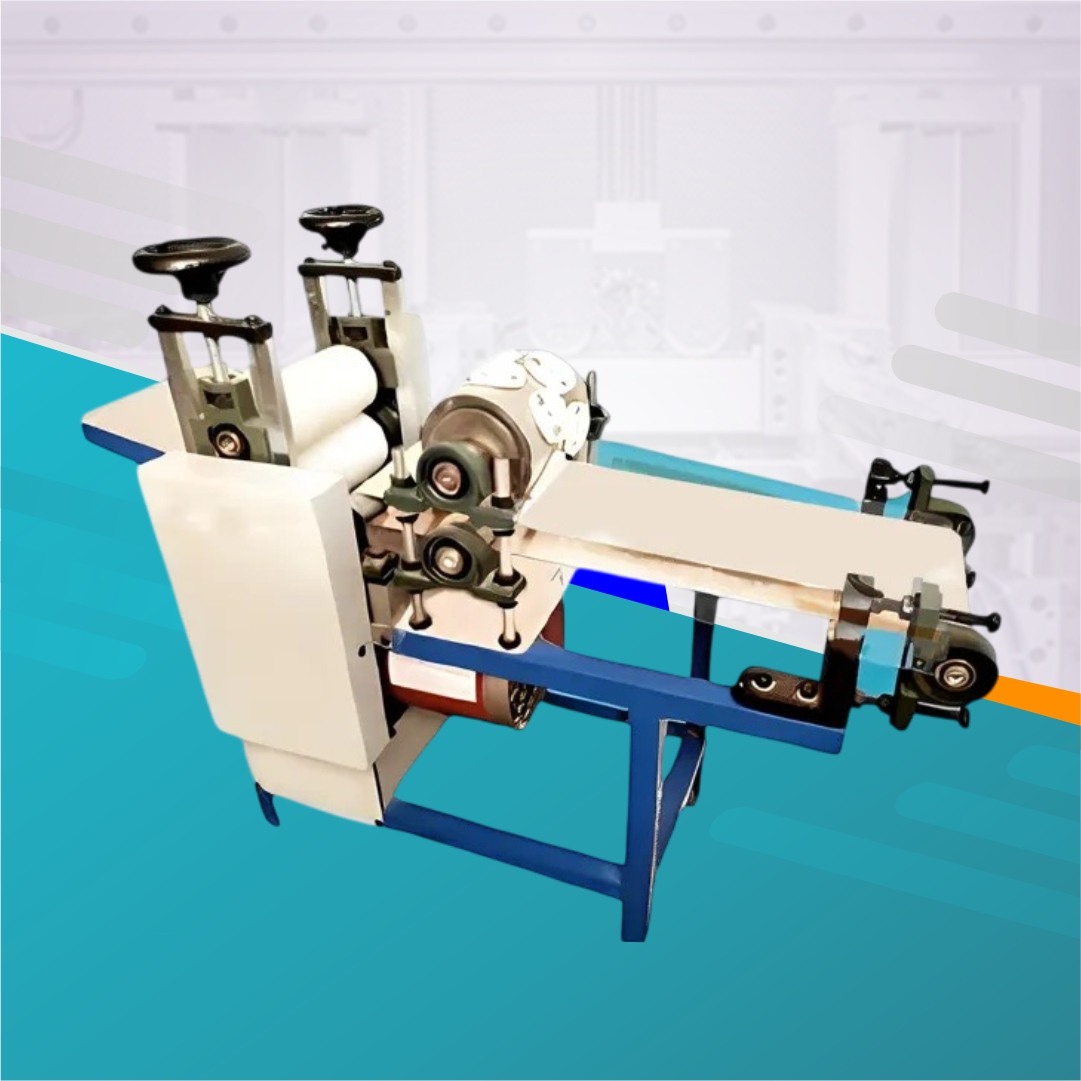

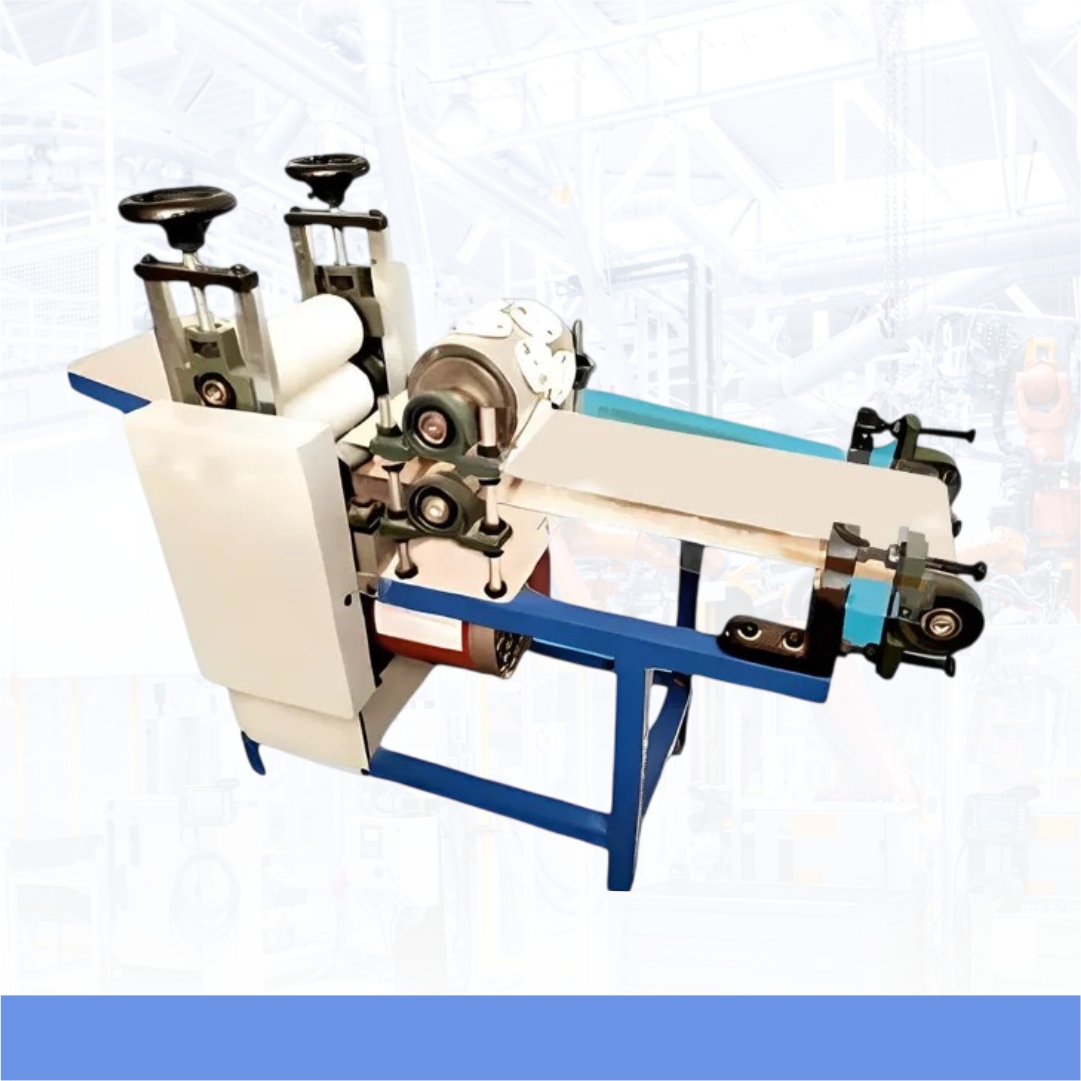

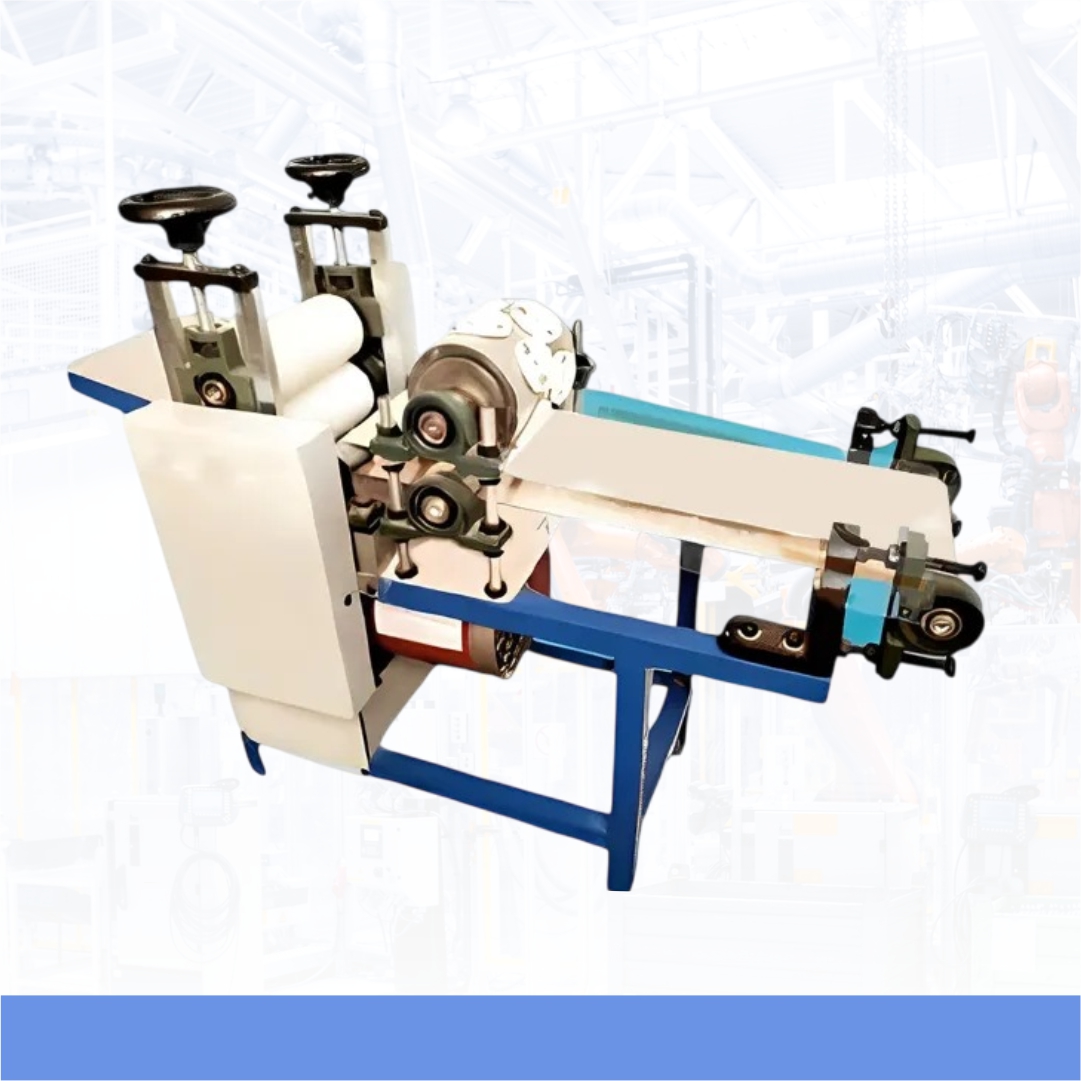

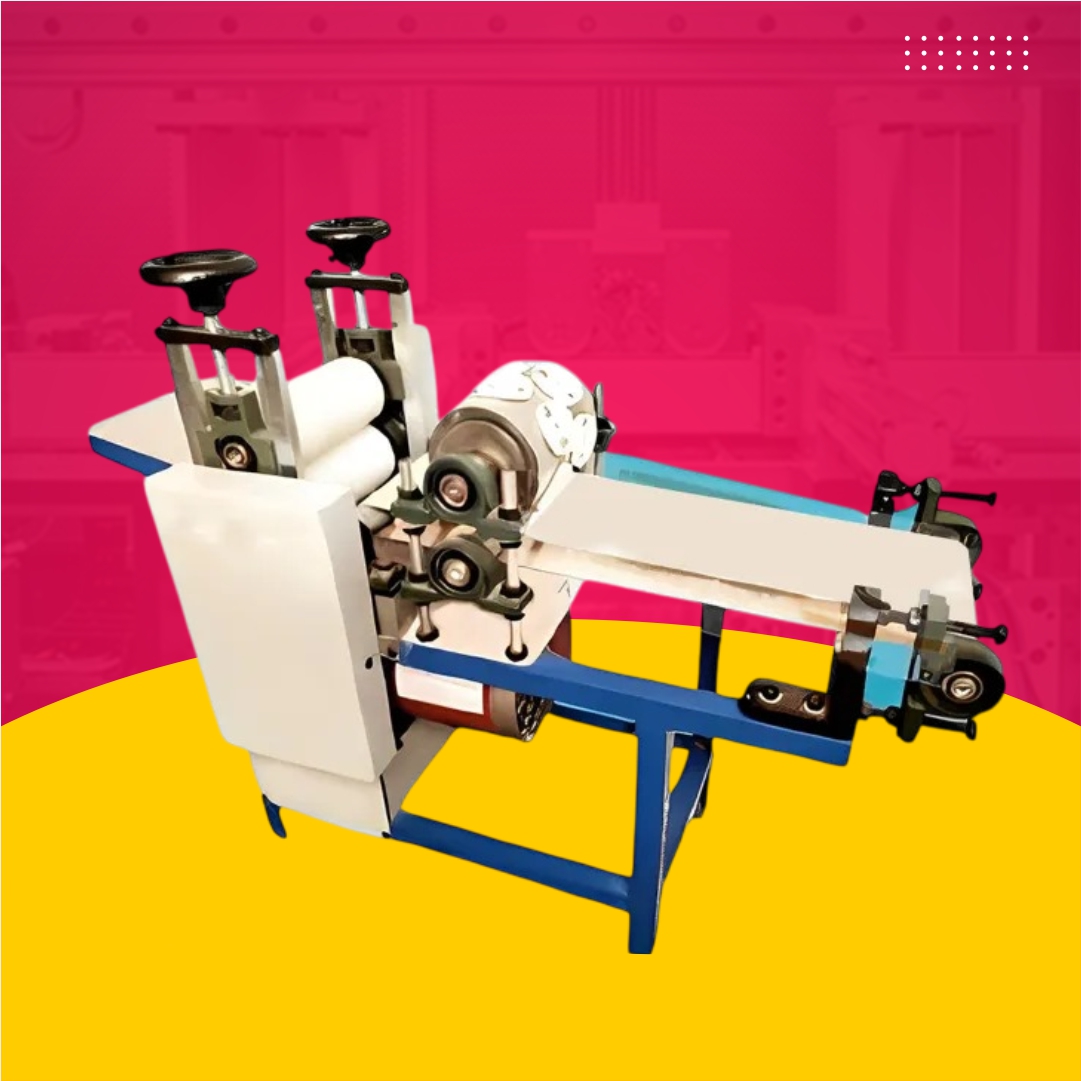

Automatic Pani Puri Making Machine

Price: ₹72000

Pani Puri, also known as Golgappa or Puchka, is not just a street snack—it is an emotion for millions across India and abroad. From bustling roadside vendors to premium food courts and packaged snack brands, the demand for crispy, uniform, and hygienically produced pani puri shells has increased tremendously. To meet this growing demand, traditional manual preparation is no longer sufficient. This is where an Automatic Pani Puri Making Machine becomes an essential investment for modern food entrepreneurs.

An automatic pani puri making machine is designed to streamline the entire production process—starting from dough preparation to shaping, frying, and final output—while maintaining consistent quality, high hygiene standards, and impressive production capacity. Whether you are planning to start a pani puri manufacturing unit or scale an existing setup, this machine offers reliability, efficiency, and long-term profitability.

What is an Automatic Pani Puri Making Machine?

An automatic pani puri making machine is an advanced food processing system that produces perfectly round, crispy pani puri shells with minimal human intervention. Unlike semi-automatic or manual machines, fully automatic systems handle multiple stages of production in a continuous flow. The result is uniform size, controlled thickness, optimal frying, and a high output rate suitable for commercial and industrial use.

