Authorized Cage Mill Dealers Providing Durable, Energy-Efficient & Cost-Effective Milling Machines

Authorized Cage Mill Dealers Providing Durable, Energy-Efficient & Cost-Effective Milling Machines

In today’s competitive industrial environment, productivity, reliability, and energy efficiency are no longer optional—they are essential. Across industries such as minerals, chemicals, fertilizers, construction materials, food processing, and recycling, manufacturers demand milling solutions that deliver consistent output while keeping operational costs under control. This is where ASVR Engineering stands apart as an authorized cage mill dealer, supplying robust, high-performance, and cost-effective cage mill machines designed to meet modern industrial needs.

ASVR Engineering has built a strong reputation by focusing on quality engineering, practical design, and customer-centric service. Our cage mill machines are developed to handle a wide variety of materials with precision and efficiency, ensuring long service life and dependable performance even in demanding working conditions.

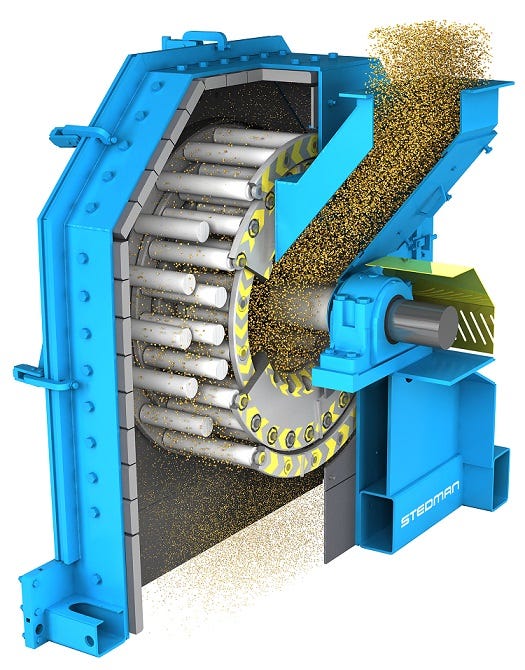

Understanding Cage Mill Technology

A cage mill is a highly versatile impact-type size reduction machine. Unlike traditional grinding systems that rely on compression or shear, a cage mill uses multiple rows of rotating cages fitted with pins or bars. As material enters the mill, it is repeatedly impacted by these rotating elements, breaking it down into uniform, fine particles.

This impact-based working principle makes cage mills ideal for applications where precise particle size control, high throughput, and low energy consumption are critical. The absence of screens in many cage mill designs also minimizes clogging, reduces maintenance downtime, and allows the processing of materials with varying moisture levels.

Why Choose ASVR Engineering as Your Authorized Cage Mill Dealer?

Selecting the right dealer is as important as selecting the right machine. ASVR Engineering is not just a supplier—we are a long-term technology partner for industries seeking dependable milling solutions.

1. Authorized & Trusted Supply

As an authorized cage mill dealer, ASVR Engineering ensures that every machine supplied meets stringent quality standards. Our products are sourced and manufactured using premium materials and proven engineering practices, ensuring safety, reliability, and compliance with industrial norms.

2. Durable Construction for Long Service Life

Our cage mills are built with heavy-duty frames, wear-resistant components, and precision-engineered rotating cages. This robust construction allows the machines to operate continuously under high loads without compromising performance, making them suitable for both small-scale and large-scale industrial operations.

3. Energy-Efficient Performance

Energy consumption is a major operational cost in milling operations. ASVR Engineering’s cage mill machines are designed to deliver maximum output with optimized power usage. Efficient rotor design, balanced components, and advanced drive systems help reduce energy losses, resulting in lower electricity bills and a smaller environmental footprint.

4. Cost-Effective Milling Solutions

We understand that capital investment and operating costs are key considerations for our clients. Our cage mills are competitively priced and engineered to minimize maintenance and downtime. This combination ensures faster return on investment and long-term cost savings.

Applications of Cage Mill Machines

Cage mill machines supplied by ASVR Engineering are used across a wide range of industries due to their flexibility and efficiency.

Mineral Processing

Cage mills are ideal for grinding limestone, gypsum, dolomite, coal, and other minerals. The uniform particle size output improves downstream processing and enhances product quality.

Chemical Industry

In chemical processing, precision and consistency are critical. Cage mills effectively process chemicals, pigments, fertilizers, and resins while maintaining uniformity and reducing material wastage.

Construction Materials

For cement additives, fly ash, slag, and other construction materials, cage mills deliver reliable size reduction that supports consistent mixing and improved final product strength.

Food & Agro Processing

Cage mills are also used for grinding grains, spices, and agro-based materials where controlled particle size and hygiene-friendly design are essential.

Recycling & Waste Processing

In recycling operations, cage mills help in reducing waste materials into reusable forms, supporting sustainable and eco-friendly industrial practices.

Key Features of ASVR Engineering Cage Mill Machines

-

High Throughput Capacity: Designed to handle large volumes without sacrificing efficiency.

-

Uniform Particle Size: Consistent output improves process control and product quality.

-

Low Maintenance Design: Fewer wear parts and easy access for inspection reduce downtime.

-

Flexible Configuration: Multiple cage arrangements allow customization based on material type and required fineness.

-

Safe & Reliable Operation: Precision balancing and quality components ensure smooth, vibration-free performance.

4

Commitment to Quality & Engineering Excellence

Quality is at the core of everything we do at ASVR Engineering. From design and fabrication to testing and final delivery, every stage is monitored to ensure that our cage mill machines meet the highest performance standards. Our engineering team continuously evaluates new technologies and materials to enhance durability, efficiency, and user convenience.

We believe that a machine should not only perform well on day one but continue to deliver consistent results over years of operation. This philosophy drives our focus on precision manufacturing, rigorous quality checks, and continuous improvement.

Customized Solutions for Diverse Industrial Needs

No two industrial processes are exactly the same. ASVR Engineering offers customized cage mill solutions tailored to specific material characteristics, capacity requirements, and operational conditions. Whether you need a compact unit for limited space or a high-capacity system for continuous production, our team works closely with you to deliver the right solution.

Customization options may include rotor configuration, motor capacity, feeding arrangement, discharge design, and wear-resistant materials. This flexibility ensures that your cage mill integrates seamlessly into your existing production line.

Reliable After-Sales Support & Service

A high-quality machine deserves equally reliable service support. ASVR Engineering provides comprehensive after-sales assistance, including installation guidance, operational training, maintenance support, and spare parts availability. Our responsive service team ensures that your operations run smoothly with minimal interruptions.

We view after-sales service as a long-term partnership rather than a one-time obligation. Our goal is to help you maximize productivity and extend the lifespan of your equipment.

Why Industries Across India Trust ASVR Engineering

Over the years, ASVR Engineering has earned the trust of clients across India by consistently delivering dependable machinery and professional service. Our focus on transparency, technical expertise, and customer satisfaction has helped us build long-lasting relationships with businesses in diverse sectors.

Clients choose us because we combine engineering knowledge with practical industry experience. We understand operational challenges and design our cage mill solutions to address real-world production demands.

Get in Touch with ASVR Engineering

If you are looking for authorized cage mill dealers providing durable, energy-efficient, and cost-effective milling machines, ASVR Engineering is your trusted partner.

Company Name: ASVR Engineering

Contact Numbers: +91-8076004849, +91-8800971968

Website: https://www.asvrengineering.com

Our team is ready to help you select the right cage mill solution to enhance productivity, reduce costs, and support sustainable industrial growth.

Buy Now