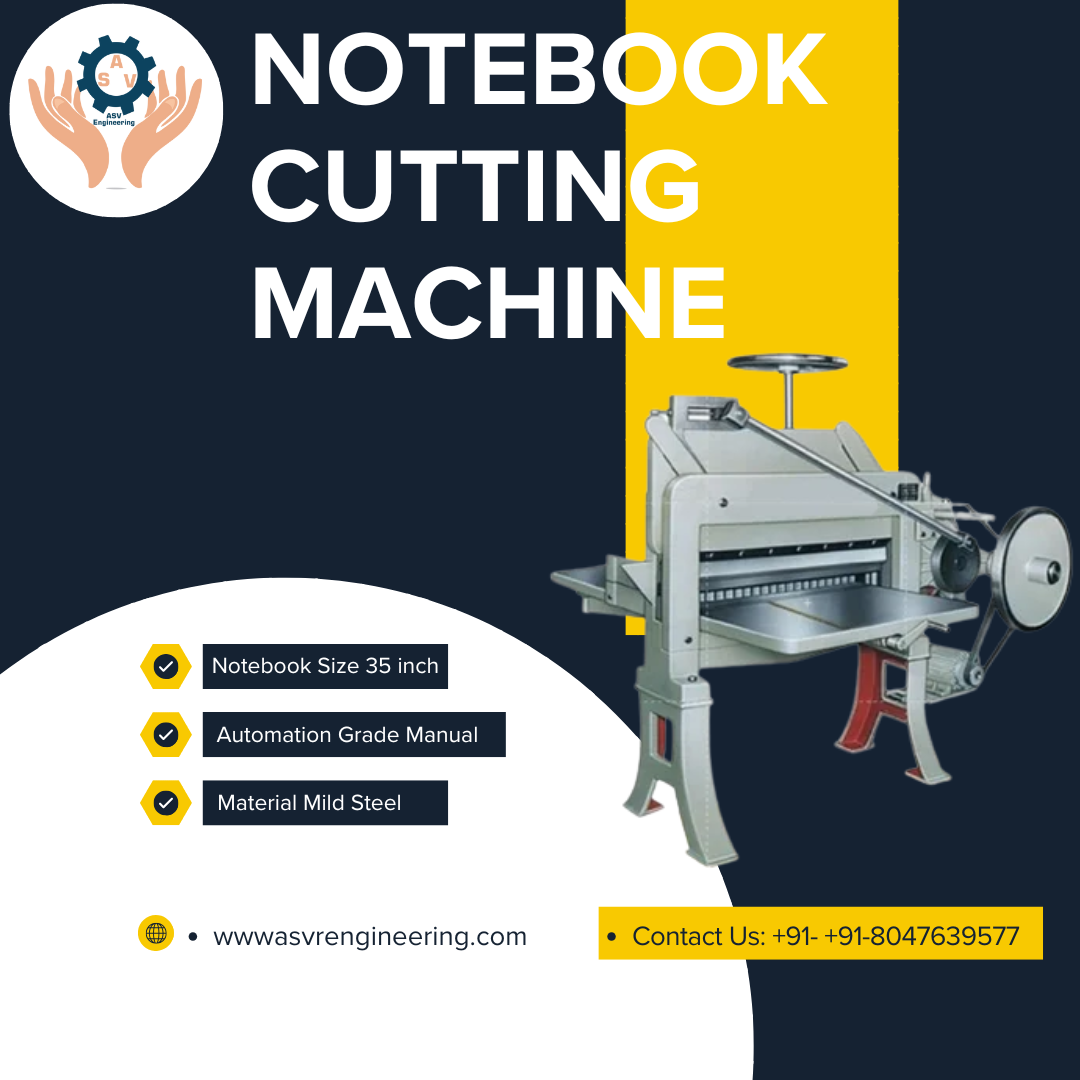

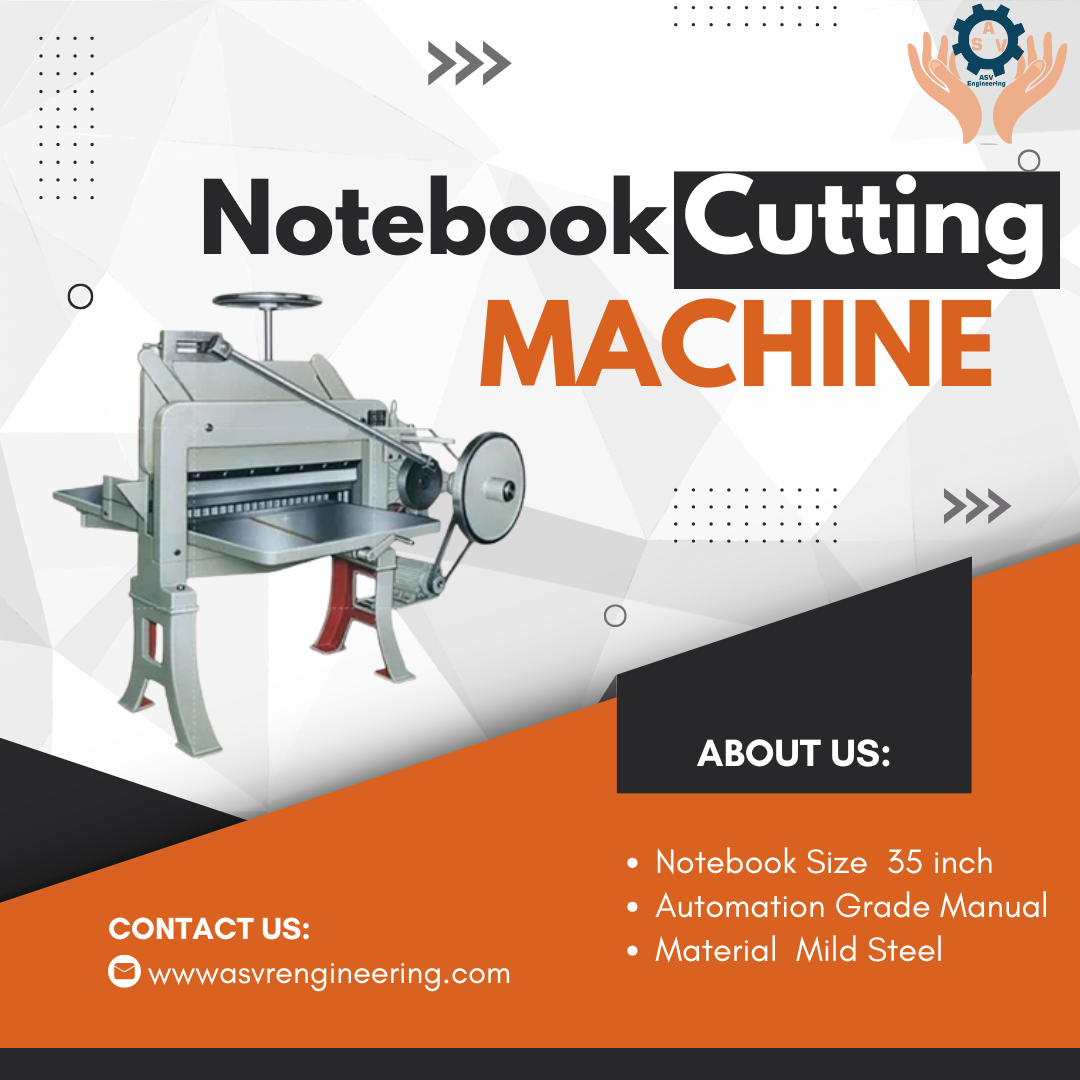

1. Manual Cutting Machines

-

Operated by hand pressure (guillotine-type).