These machines are widely used by:

-

Large pani puri manufacturers

-

Packaged snack brands

-

Cloud kitchens and food factories

-

Export-oriented food processing units

-

Wholesale suppliers for street vendors

Why Choose an Automatic Pani Puri Making Machine?

1. High Production Capacity

One of the biggest advantages of an automatic pani puri making machine is its ability to produce thousands of pani puris per hour. This high output makes it ideal for businesses aiming to supply bulk orders without compromising quality.

2. Consistent Shape and Size

Manual preparation often results in uneven shells. Automatic machines ensure every pani puri is uniform in size, thickness, and crispiness, which is crucial for brand consistency and customer satisfaction.

3. Superior Hygiene Standards

Food safety is a major concern today. Automatic pani puri machines are made from food-grade stainless steel and designed to minimize human contact, ensuring hygienic production that meets FSSAI and export standards.

4. Reduced Labor Dependency

With automation, the need for skilled labor is drastically reduced. One or two operators can easily manage the entire machine, helping businesses save significantly on operational costs.

5. Energy and Cost Efficiency

Modern automatic pani puri making machines are engineered to consume less power while delivering higher output. This balance results in lower per-unit production costs and better profit margins.

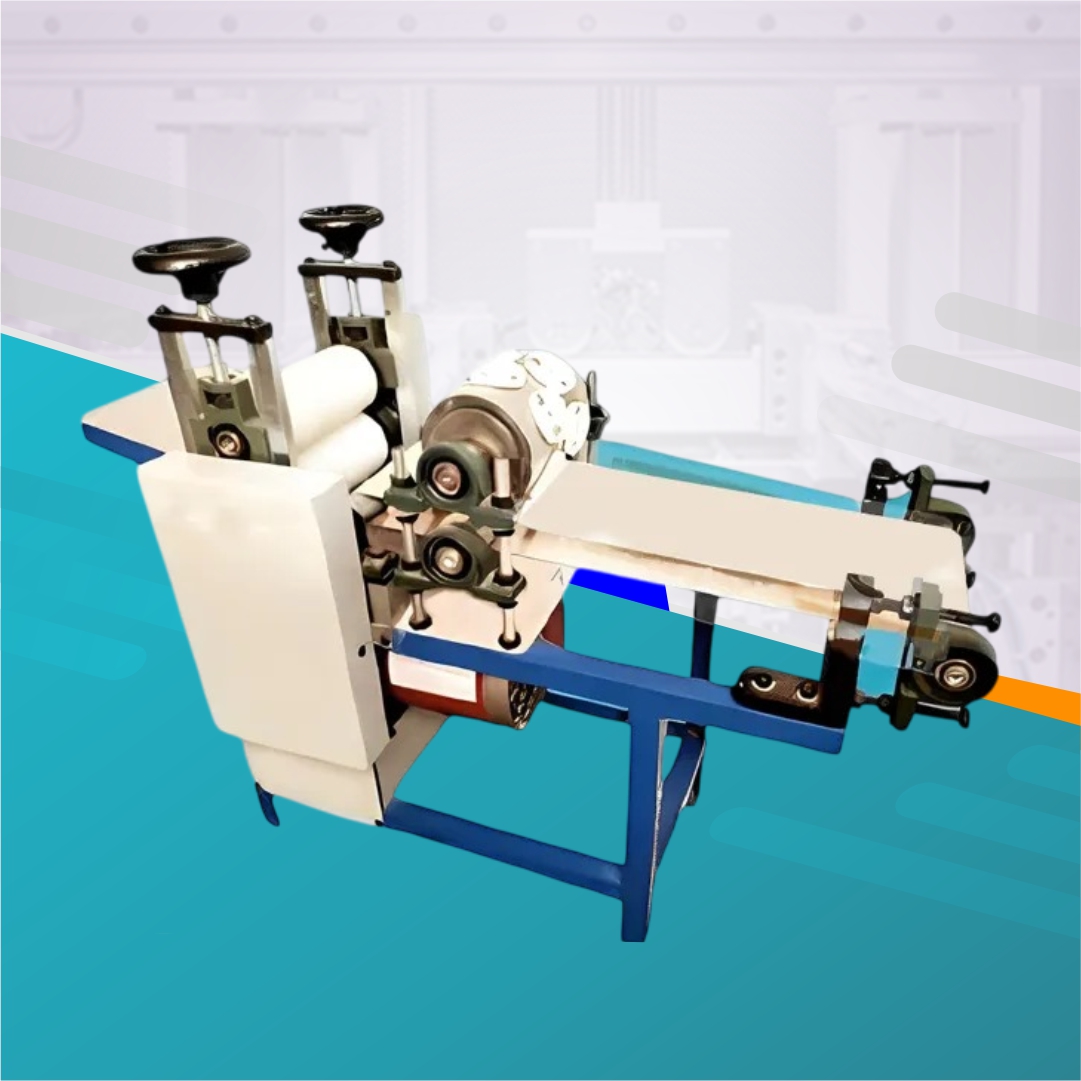

Working Process of an Automatic Pani Puri Making Machine

The machine operates through a systematic and synchronized process:

-

Dough Preparation

The process begins with mixing semolina (suji/sooji), flour, and water in a controlled ratio. Some systems include an inbuilt dough mixer to ensure uniform consistency. -

Sheeting and Cutting

The dough is flattened into thin sheets and cut into precise circular shapes. Thickness control is crucial at this stage to achieve the perfect crisp texture. -

Forming and Shaping

Cut dough discs are shaped into pani puri shells using specialized molds that maintain uniformity. -

Automatic Frying

The shaped puris are transferred into an automatic fryer where temperature and frying time are precisely controlled. This ensures evenly puffed, golden-brown shells. -

Cooling and Collection

After frying, the pani puris are cooled and collected, ready for packaging or immediate distribution.

Key Features of Automatic Pani Puri Making Machine

-

Fully automatic operation

-

Food-grade stainless steel construction

-

Adjustable size and thickness settings

-

High-speed production capability

