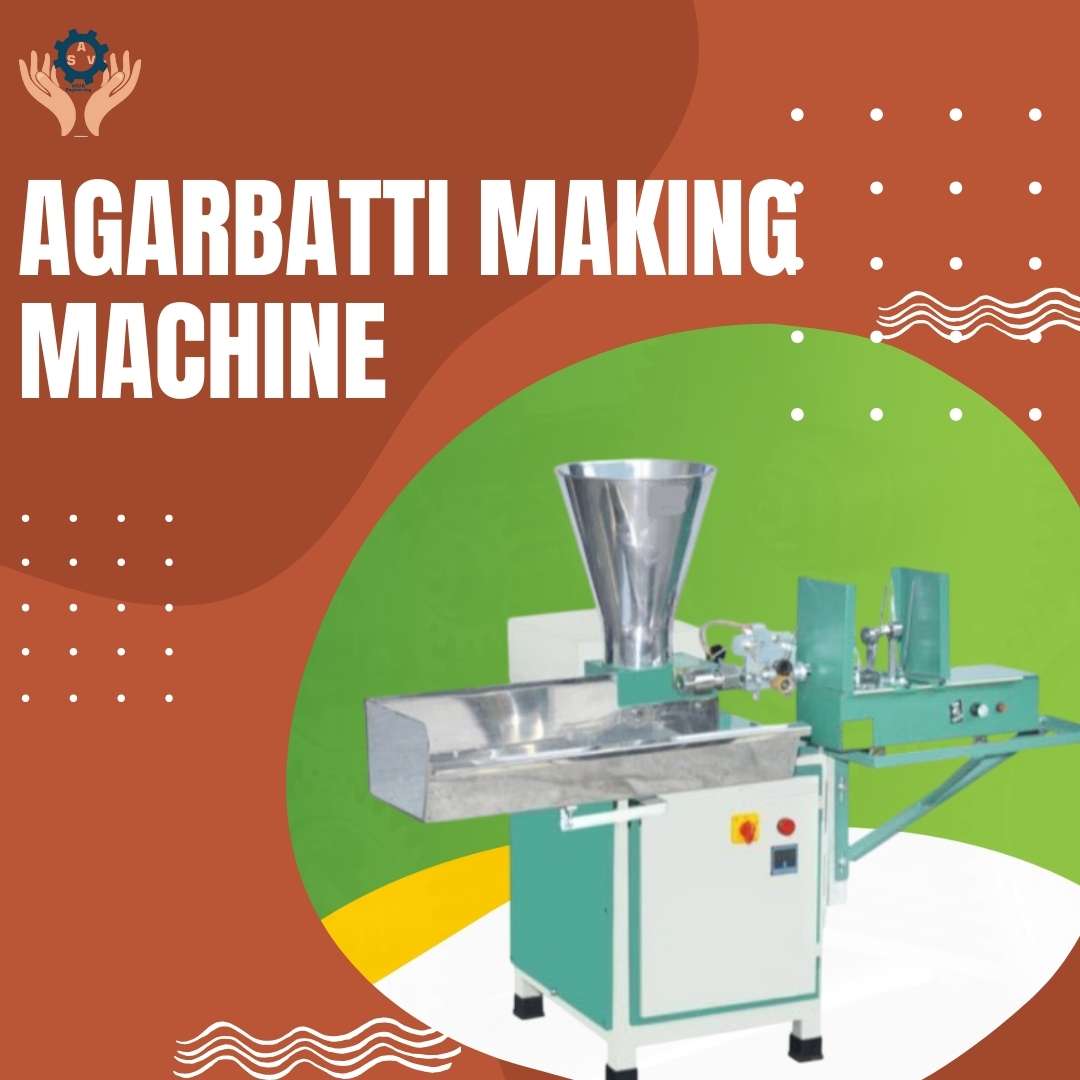

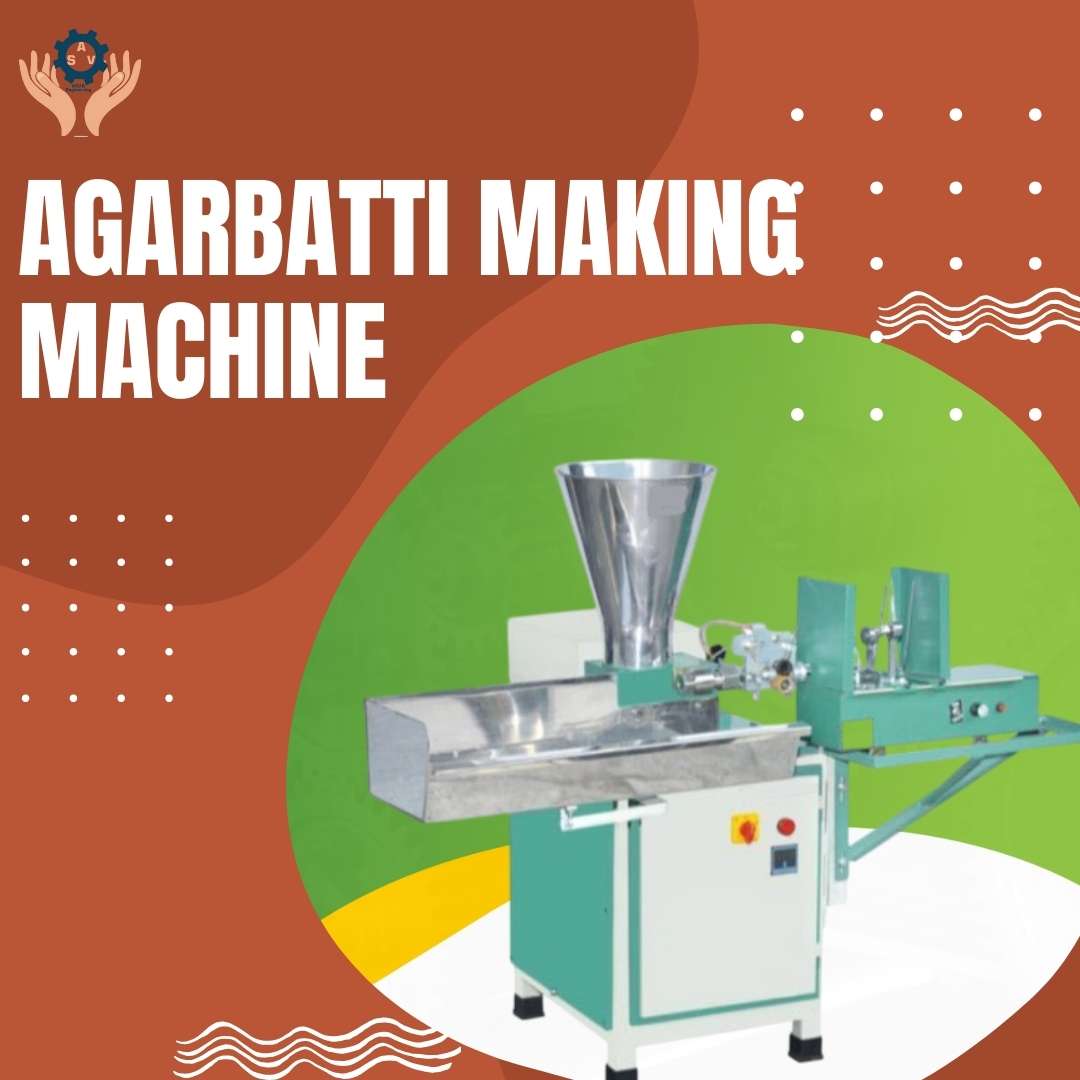

Leading Agarbatti Making Machine Manufacturers for Small & Large-Scale Production

Introduction

The agarbatti (incense stick) industry in India has grown from a traditional cottage activity into a well-organized manufacturing sector supplying both domestic and international markets. With rising demand from temples, households, wellness centers, hotels, and export buyers, manufacturers today require machines that are consistent, durable, and capable of handling high-volume production without compromising quality.

ASVR Engineering has emerged as one of the most trusted names in this field by delivering precision-engineered agarbatti making machines suitable for small startups, growing enterprises, and large-scale production units. Backed by practical industry knowledge, robust manufacturing standards, and dependable after-sales support, ASVR Engineering helps businesses build a profitable incense stick manufacturing operation.

Understanding the Agarbatti Manufacturing Process

Before choosing the right machine, it is important to understand how agarbatti is produced. The process involves multiple stages that must work in harmony for consistent output:

-

Raw Material Preparation

Ingredients such as charcoal powder, jigat powder, wood powder, and fragrance binders are mixed to form a smooth dough. -

Stick Rolling / Extrusion

The prepared dough is evenly applied to bamboo sticks using a raw agarbatti making machine. -

Drying

Freshly rolled sticks are dried naturally or in controlled drying systems to maintain shape and strength. -

Perfume Dipping

Dry sticks are dipped into aromatic oils to impart fragrance. -

Packaging

Finished agarbattis are packed for wholesale or retail distribution.

