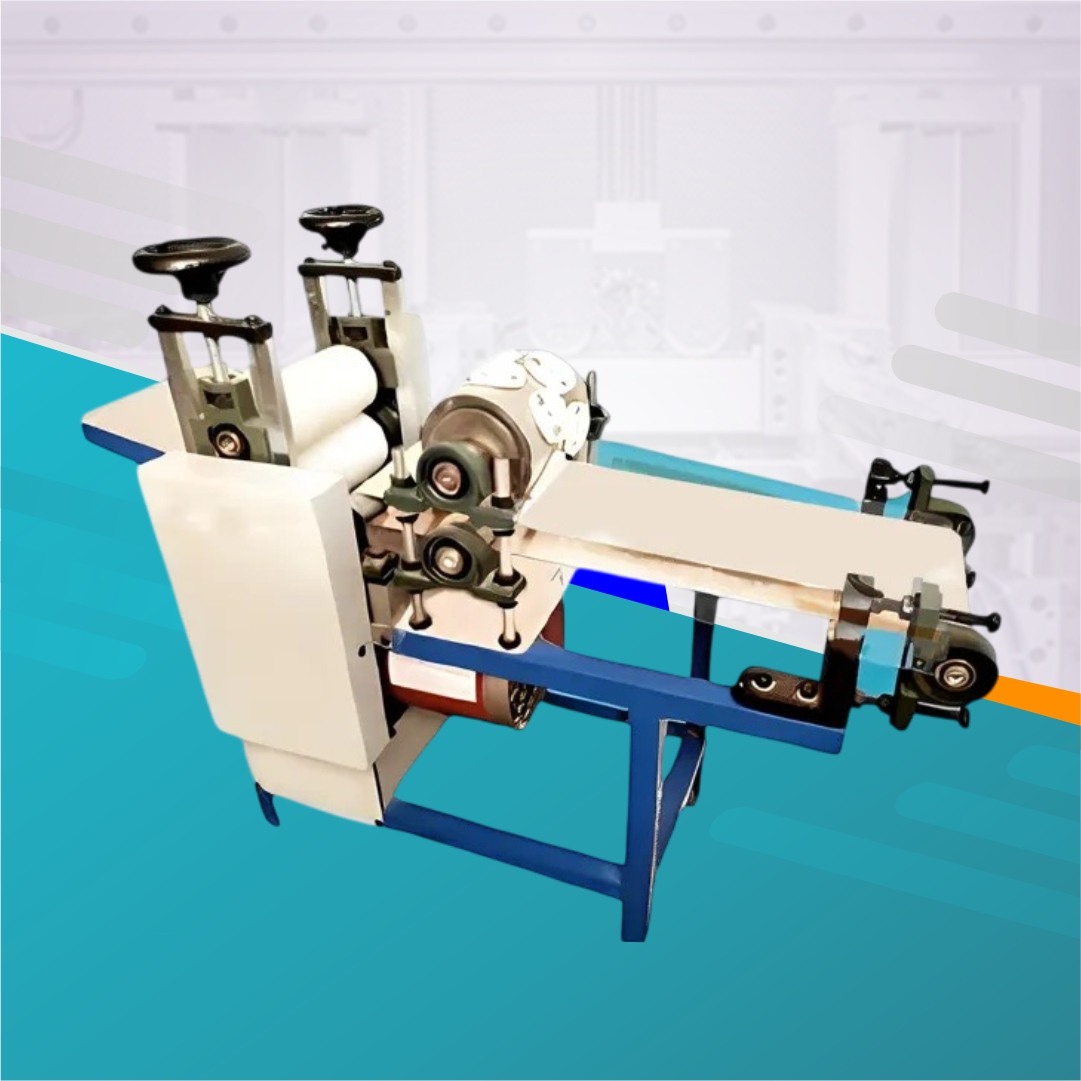

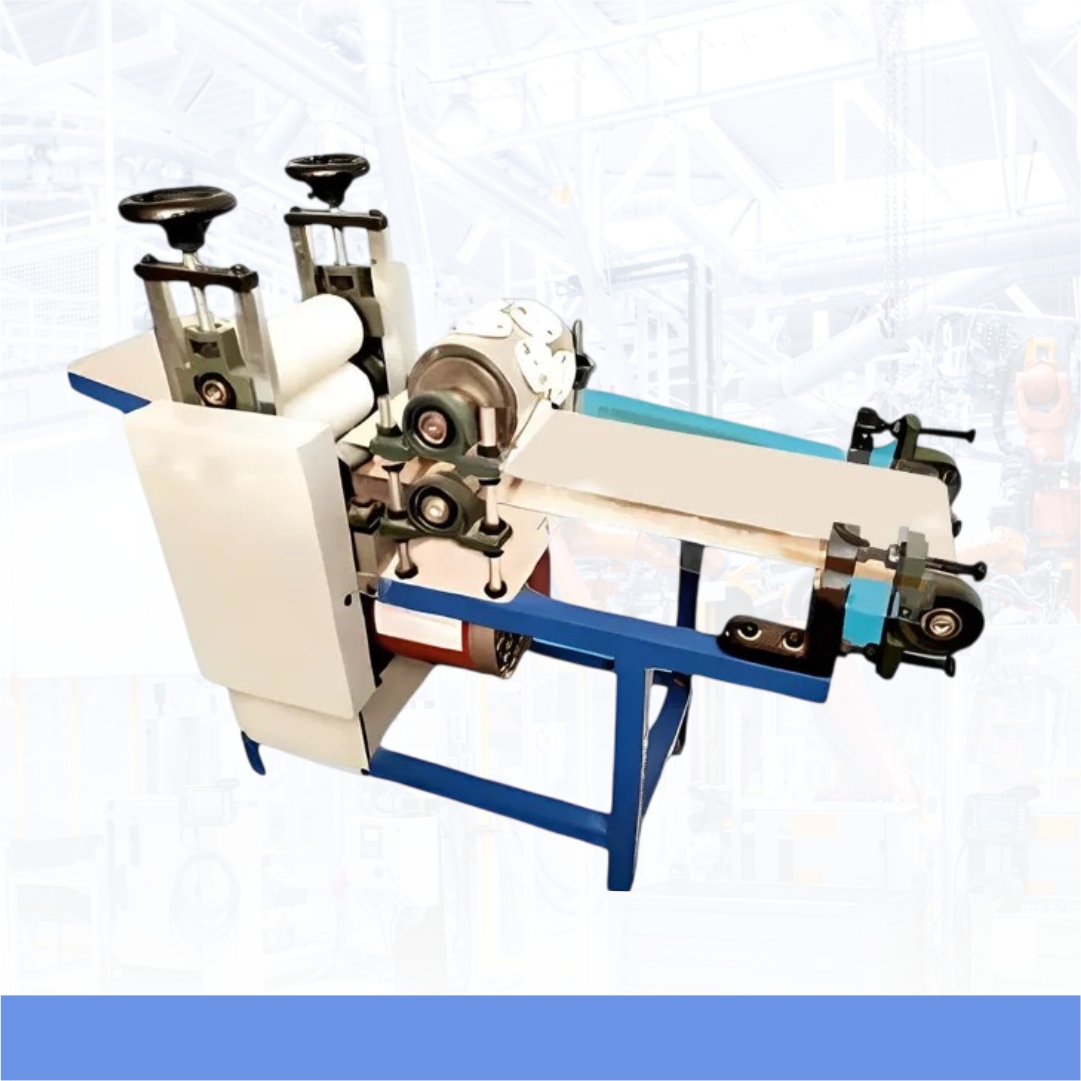

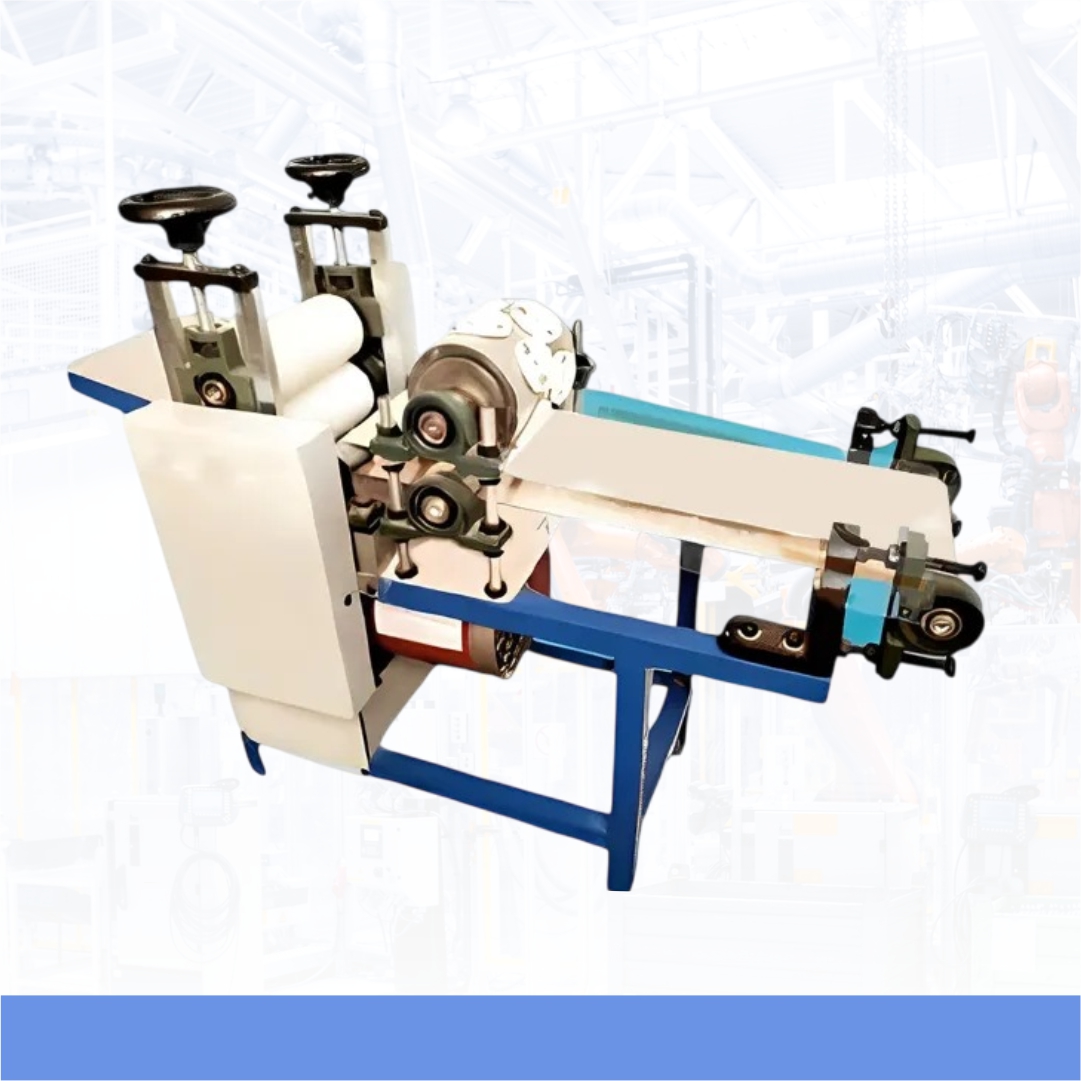

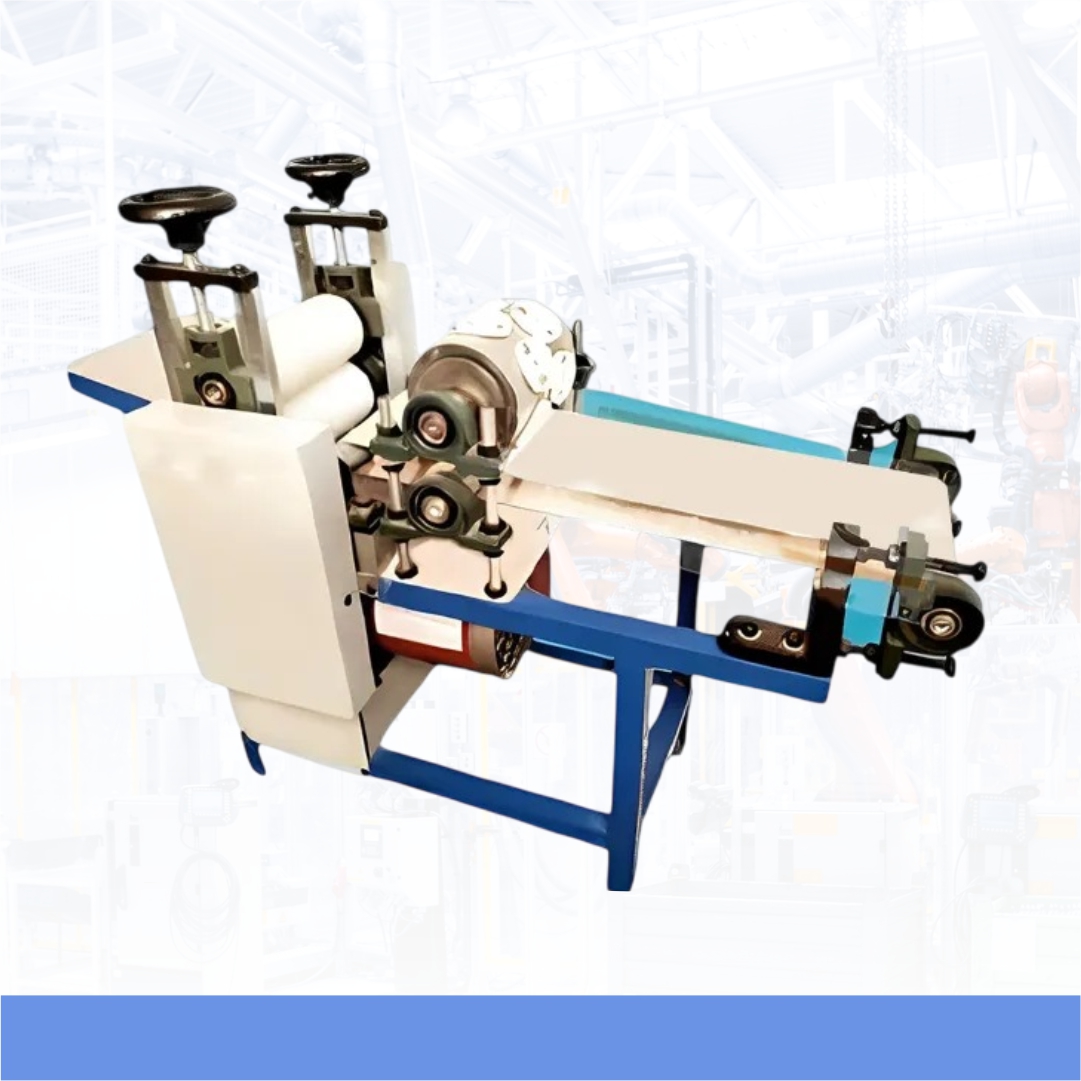

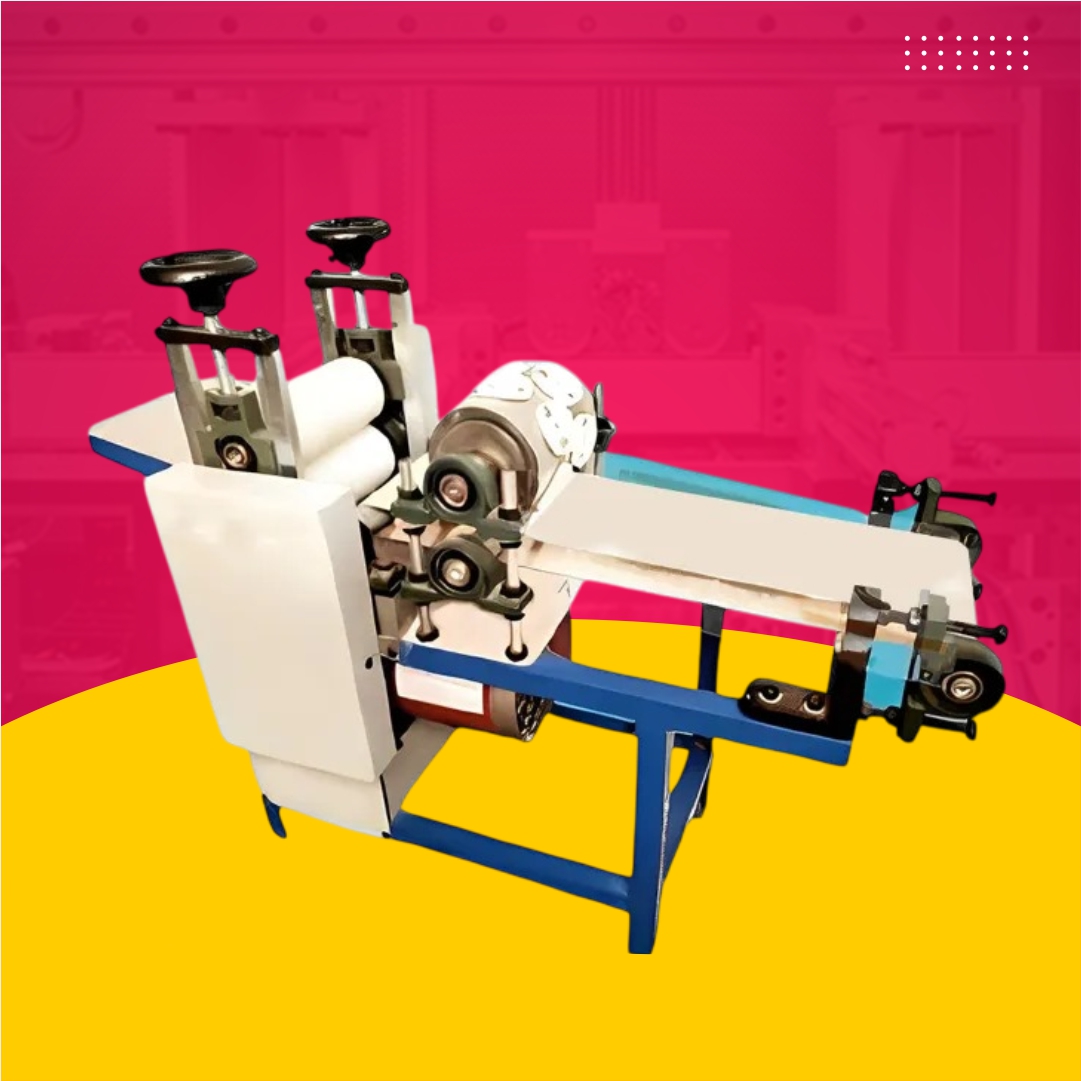

Automatic Pani Puri Making Machine

Price: ₹72000

In India, pani puri is not just a snack; it is an emotion enjoyed by people of all ages, across cities, towns, and villages. From roadside vendors to premium food courts and packaged snack brands, the demand for fresh, crispy, and hygienic pani puri has grown rapidly. To meet this rising demand while maintaining quality, consistency, and hygiene, businesses are now shifting from manual production to advanced Automatic Pani Puri Making Machines.

An automatic pani puri making machine is designed to produce large quantities of uniform, perfectly puffed pani puris with minimal human intervention. It eliminates inconsistencies caused by manual processes, ensures better hygiene standards, and significantly reduces labor costs. For entrepreneurs, food manufacturers, cloud kitchens, exporters, and snack brands, this machine has become a profitable and future-ready investment.

What Is an Automatic Pani Puri Making Machine?

An automatic pani puri making machine is an industrial-grade food processing machine that converts raw ingredients such as semolina (suji), flour, and water into perfectly shaped, evenly cooked pani puris. From dough preparation to sheet rolling, cutting, frying, and sometimes even oil filtration, the entire process can be automated or semi-automated depending on the model.

Unlike traditional hand-made methods, this machine produces pani puris that are identical in size, thickness, and crispiness. This uniformity is extremely important for commercial packaging, branding, and bulk supply.

