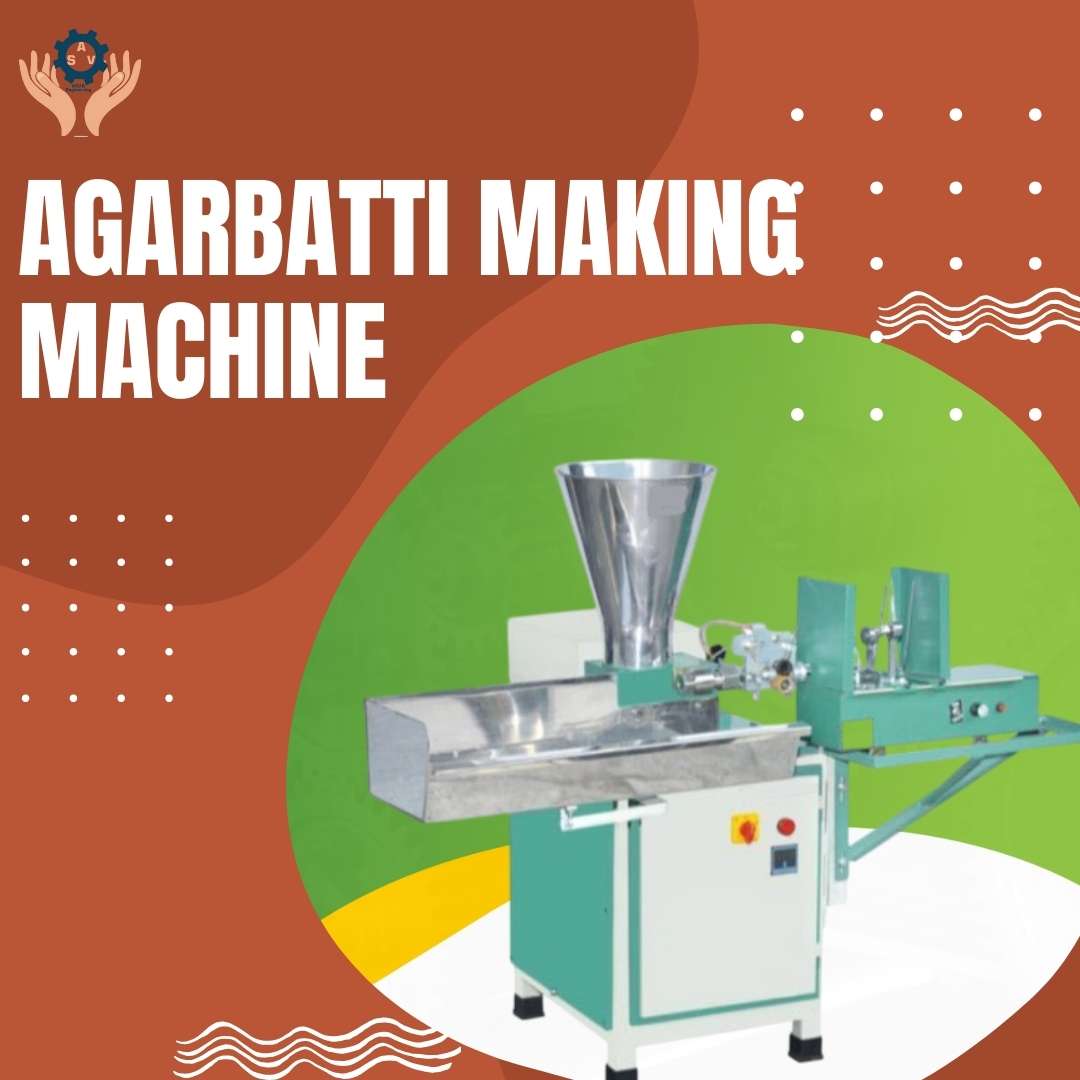

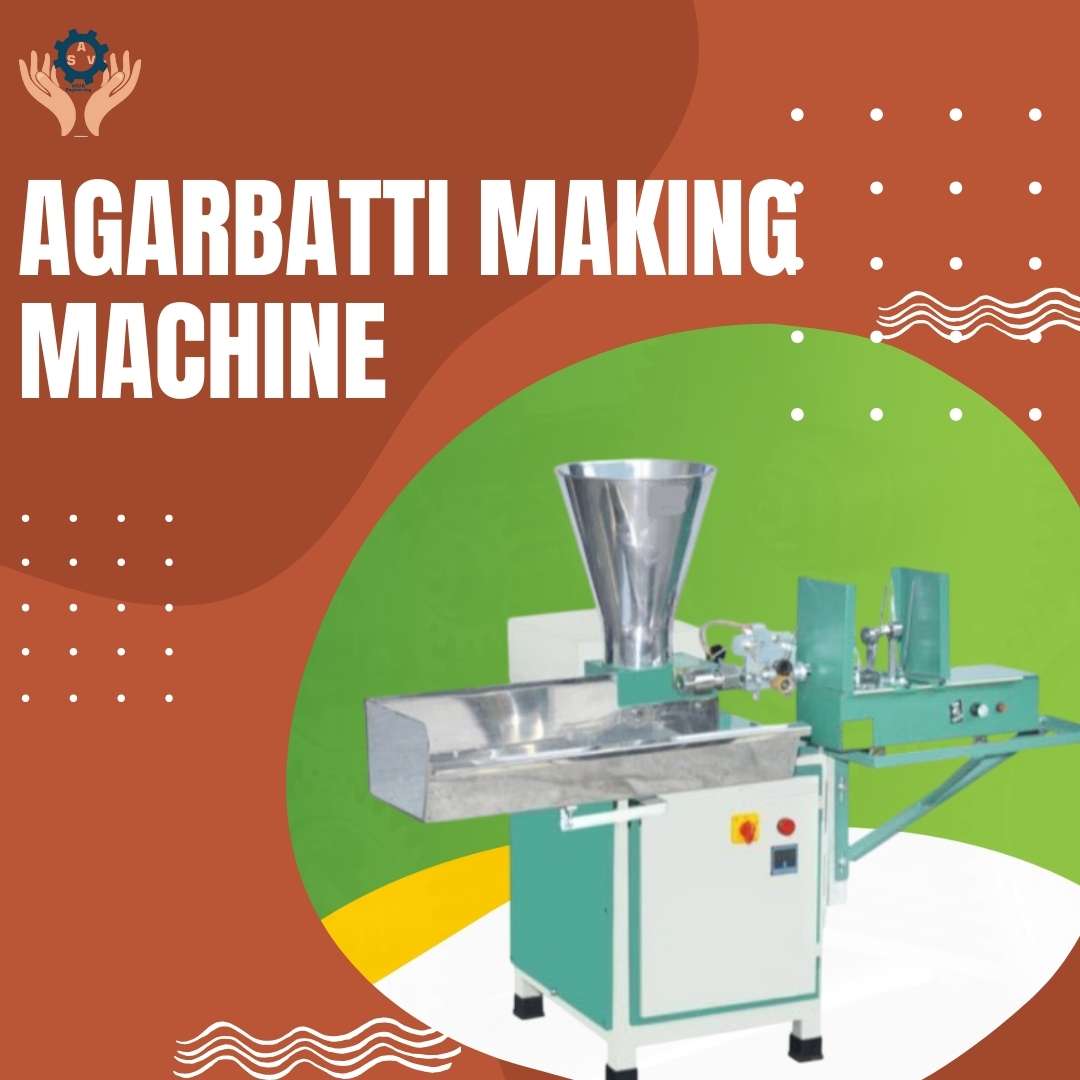

Agarbatti Making Machine Manufacturers

Introduction

The agarbatti (incense stick) industry in India has grown steadily over the years, driven by cultural traditions, daily religious practices, meditation, and increasing global demand for Indian incense products. From homes and temples to wellness centers and export markets, agarbatti continues to be a product with consistent consumption throughout the year.

To meet this demand efficiently and maintain consistent quality, modern manufacturers rely on advanced agarbatti making machines. Choosing the right Agarbatti Making Machine Manufacturer plays a crucial role in the success of any incense production business. This is where ASVR Engineering stands out as a dependable name, offering robust, high-performance machines designed for Indian manufacturing conditions.

ASVR Engineering focuses on providing practical, durable, and cost-effective agarbatti making solutions that help startups, MSMEs, and large-scale manufacturers achieve higher productivity with controlled costs.

Understanding the Agarbatti Manufacturing Process

Before investing in a machine, it is important to understand how agarbatti is produced:

-

Raw Material Preparation – Mixing charcoal powder, jigat powder, white chips powder, fragrance binders, and water to form a smooth dough.

-

Extrusion or Rolling – The dough is applied onto bamboo sticks using manual, semi-automatic, or automatic machines.

-

Drying – Freshly made sticks are dried naturally or in controlled drying chambers.

-

Scenting & Packaging – Dried sticks are dipped in fragrance oils and packed for retail or bulk supply.

