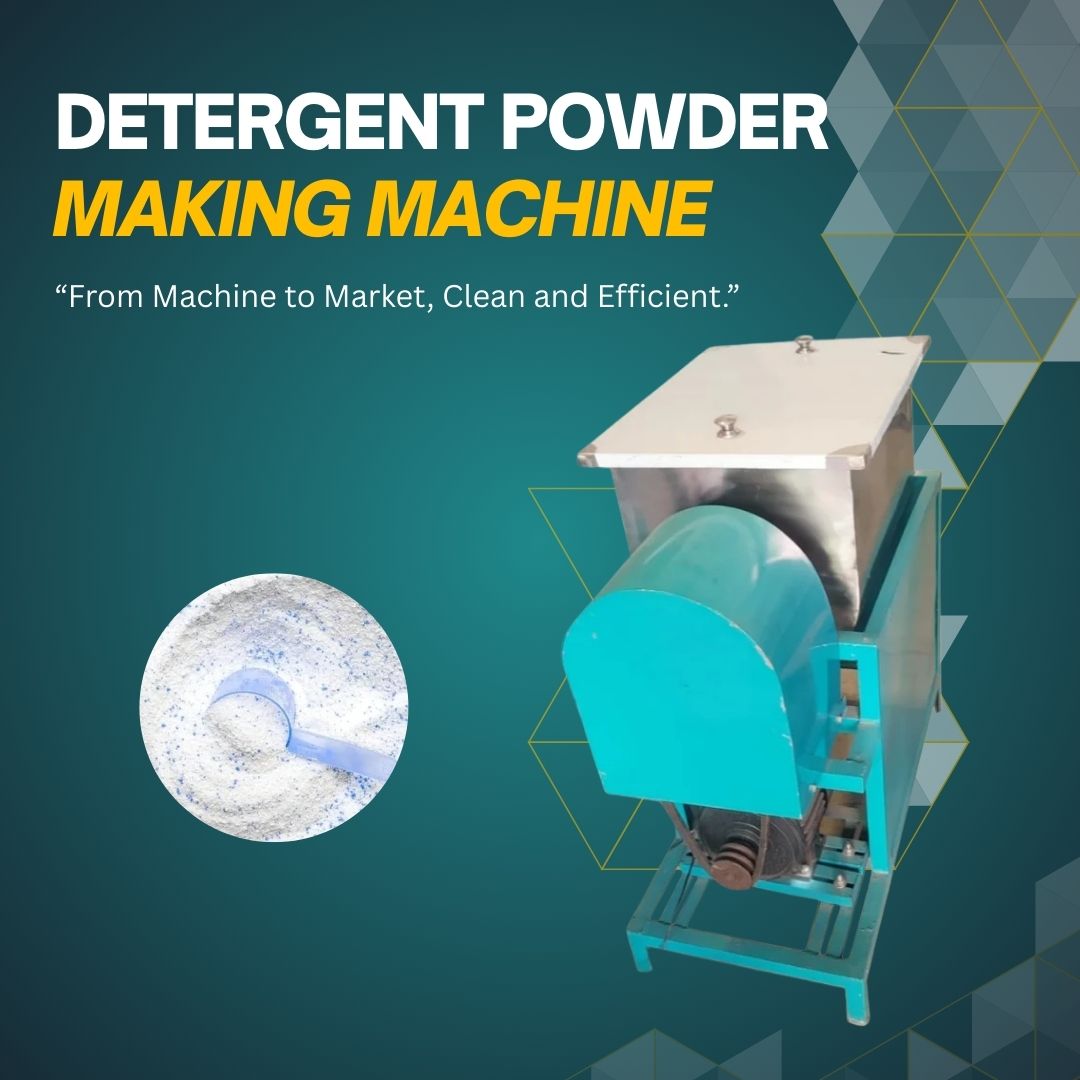

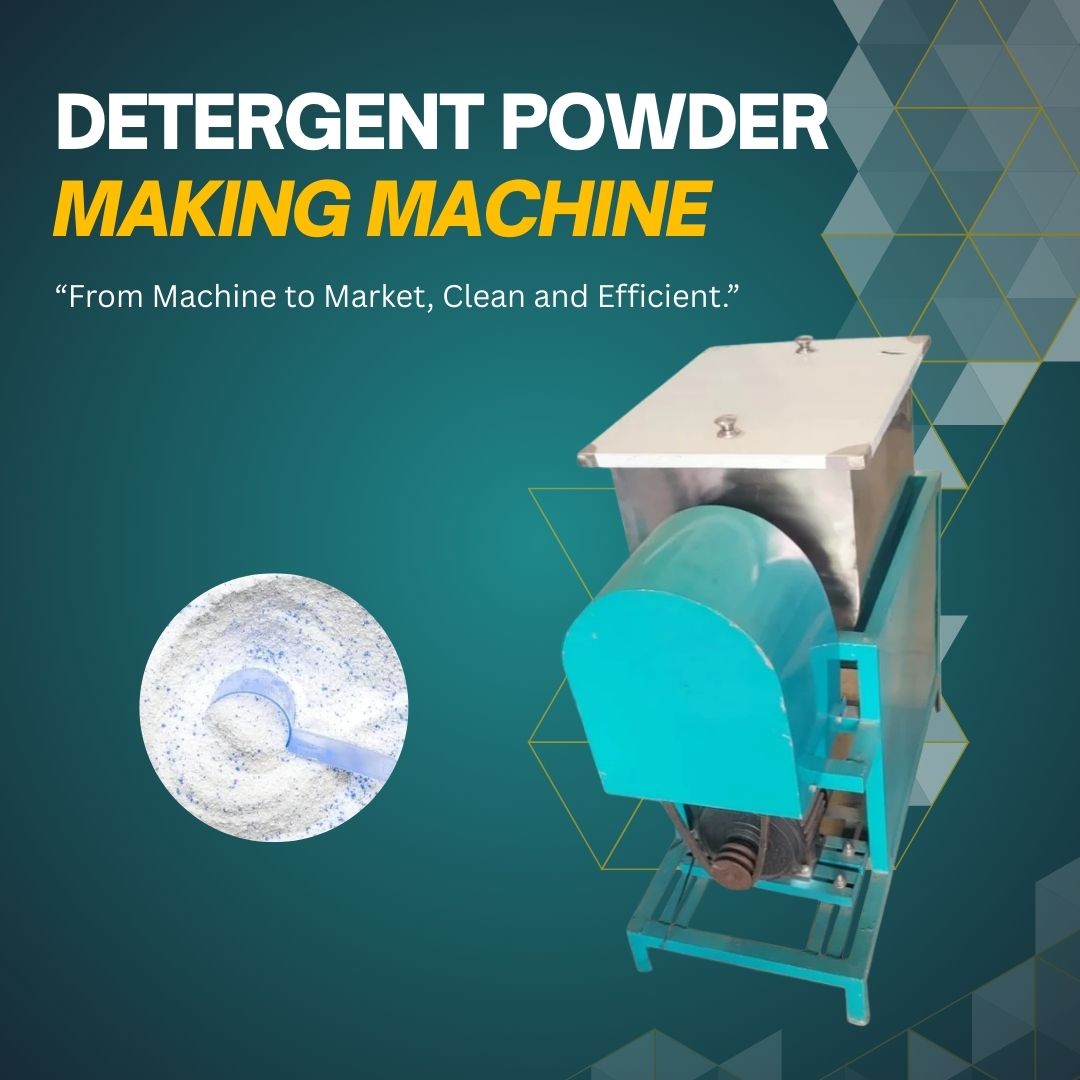

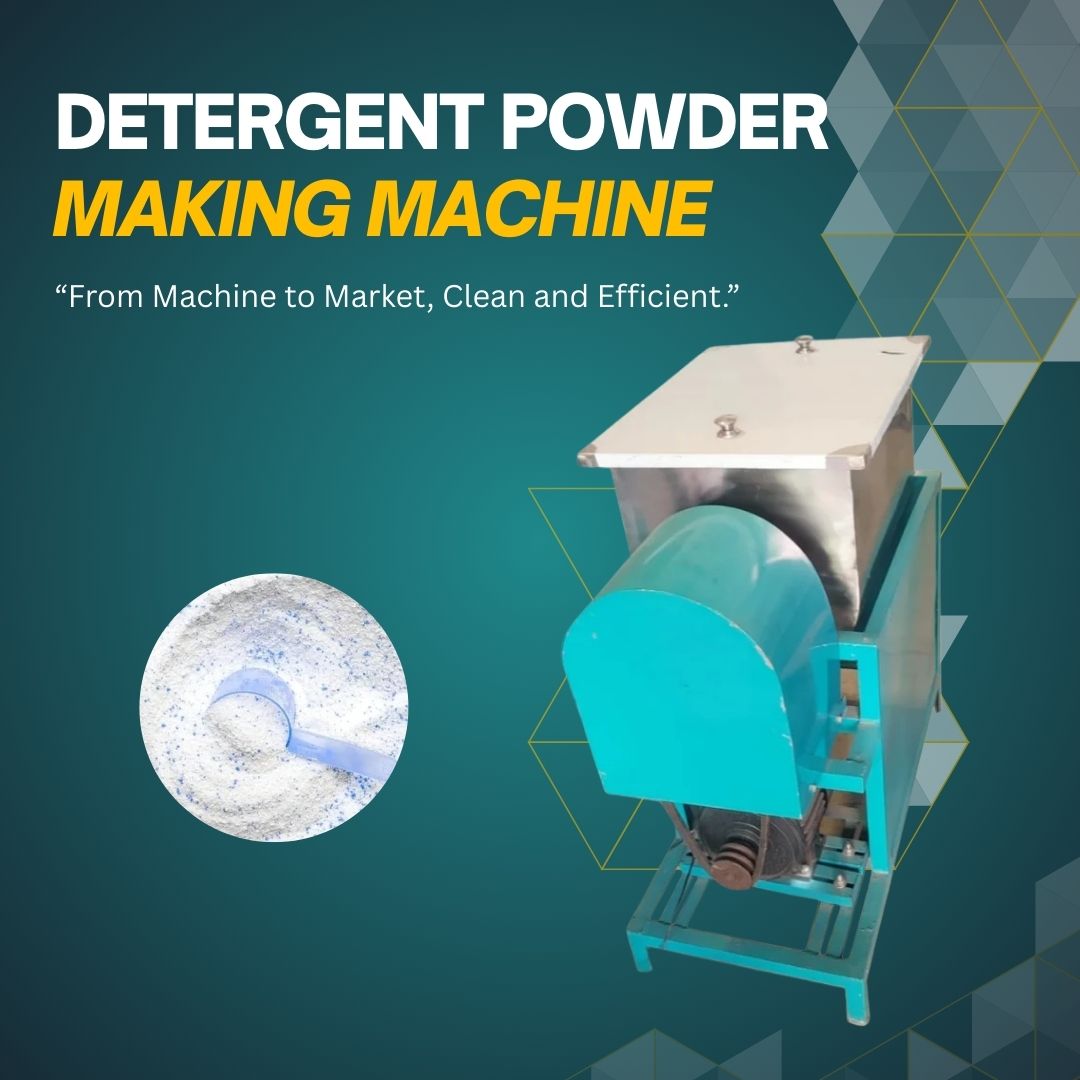

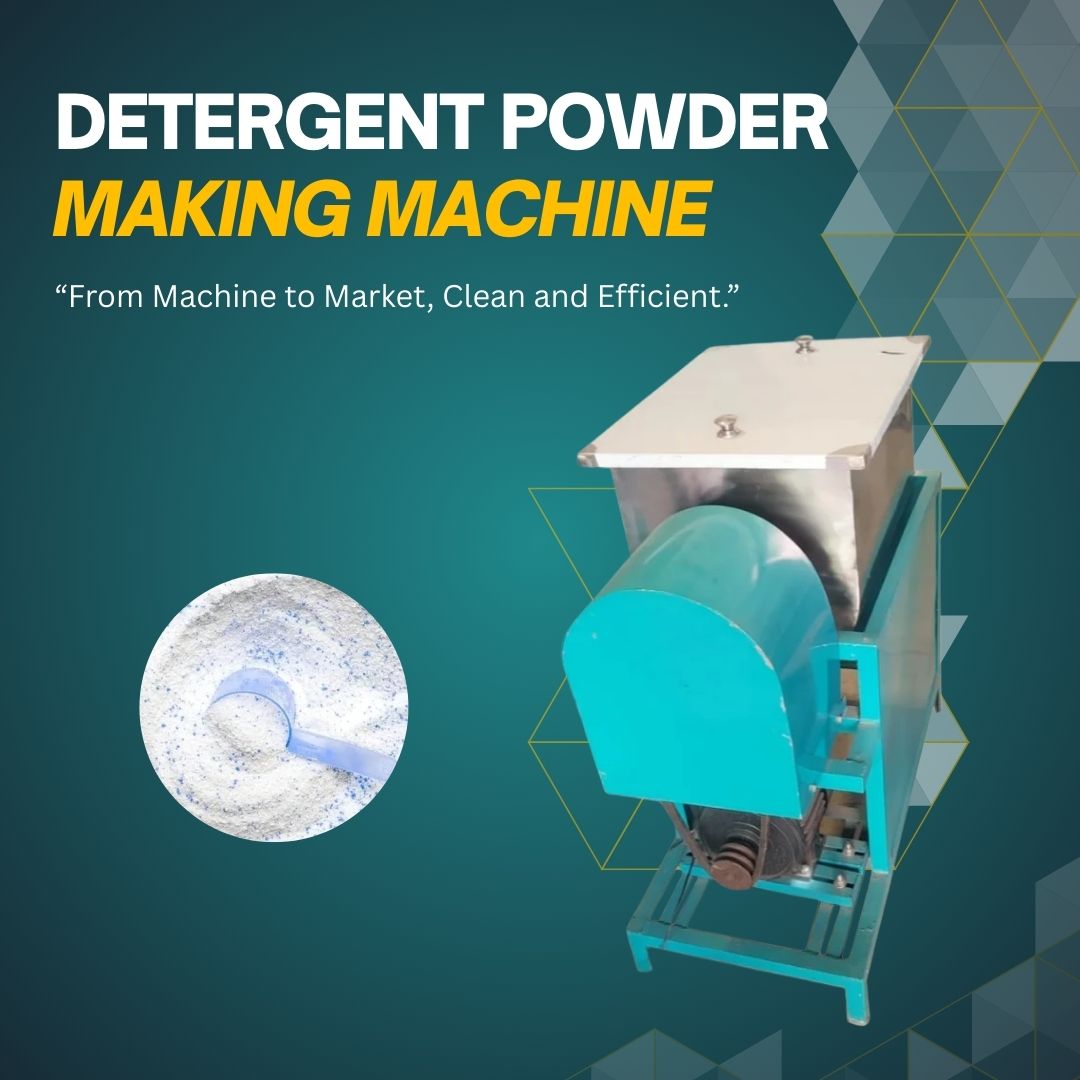

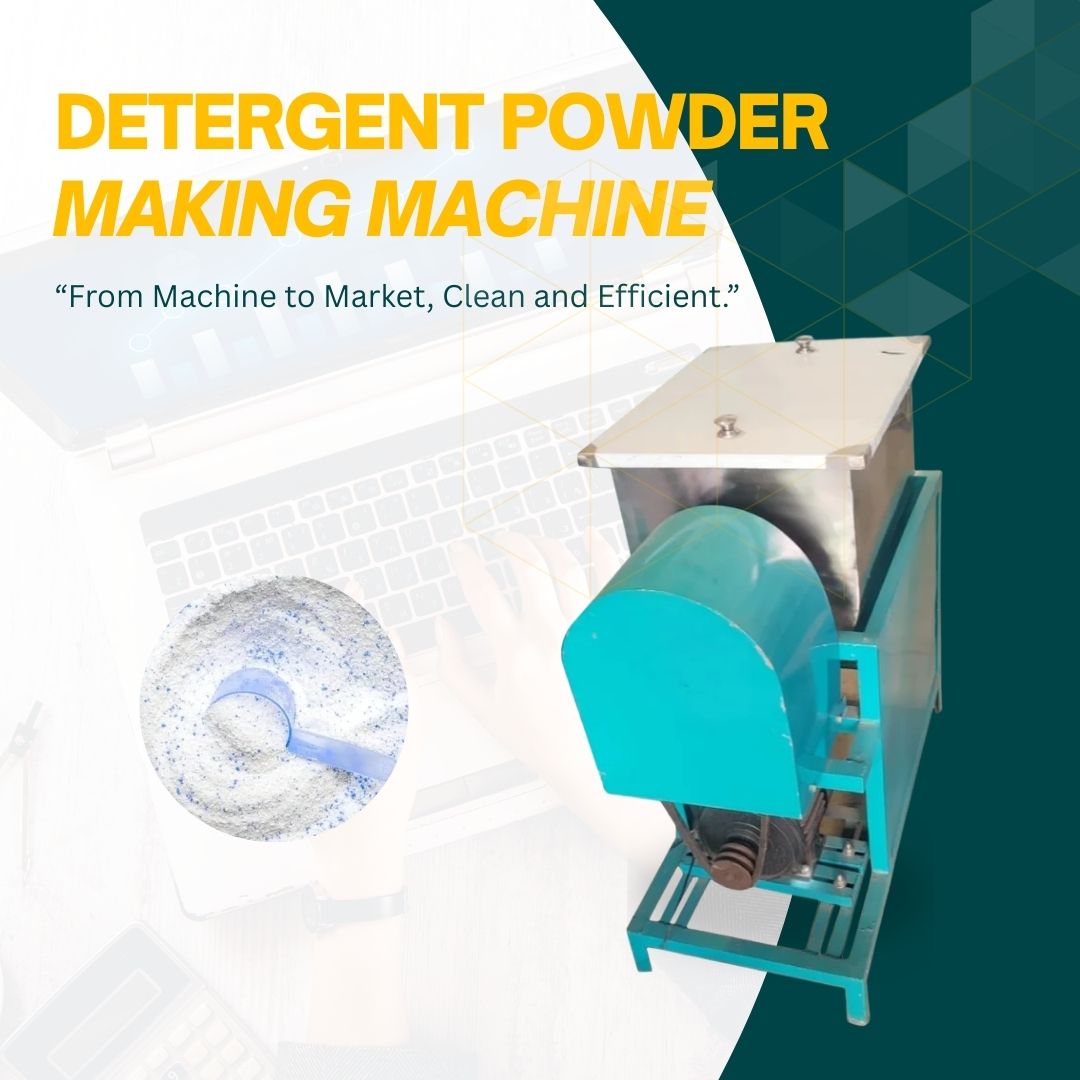

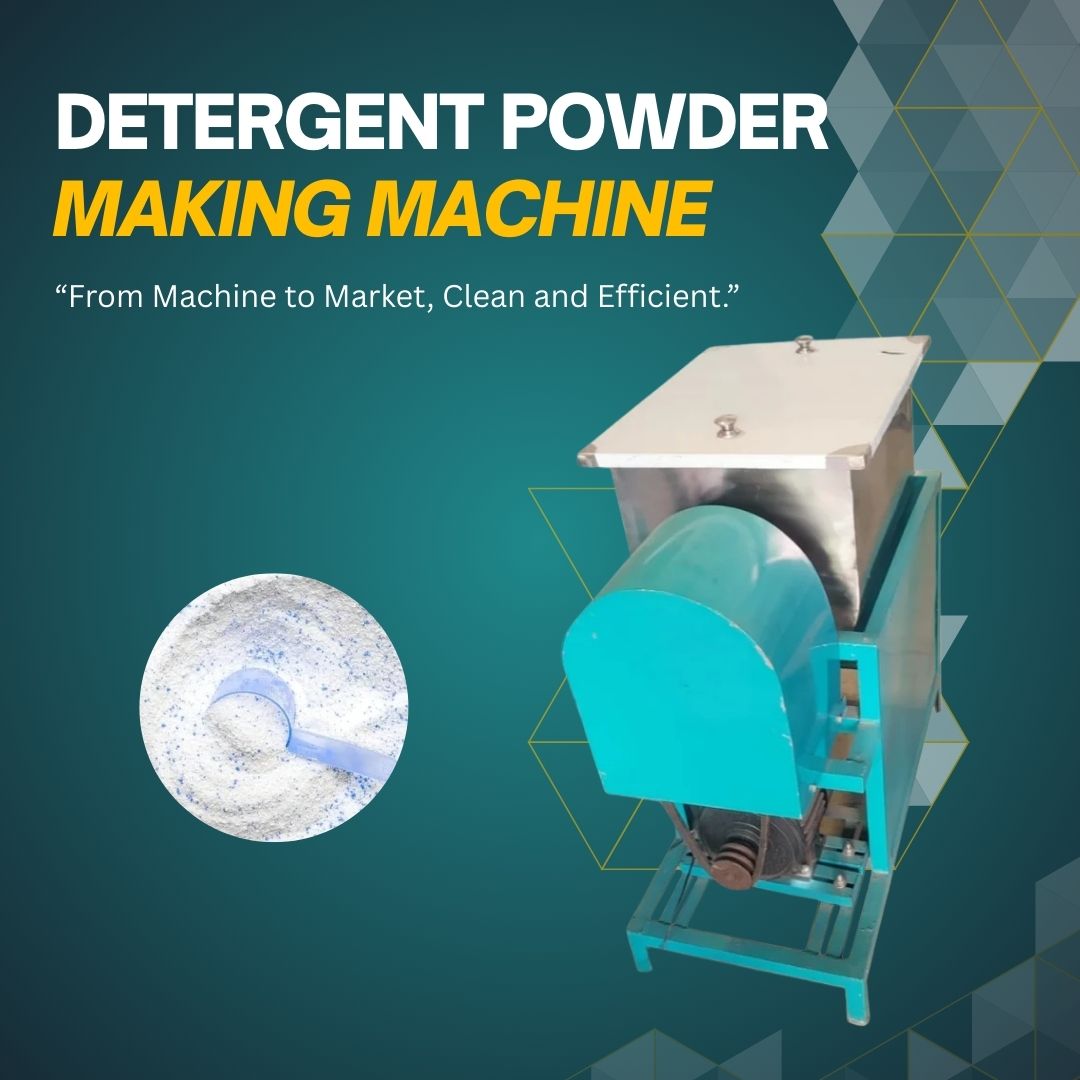

Modern Detergent Powder Making Line with Custom Capacity

Modern Detergent Powder Making Line with Custom Capacity – ASVR Engineering Pvt Ltd