-

Suitable for very small workshops.

-

Affordable but labor-intensive.

-

Best for small-scale or custom orders.

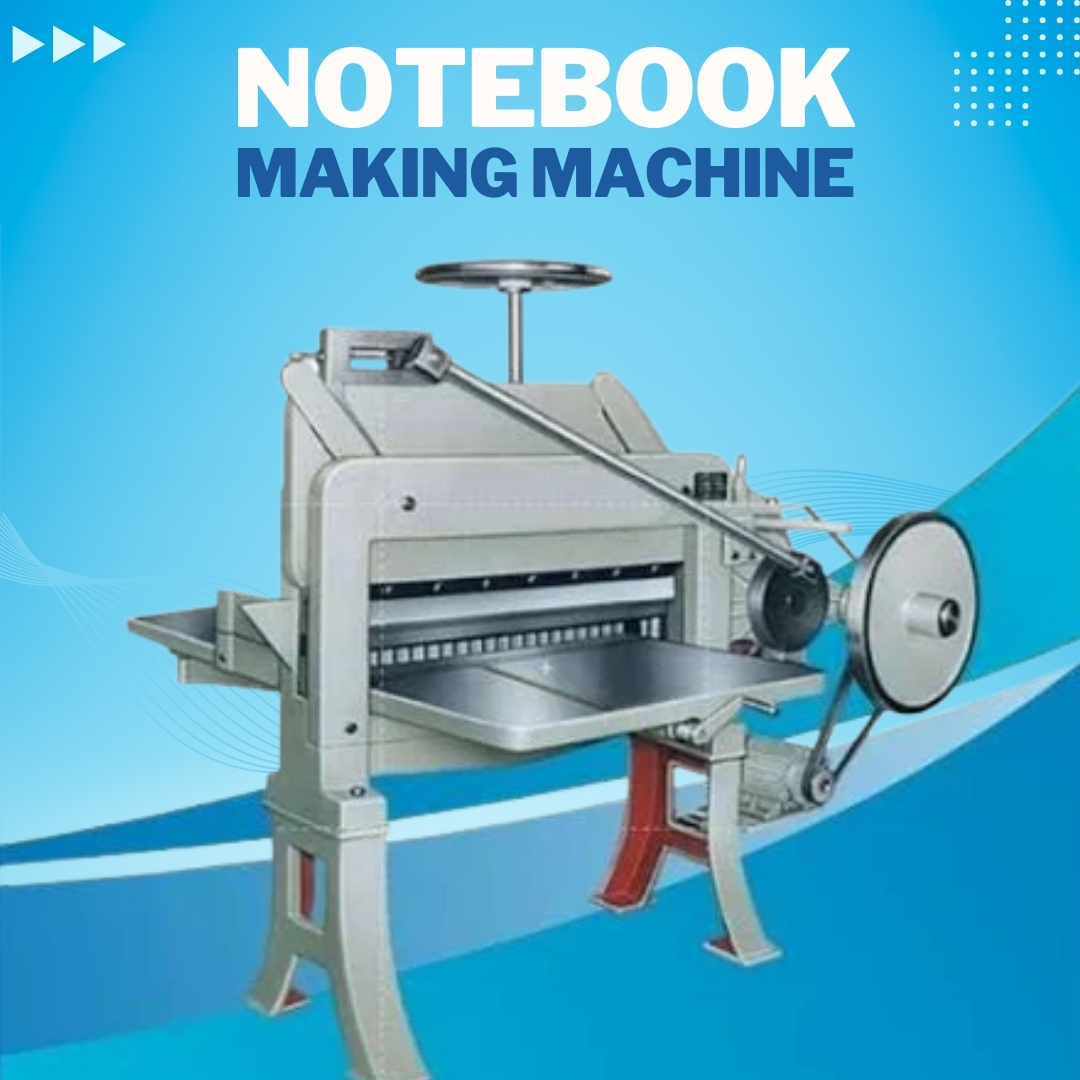

2. Semi-Automatic Cutting Machines

-

Equipped with hydraulic or motorized cutting blades.

-

Faster than manual cutters.

-

Medium-level investment.

-

Best for small to medium notebook businesses.