Modern agarbatti machines automate the extrusion and rolling stages, significantly increasing output while maintaining uniform thickness and smooth finishing.

Why Choosing the Right Agarbatti Making Machine Manufacturer Matters

The agarbatti business may look simple, but machine quality directly affects production speed, wastage, labor cost, and final product consistency. A reliable manufacturer ensures:

-

Strong machine build quality

-

Smooth and uninterrupted operation

-

Easy availability of spare parts

-

Technical guidance and training

-

Long-term after-sales support

ASVR Engineering designs machines keeping real-world factory challenges in mind, making them suitable for both rural and urban production units.

Types of Agarbatti Making Machines Offered by ASVR Engineering

1. Manual Agarbatti Making Machines

Ideal for home-based businesses and micro-entrepreneurs, manual machines require minimal investment and are easy to operate. These machines are best suited for low-volume production and skill-based operations.

Key benefits:

-

Low cost

-

Simple operation

-

Suitable for self-employment and SHGs

2. Semi-Automatic Agarbatti Making Machines

Semi-automatic machines balance affordability and productivity. They reduce physical effort while maintaining decent output levels.

Key benefits:

-

Consistent stick thickness

-

Lower labor dependency

-

Moderate power consumption

-

Suitable for small to medium production units

3. Automatic Agarbatti Making Machines

Automatic machines are designed for large-scale manufacturing where speed, uniformity, and continuous operation are critical.

Key benefits:

-

High production capacity

-

Uniform quality and smooth finish

-

Reduced raw material wastage

-

Long operational life

ASVR Engineering’s automatic models are engineered to run continuously with minimal downtime, making them ideal for factories supplying bulk orders and export markets.

Key Features of ASVR Engineering Agarbatti Machines

-

Heavy-Duty Construction: Built with industrial-grade components for long-term reliability

-

User-Friendly Design: Easy controls and simple maintenance

-

Consistent Output: Uniform agarbatti size and texture

-

Energy Efficient: Optimized motor and power usage

-

Low Maintenance Cost: Easy access to spares and service support

Every machine is tested before dispatch to ensure performance stability and durability under Indian working conditions.

Who Can Start an Agarbatti Manufacturing Business?

Agarbatti manufacturing is one of the most accessible manufacturing businesses in India. It is suitable for:

-

First-time entrepreneurs

-

Women self-help groups (SHGs)

-

Rural and semi-urban businesses

-

Small factories and cottage industries

-

Export-oriented incense manufacturers

With the right guidance and machine selection from ASVR Engineering, even beginners can set up a profitable unit with controlled investment.

Profitability and Market Demand

The agarbatti market enjoys steady demand due to its cultural and spiritual significance. Profit margins improve significantly when production is mechanized.

Business advantages include:

-

Low raw material cost

-

Continuous year-round demand

-

Scalability from small to large production

-

Domestic and international export opportunities

By using high-output agarbatti making machines, manufacturers can meet bulk orders without compromising quality.

Why ASVR Engineering is a Trusted Agarbatti Making Machine Manufacturer

ASVR Engineering has built a reputation based on quality, transparency, and customer satisfaction. Their approach is not limited to selling machines; they aim to build long-term partnerships with manufacturers.

What sets ASVR Engineering apart:

-

Honest machine recommendations based on business size

-

Technical consultation before purchase

-

Installation guidance and operator training

-

Prompt after-sales service and spare support

Their machines are used by manufacturers across India who value consistency, durability, and dependable performance.

After-Sales Support & Customer Assistance

Reliable after-sales service is critical in manufacturing. ASVR Engineering provides:

-

Phone-based technical support

-

Spare parts availability

-

Operation and maintenance guidance

-

Long-term service commitment

This ensures that production units run smoothly without extended downtime.

How to Choose the Right Agarbatti Machine for Your Business

Before purchasing, consider:

-

Your daily production target

-

Available manpower

-

Power availability

-

Budget and scalability plans

The ASVR Engineering team helps customers choose the most suitable machine, ensuring maximum return on investment.

Conclusion

The agarbatti manufacturing industry offers excellent growth potential when supported by the right machinery. Choosing a trusted Agarbatti Making Machine Manufacturer ensures product quality, consistent output, and long-term business stability.

ASVR Engineering continues to support entrepreneurs and manufacturers by delivering reliable agarbatti making machines backed by expert guidance and dependable service. Whether you are starting small or planning large-scale production, their solutions are designed to grow with your business.

Contact Details

Company Name: ASVR Engineering

Phone: +91-8076004849, +91-8800971968

Website: https://www.asvrengineering.com

Buy Now