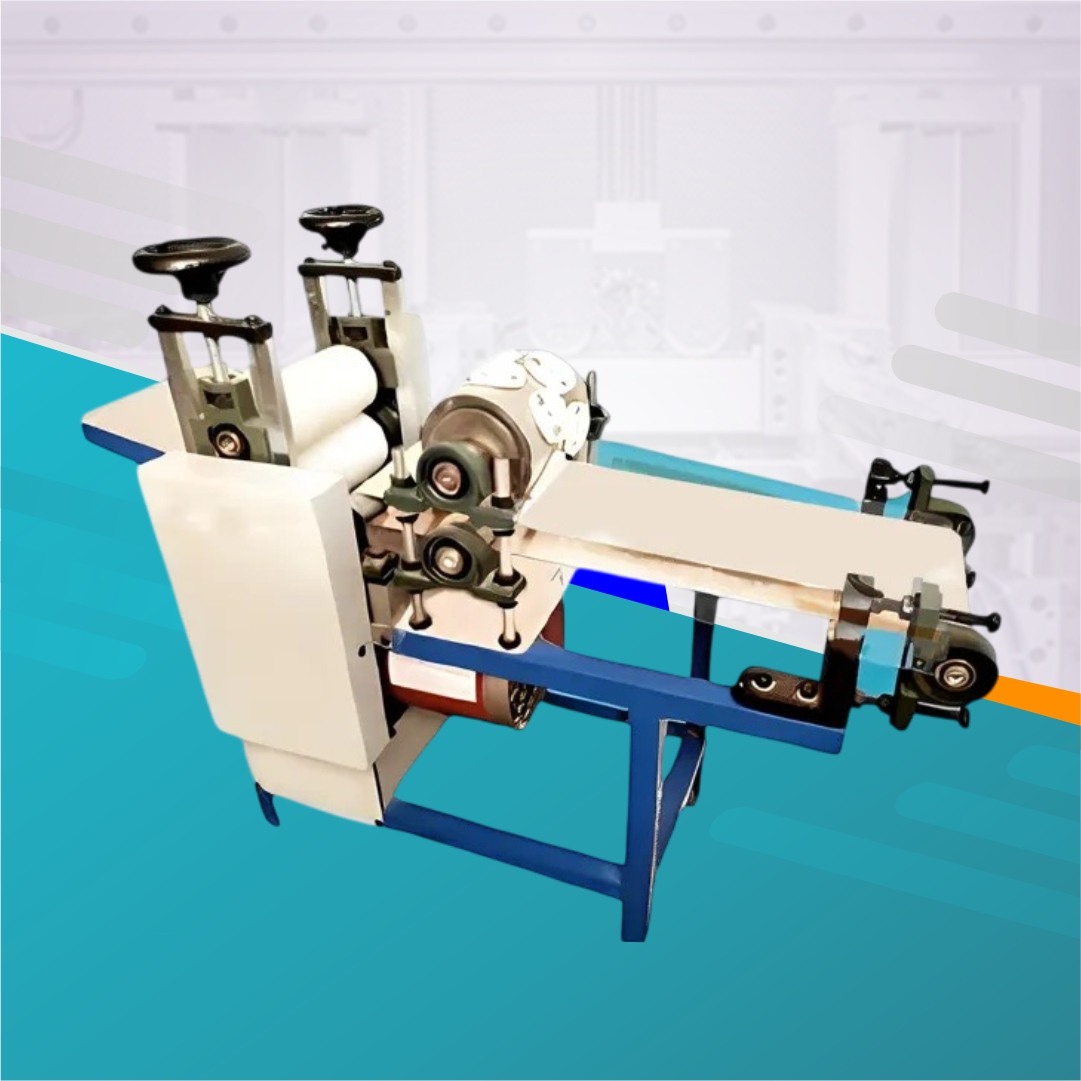

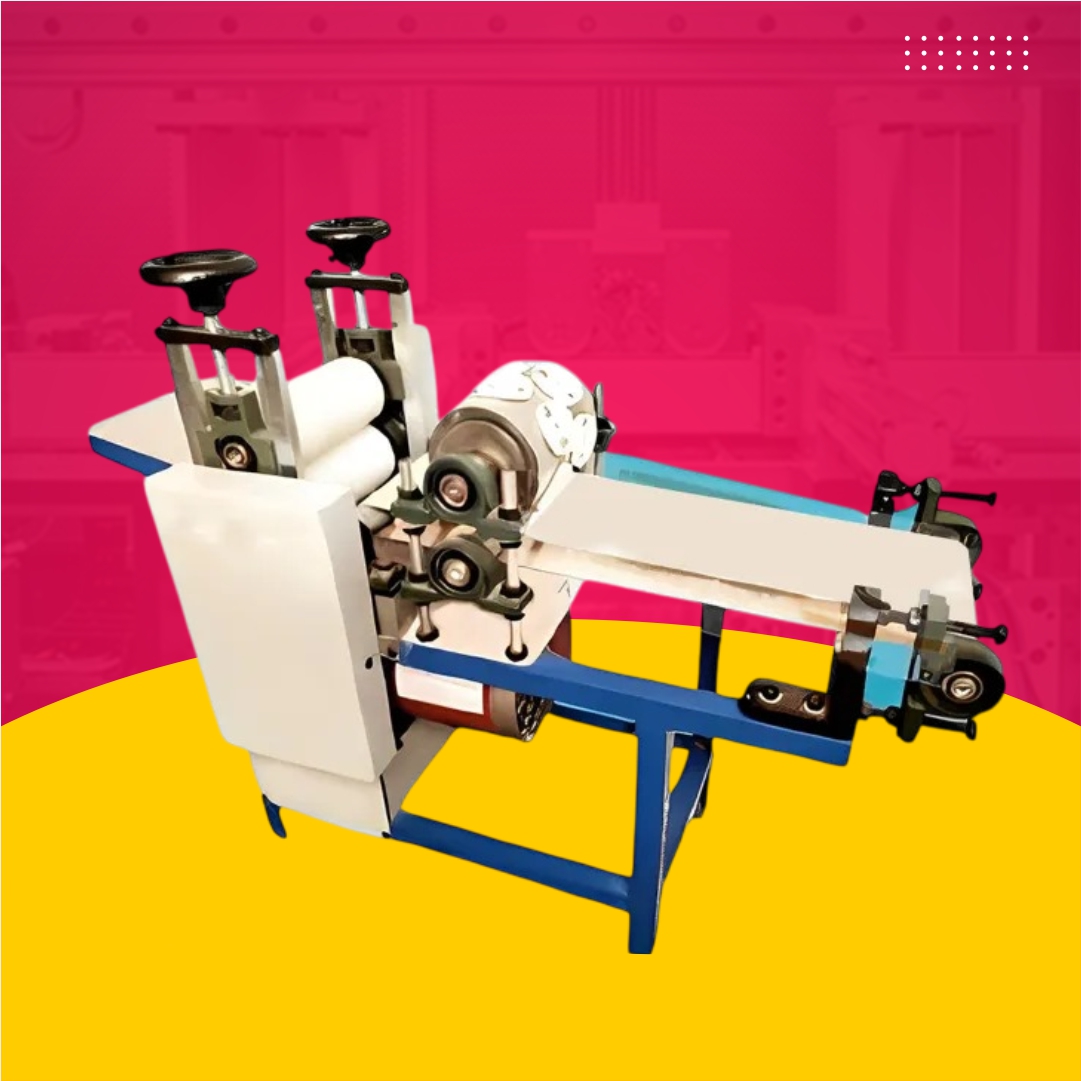

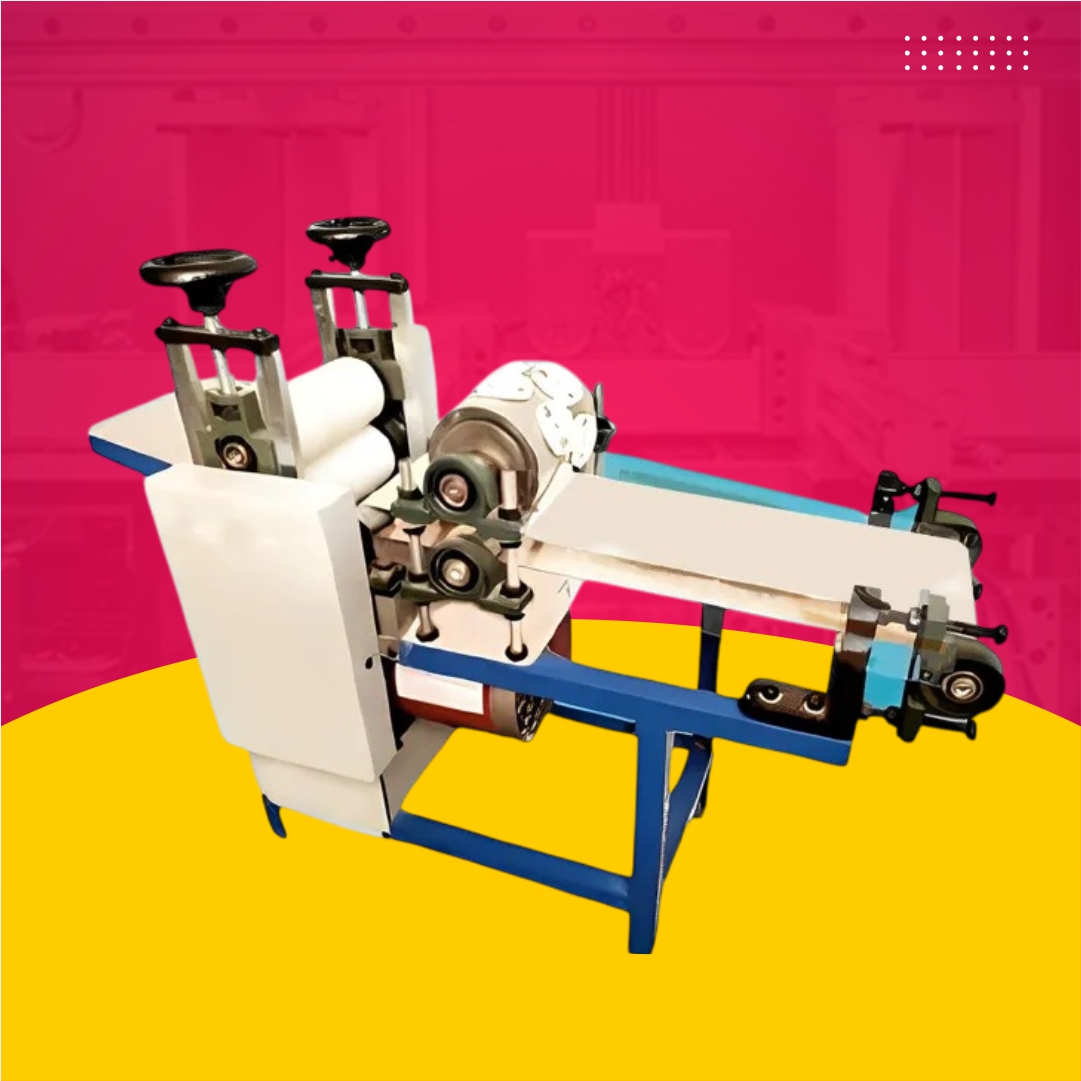

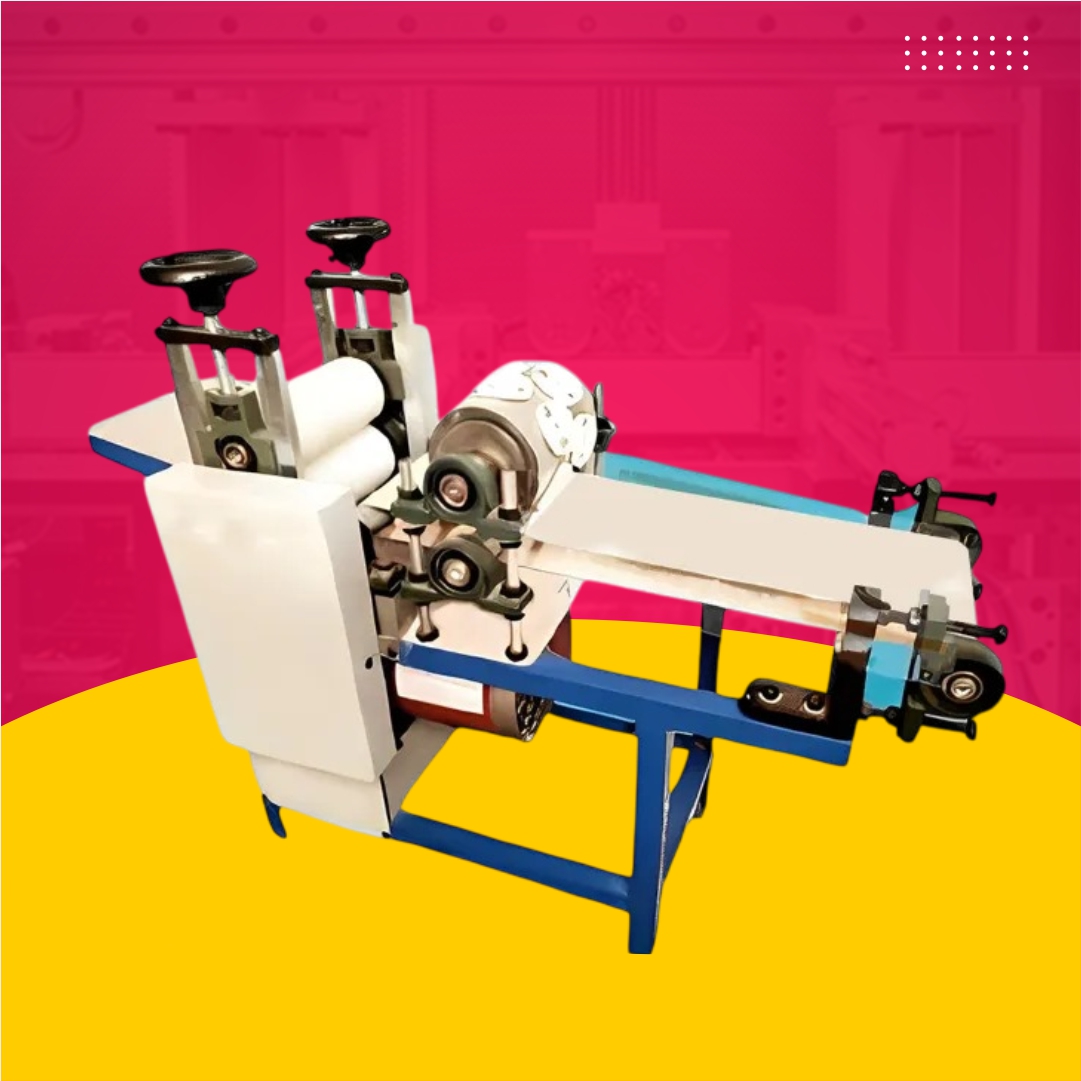

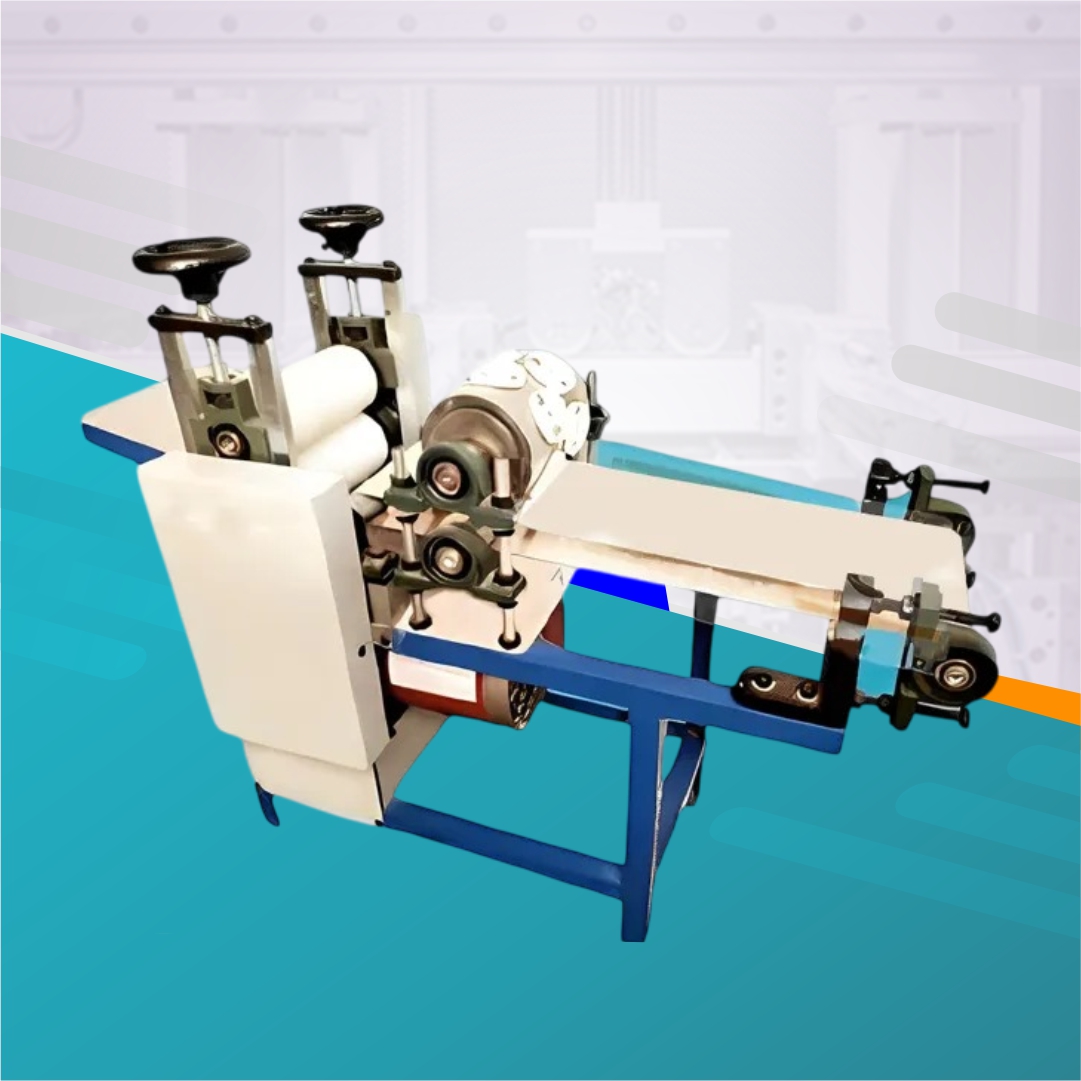

Trusted Automatic Pani Puri Making Machine Exporters for Commercial & Industrial Pani Puri Plants

Price: ₹73000

In India and across the globe, pani puri is more than a snack—it is an emotion shared by millions. With the rising demand for hygienic, standardized, and high-volume street food production, the traditional hand-made process is no longer sufficient for commercial needs. This is where automatic pani puri making machines have transformed the industry. Businesses today are actively searching for trusted automatic pani puri making machine exporters who can deliver reliable, scalable, and food-grade solutions for commercial and industrial plants.

Growing Global Demand for Automated Pani Puri Production

The popularity of Indian street food has crossed borders. From the Middle East to Africa, Europe, and Southeast Asia, pani puri has found a loyal audience. Restaurants, cloud kitchens, QSR chains, and packaged snack manufacturers require consistent quality, high output, and strict hygiene standards—all achievable only through automation.

Manual production often leads to inconsistency in size, breakage, contamination, and low daily output. An automatic pani puri plant eliminates these challenges by offering:

-

Uniform puri size and thickness

-

High-speed continuous production

-

Minimal human contact for better hygiene

-

Reduced labor dependency

-

Lower wastage and higher profitability

This shift has positioned India as a major hub for exporting automatic pani puri making machines worldwide.

Why Choose Automatic Pani Puri Making Machines?