Why the Demand for Automatic Pani Puri Machines Is Growing

The food industry has witnessed a major shift toward automation due to rising labor costs, strict hygiene regulations, and growing consumer awareness. Manual pani puri production often fails to meet modern food safety standards, especially for packaged and exported products. Automatic machines solve these challenges efficiently.

Food startups, established snack manufacturers, and exporters prefer automatic pani puri making machines because they provide higher output, better quality control, and long-term cost savings. With consistent demand throughout the year, pani puri production has become a stable and scalable business.

Key Features of an Automatic Pani Puri Making Machine

High Production Capacity

Automatic pani puri machines are built for continuous production. Depending on the model, they can produce thousands of pani puris per hour, making them suitable for both medium-scale and large-scale operations.

Uniform Size and Shape

One of the biggest advantages of automation is consistency. Every pani puri comes out with the same size, thickness, and texture, which is essential for branding and packaging.

Hygienic Manufacturing Process

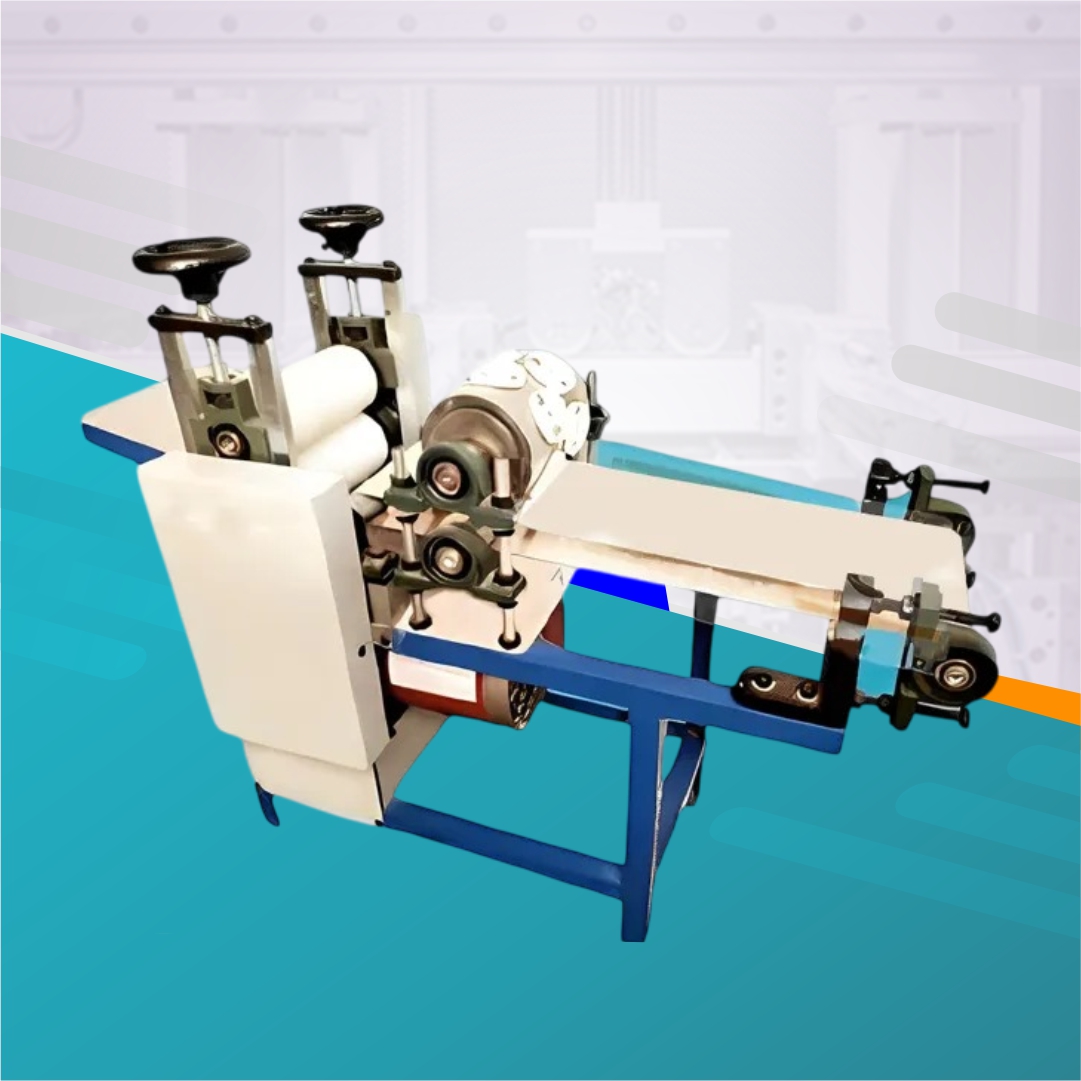

These machines are manufactured using food-grade stainless steel. Minimal human contact ensures compliance with hygiene and food safety standards required by modern markets.

Energy and Cost Efficient

Designed for optimal power consumption, automatic pani puri making machines reduce wastage of raw materials and oil, lowering the overall production cost.

Easy Operation and Maintenance

User-friendly controls, simple settings, and low maintenance requirements make these machines suitable even for operators with minimal technical skills.