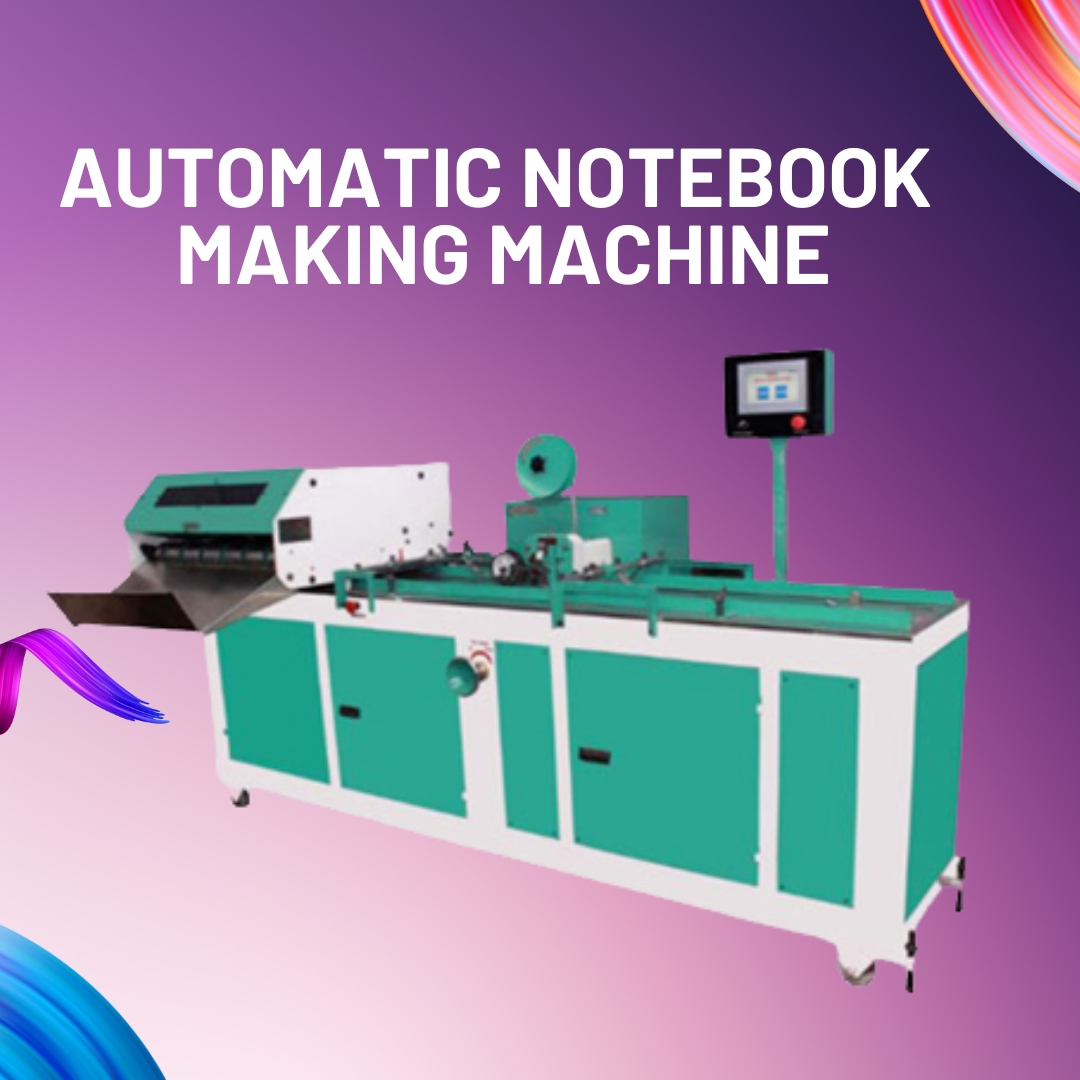

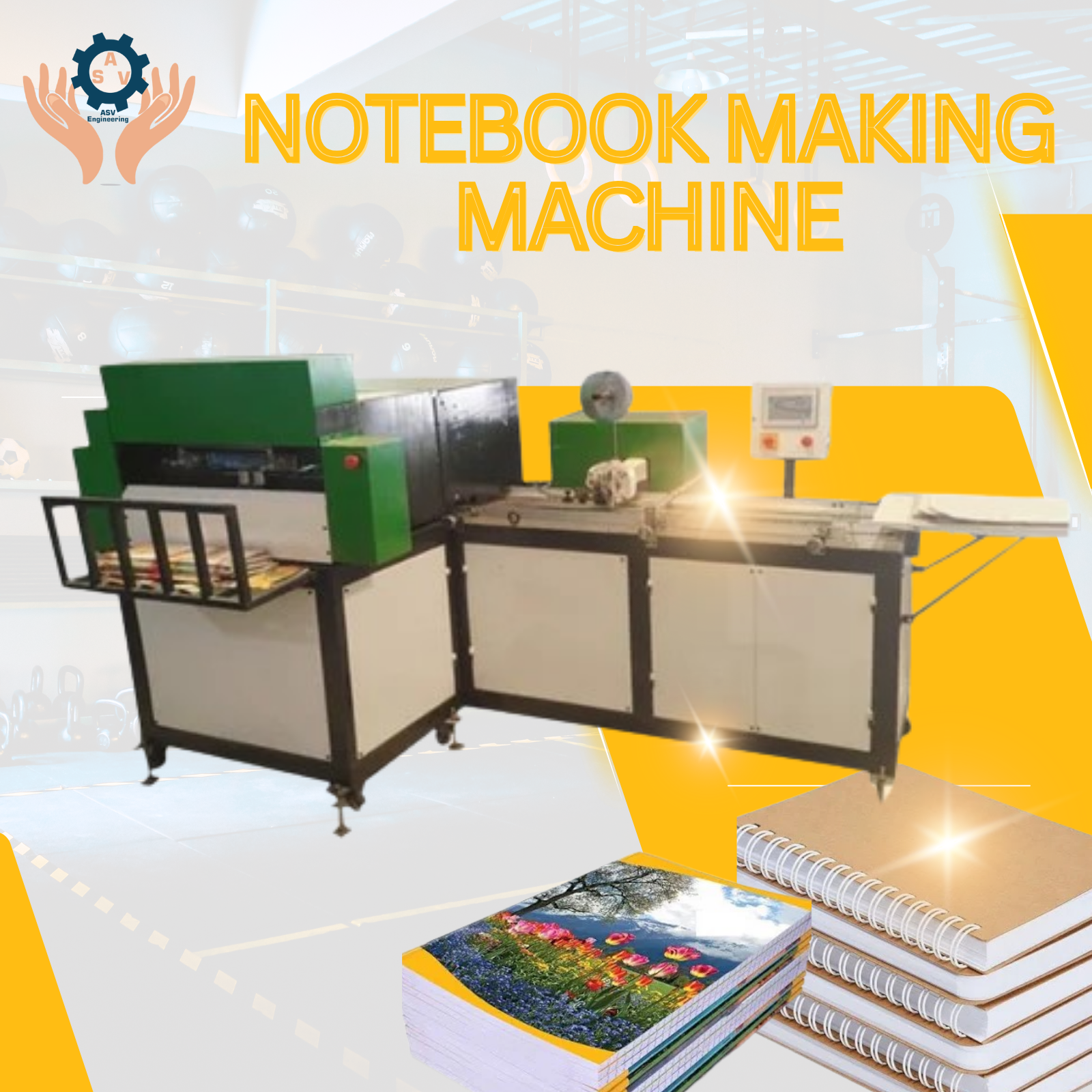

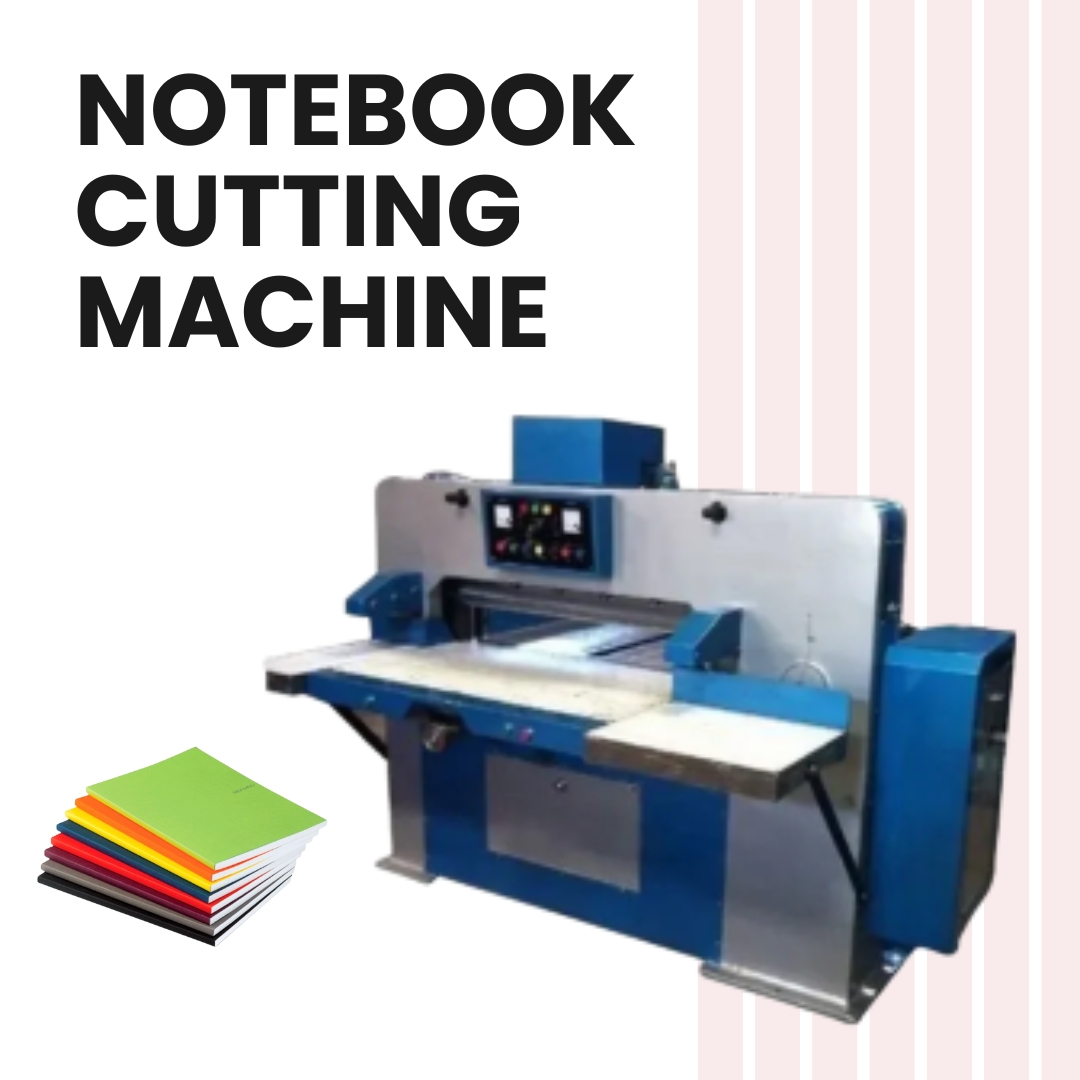

