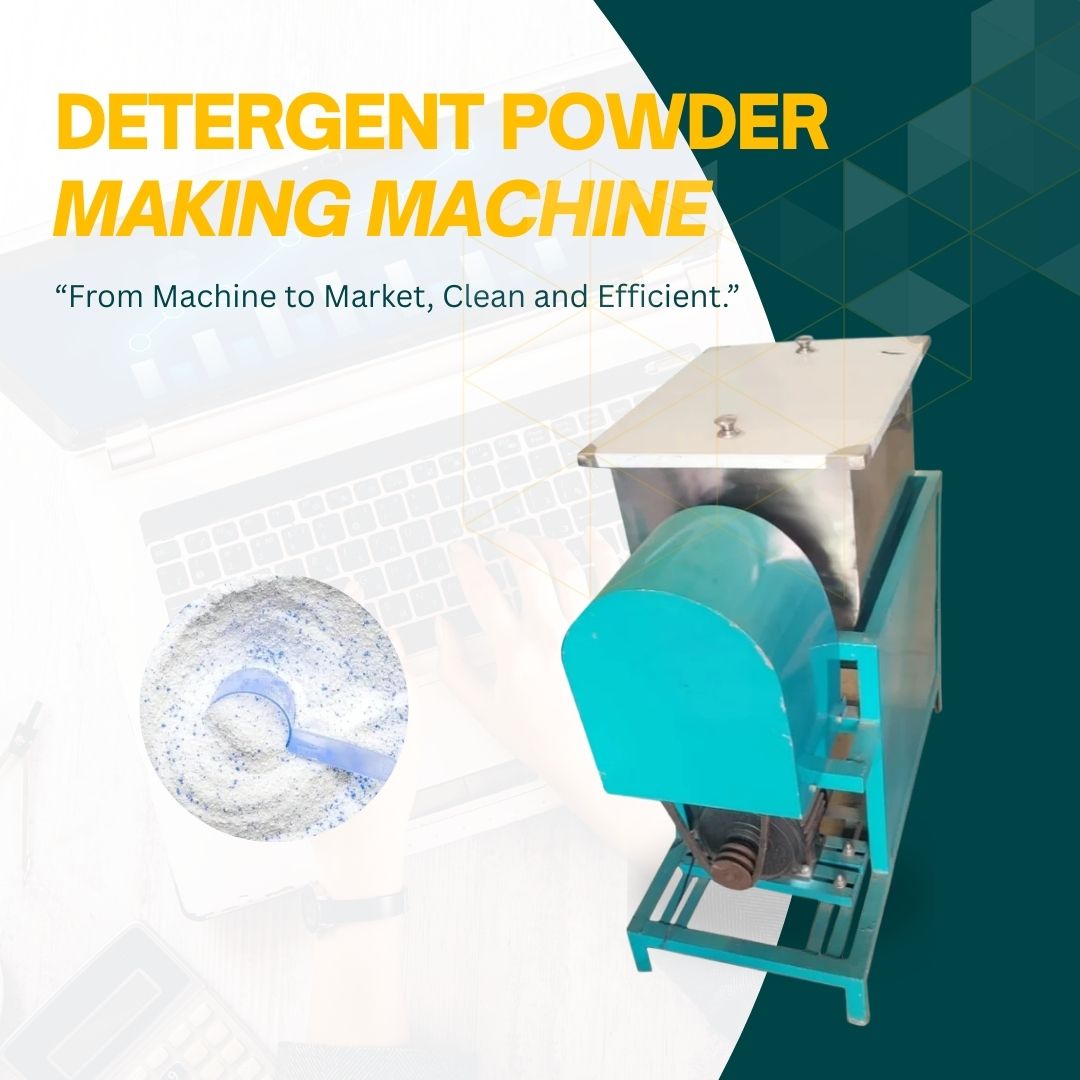

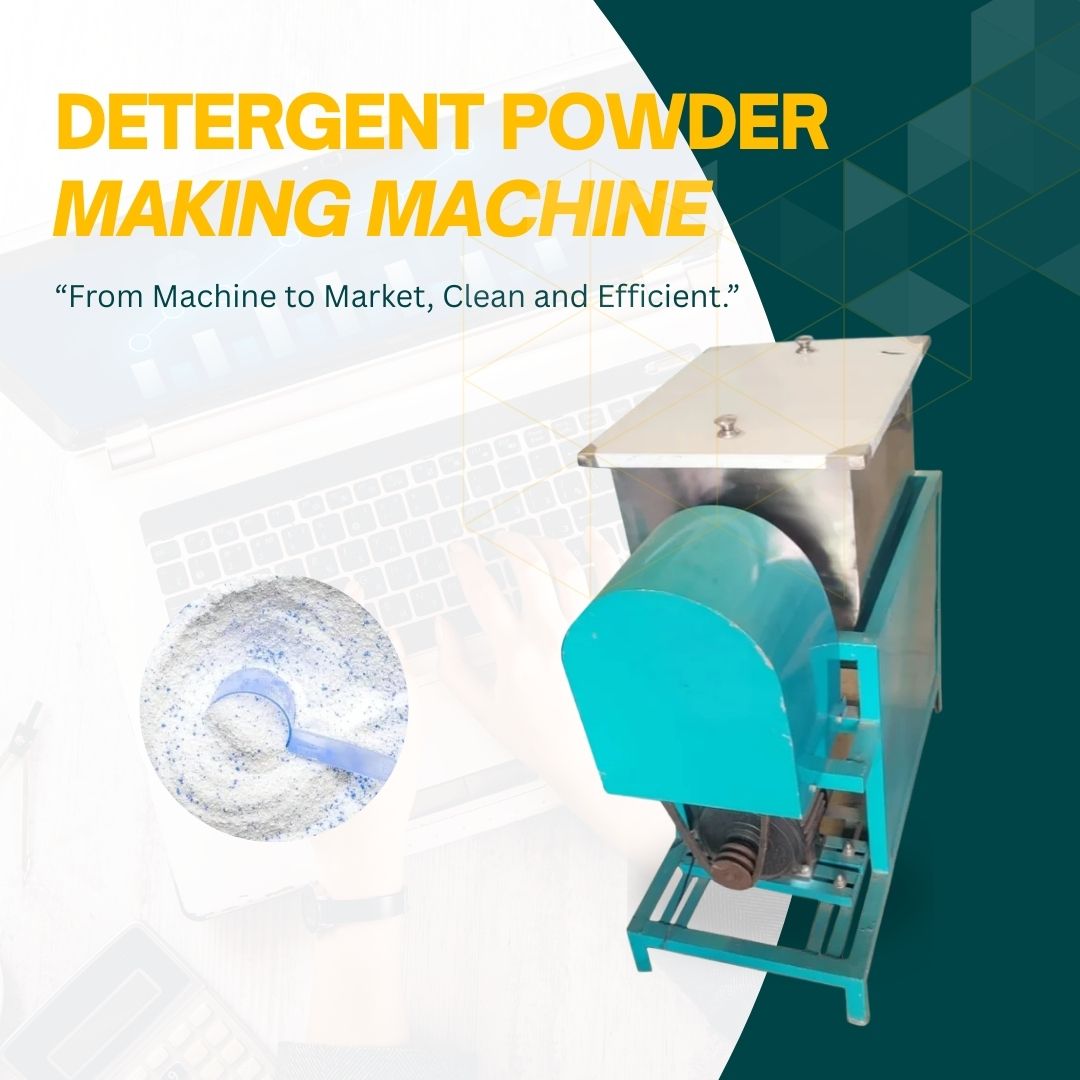

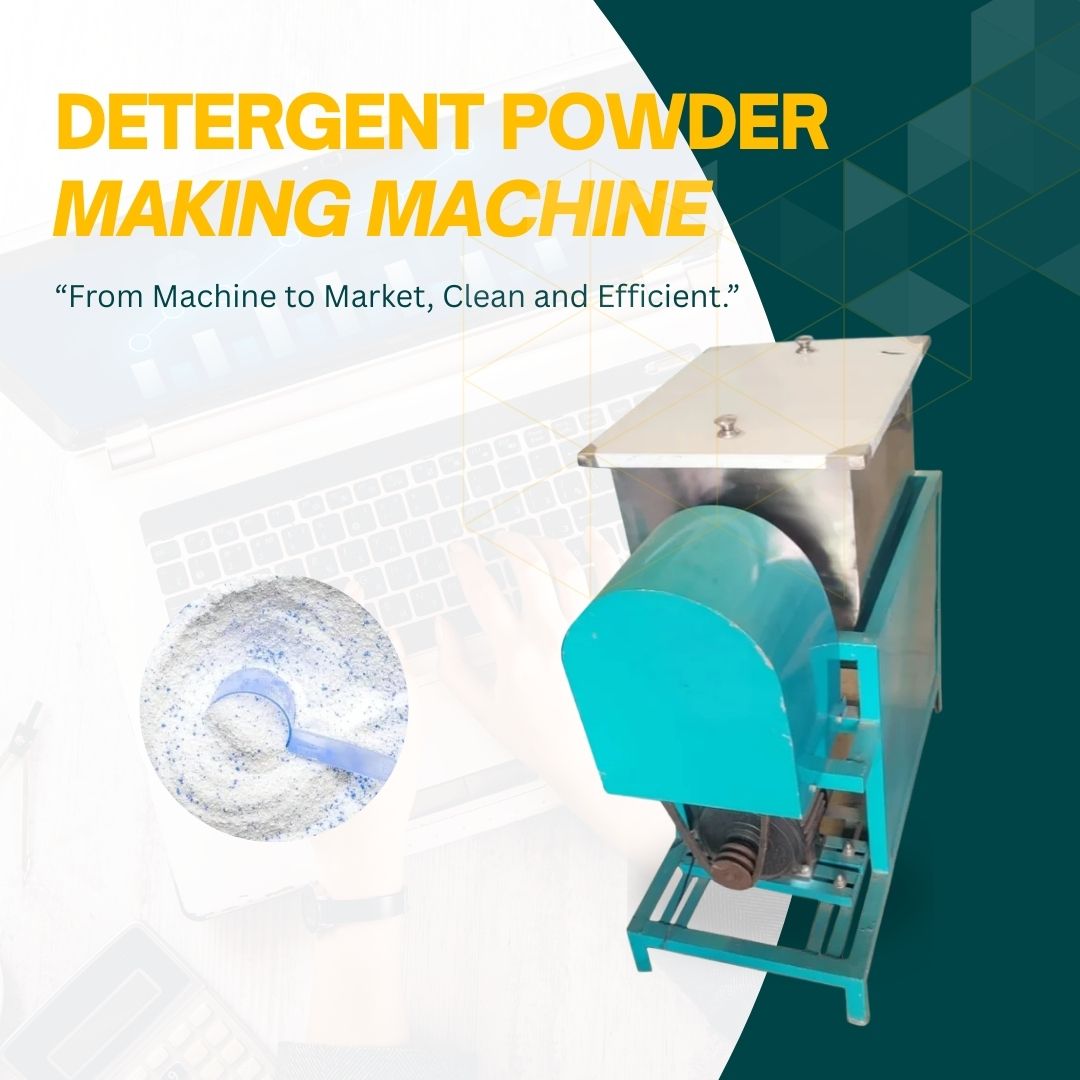

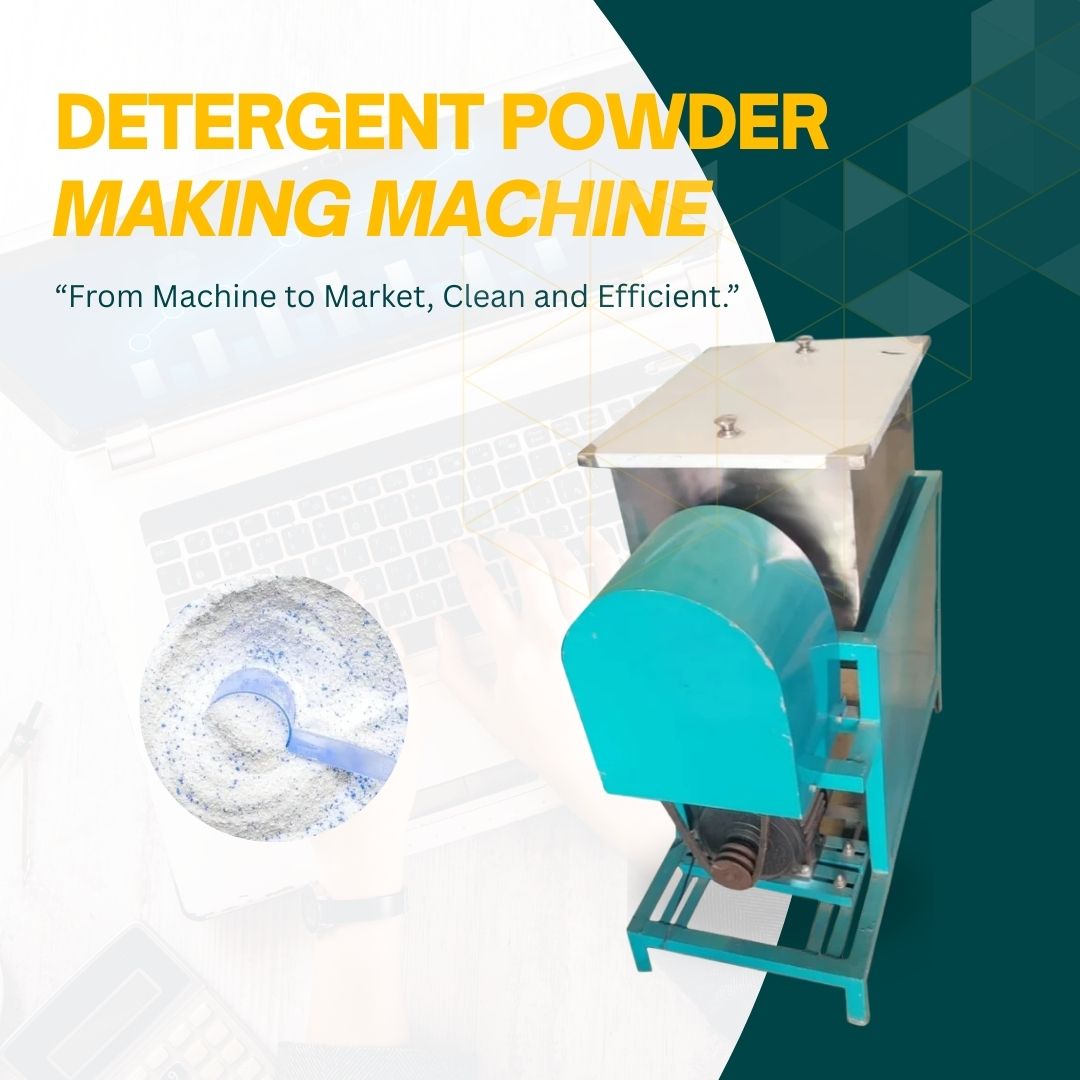

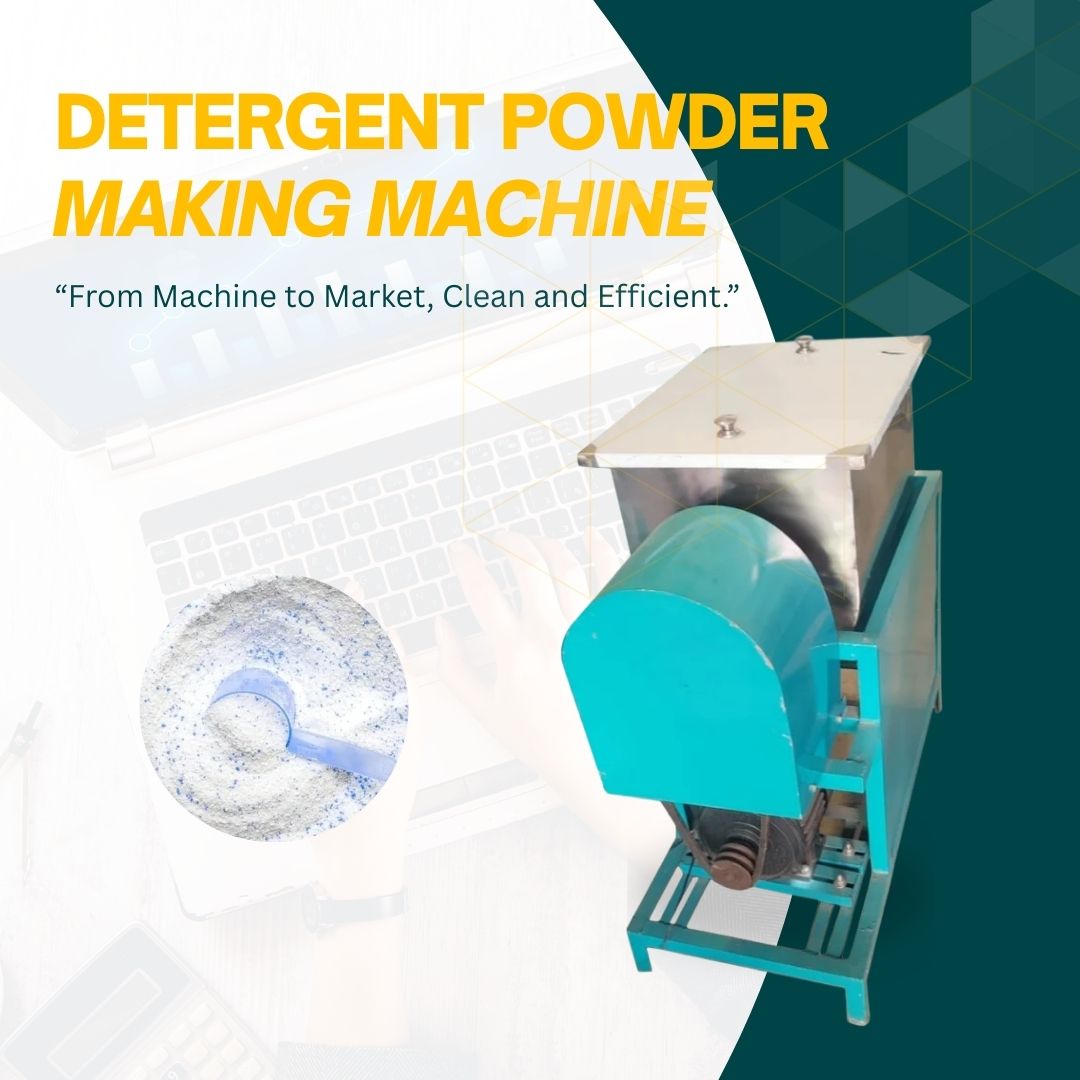

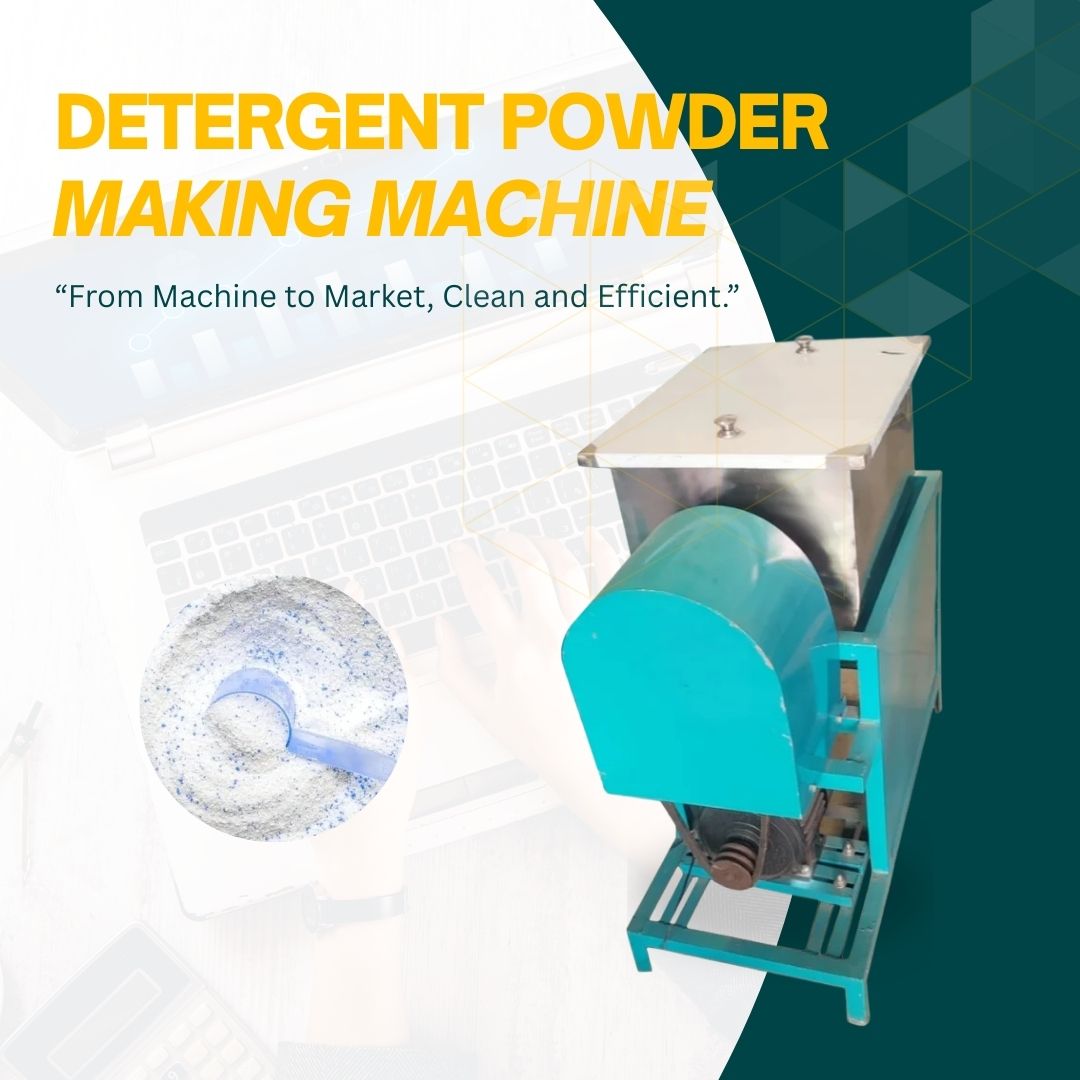

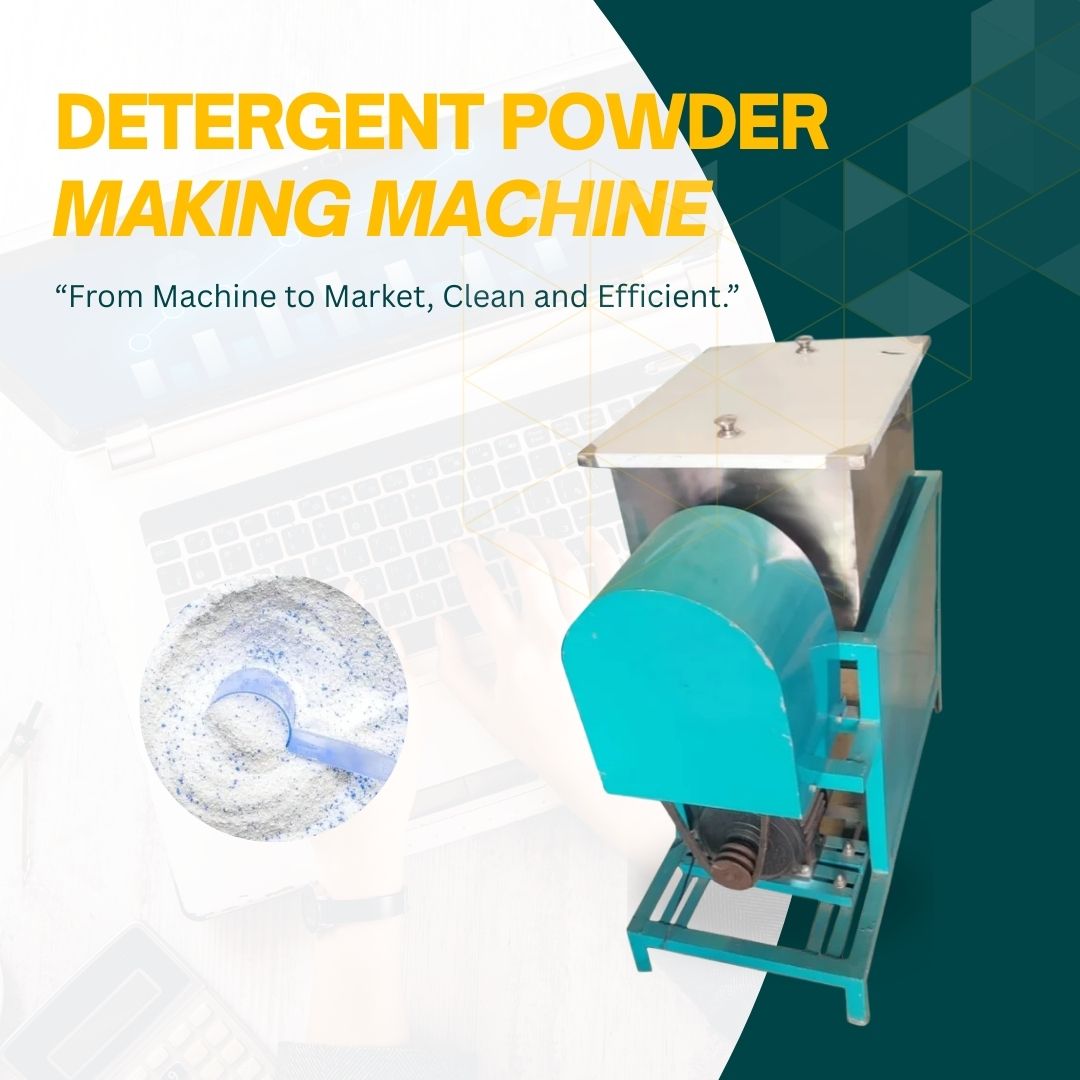

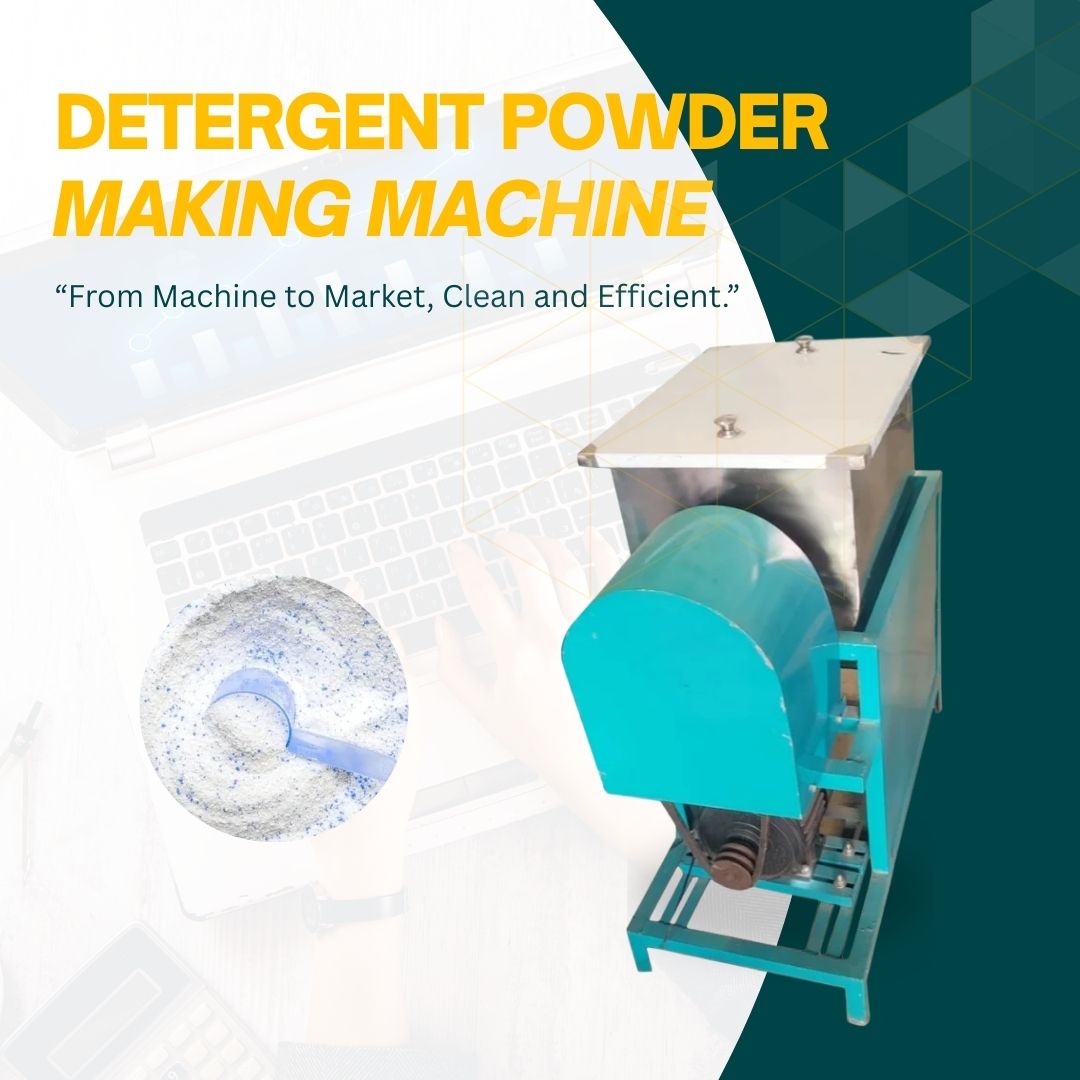

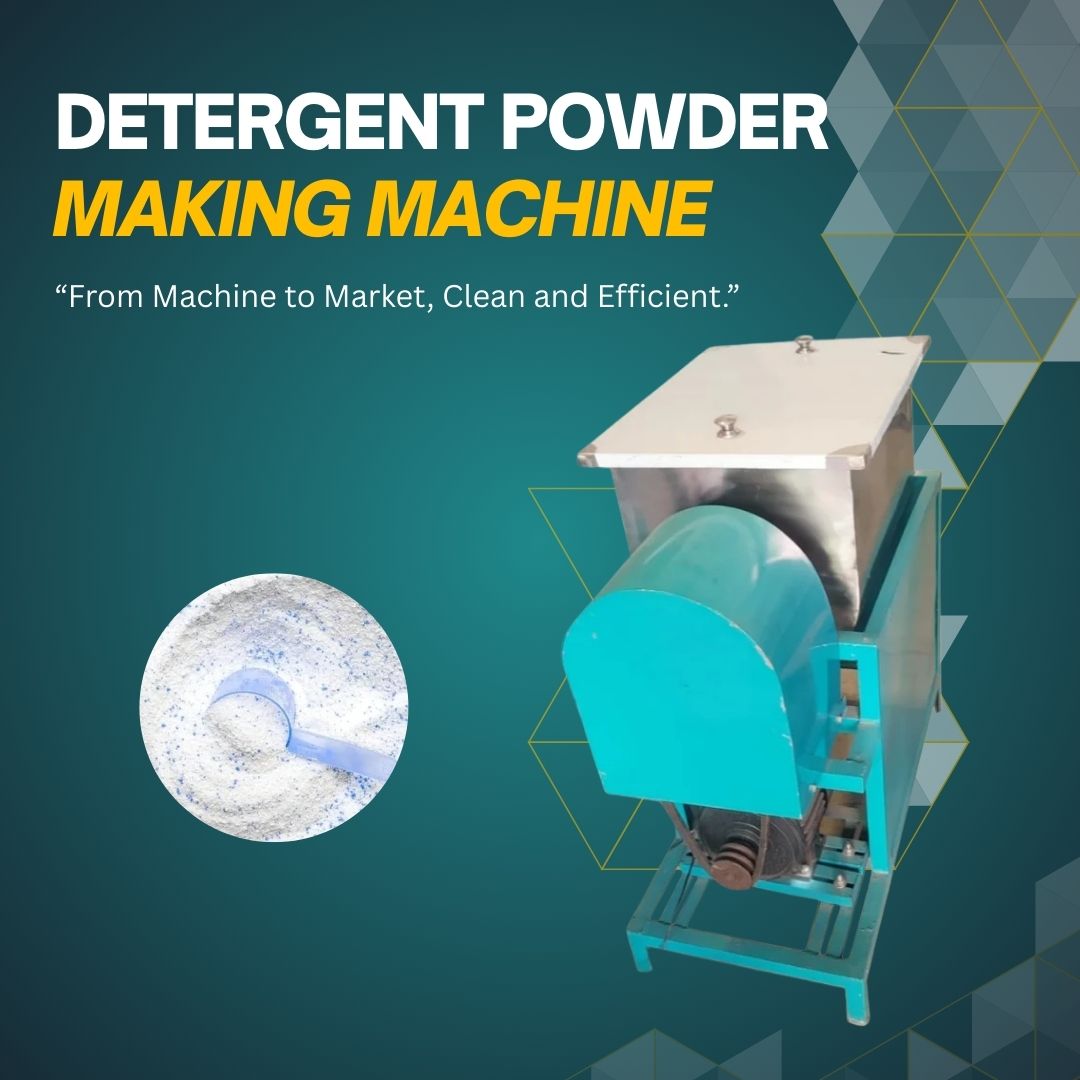

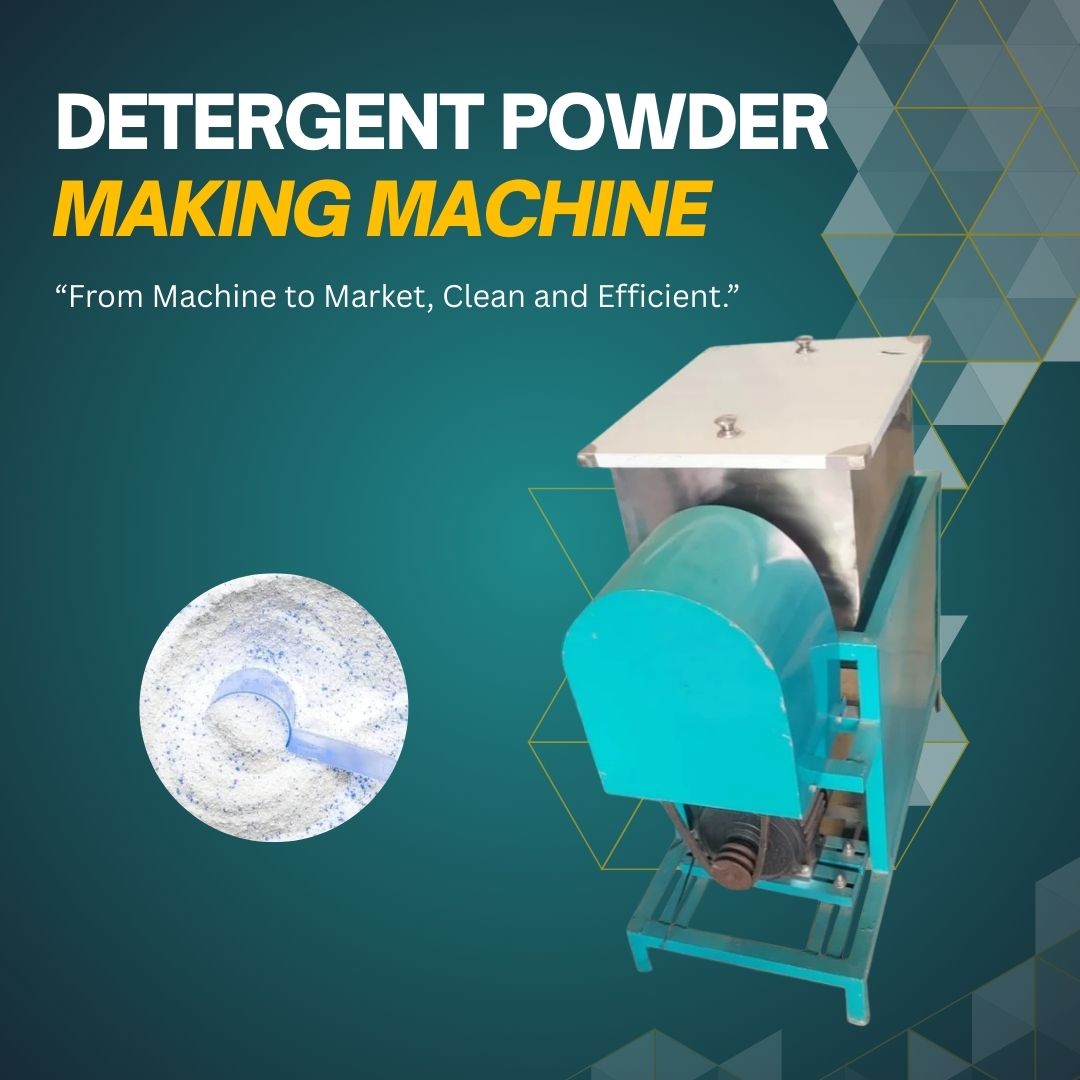

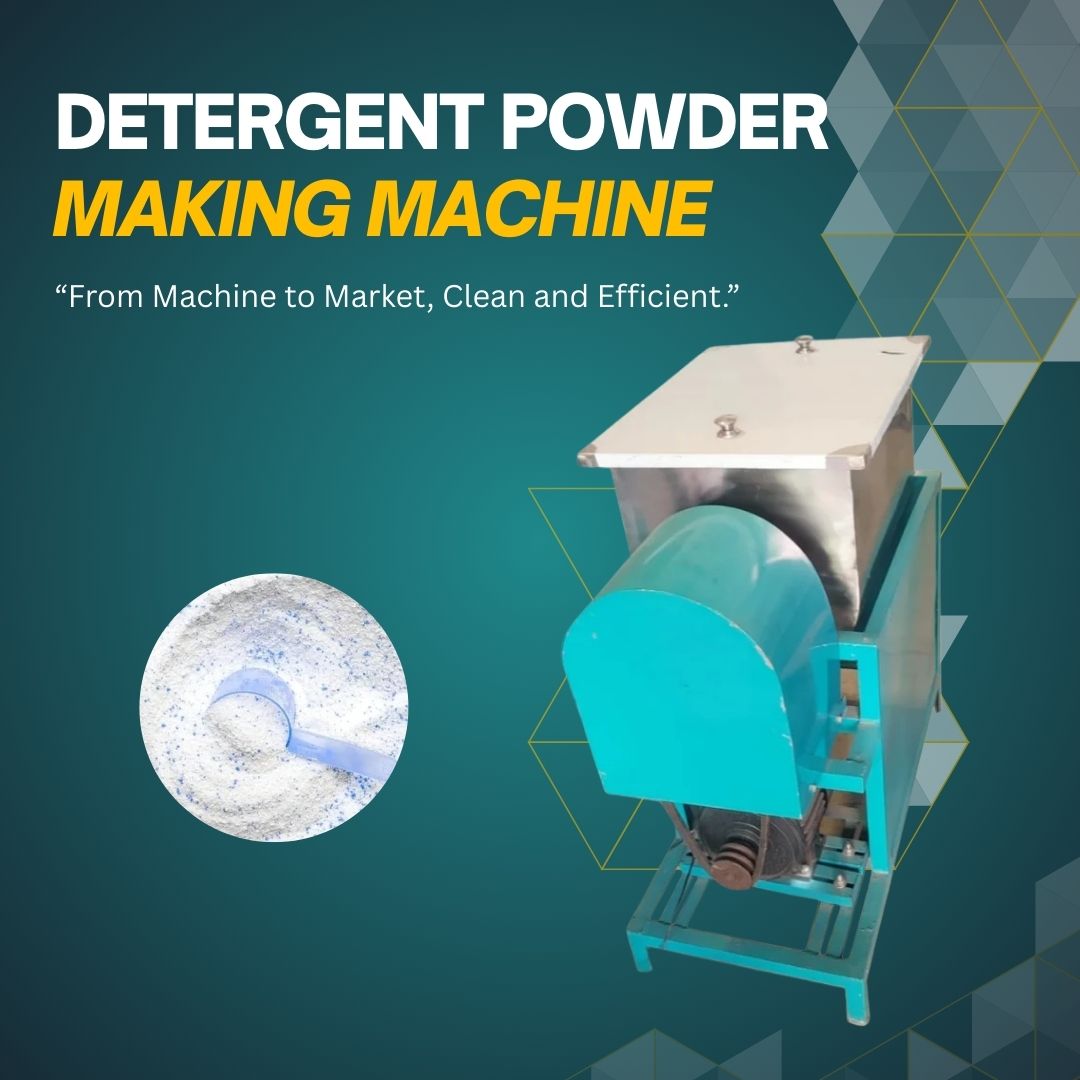

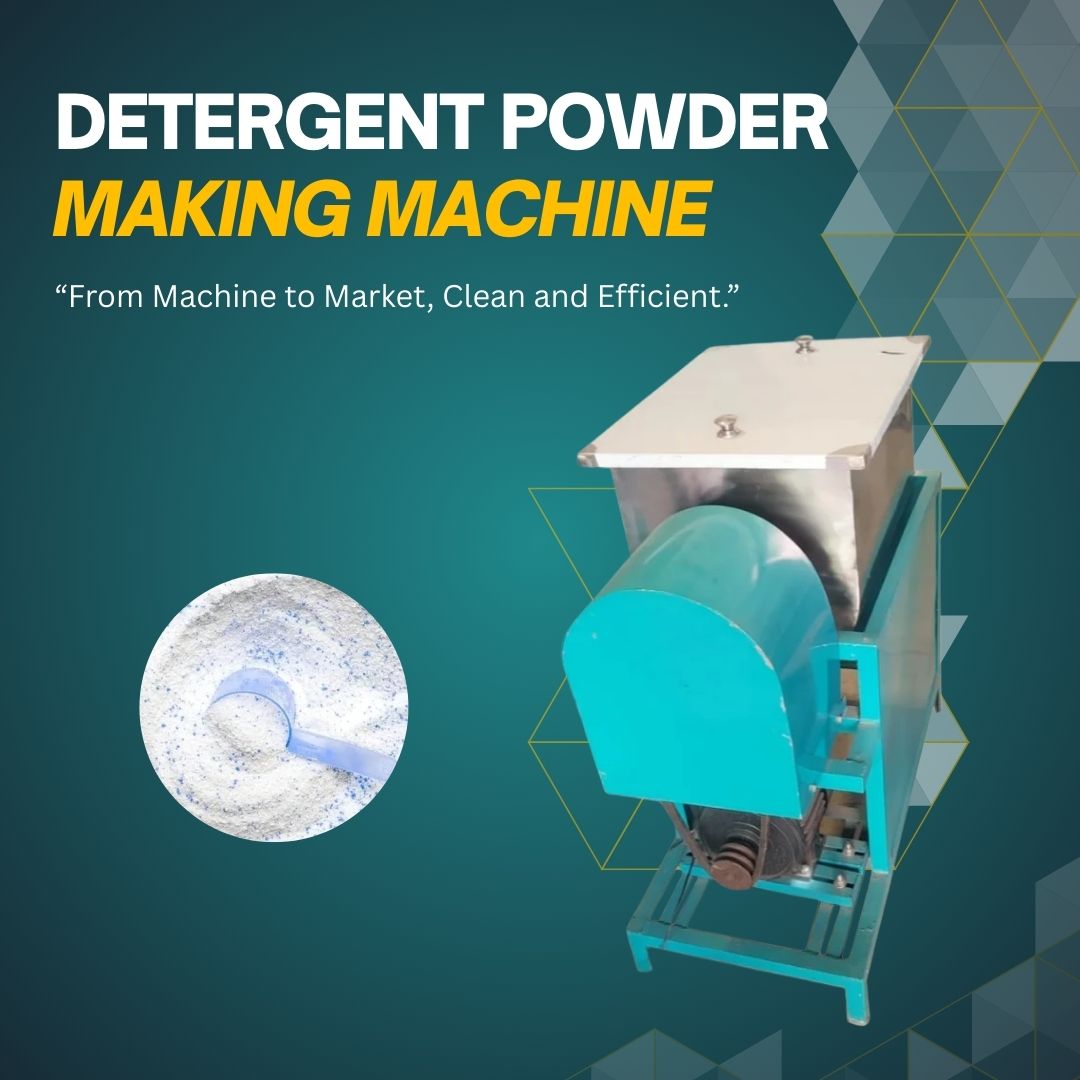

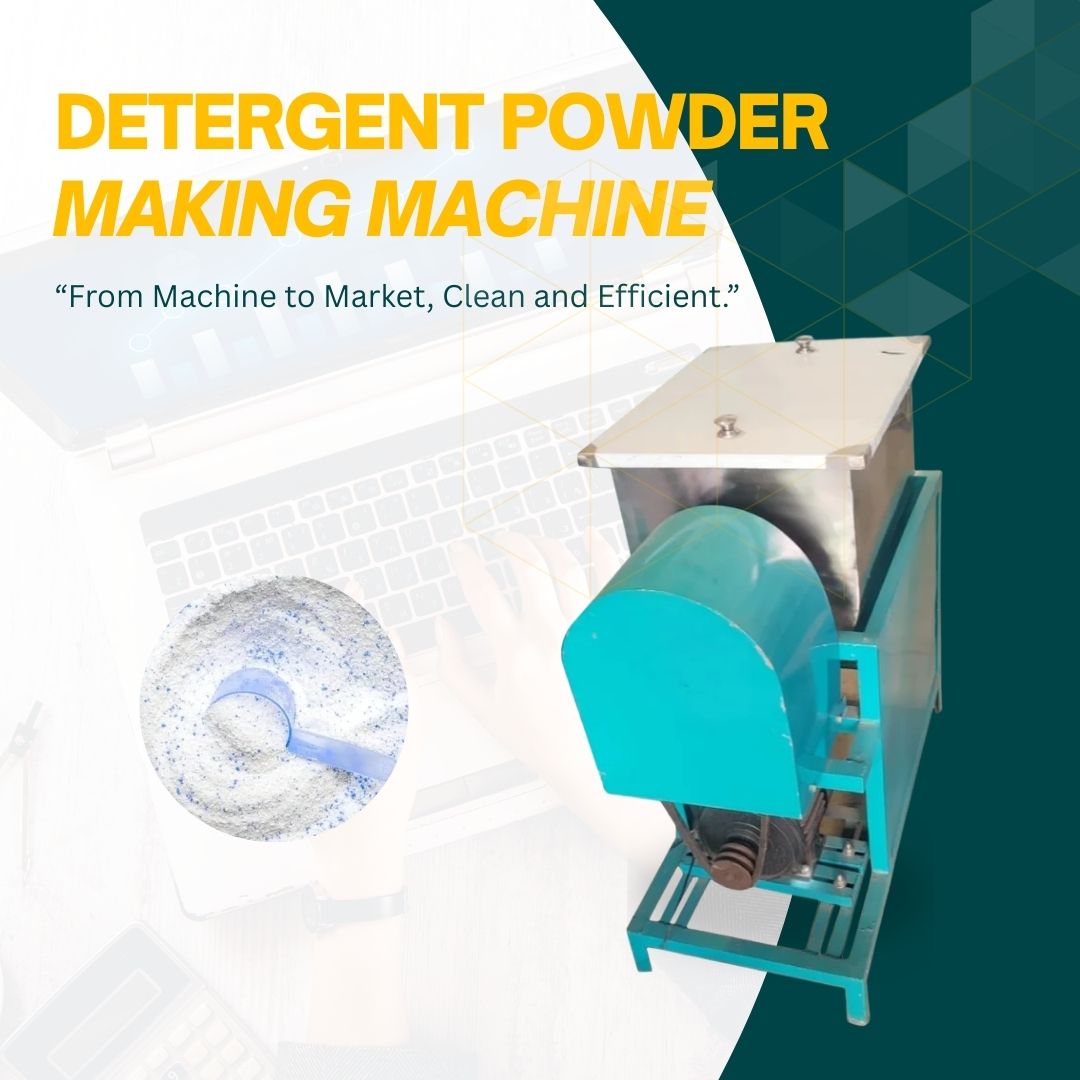

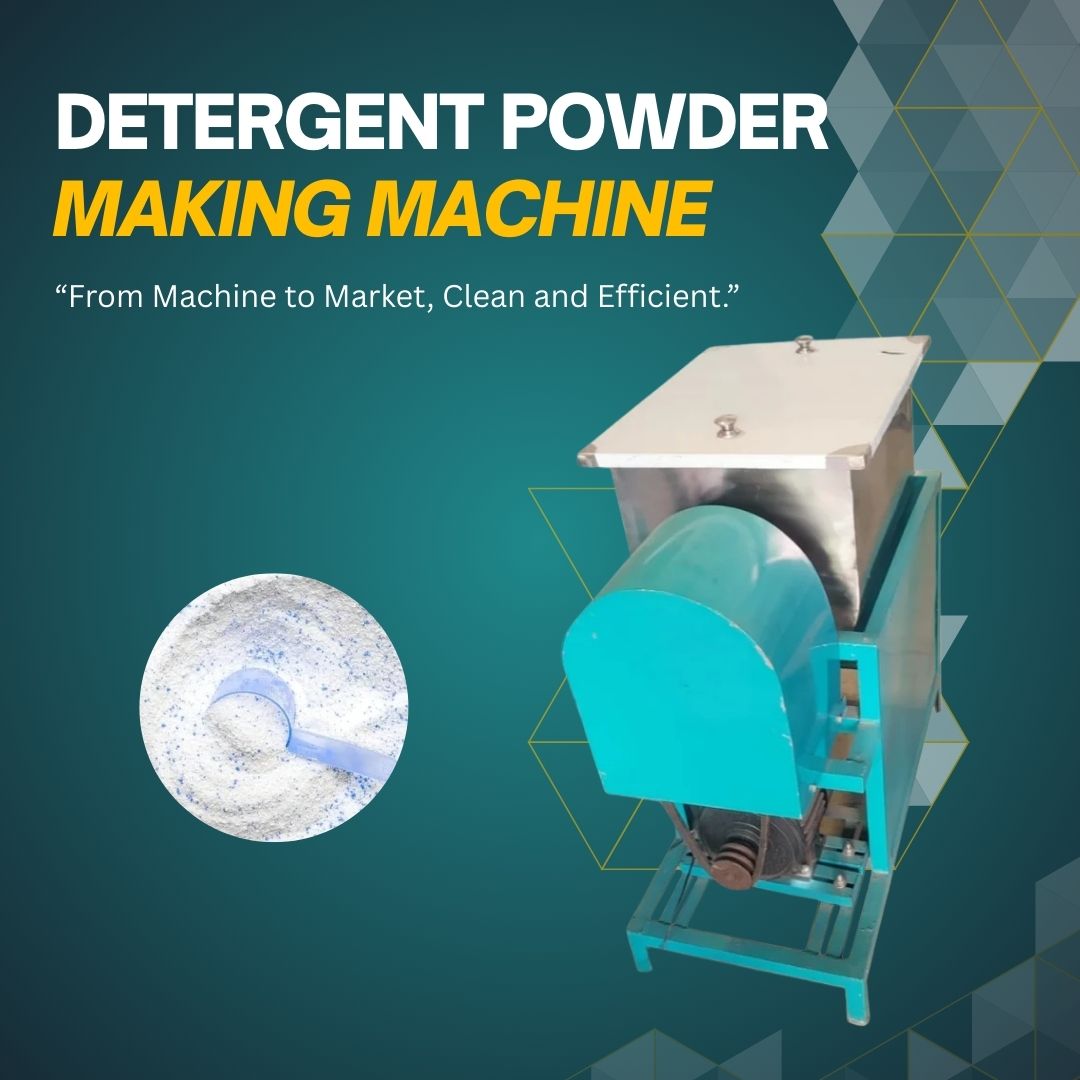

Detergent Powder Plant Machinery with High Mixing Accuracy

Price: ₹50000

Detergent Powder Plant Machinery with High Mixing Accuracy – ASVR Engineering Pvt Ltd