Looking to upgrade your detergent manufacturing unit with advanced, scalable equipment? At ASVR Engineering Pvt Ltd, we offer a modern detergent powder making line built with cutting-edge technology and tailored to your required capacity—from small-scale startups to full industrial production.

Our complete production lines ensure high-quality detergent output, energy efficiency, and smooth integration of all stages—from raw material handling to packaging.

What is a Detergent Powder Making Line?

A detergent powder making line is a fully integrated production system that automates the entire process of detergent powder manufacturing. It typically includes:

-

Raw Material Feeding System

-

Mixing & Blending Unit (Ribbon Blender or Paddle Mixer)

-

Sieving System

-

Storage Hopper

-

Conveying System

-

Packaging Machine

ASVR Engineering’s detergent lines are designed to minimize manual labor, optimize mixing accuracy, and allow easy scalability.

Key Features of Our Modern Detergent Powder Line

-

Customizable Capacities: From 100 kg/hr to 5,000+ kg/hr

-

Stainless Steel or Mild Steel Construction

-

PLC Automation & Touchscreen Controls

-

Dust-Free Operation with Enclosed Systems

-

Low Energy Consumption Motors

-

Quick Changeover & Easy Maintenance

Whether you're producing regular detergent, low-foam formulations, or perfumed powder, our systems offer high flexibility and product consistency.

Custom Capacity Options

At ASVR Engineering, we understand that every detergent business is unique. That’s why we offer custom-built plants with the following capacity options:

| Model | Capacity | Best For |

|---|---|---|

| ASVR-MDL100 | 100 – 300 kg/hr | Home businesses, small units |

| ASVR-MDL500 | 500 – 1000 kg/hr | Medium manufacturers |

| ASVR-MDL2000+ | 2000 – 5000+ kg/hr | Full-scale industrial plants |

We also offer modular upgrades, allowing you to expand your line as your business grows.