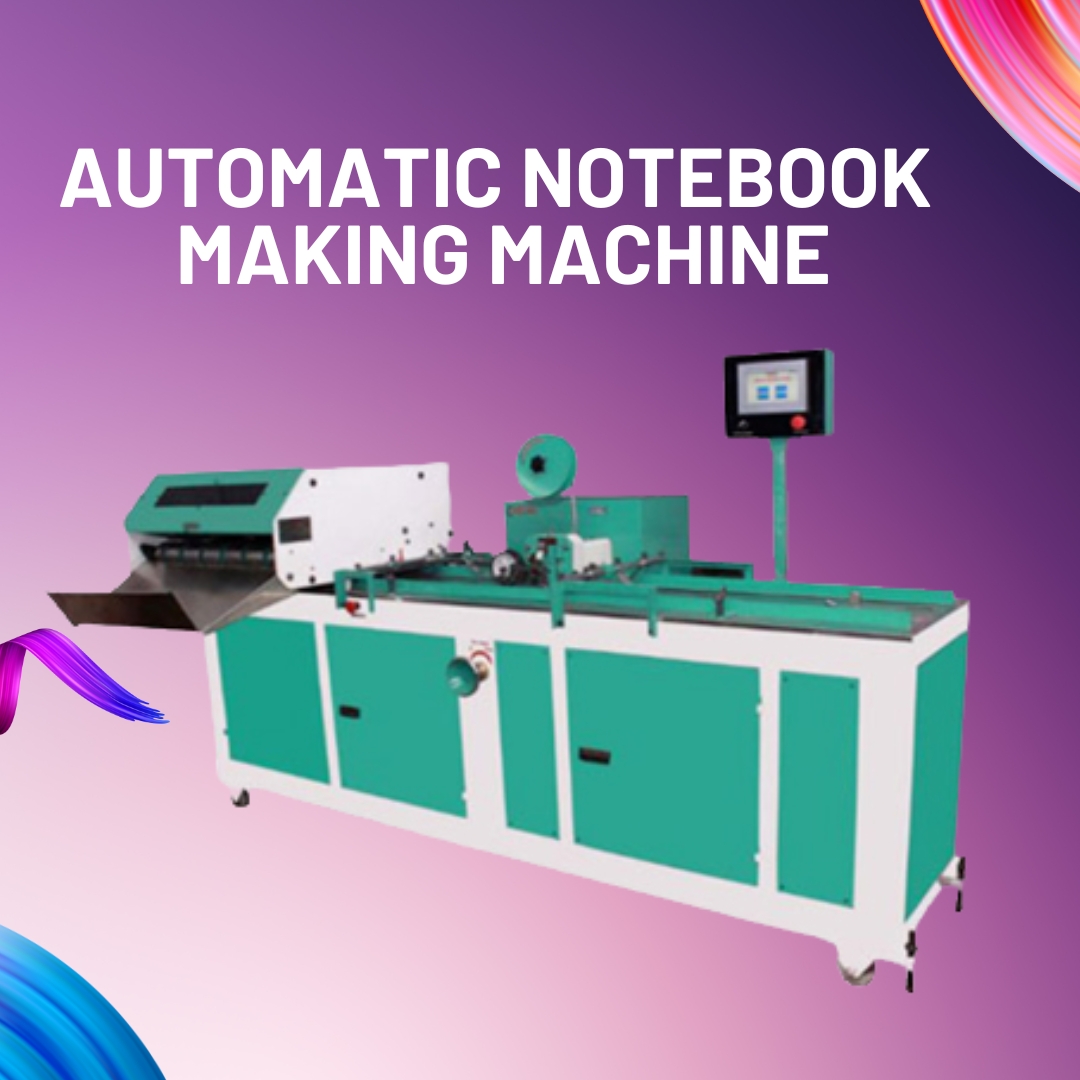

3. Fully Automatic Cutting Machines

-

Integrated with computerized controls.