In detergent manufacturing, mixing accuracy is one of the most critical factors that influence product quality, consistency, and performance. A slight variation in the blend can impact the cleaning effectiveness of the final product, leading to customer dissatisfaction and brand damage.

That’s why ASVR Engineering Pvt Ltd specializes in delivering detergent powder plant machinery with high mixing accuracy, designed for superior output, durability, and efficiency. Whether you run a small-scale detergent business or a full-scale industrial production plant, our machines are engineered to meet your specific needs.

Why Mixing Accuracy Matters in Detergent Production

1. Consistent Quality

Accurate mixing ensures that each batch of detergent has the same proportion of active ingredients, fillers, fragrance, and color.

2. Cost Control

Precise dosing reduces overuse of expensive raw materials, helping control production costs.

3. Homogeneous Product

Uniform blending eliminates hotspots or under-mixed regions, resulting in a smooth, free-flowing powder with optimal cleaning power.

ASVR's High-Precision Detergent Mixing Solutions

Ribbon Blender with Helical Blade Design

Our ribbon blender is a heavy-duty, stainless steel mixing vessel equipped with specially designed inner and outer helical ribbons. This configuration ensures:

-

Complete axial and radial mixing

-

No dead zones inside the drum

-

Gentle yet thorough blending of fragile components

Available in capacities ranging from 100 liters to 5000 liters, our ribbon mixers are ideal for both small and industrial applications.

Optional Features:

-

Heating jacket (for moisture-sensitive ingredients)

-

Liquid spray nozzle (for perfumes or binders)

-

Dust collection system

-

Load cell integration for accurate weight batching

Complete Detergent Powder Plant Machinery Includes