Each of these stages depends heavily on machine accuracy and reliability, especially when production volumes increase.

Why Choosing the Right Agarbatti Making Machine Matters

In agarbatti manufacturing, even small inconsistencies can lead to product rejection, wastage, or reduced fragrance retention. A high-quality machine ensures:

-

Uniform thickness and smooth finish

-

Reduced raw material wastage

-

Higher production speed

-

Lower labor dependency

-

Long-term operational stability

ASVR Engineering designs machines that balance product quality with production efficiency, making them suitable for both entry-level entrepreneurs and established manufacturers.

ASVR Engineering – Trusted Manufacturer for All Production Scales

ASVR Engineering has built its reputation by focusing on practical performance rather than theoretical specifications. Every machine is developed keeping Indian working conditions, raw material variations, and long operating hours in mind.

What Sets ASVR Engineering Apart?

-

Heavy-duty construction using high-grade steel

-

Smooth extrusion systems for consistent stick coating

-

Low maintenance design to reduce downtime

-

Energy-efficient motors for cost-effective operation

-

Operator-friendly controls requiring minimal training

Whether you are producing a few kilograms per day or running a continuous high-output unit, ASVR Engineering offers machines that adapt to your scale.

Types of Agarbatti Making Machines Offered

4

1. Raw Agarbatti Making Machines

Ideal for startups and small manufacturers, these machines provide excellent control over dough application. They are cost-effective, easy to maintain, and perfect for learning the production process.

2. Semi-Automatic Agarbatti Machines

Designed for medium-scale production units, semi-automatic machines offer improved speed and uniformity while still allowing manual oversight.

3. Fully Automatic Agarbatti Making Machines

These machines are built for large-scale production where output consistency and speed are critical. Fully automatic models reduce labor costs significantly and maintain uniform quality across large batches.

4. Customized Production Solutions

ASVR Engineering also provides custom-built solutions based on production targets, space availability, and budget considerations.

Small-Scale Production: A Strong Start for New Entrepreneurs

For many first-time manufacturers, agarbatti production is attractive because of its low entry barrier and steady demand. ASVR Engineering supports small-scale entrepreneurs with:

-

Affordable machine options

-

Guidance on raw materials

-

Practical production tips

-

Reliable after-sales service

These machines are designed to help beginners grow steadily without unnecessary financial pressure.

Large-Scale Manufacturing: Built for Volume and Consistency

For established manufacturers and exporters, production consistency is as important as volume. ASVR Engineering’s large-scale machines are engineered for:

-

Continuous operation

-

High output per shift

-

Minimal breakdowns

-

Consistent stick thickness and weight

Such reliability ensures uniform branding, better fragrance absorption, and improved market reputation.

Quality Control and Manufacturing Standards

ASVR Engineering follows strict quality checks at every stage of machine manufacturing. From raw material selection to final testing, each machine is inspected for:

-

Mechanical strength

-

Smooth operation

-

Noise and vibration control

-

Output consistency

This commitment to quality ensures that customers receive machines that perform reliably year after year.

After-Sales Support and Technical Assistance

One of the key reasons customers choose ASVR Engineering is dependable service support. The company provides:

-

Installation guidance

-

Operational training

-

Spare parts availability

-

Technical troubleshooting support

This ensures that production continues smoothly even after long-term use.

Why Indian and International Buyers Trust ASVR Engineering

-

Proven track record in agarbatti machinery

-

Transparent communication and pricing

-

Machines suited for Indian climatic and working conditions

-

Strong customer satisfaction across India

With growing exports of incense products, ASVR Engineering machines are also suitable for manufacturers targeting international markets.

Applications of Agarbatti Making Machines

ASVR Engineering machines are widely used by:

-

Household agarbatti brands

-

Temple supply manufacturers

-

Wellness and meditation product companies

-

Export-oriented incense manufacturers

-

Private-label incense producers

Future Growth Opportunities in Agarbatti Manufacturing

The global demand for incense sticks continues to rise due to increased focus on spirituality, wellness, and aromatherapy. By investing in reliable machinery today, manufacturers can easily scale operations and diversify into premium incense products tomorrow.

ASVR Engineering supports this growth by offering machines that are upgrade-friendly and production-ready for future expansion.

Contact ASVR Engineering

If you are planning to start or expand your agarbatti manufacturing business, choosing the right machinery partner is crucial.

Company Name: ASVR Engineering

Website: https://www.asvrengineering.com

Contact Numbers:

📞 +91-8076004849

📞 +91-8800971968

Their team is ready to guide you in selecting the most suitable agarbatti making machine based on your production goals and budget.

Buy Now