Working Process of an Automatic Pani Puri Making Machine

The process starts with preparing the dough using suji, flour, and water. The dough is fed into the machine, where it is rolled into thin sheets. These sheets are then cut into small circular shapes. The cut discs are transferred into a frying system, where they puff up into crispy pani puris.

Advanced machines maintain accurate temperature control during frying, ensuring even cooking and a golden finish. The finished pani puris are then collected, cooled, and ready for packaging or immediate use.

Applications of Automatic Pani Puri Making Machines

Automatic pani puri making machines are widely used across different segments of the food industry:

-

Commercial pani puri manufacturers

-

Packaged snack brands

-

Cloud kitchens and food processing units

-

Catering companies and event suppliers

-

Export-oriented snack manufacturers

-

Large pani puri vendors and franchises

These machines are ideal for businesses that require consistent quality, high output, and reliable performance.

Business Benefits of Investing in an Automatic Pani Puri Machine

Higher Profit Margins

By reducing labor dependency and increasing output, businesses can significantly improve profit margins. The cost per unit decreases as production volume increases.

Scalability

As demand grows, production can be scaled up easily by increasing machine capacity or adding additional units.

Better Market Reach

Uniform, hygienic pani puris are easier to package and distribute, allowing businesses to expand into supermarkets, online platforms, and export markets.

Brand Value

Consistency in product quality builds trust among customers and helps in establishing a strong brand presence.