| Machine | Function |

|---|---|

| Ribbon Blender | Uniform mixing of all powder ingredients |

| Screw Conveyor | Transfers powder between equipment |

| Vibratory Sieve / Screen | Removes lumps and enhances texture |

| Automatic Weighing System | Ensures accurate raw material input |

| Packing Machine | Fills and seals detergent powder in pouches |

| Control Panel (PLC-based) | Controls and monitors all plant operations |

Each machine is designed to integrate smoothly with the others, forming a seamless production line with high reliability.

Key Benefits of Our Machinery

-

High Mixing Precision: Variance of less than ±2% in ingredient ratio

-

Energy Efficient: Optimized motor power reduces operational costs

-

Easy Cleaning: Smooth internal surfaces prevent residue build-up

-

Low Maintenance: Rugged construction and wear-resistant parts

-

Scalable Design: Machines available for 100 kg/hr to 5 tons/hr capacity

Raw Materials Compatible with ASVR Mixing Systems

-

Soda ash (sodium carbonate)

-

Sodium sulfate

-

Acid slurry (LABSA)

-

STPP (sodium tripolyphosphate)

-

Perfumes and colorants

-

Optical brighteners

-

Binders and anti-caking agents

Our equipment can handle both free-flowing and slightly cohesive powders, ensuring uniform results regardless of material properties.

Industries We Serve

-

Household detergent manufacturers

-

Commercial and industrial cleaning product companies

-

Private-label detergent brands

-

Institutional supply companies

-

Export-based detergent production units

Capacity Options

| Plant Capacity | Ideal For |

|---|---|

| 100–300 kg/hr | Startups and small production units |

| 500–1000 kg/hr | Medium-scale detergent manufacturers |