-

Can handle large volumes of paper in minutes.

-

Ensures precision and consistency.

-

Ideal for large-scale notebook factories.

🔹 Types of Notebook Binding Machines

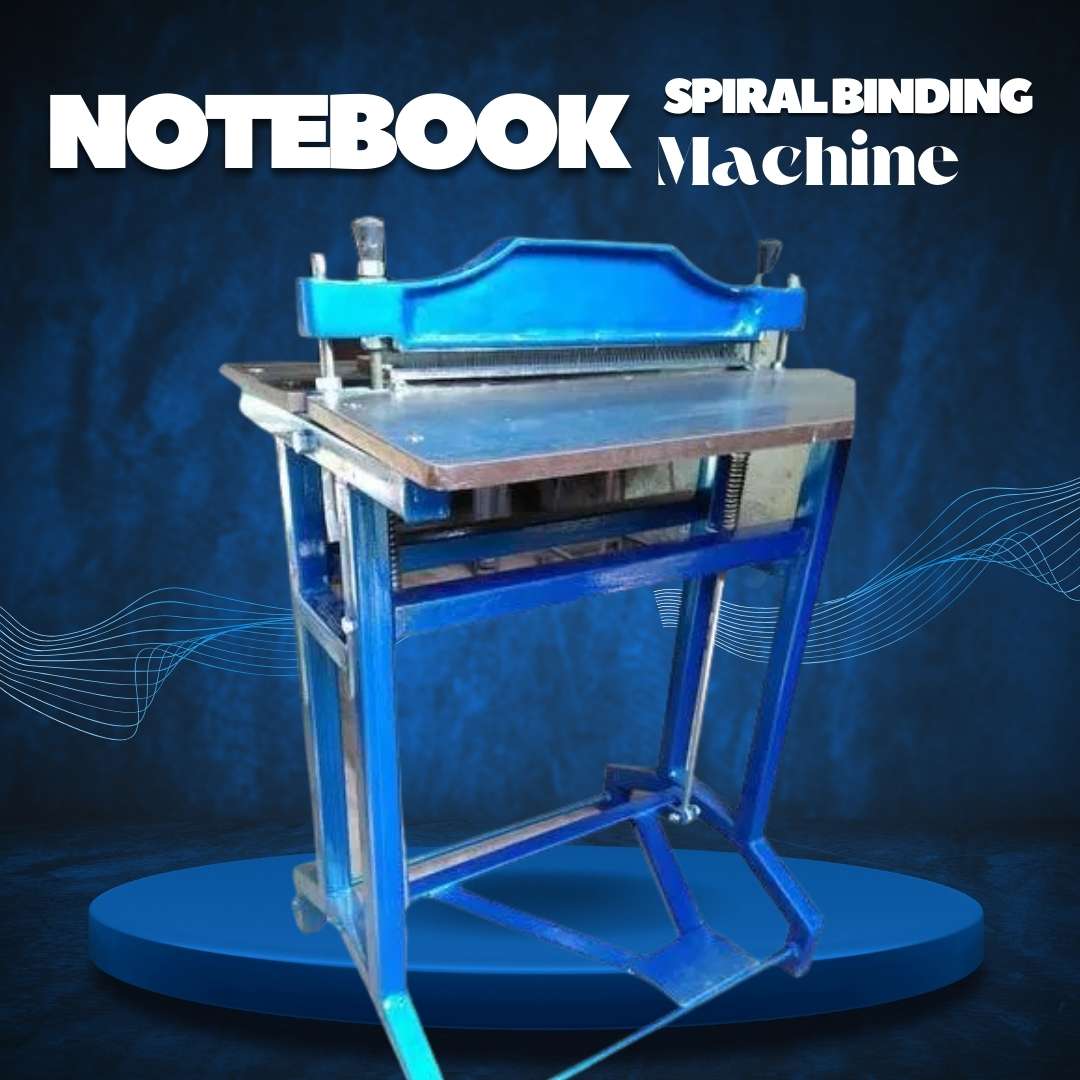

1. Spiral Binding Machine

-

Uses plastic or metal spirals.

-

Durable and flexible.

-

Popular for school notebooks and diaries.

2. Wire-O Binding Machine

-

Uses double-loop wire.

-

Provides a premium, professional finish.

-

Mostly used for corporate stationery, planners, and catalogs.

3. Perfect Binding Machine

-

Uses hot glue to attach pages with the cover.

-

Similar to paperback books.

-

Gives a neat, high-quality appearance.