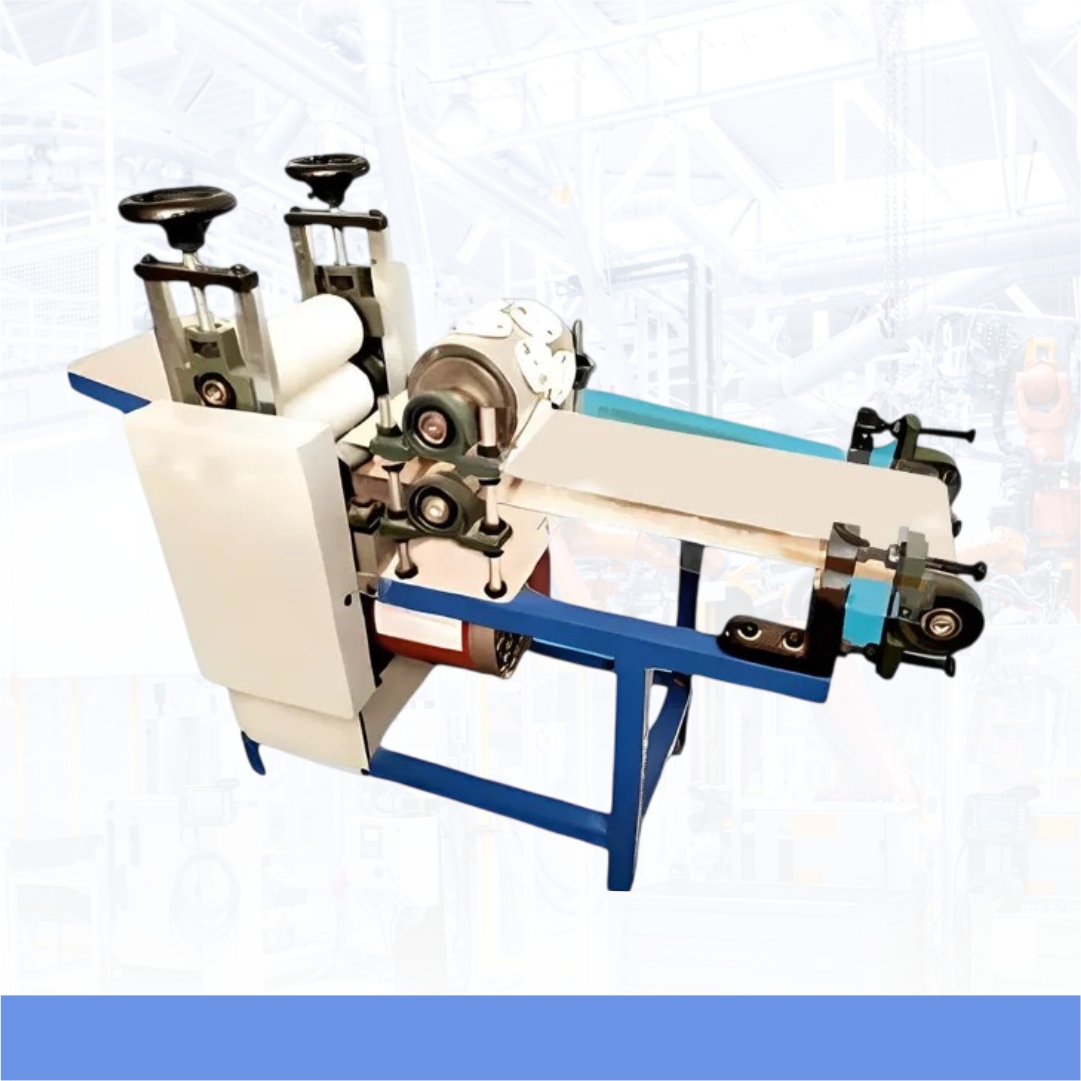

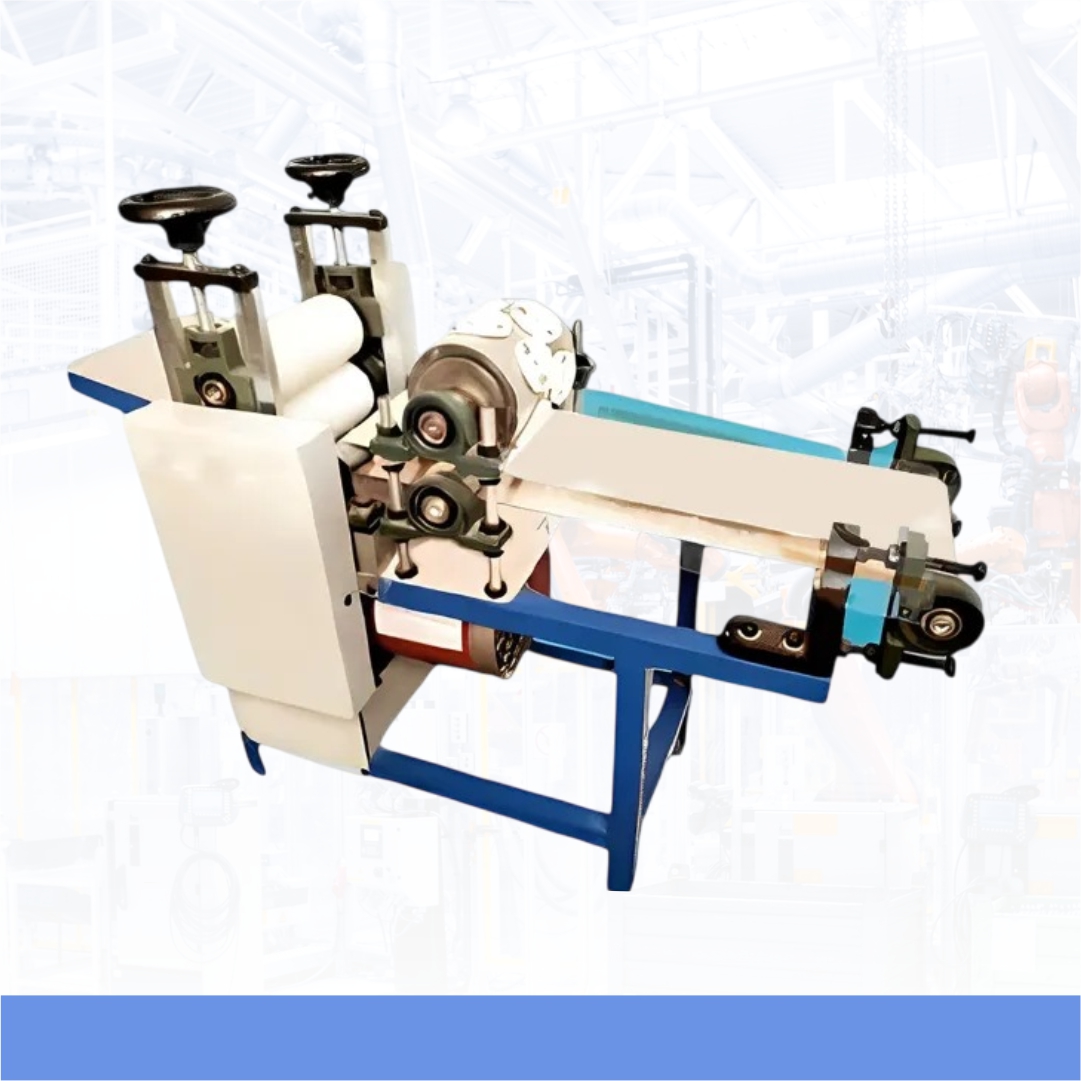

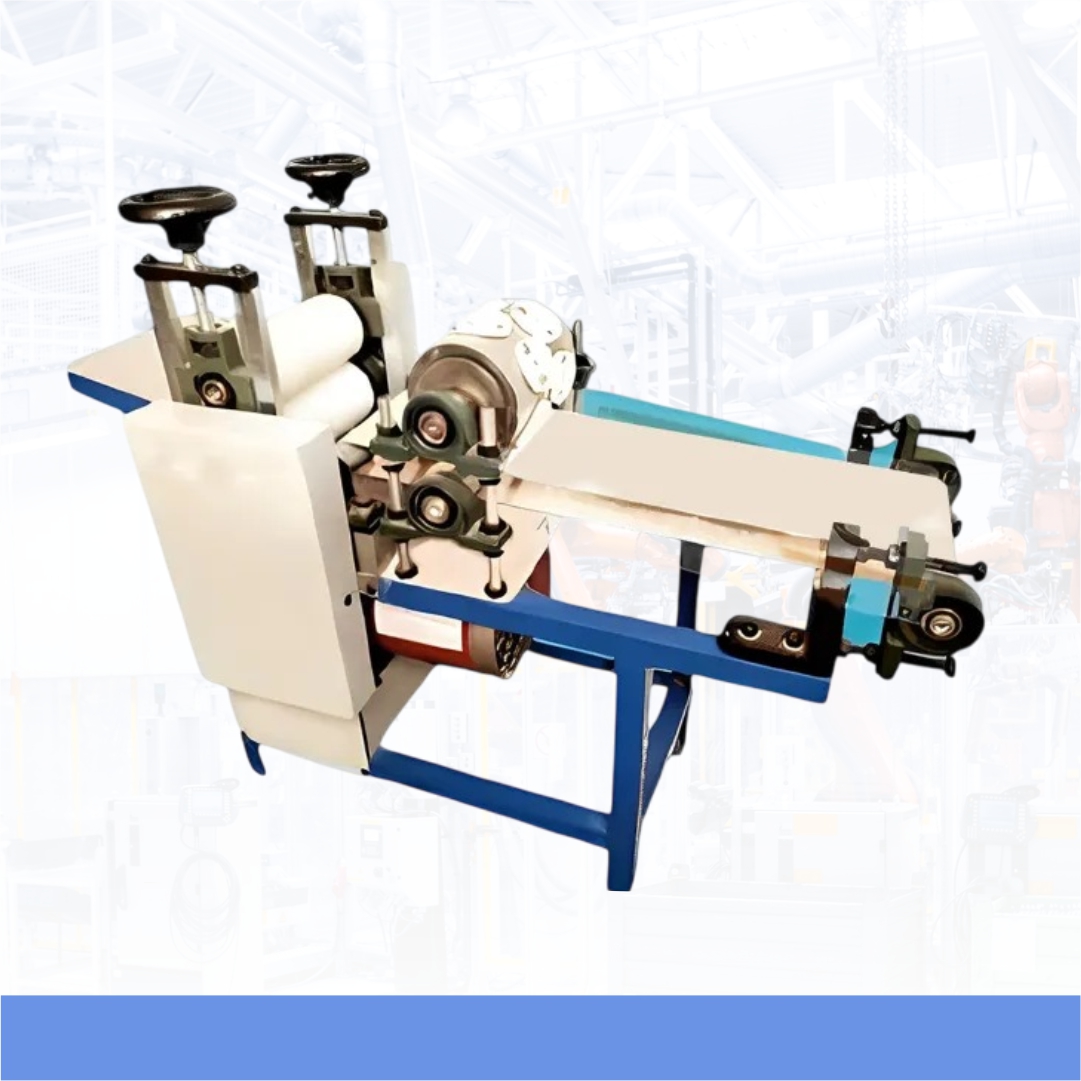

Automatic machines are designed to handle the entire process—from dough mixing to sheeting, cutting, frying, and cooling—within a controlled system. For commercial and industrial plants, these machines are not a luxury but a necessity.