| 2000–5000+ kg/hr | Industrial-level operations |

Machines are available in manual, semi-automatic, and fully automatic configurations to suit different production needs and budgets.

Why Choose ASVR Engineering Pvt Ltd?

-

100% in-house design and manufacturing

-

More than 10 years of industry experience

-

Customized plant layouts and engineering drawings

-

Complete installation, training, and after-sales support

-

PAN India and international exports

-

Trusted by detergent manufacturers across India and abroad

Pricing Guide

The cost of a detergent powder plant depends on:

-

Desired production capacity

-

Level of automation

-

Material selection (Mild Steel vs Stainless Steel)

-

Extra features like heating, dust control, or liquid dosing

Indicative Price Range:

-

Small-scale mixers: ₹2.5 – ₹5 Lakhs

-

Mid-size plants: ₹6 – ₹12 Lakhs

-

Large automatic plants: ₹15 Lakhs and above

Contact us at 8800971968 for a customized quote tailored to your requirements.

Success Stories

Shri Detergents – Gujarat:

"ASVR’s ribbon blender gives us perfect batch uniformity. No lumps, no residue. Perfect for our premium product line."

BrightWash Enterprises – Tamil Nadu:

"Very happy with the mixing precision and build quality. It has improved our product consistency significantly."

Frequently Asked Questions (FAQs)

Q. Do you offer complete plant setup or just individual machines?

We offer both. You can purchase individual machines or opt for a complete turnkey detergent plant.

Q. Can I add automation later to my plant?

Yes. Our systems are modular and can be upgraded over time based on your growth.

Q. Is operator training provided?

Absolutely. We offer on-site and video-based training to ensure your team can run the machines efficiently.

Get in Touch with ASVR Engineering Pvt Ltd

If you are looking to set up or upgrade your detergent manufacturing facility with high-performance, accurate mixing equipment, ASVR Engineering is your ideal partner.

-

Phone: +91 8800971968

-

Website: https://asvrengineering.com

-

Email: (Insert your email here)

-

Location: (Add for local SEO if preferred)

Conclusion

With rising consumer expectations and market competition, detergent manufacturers can no longer afford production inconsistencies. Investing in high-accuracy detergent powder plant machinery from ASVR Engineering Pvt Ltd is a smart, long-term move to ensure superior product quality, process efficiency, and brand reputation.

Reach out to us today and let us help you build a modern, reliable detergent production plant tailored to your needs.

Buy Now