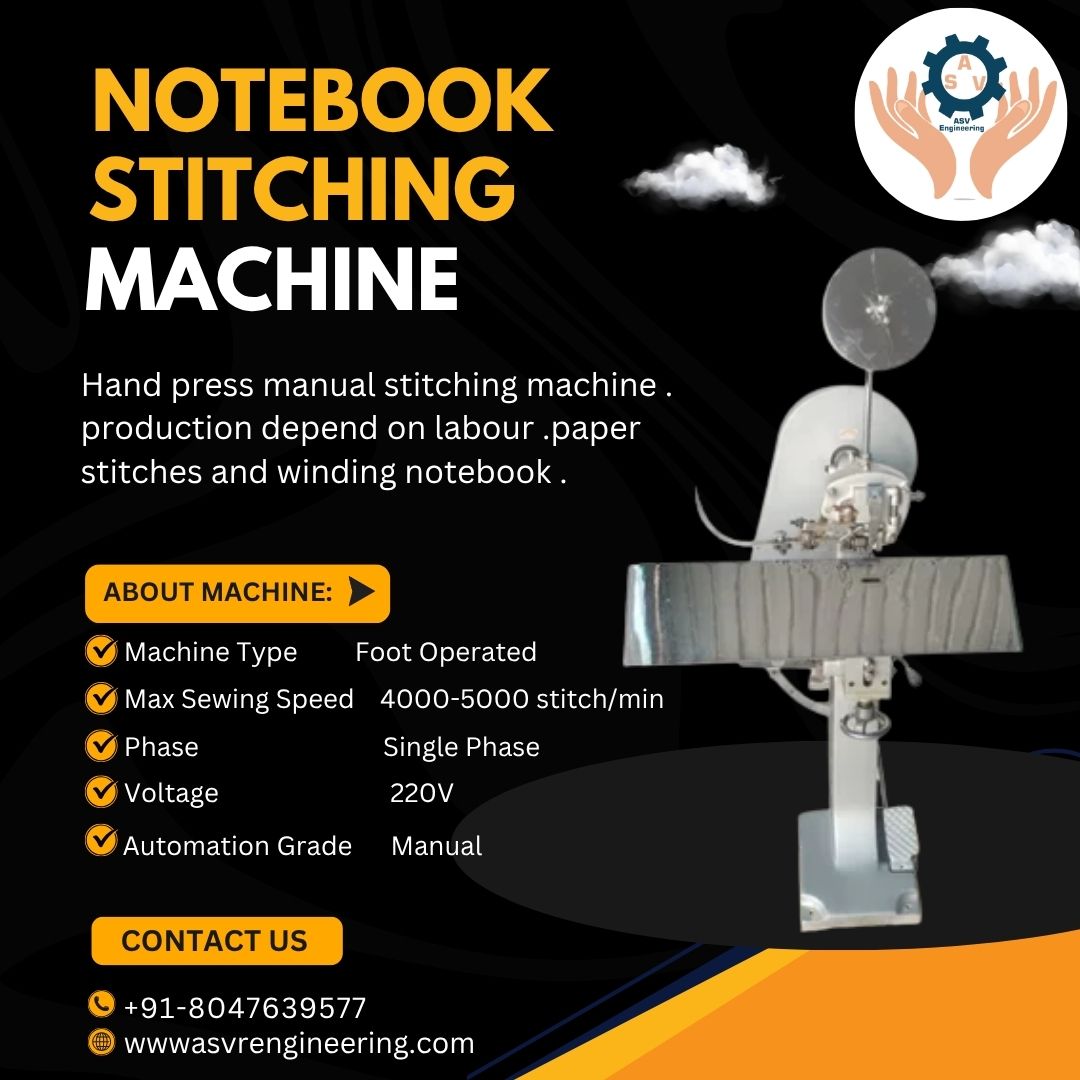

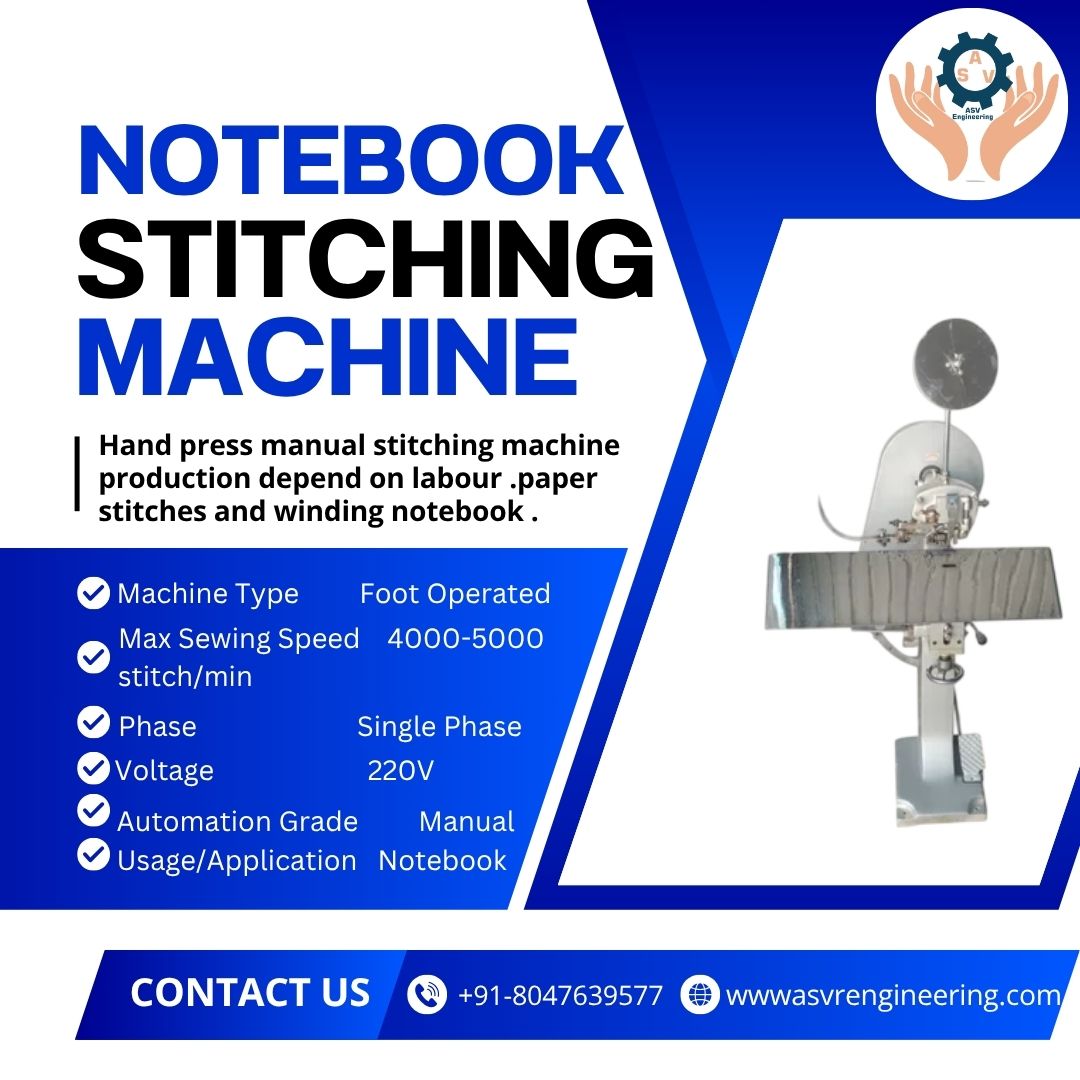

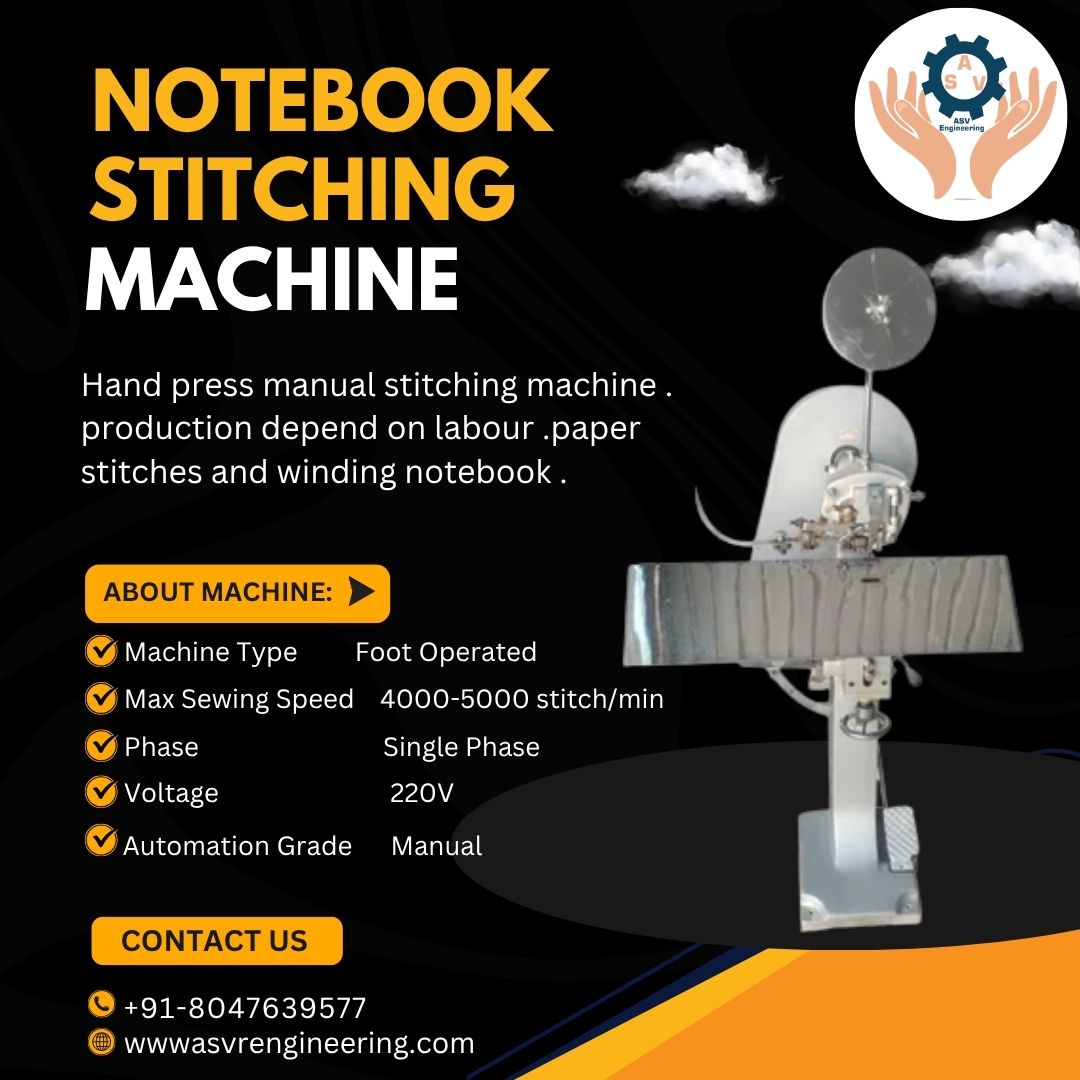

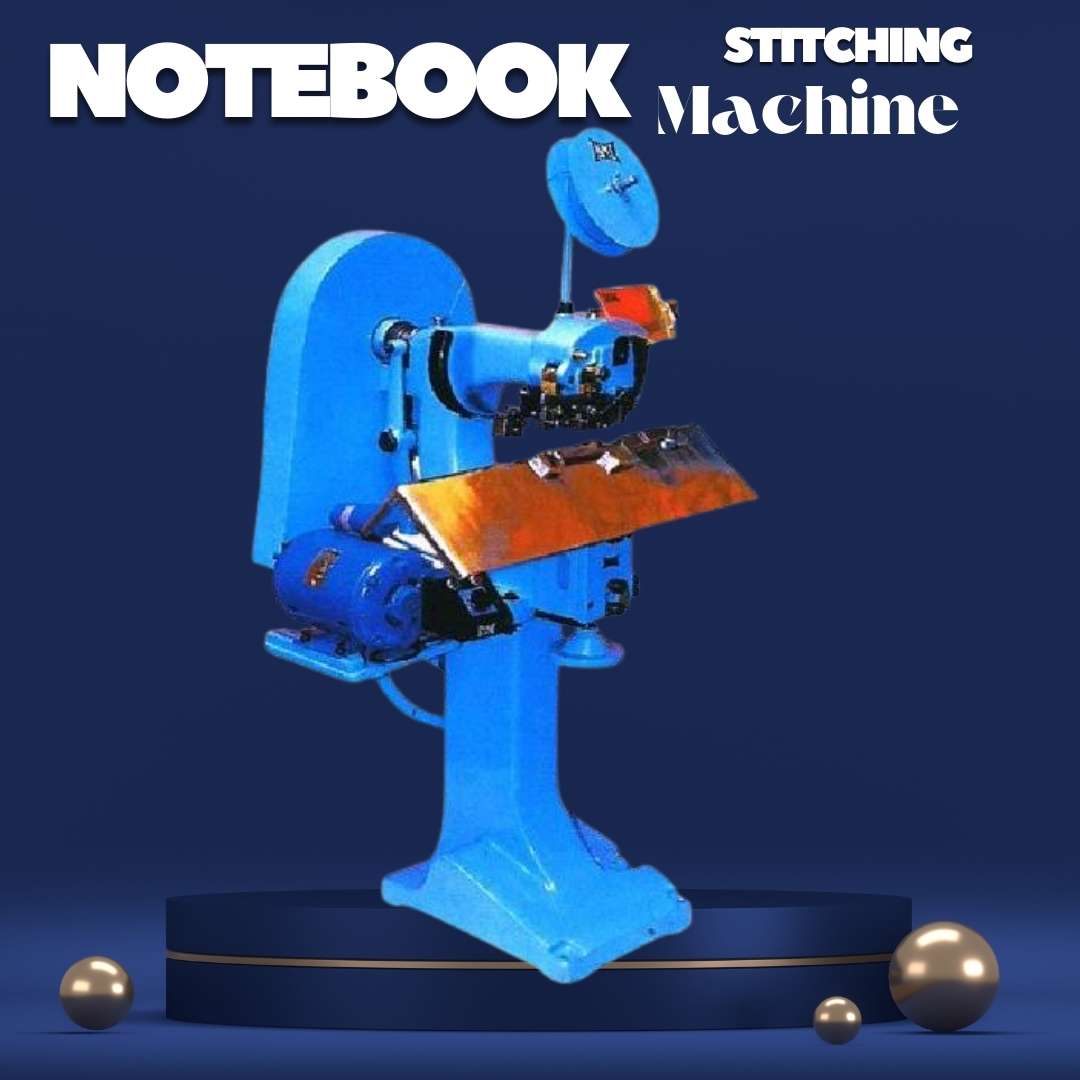

4. Staple/Stitch Binding Machine

-

Uses staples or thread stitching.

-

Affordable and simple.

-

Suitable for budget-friendly notebooks.