Key Advantages:

1. High Production Capacity

Industrial pani puri plants can produce thousands of puris per hour, making them ideal for large-scale suppliers and exporters.

2. Consistent Quality Output

Every puri is uniform in size, crispiness, and texture, ensuring brand consistency.

3. Hygienic Food-Grade Manufacturing

Machines are made with SS 304 stainless steel, compliant with food safety standards required for exports.

4. Cost Efficiency

Reduced manpower, lower wastage, and optimized oil consumption significantly decrease operational costs.

5. Easy Operation & Maintenance

Modern PLC-based controls make operation simple, even for semi-skilled workers.

Commercial vs Industrial Pani Puri Plants

Understanding your production requirement is essential before choosing a machine.

Commercial Pani Puri Machines

-

Ideal for restaurants, caterers, and medium-scale snack units

-

Moderate output capacity

-

Compact design

-

Lower investment

Industrial Pani Puri Plants

-

Suitable for FMCG manufacturers, exporters, and large food factories

-

Fully automatic, high-speed production lines

-

Continuous frying and cooling systems

-

Designed for 24/7 operation

Trusted exporters guide buyers in selecting the right configuration based on market demand and budget.

Features That Define a Trusted Export-Quality Machine

When choosing an exporter for automatic pani puri making machines, quality and engineering precision matter the most.

Essential Features:

-

Heavy-duty structure for long machine life

-

Precision die and cutting system for uniform puris

-

Temperature-controlled frying system

-

Energy-efficient motors and burners

-

Low oil absorption technology

-

International safety and quality compliance

Reputed exporters ensure machines are tested under real production conditions before dispatch.

Why Global Buyers Prefer Indian Exporters

India has become the preferred destination for sourcing food processing machinery, especially pani puri plants.

Reasons Include:

-

Decades of expertise in traditional snack machinery

-

Competitive pricing without compromising quality

-

Custom-built solutions as per country regulations

-

Strong after-sales support and spare availability

-

Experience in exporting to multiple countries

Indian exporters understand both traditional taste requirements and modern automation standards, giving them a global edge.

Customization & Turnkey Pani Puri Plant Solutions

A trusted exporter does more than sell a machine—they deliver a complete solution.

Turnkey Services Include:

-

Plant layout design

-

Machine customization based on capacity

-

Installation and commissioning support

-

Operator training

-

Export documentation assistance

Such end-to-end services help international buyers set up production quickly and confidently.

Export Compliance & Quality Standards

For international trade, machines must meet strict standards.

Trusted exporters ensure:

-

Food-grade material compliance

-

Electrical safety standards

-

Export-grade packing

-

Documentation as per destination country

-

Pre-shipment inspection

This professionalism minimizes risks and ensures smooth customs clearance.

Applications of Automatic Pani Puri Making Machines

These machines are widely used across multiple sectors:

-

Street food chains

-

Cloud kitchens

-

Packaged snack manufacturers

-

Supermarket private labels

-

Export-oriented snack units

With rising demand for ready-to-fry and ready-to-eat pani puri, automated plants are becoming highly profitable investments.

Why ASVR Engineering Is a Preferred Export Partner

Among trusted names in the industry, ASVR Engineering has built a strong reputation as a reliable exporter of automatic pani puri making machines for commercial and industrial plants.

What Sets ASVR Engineering Apart:

-

Proven expertise in food processing machinery

-

Robust machine design with export-quality standards

-

Custom capacity solutions for domestic and international markets

-

Strong technical support and service network

-

Transparent pricing and timely delivery

With a customer-centric approach and engineering excellence, the company supports businesses from concept to commissioning.

Investment & ROI Perspective

Automatic pani puri plants offer excellent returns due to:

-

High daily production capacity

-

Low operational costs

-

Increasing global demand

-

Long machine life

For exporters and large-scale manufacturers, the return on investment is both fast and sustainable.

Future of Automated Pani Puri Production

The future lies in automation, hygiene, and scalability. As food regulations tighten and consumer awareness increases, automated pani puri production will become the industry standard. Exporters who invest today gain a long-term competitive advantage.

Contact Details

📞 Phone: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

If you are searching for trusted automatic pani puri making machine exporters for commercial & industrial pani puri plants, partnering with the right manufacturer ensures quality, profitability, and global success.

Buy Now