-

Low power consumption

-

Minimal maintenance requirement

-

User-friendly control panel

-

Robust and durable design

Applications and Business Opportunities

An automatic pani puri making machine opens doors to multiple business opportunities:

-

Commercial Manufacturing Units: Supply pani puri to wholesalers and retailers.

-

Packaged Snack Industry: Produce branded pani puri packets for supermarkets.

-

Street Food Supply Chain: Bulk supply to local vendors.

-

Export Market: Cater to international demand for Indian snacks.

-

Food Courts & Cloud Kitchens: In-house production ensures freshness and cost control.

With the rising popularity of Indian snacks globally, investing in this machine can be a highly profitable long-term venture.

Why Buy from ASVR Engineering?

ASVR Engineering is a trusted name in the field of food processing and industrial machinery. Known for precision engineering, robust build quality, and customer-centric solutions, the company offers automatic pani puri making machines that are designed to deliver consistent performance even under heavy production loads.

What Sets ASVR Engineering Apart?

-

Years of industry experience

-

High-quality raw materials and components

-

Customizable machine configurations

-

Competitive pricing

-

Strong after-sales support

-

On-time delivery and installation assistance

When you choose ASVR Engineering, you are not just buying a machine—you are investing in reliability, efficiency, and long-term business growth.

Maintenance and Long-Term Performance

Automatic pani puri making machines from ASVR Engineering are designed for easy maintenance. Regular cleaning, periodic lubrication, and basic inspections are enough to keep the machine running smoothly for years. The use of high-quality components reduces breakdowns and ensures uninterrupted production.

Conclusion

The Automatic Pani Puri Making Machine is an essential solution for anyone looking to enter or expand in the pani puri manufacturing business. With its ability to deliver high output, consistent quality, hygienic production, and cost efficiency, it stands as a smart investment in today’s competitive food industry.

If you are serious about scaling your snack business and meeting growing market demand, choosing a fully automatic pani puri making machine from ASVR Engineering can give you a decisive edge. From small entrepreneurs to large-scale manufacturers, this machine empowers businesses to grow faster, smarter, and more profitably.

Contact Details

Company Name: ASVR Engineering

Website: https://www.asvrengineering.com

Phone: +91-8076004849, +91-8800971968

Buy Now