🔹 How a Notebook Cutting and Binding Machine Works

-

Paper Cutting – Reams of paper are placed in the cutting machine and trimmed into notebook-sized sheets.

-

Folding & Collating – Sheets are folded (if required) and arranged in order.

-

Punching Holes (if spiral/wire-o binding) – Binding holes are created using a punching system.

-

Binding – Pages are secured using spiral coils, wires, glue, or staples.

-

Covering & Finishing – Covers are attached, and notebooks are trimmed for a polished look.

-

Final Packaging – Ready notebooks are packed for distribution.

🔹 Advantages of Notebook Cutting and Binding Machines

✅ Time-Saving – Automates multiple stages of production.

✅ Cost-Effective – Reduces dependency on labor.

✅ Consistent Quality – Ensures accuracy in cutting and binding.

✅ Scalability – Suitable for both small-scale and large-scale businesses.

✅ Customization – Supports different notebook sizes and binding styles.

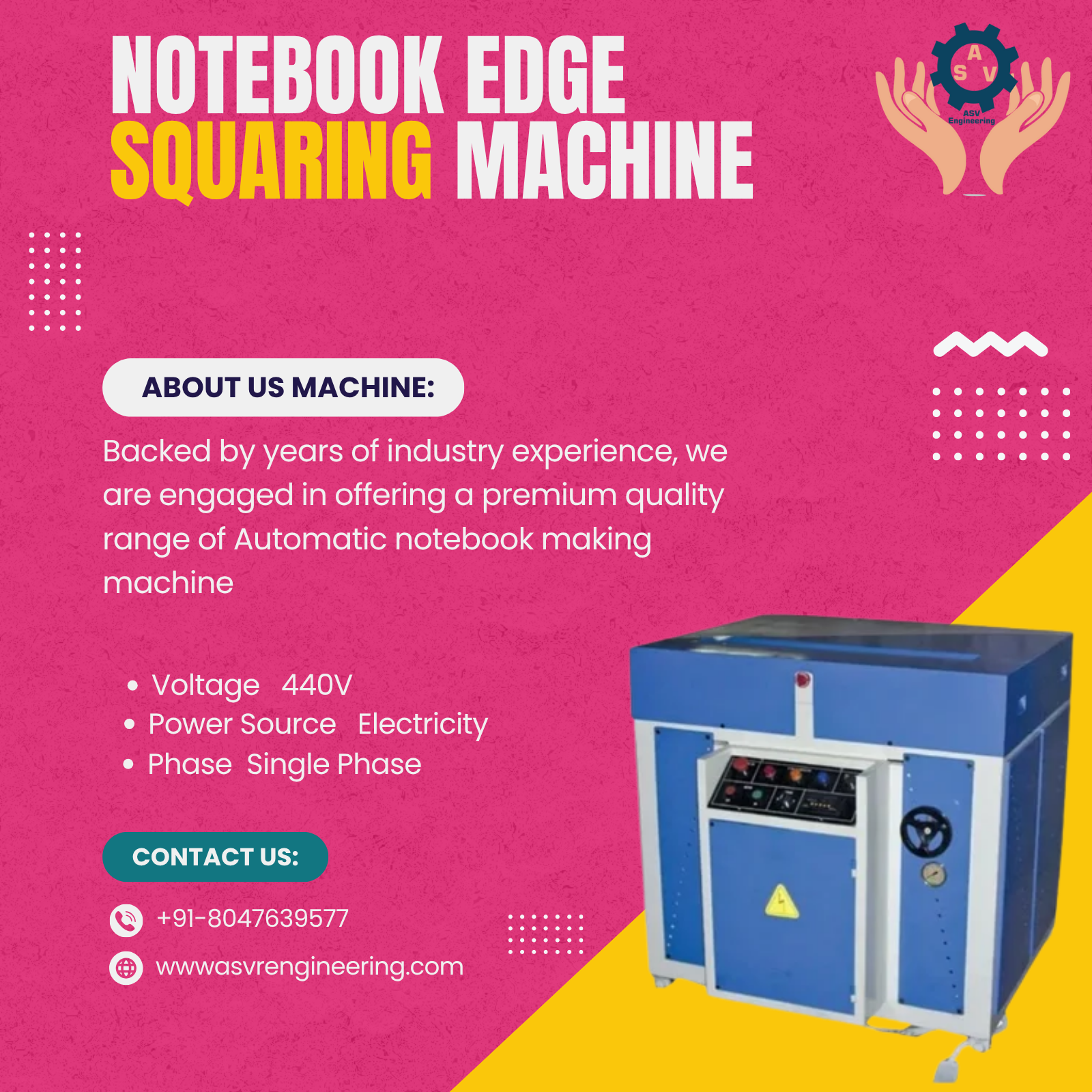

🔹 Investment & Cost of Machines

-

Manual Cutting Machine: ₹30,000 – ₹80,000

-

Semi-Automatic Cutting Machine: ₹1.5 – ₹3.5 Lakhs

-

Fully Automatic Cutting Machine: ₹5 – ₹15 Lakhs

-

Spiral/Wire Binding Machine: ₹50,000 – ₹3 Lakhs

-

Perfect Binding Machine: ₹2 – ₹6 Lakhs

💡 Pro Tip: For small notebook businesses, a semi-automatic cutting machine + spiral binding machine is a cost-effective combination.

🔹 Best Use Cases

-

Small Scale Businesses – Use manual/semi-automatic cutting + spiral binding.

-

Medium Enterprises – Semi-automatic cutting + wire-o/perfect binding.

-

Large Factories – Fully automatic cutting and binding lines for mass production.

🔹 Steps to Start a Small Notebook Cutting & Binding Business

-

Market Research – Identify demand in schools, offices, or wholesalers.

-

Select Machines – Choose based on your budget and target production volume.

-

Arrange Raw Materials – Paper, covers, wires/spirals, and glue.

-

Set Up a Workshop – Even a 500 sq. ft. space is enough for small-scale units.

-

Hire Skilled Labor – Operators for cutting & binding machines.

-

Marketing & Sales – Supply to local stationery shops, wholesale markets, and online platforms.

🔹 Future Trends in Notebook Binding

-

Eco-Friendly Notebooks – Using recycled paper and biodegradable spirals.

-

Customized Binding – Personalized planners, diaries, and branded notebooks.

-

Smart Integration – Machines with digital controls for precision cutting and binding.

Final Words

A notebook cutting and binding machine is the backbone of any notebook manufacturing business. Whether you’re starting with a small workshop or aiming for mass production, investing in the right machinery will ensure consistent quality, faster production, and higher profits.

If you are planning to step into the stationery manufacturing industry, choosing the right combination of cutting and binding machines will give your notebook business the competitive edge it needs.

Buy Now

.jpg)