Components of the Line

1. Feeding & Dosing System

Accurate feeding of raw materials using manual hoppers or automatic feeders.

2. Mixing Machine

Ribbon Blender or Paddle Mixer ensures homogeneous mixing of ingredients.

3. Sieving Machine

Removes lumps and foreign particles for a fine, smooth finish.

4. Storage Hopper

Holds mixed material before packing. Can be integrated with sensors for inventory tracking.

5. Screw Conveyor or Belt Conveyor

Moves powder between stages with minimal spillage and dust.

6. Packaging System

Fills and seals pouches of various sizes (50g to 5kg) with precision.

Why Choose ASVR’s Detergent Powder Line?

-

Turnkey Project Execution

-

In-House Manufacturing

-

End-to-End Support

-

Indian and Export Compliant Standards

-

Cost-Effective Solutions for Every Scale

Whether you need a semi-automatic line or a fully automated smart plant, we’ll tailor it to meet your production goals and budget.

Machine Materials & Specs

| Component | Material Options | Automation |

|---|---|---|

| Mixing Unit | MS, SS304, SS316 | Manual / Auto |

| Sieve System | SS mesh, Vibro sieve | Auto vibration |

| Conveyor | Powder-coated or SS | Motorized / Inclined |

| Packaging Machine | Servo-based / Pneumatic | Fully automatic |

| Control System | PLC + HMI (Optional) | Yes |

Energy & Utility Requirements

-

Small Scale: Single-phase, 220V

-

Industrial Line: 3-phase, 440V

-

Power Usage: Energy-efficient motors with overload protection

-

Optional Upgrades: Dust collector, batch counter, automated raw material feeder

Industries We Serve

-

Detergent powder manufacturers

-

FMCG companies

-

Private label cleaning brands

-

Institutional & contract manufacturers

-

Entrepreneurs starting detergent businesses

Client Testimonials

ShinePro Cleaners – Maharashtra

“We upgraded to ASVR’s 500 kg/hr custom line last year. Great build quality and automation. Output doubled.”

FreshSpark Pvt Ltd – Tamil Nadu

“The mixing and packing integration saved us time and reduced waste. Highly recommend their engineering team.”

FAQ – Detergent Powder Making Line

Q. Can I add automation later?

Yes. Our systems are modular and can be upgraded to semi or fully automatic based on future requirements.

Q. How long does it take to install a full line?

Typically, 2–4 weeks depending on the complexity and customization.

Q. Is the line suitable for colored and scented powders?

Absolutely. Our blenders ensure even mixing of colors, scents, and softening agents.

Q. Do you offer onsite training?

Yes. Our engineers provide hands-on training and detailed user manuals.

Pricing Overview

| Line Capacity | Estimated Price Range |

|---|---|

| 100–300 kg/hr | ₹4 – ₹6 Lakhs |

| 500–1000 kg/hr | ₹8 – ₹14 Lakhs |

| 2000+ kg/hr | ₹15 Lakhs and above |

Note: Custom features, material choice, and automation level will affect final pricing.

Why ASVR Engineering Pvt Ltd?

-

10+ years in detergent plant manufacturing

-

Trusted by over 150+ detergent businesses

-

Made-in-India machinery with international standards

-

Lifetime support, AMC, and genuine spare parts

-

Transparent pricing and quick delivery

Contact Us Today

Ready to build your own custom detergent powder making line? Let's get started.

-

Phone: +91 8800971968

-

Website: https://asvrengineering.com

-

Email: (Add your email here)

-

Office Location: (Add for local SEO)

We’ll help you choose the right model, install it at your site, and provide full training and support.

Conclusion

A modern detergent powder making line with custom capacity is the backbone of a successful detergent business. At ASVR Engineering Pvt Ltd, we combine engineering excellence with deep industry insight to deliver machines that meet your exact production needs.

Whether you're just starting out or scaling up, we have the right solution for you.

Buy Now