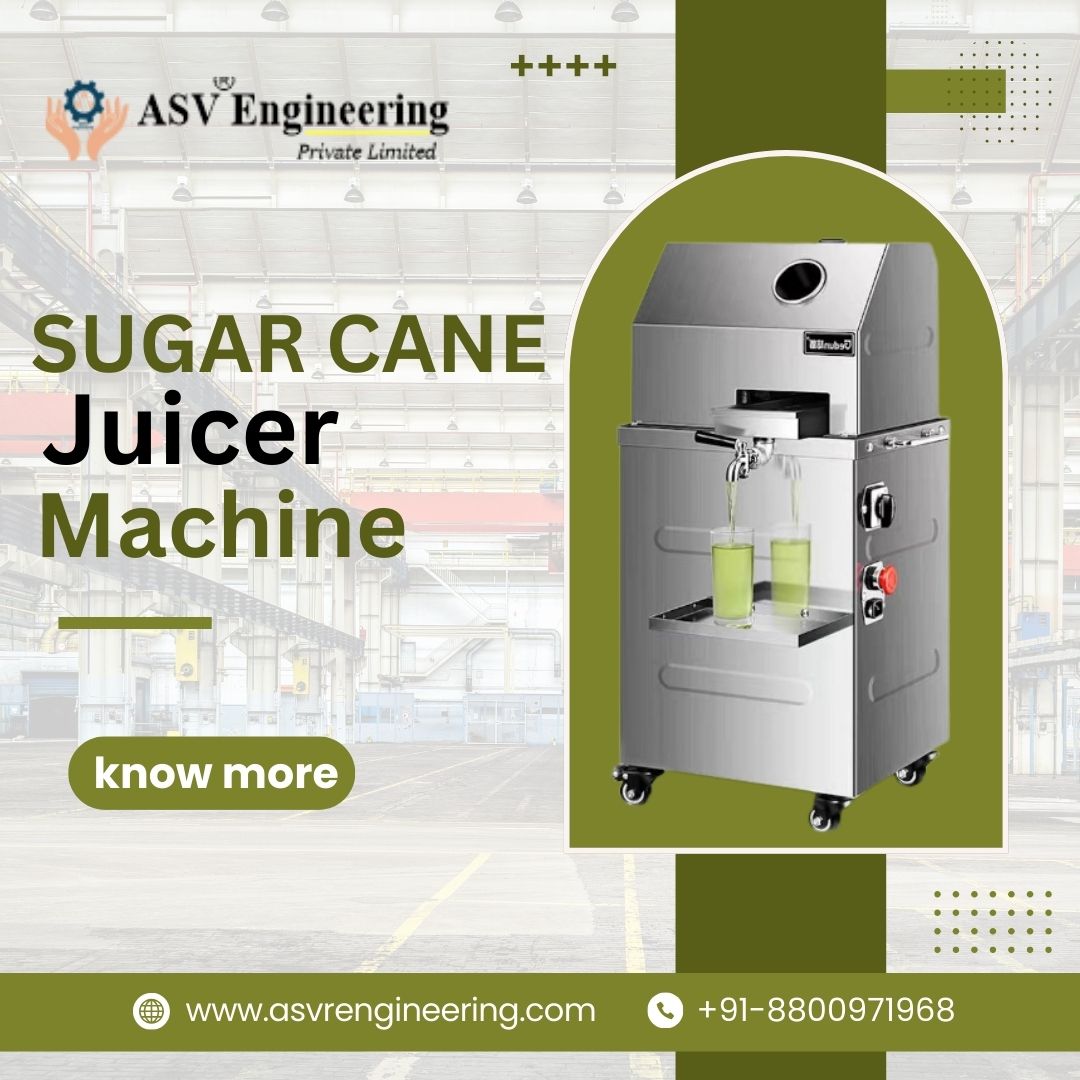

Why Choose ASVR Engineering?

ASVR Engineering is a trusted name in the field of food processing machinery, offering reliable and high-performance automatic pani puri making machines. With a strong focus on quality, innovation, and customer satisfaction, the company provides machines that meet industry standards and long-term business needs.

Every machine is designed using advanced technology and robust materials to ensure durability and efficient performance. ASVR Engineering also provides excellent after-sales support, technical guidance, and customized solutions based on production requirements.

Quality, Durability, and Compliance

Automatic pani puri making machines from ASVR Engineering are manufactured using premium-grade components and stainless steel structures. They are designed to comply with food safety norms and are suitable for continuous industrial use. The machines undergo strict quality checks before delivery to ensure flawless operation at the customer’s facility.

Suitable for Indian and International Markets

With the increasing popularity of Indian snacks worldwide, automatic pani puri making machines are in high demand in international markets as well. These machines help exporters meet global hygiene standards while maintaining authentic taste and texture.

Businesses targeting overseas markets benefit greatly from automation, as it ensures consistent quality across large production batches.

Return on Investment (ROI)

An automatic pani puri making machine is not an expense but a long-term investment. With steady demand, low operational costs, and high output, most businesses recover their investment within a short period. The machine continues to generate profits for years with proper maintenance.

Conclusion

The automatic pani puri making machine has transformed the way this beloved snack is produced. It brings speed, hygiene, consistency, and profitability to pani puri manufacturing. Whether you are starting a new food business or upgrading an existing setup, investing in an automatic pani puri making machine is a smart and future-ready decision.

For reliable machines, technical expertise, and long-term support, ASVR Engineering stands out as a trusted partner in the food processing industry.

Contact Details

📞 Phone: +91-8076004849, +91-8800971968

🌐 Website: https://www.asvrengineering.com

Buy Now